Used NOVELLUS Gamma Express #293618750 for sale

URL successfully copied!

Tap to zoom

ID: 293618750

Wafer Size: 12"

Stripper / Asher, 12"

Wet process

OHT PIO Sensor

FOUP Carrier

(3) Carrier stages

GEM / CIM JGJ

Earth leakage breaker

Signal tower: Red / Yellow / Green / Blue

EMO:

Front

(2) Rears

Interconnect hardware: PM to pump 50 ft

Interconnect cables: TM to subpanel 100 ft

MDP Power box

External interlocks

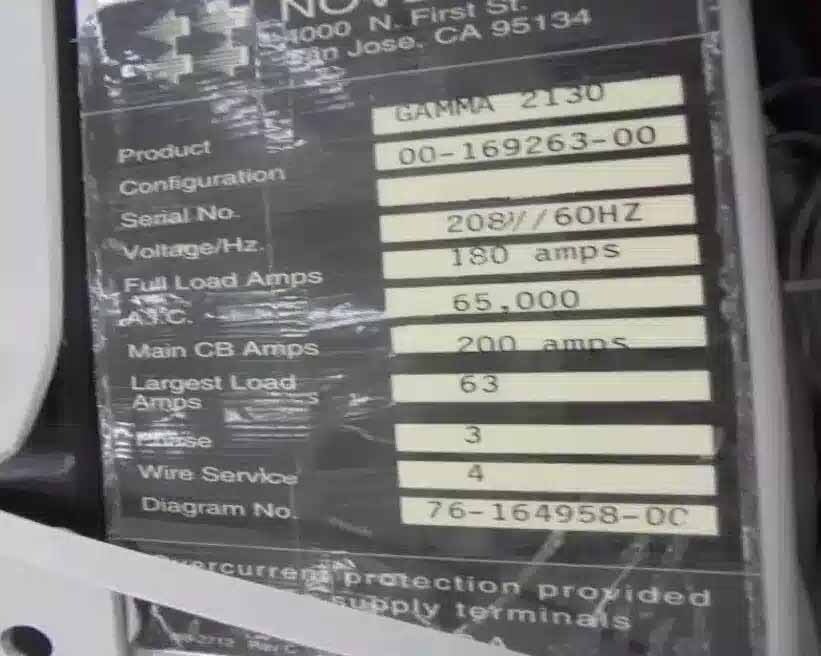

MF: Gamma 2130 upgrade to gamma express

Etch chamber: Gamma 2130 / Position 1 to 6

RF Cable length: RFG to matcher, 30 ft

MKS GHW-50A Generator

Maximum power 5000 W + RF Match COMET 5 kW

HI-THLD (XPR type)

Standard chamber kit

Wafer lift mechanism: Fin

O-Rings: Fluorosilicon / TEV

Gate valve: Barrier seal door

Gas system type: (4) Gases

FOUP / ATM Robot / 3 FOUP Backend / YASKAWA MP2300i controller

Cassette ID: Hermos carrier ID

User interface options: Side and front monitor UI

Conditioning station

(2) Monitors

UPS

Gas no / MFC Model / Gas / MFC Size

1 / STEC SEC-Z500 / SEC-Z512/Z522 / O2 / 50 SLM

2 / STEC SEC-Z500 / SEC-Z512/Z522 / N2 / 7 SLM

3 / STEC SEC-Z500 / SEC-Z512/Z522 / 4%H2N2 / 20 SLM

4 / STEC SEC-Z500 / SEC-Z512/Z522 / CF4 / 50 SCCM

Does not include:

Dry pumps

Hard Disk Drive (HDD)

No monitor (Windows)

Lamp and lamp holder non-functional.

NOVELLUS Gamma Express is a state-of-the-art etching/ashing machine designed to provide precision etching and ashing of thin films on a broad range of materials. The unit is highly versatile, capable of handling a wide variety of substrates and implementing multiple processes including dry etch, wet etch, maskless lithography, and plasma ashing. Gamma Express is an ideal choice for any industry requiring precise and repeatable thin film processing, from semiconductor to MEMS devices. NOVELLUS Gamma Express features a fully adjustable process chamber, allowing for a wide range of substrates and process parameters to be used. The chamber is pressurized to keep the temperature and pressure stable for precise etching/ashing. It accommodates a large substrate size ranging from 2x2mm to 5x5mm, increasing process throughput. The machine is also fitted with a set of high-resolution digital image sensors to provide feedback control for the process. The integrated process module has direct input for controlling the power supplied to different process steps, enabling precise control over etching/ashing depth and selectivity. The system also has a proprietary image matrix metrology system which accurately measures etching and ashing results in real-time. The integrated process software provides a full range of statistics, including etch rate, oxide thinning rate, selectivity, and uniformity. Gamma Express is a highly reliable etching/ashing machine, featuring very low maintenance costs and easy serviceability. It is designed to be quickly set up in a minimum amount of time, with minimal operator training needed. The machine meets all automation requirements, allowing for integration into a production line. The unit is driven by a powerful PLC capable of driving multiple processes, including auto-dosing chemicals for large substrates. NOVELLUS Gamma Express is an ideal tool for thin film processing, providing precise etching and ashing capabilities. The integrated process software ensures repeatable results, with no operator errors. The machine provides accurate results while quickly and reliably delivering high throughput. With its high-precision etching and ashing capabilities, Gamma Express is an essential tool for numerous industries requiring thin film processing.

There are no reviews yet