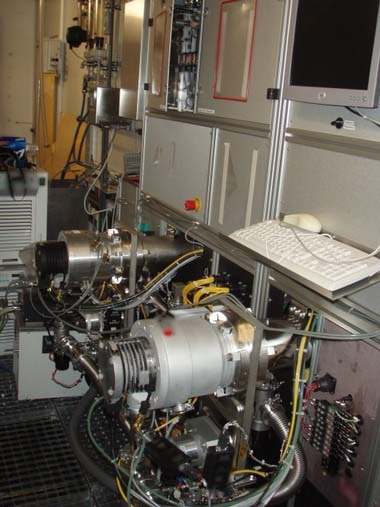

Used PLASMATHERM 770 ICP #9123970 for sale

URL successfully copied!

Tap to zoom

ID: 9123970

Wafer Size: 8"

Vintage: 1997

Ion coupled plasma etcher system

Dual chamber

Load lock shuttle lock transfer

RFPP–RF5S RF power supply w/AM5

Six zone heater

Pressure controller: PM5

RF20M with phase

Model 919 hot cathode controller

VAT PM5 adaptive pressure controller

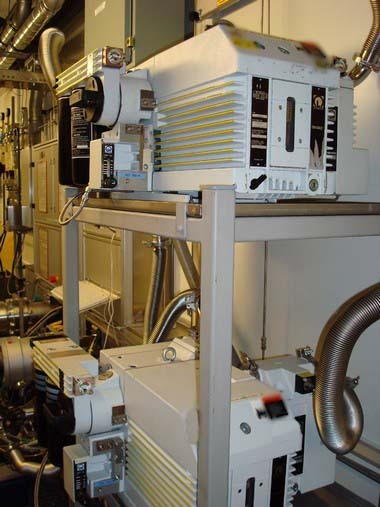

Dual pumping stack with Leybold 600C

Leybold D65BCS

Dual sofie endpoint detectors

Gas chemistry:

Non-chlorine side:

(5) MFCs

(1) N2 Purge

Clorine side:

(4) MFCs

(2) N2 Purges

Plasmatherm windows based OS

208V, 3 Phase, 50/60 Hz

1997 vintage.

PLASMATHERM 770 ICP is an advanced dry-etching etcher/asher equipment originally designed for development and process integration in the semiconductor industry. It is specifically engineered to meet the challenges of high aspect ratio etch, making it suitable for the most difficult processes and applications. The system utilizes an inductively coupled plasma (ICP) source that produces higher high-density plasma with low ionized species to achieve greater accuracy and uniformity than alternative etching systems. The ICP operates at 10.2MHz and has a power range of up to 400 watts, allowing for precise control over power and etching depth. The ICP also operates at temperatures between 450 and 950°C and has a pressure range of 0-1000 mTorr for enhanced flexibility and accuracy. The unit also features an Energy Neutral Charged Particles (ENCP) source, which is designed to reduce long-term damage to the wafer. This source eliminates ionized particles, creating a more uniform etching process which reduces damage to micro features and improves overall accuracy. The ENCP is also capable of providing a higher etching rate and a decreased surface roughness compared to alternative etching techniques. The machine also features three axes of motion and opto-mechanical auto centering to increase productivity and precision. With a 5.8" process chamber, 770 ICP can fit any size wafer and execute etch processes up to 8.0" in diameter. The ceramic-lined process chamber also features a uniform temperature design that creates a stable etching environment. For advanced process control, the tool utilizes advanced automation functions including thermal control, Process Recipe Manager, and semi-automated wafer transfer. A fully automated robotic gas asset is also available to reduce operator intervention and improve productivity, as well as a traceable gas delivery model for greater control over gas mixture composition. Overall, PLASMATHERM 770 ICP etcher/asher equipment is a powerful and reliable tool designed for the most difficult processes and applications in the semiconductor industry. With high-density plasma, uniform power distribution, and automated gas system, the unit offers superior etching accuracy and repeatability.

There are no reviews yet