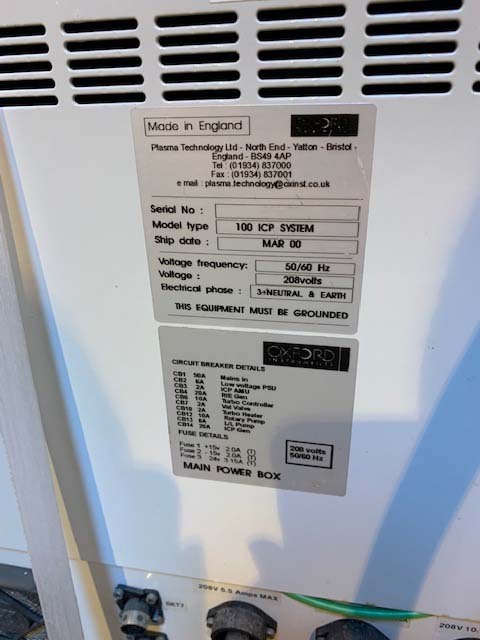

Used OXFORD Plasmalab 100 #9410020 for sale

URL successfully copied!

Tap to zoom

ID: 9410020

Wafer Size: 3"-8"

Vintage: 2000

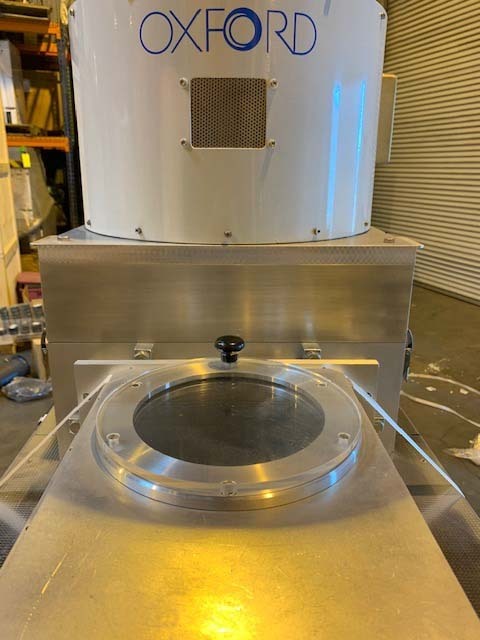

ICP Reactive Ion Etcher (RIE), 3"-8"

Chamber

Low temperature silicon etching system

Unique process gases:

Hexafluoroethane (C2F6)

Octafluorocyclobutane (C4F8)

Trifluoromethane (CHF3)

Hydrogen

Anisotropic etching system:

Silicon

Silicon oxide

Silicon nitride

Electrode temperature range: -150 °C to 300 °C

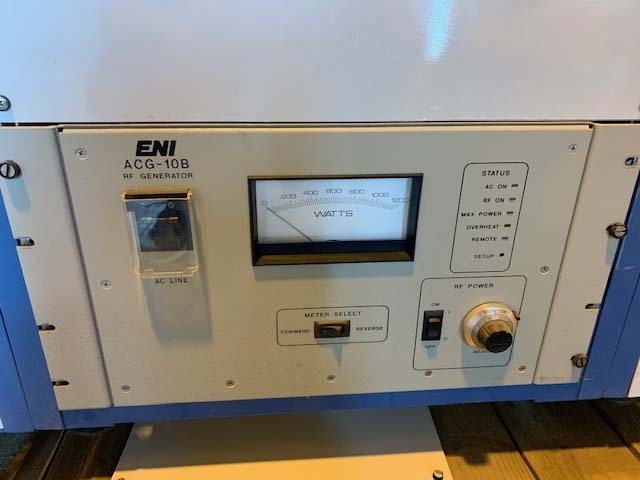

Power source: Up to 600 W at 13.56 MHz

Radio Frequency (RF) Power source: Up to 600 W at 13.56 MHz

2000 vintage.

OXFORD Plasmalab 100 is a state-of-the-art etcher and asher systems designed for precision and surface etching, as well as for precise sample preparation. It is ideal for advanced plasma surface modification and nanoscale processing. The device offers superior performance in higher temperature, higher aspect-ratio, low resistivity and higher power etching processes. Plasmalab 100 consists of two components: the plasma processor, and the chamber. The plasma processor consists of the power supply, gas distribution system, etching chamber and two viewports for monitoring. The power supply outputs up to 55 kW of power to the etching chamber, and features digital temperature control as well as direct control of gas flow and pressure, allowing precise adjustments and maintenance of the process. The chamber is fitted with 480mm x 480mm electrostatic chuck, with an adjustable bias. The face of the chuck can also be adjusted to different angles when needed. High-precision height and angle adjustments are possible using precision linear actuators. The gas distribution system consists of up to 4 independent valves and four distinct gas supply lines, which provide a precise control of pressure and composition within the chamber. The valves are automated, so they can be precisely controlled to vary the process conditions. The etching chamber is constructed from stainless steel and passivated silicon oxide, which is ideal for maintaining high levels of cleanliness as well as low adhesion surfaces. The chamber is temperature controlled and has a primarily internal architecture for shielding the user from radiation. It is also equipped with a pressure control valve for controlling the pressure. OXFORD Plasmalab 100 is designed for high-precision etching and surface modification of a wide range of materials, It is particularly well-suited for the nanomanufacturing of small parts, such as micro-gears and nanowires, as well as complex devices such as nanodevices and MEMS. It can also be used for photoresist etching, RIE/ICP etching, and other forms of processing. The system is highly flexible and configurable, with a wide range of gas types, fixturing and automation options. It is easy to set up, operate and maintain.

There are no reviews yet