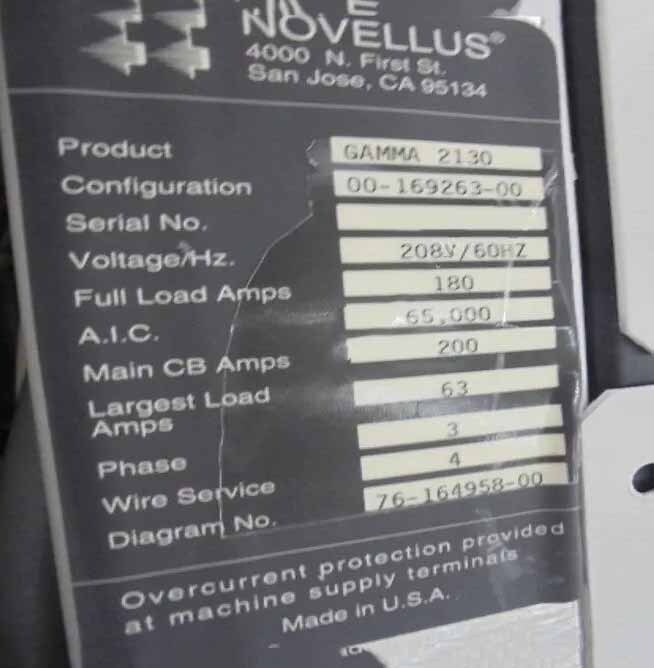

Used NOVELLUS Gamma Express #293618743 for sale

URL successfully copied!

Tap to zoom

ID: 293618743

Wafer Size: 12"

Stripper / Asher, 12"

MF: GAMMA 2130 Upgrade

Wet process

OHT PIO Sensor

FOUP

(3) Carrier stages

GEM / CIM JGJ

Earth leakage breaker

Signal tower: Red / Yellow / Green / Blue

EMO:

Front

(2) Rears

Interconnect hardware: PM to pump 50 ft

Cables: TM to sub panel, 100 ft

MDP Powerbox

External interlocks

Etcher chamber: Positions 1 to 6

RF Cable length: RFG to matcher 30 ft

MKS GHW-50A Generator

HI-THLD (XPR Type)

Standard chamber kit

Wafer lift mechanism: Fin

O-Rings: Fluorosilicon / TEV

Gate valve: Barrier seal door

Gas system type: (4) Gases

FOUP / ATM Robot / 3 FOUP Backend / YASKAWA MP2300i controller

Cassette ID: Hermos carrier ID

User interface options: Side and front monitor UI

Conditioning station

Monitor: Flat panel display touch screen type

Maximum power 5000 W + RF Match COMET 5 kW

UPS

Gas no / MFC Model / Gas / MFC Size

1 / STEC SEC-Z500 / SEC-Z512/Z522 / O2 / 50 SLM

2 / STEC SEC-Z500 / SEC-Z512/Z522 / N2 / 7 SLM

3 / STEC SEC-Z500 / SEC-Z512/Z522 / 4%H2N2 / 20 SLM

4 / STEC SEC-Z500 / SEC-Z512/Z522 / CF4 / 50 SCCM

Does not include:

Dry pumps

Hard Disk Drive (HDD)

No monitor (Windows)

Lamp and lamp holder non-functional.

NOVELLUS Gamma Express is an etcher / asher device that is used in the production of high-performance integrated circuits. It is capable of producing a variety of high-resolution masks, contact layers and metal traces in a number of advanced materials, including amorphous silicon, polysilicon, tungsten, gold, and other conductive materials. It is an important tool in microelectronics fabrication, and can produce complex patterns in short periods of time with high reliability. The main components of Gamma Express are its mainframe and associated control system. The mainframe houses the actual etcher / asher, which is capable of performing highly precise and controllable etch and deposition steps. The system can be operated over a wide range of process conditions such as pressure, temperature, dwell time and etching environment. It is also capable of multiple etch cycles and can accurately etch a wide range of materials for prototyping. NOVELLUS Gamma Express is also capable of producing precise and reproducible images for inspection and verification. It has advanced optical inspection capabilities using non-contact, non-destructive technology to detect any defects before etching. This can also be used to detect any functional issues prior to etching and protect the accuracy of the etching process. Gamma Express is built for high speed, high performance and high accuracy. It achieves a very high deposition rate, and is able to achieve the desired result in a matter of minutes. The system also has multiple gas sources allowing for excellent control over the etching process. NOVELLUS Gamma Express has advanced control features and is capable of working with both wet and dry process gases, allowing for the highest levels of etching precision. Gamma Express is also equipped with advanced safety features for the protection of personnel and equipment. These features include advanced monitoring, alarms, and a built-in emergency stop which activates in case of any irregularities. In summary, NOVELLUS Gamma Express is a highly advanced etcher / asher device that can produce highly precise and reproducible patterns in a variety of materials quickly and reliably. It is designed for high speed and high accuracy and is equipped with a variety of safety functions to protect personnel and equipment.

There are no reviews yet