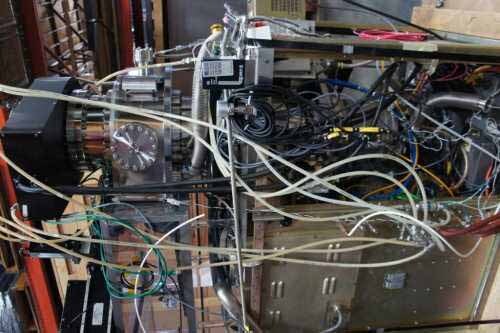

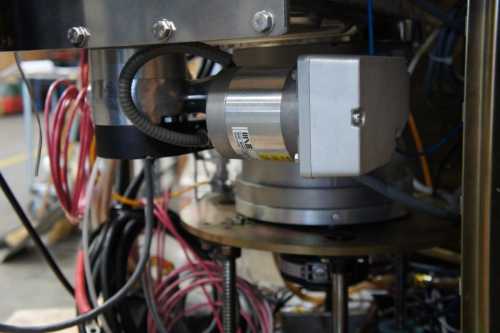

Used OXFORD 80 PECVD #9131938 for sale

URL successfully copied!

Tap to zoom

OXFORD 80 PECVD (Plasma Enhanced Chemical Vapor Deposition) is an advanced dry etch/asher equipment capable of processing a wide range of materials in a precise and cost-effective manner. The PECVD process utilizes a gas mixture of oxidizing and reducing chemicals, which are mixed and ionized in a plasma chamber to create a highly reactive environment. The result is the deposition of thin film layers while simultaneously etching or ashing away undesired material, allowing for the precise control and manipulation of the material characteristics. OXFORD 80 + PECVD model is built for process flexibility and performance. It includes a 6-zone process chamber with an internal baseplate temperature control system from 15 °C to 250 °C. An advanced process control unit allows for precisely tuned and repeatable process parameters. The machine also utilizes an optional rf-only channel addition, which provides additional ions for optimize etching and ashing process without the risk of plasma damage. 80 PECVD can etch materials such as aluminum, copper, gold, and platinum. It can also ashing materials such as polyimide, photoresist, low-k dielectrics, and GaAs structures. The process is capable of rectifying fine deposition steps with high-throughput in a single chamber, allowing for increased process efficiency. In addition, 80 + PECVD provides excellent process repeatability, allowing maximum yields and reliability. OXFORD 80 PECVD is an ideal tool for semiconductor device fabrication and microfabrication applications. It is widely used in industries such as automotive, aerospace, consumer electronics, and more. The etcher / asher delivers superior etch and ash qualities, enabling the installation of complex and delicate integrated circuit components that require precise performance and reliable operation. Overall, OXFORD 80 + PECVD is an efficient and cost-effective etch/asher for a full range of materials. It offers great flexibility, process control, and reliability, making it ideal for a wide range of microfabrication processes.

There are no reviews yet