Used OXFORD Plasmalab uEtch 300 / RIE/PE #188102 for sale

URL successfully copied!

Tap to zoom

ID: 188102

RIE System, 12"

Process:

SiO2

Nitrides

Polymers

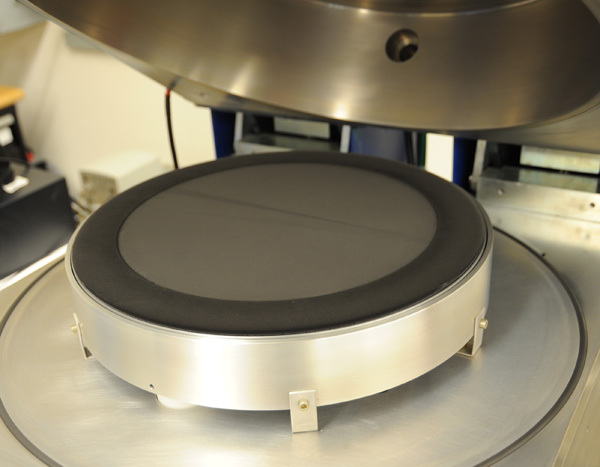

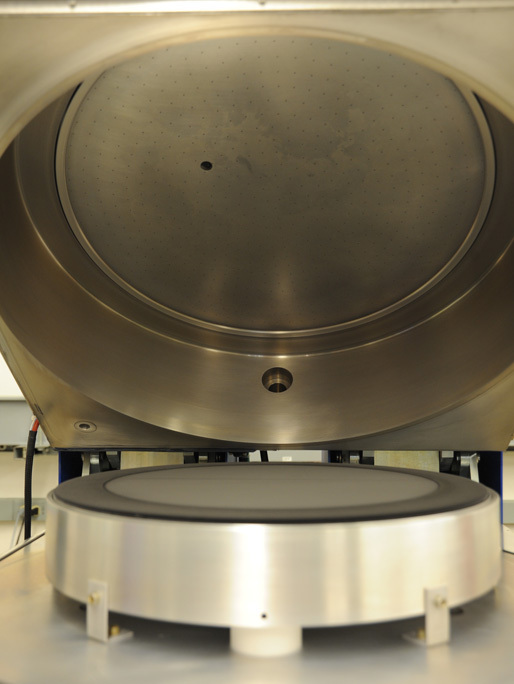

Lower platten: 380mm diameter

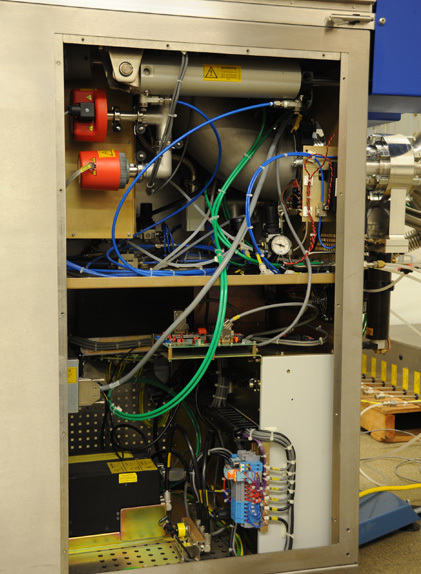

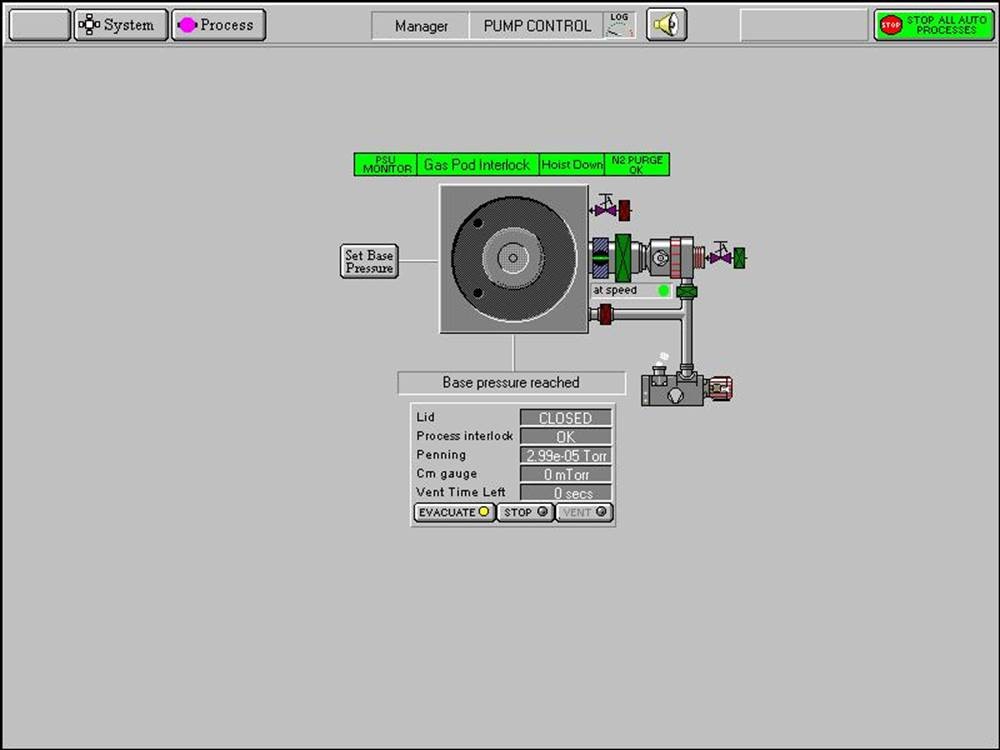

Adixen ATH 400HPC Turbo pump

HP Computer

Pentium dual core processor

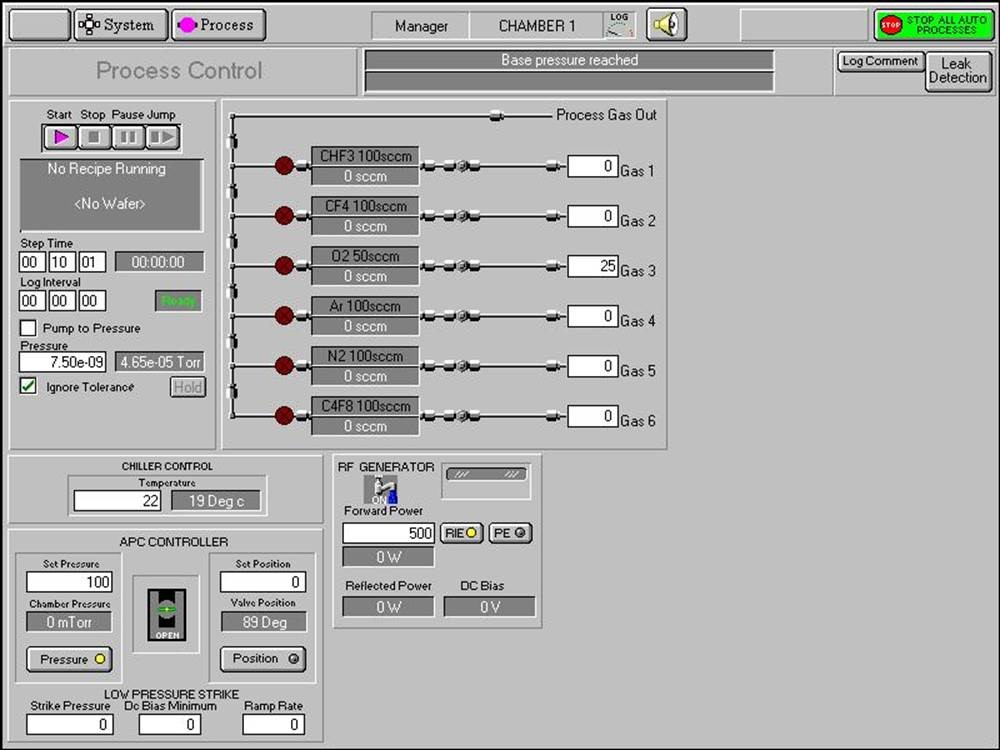

ADVANCED ENERGY: RFG 1251 RF Generator(13.56MHz)

Plasma mode: RIE / PE Recipe controlled

Wafer stage temperature control: NESLAB RTE-7 Chiller

Gas Box:

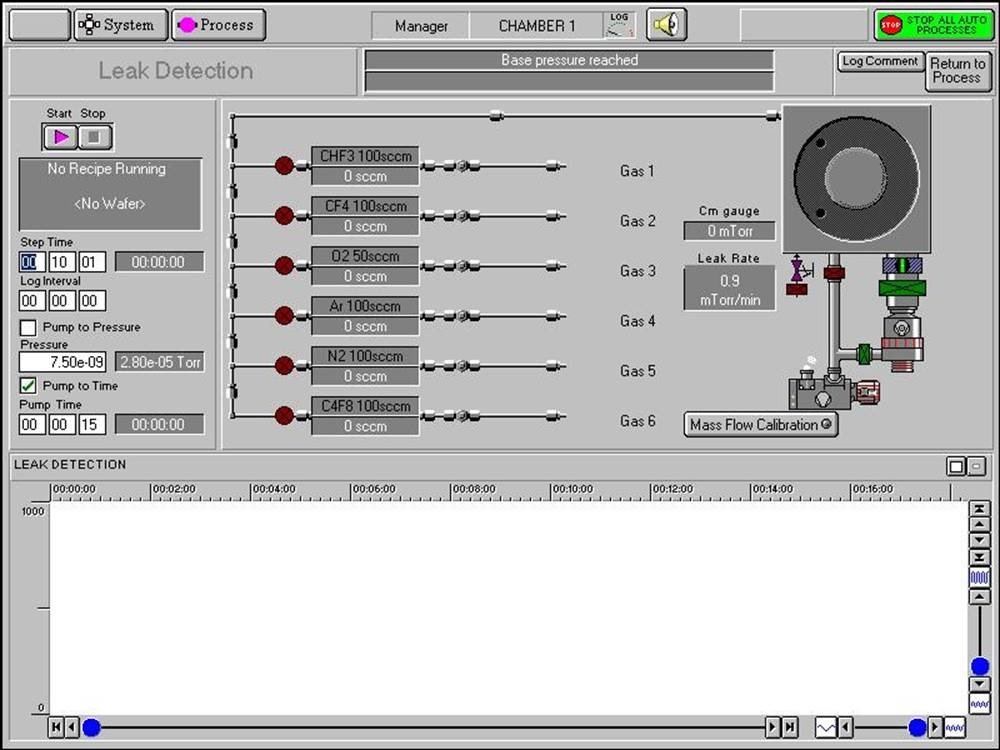

(6) Gas lines

6 MKS 1179A MFC's installed

MFC 1 Gas: CHF3, Range: 100 SCCM

MFC 2 Gas: CF4, Range: 100 SCCM

MFC 3 Gas: O2, Range: 50 SCCM

MFC 4 Gas: AR, Range: 100 SCCM

MFC 5 Gas: N2, Range: 100 SCCM

MFC 6 Gas: C4F8, Range: 100 SCCM

Chamber heating jacket: 20°-80°C

Manual control

Graphite wafer holder: 12"

ALCATEL 2033C Corrosive roughing pump

EMO Button

Chamber up / down selector switch

Hoist up / down buttons

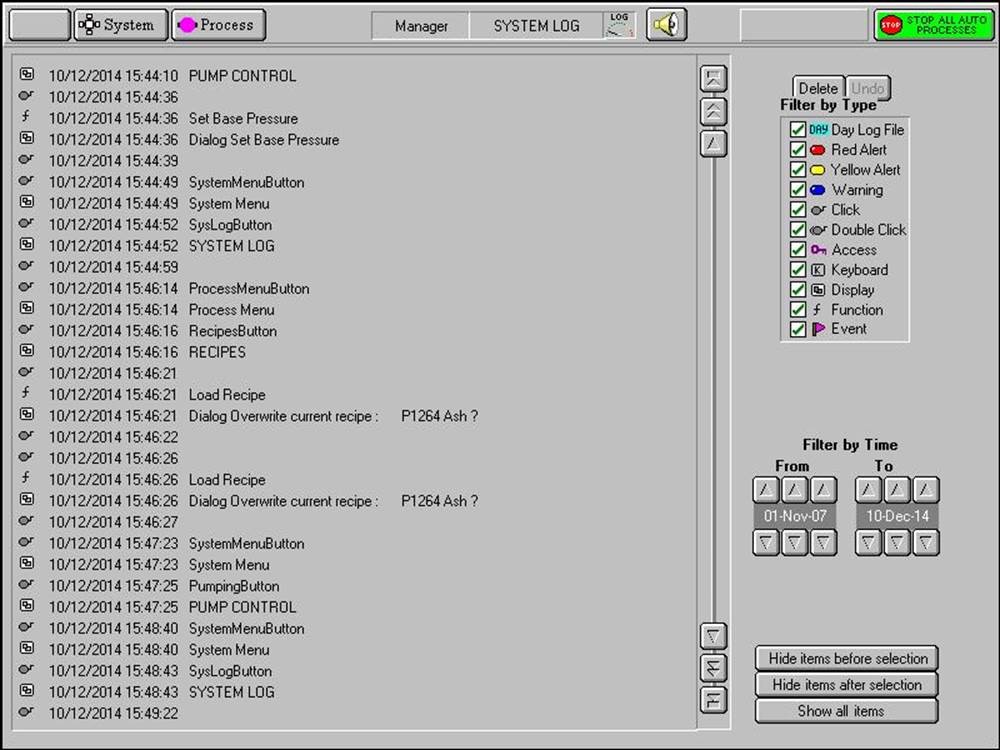

Operations manuals

System restore disk

System power: 208V, 3ph, 50 / 60Hz, 20A.

OXFORD Plasmalab uEtch 300 is a RIE/PE (Reactive Ion Etching/Plasma Etching) equipment designed to etch or asher a variety of materials. It is a powerful and reliable system for etching, deposition, sputter, and implant processes. The unit consists of a low-pressure pilot and "cold wall" technology to minimize gas consumption. Magnetic field confinement fully enables the plasma to move freely and vigorously react with the material in a repeatable process. The power supply can be adjusted to provide users with a wide range of RF power and frequency settings. The chamber has a hemispherical shape with a maximum single-wafer capacity of 2 inches. It offers a continuous-flow gas supply machine with an automated active gas balance and temperature control to ensure uniform processing and repeatability. The tool has two primary gas sources (NF3, SF6 and CF4) and can also be used with a range of other gases as well as different gases for different processing techniques. The gas delivery asset features a neat design with all the control and monitoring easily accessible at the front of the chamber. The front-mounted digital indicators and operability allow the user to observe the process while maintaining full control. The model includes an exhaust equipment with a pressure regulator and corrosion resistive material to guarantee long-term reliability. An autoloader provides users with 6 slots and allows for automatic loading, unloading, and processing of wafers. OXFORD Plasmalab uEtch 300 RIE/PE is an ideal system for those in the industry looking for reliable, repeatable, and cost-effective etching and/or ashing results. The unit requires minimal operator involvement, provides high accuracy and uniformity in etch results, and has all the necessary safety features to ensure compliance with the latest industrial regulations.

There are no reviews yet