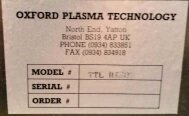

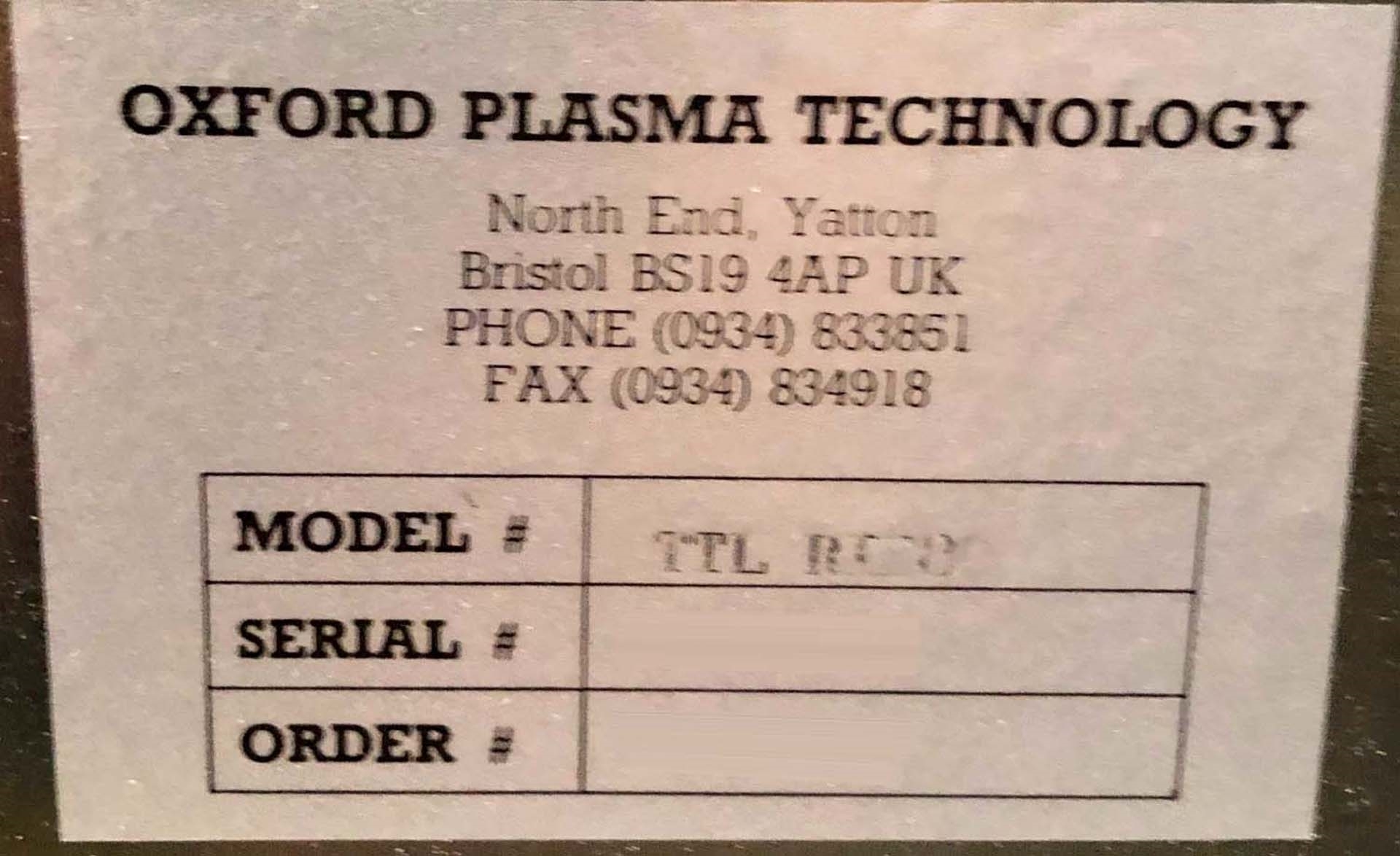

Used OXFORD Plasmalab TTL RIE80 #9249677 for sale

URL successfully copied!

Tap to zoom

ID: 9249677

Wafer Size: 6"

Vintage: 1992

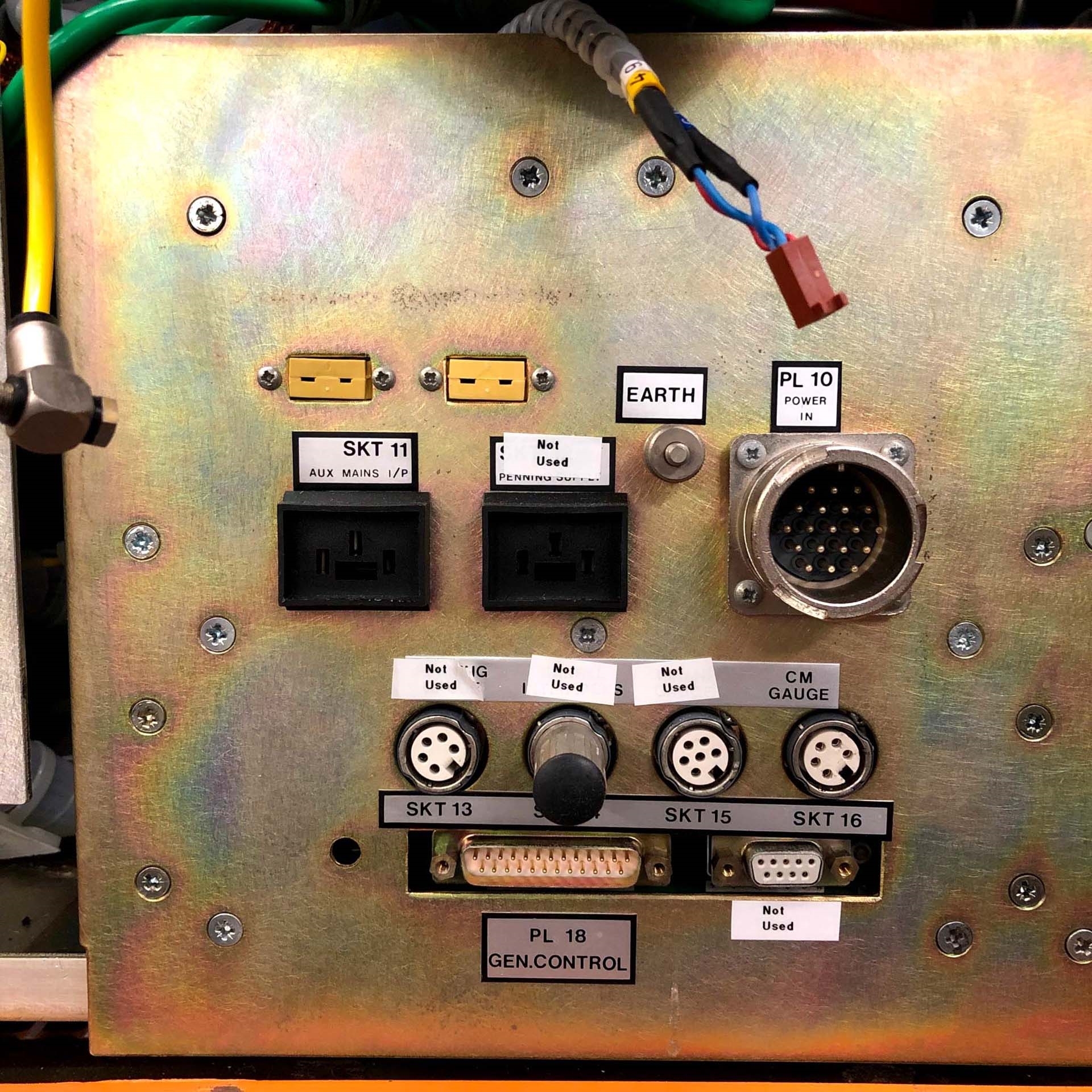

Reactive Ion Etcher (RIE), 6"

Automatch automatic RF tuning system

Used to: Si, SiO2, SiC, SiN, Polymers

Gases: Ar, SF6, and O2

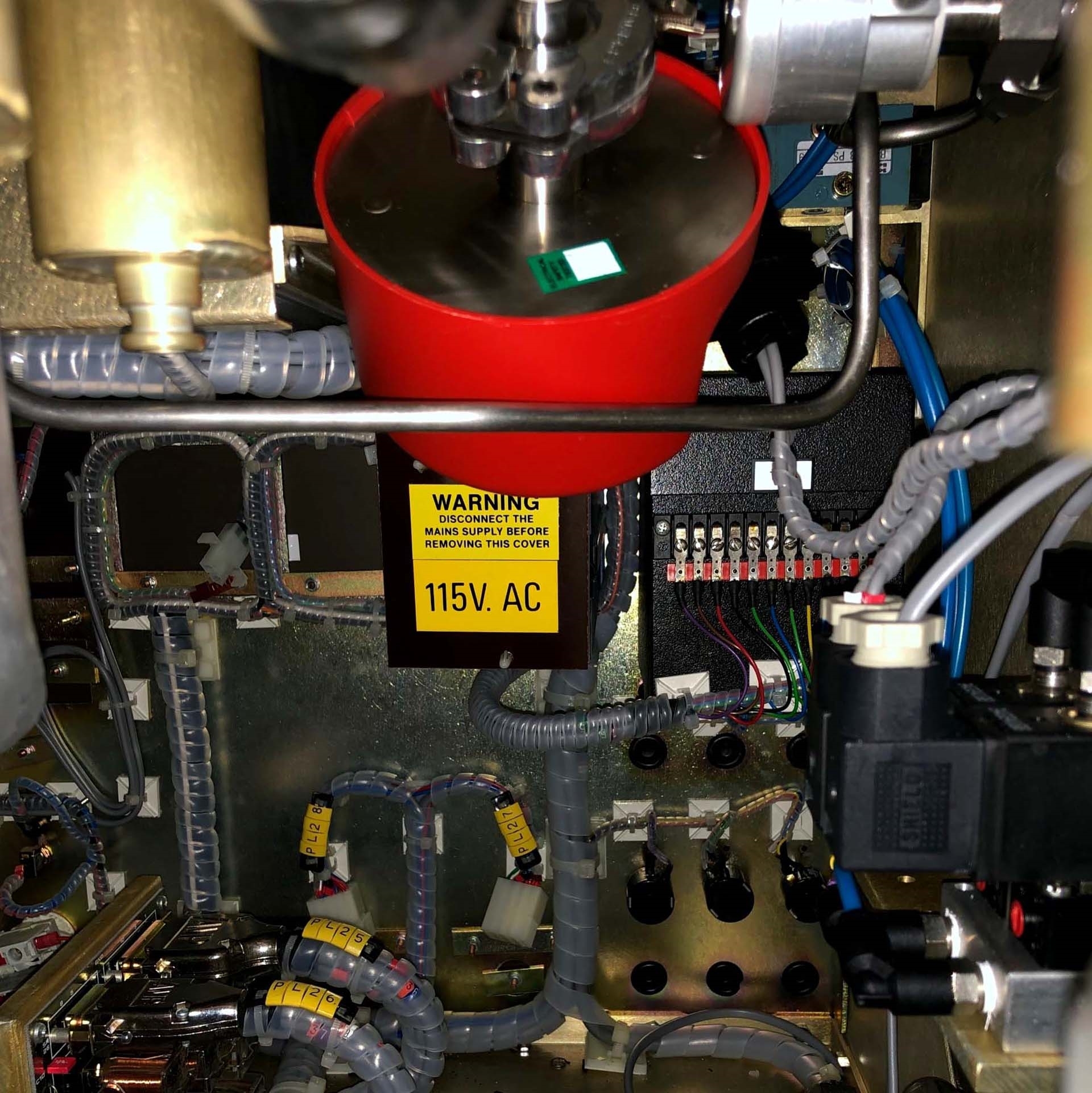

Pressure: < 5 mTorr

Maximum power: 200 W

1992 vintage.

OXFORD Plasmalab TTL RIE80 is a highly efficient, advanced etching/ashing equipment designed for semiconductor, meta/catalytic, nanofabrication, and other advanced-technology applications. This system utilizes an advanced plasma-etch process based on reactive ion etching technology, which is known for its superior feature control and uniform etching. The unit is designed to provide uniform etching with rapid cycle times, and features a titanium lock-down source that provides stable source operation and superior particle immobility in order to minimize particle contamination of the etched material. Plasmalab TTL RIE80 features a broad range of user-defined process parameters that provide users the ability to precisely tailor the etching process to their specific requirements. The machine is capable of producing ultra-fine feature sizes with resolutions of less than 2 nm, while maintaining etch uniformity of better than 5%. The tool utilizes a powerful direct-current (DC) bias to control the reactive species generated in the plasma, as well as to provide superior process control over the etched material. This allows users to tailor the etch process to their specific requirements while still maintaining high feature resolution and uniformity. In addition, OXFORD Plasmalab TTL RIE80 features automated endpoint detection, allowing users to achieve ideal etching performance for specific material thicknesses. The asset also offers industry-leading precision control of process parameters, such as etching time, temperature, pressure, and gas mixture. The model is completely integrated, with user-friendly software that allows users to quickly and easily configure their desired etching process. In summary, Plasmalab TTL RIE80 provides advanced etching capabilities with reliable, controllable process parameters, enabling users to achieve precision control and feature definitions required for advanced-technology applications. This equipment is suitable for semiconductor and meta/catalytic nanofabrication applications, and offers users the ability to tailor their etching process to their specific requirements.

There are no reviews yet