Used PINK / PLASMA TECHNOLOGY V8-G-AUTO #9401257 for sale

URL successfully copied!

Tap to zoom

ID: 9401257

Vintage: 2013

Plasma system

Protection class: IP 40

Generator: 2.45 GHz Micro Wave

LEYBOLD Trivac LSS40-65 Vacuum pump

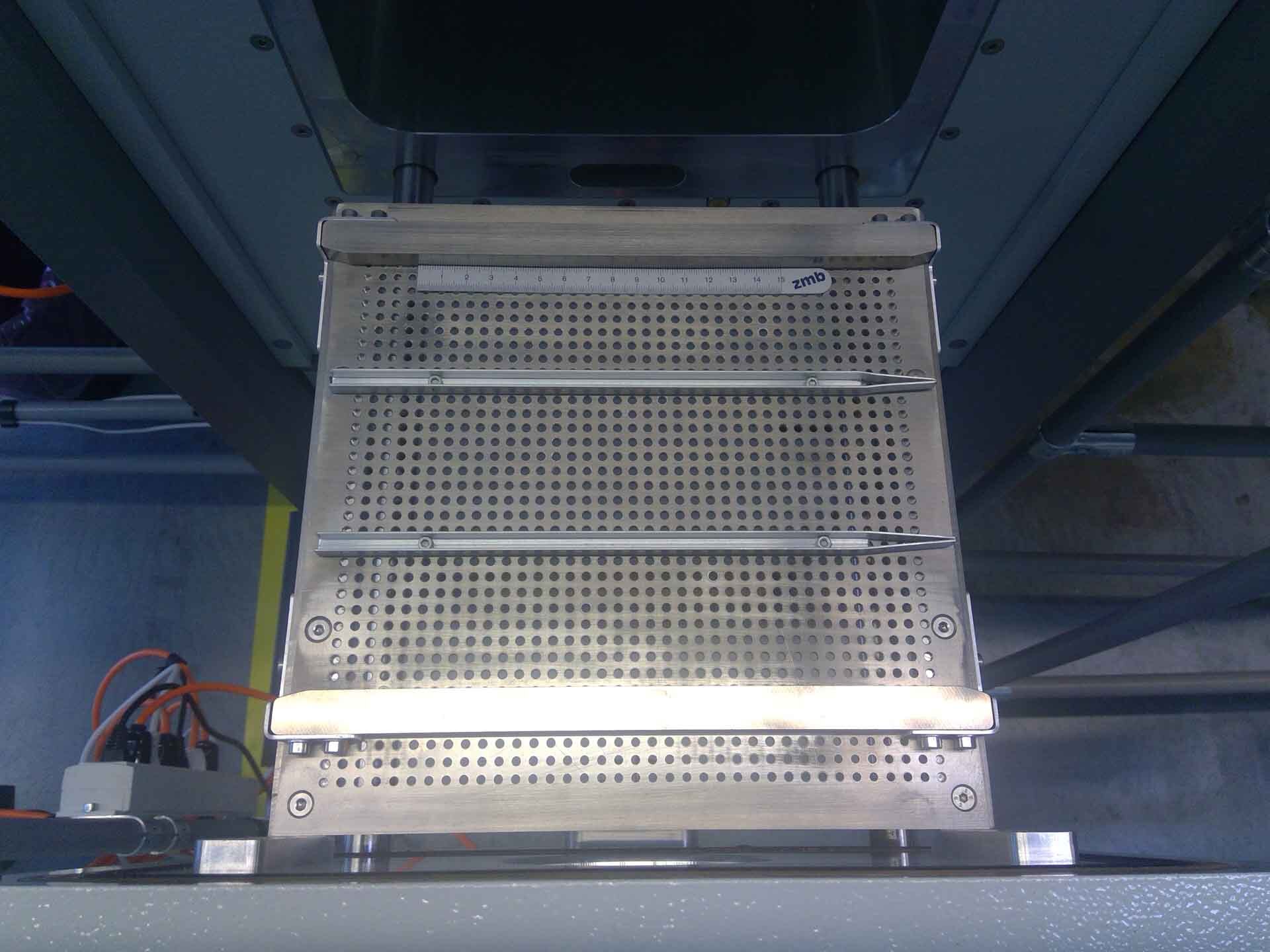

Chamber dimension:

Width: 260 mm

Height: 150 mm

Depth: 280 mm

Volume: ~11 liters

Compressed air:

Connection: Øa 8 mm

Pressure: >5.5 bar (relative)

Gas supplies:

Oxygen (O2)

Connection: Tube Øa 6 mm

Feed pressure (relative):

Minimum: 2 bar

Maximum: 6 bar

Lot:

Maximum: 1000 ml

Minimum: 5 bar

Nitrogen (N2)

Connection: Tube Øa 6 mm

Feed pressure (relative):

Minimum: 2 bar

Maximum: 6 bar

Lot:

Maximum: 50 ml

Minimum: 5 bar

Pressure measurement: 1000 - 0.1 Pa

Vacuum pump speed: 65 m³/hour

Pump exhaust air connection: Øi = 50 mm

Noise emission: 70 dB (A)

Electrical connection: (3) 230/400 V, 50/60 Hz, N/PE

Connected load: 3.3 kVA

MW Power: 600 Watts (Max)

2013 vintage.

PINK / PLASMA TECHNOLOGY V8-G-AUTO is an automated, high performance wafer etcher / asher designed to process a wide array of materials with precision, speed and accuracy. The equipment consists of two primary chambers - one with high density reactive ion plasma, and the other a vacuum chamber with a side-mounted view port. The system utilizes a chuck-based vacuum clamping unit to hold the wafer securely in place during processing, and can accommodate a range of wafer types from 4-inch to 6-inch in diameter. PINK V8-G-AUTO utilizes a high density reactive ion plasma, created by coupling a standard plasma source with an RF power supply. This combination of plasma source and RF power supply allows for precise modulation of the wafer etching process. The machine can effectively etch a wide array of materials, such as silicon, quartz, ceramic and polysilicon oxide. Input gases—such as nitrogen (N2) or argon (Ar)—are precisely metered and channeled through the plasma chamber, where they are energized and form a plasma. The reactive ions within this plasma then interact with the wafer, delivering high etching rates on a wide range of material types. Adjustable plasma parameters, such as RF and bias power, provide user control over the etching process, allowing for variation inFeature imageans via delicate control of the ion energy and etch rate. The wafer is mounted on a wafer chuck table, which can be securely clamped in place and offers precise manual or computer-controlled rotation during etching. The temperature within the vacuum chamber is adjustable, promoting uniform etching across the entire wafer surface. PLASMA TECHNOLOGY V8-G-AUTO offers excellent process repeatability and control with multiple etching cycles that can be programmed in batches. The tool includes advanced real-time process monitoring, with integrated asset diagnostics and software-selectable parameters for detailed process programming. Additionally, the model incorporates automated shipping, material loading, and unloading of wafers to facilitate consistent etching performance. It requires standard power connections, is compatible with standard cleanroom practices and meets current safety regulations. V8-G-AUTO offers excellent performance and efficiency in the etching and ashing of a wide variety of materials, making it well suited for the precise surface processing of semiconductor components. The equipment's precise manipulation of the ion-generated plasma and its ability to precisely program and control the etching process make it a valuable tool for high quality surface processing applications.

There are no reviews yet