Used PLASMATHERM 790 Series MF #9382210 for sale

URL successfully copied!

Tap to zoom

ID: 9382210

Wafer Size: 11"

Vintage: 1994

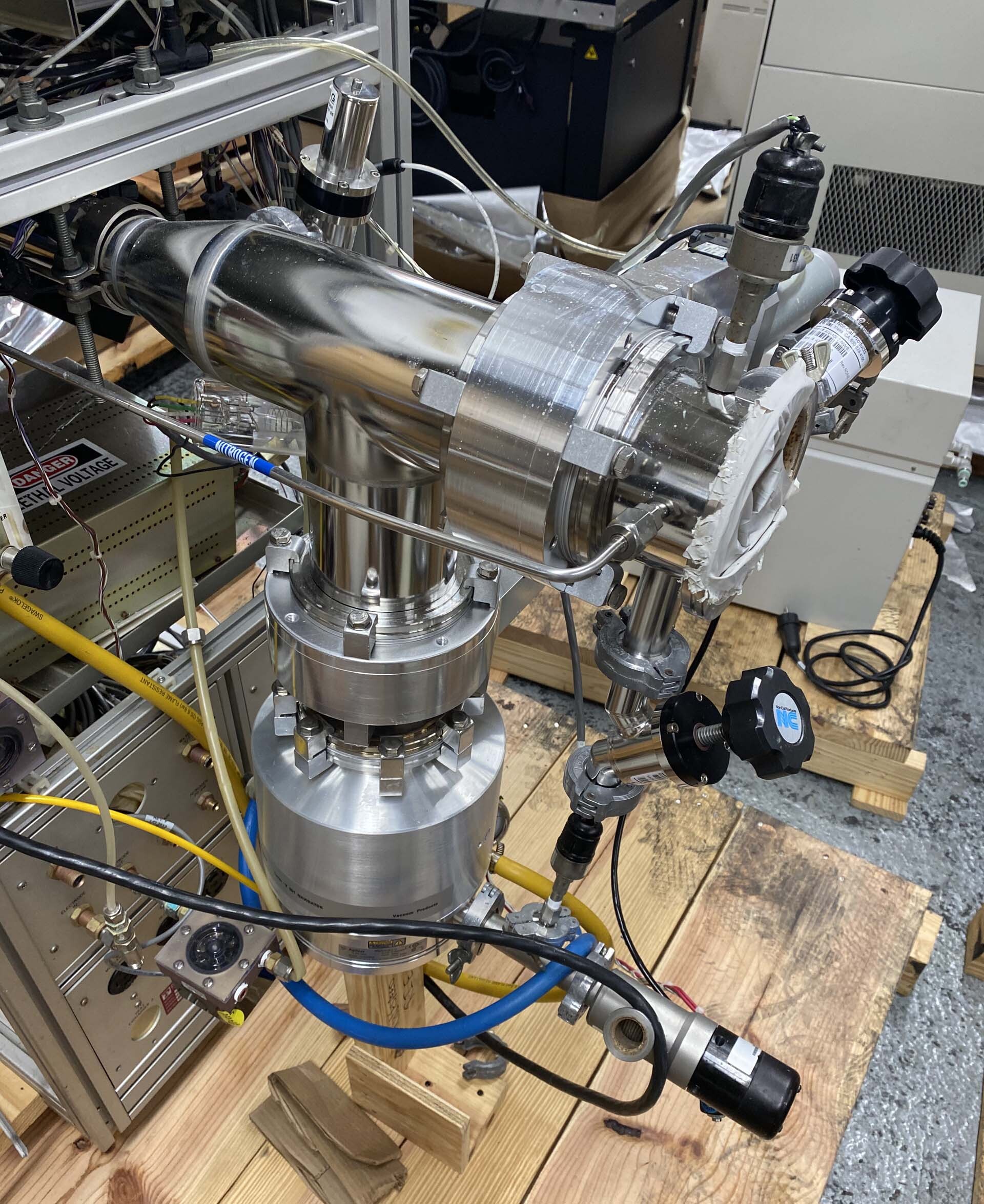

Reactive Ion Etcher (RIE), 11"

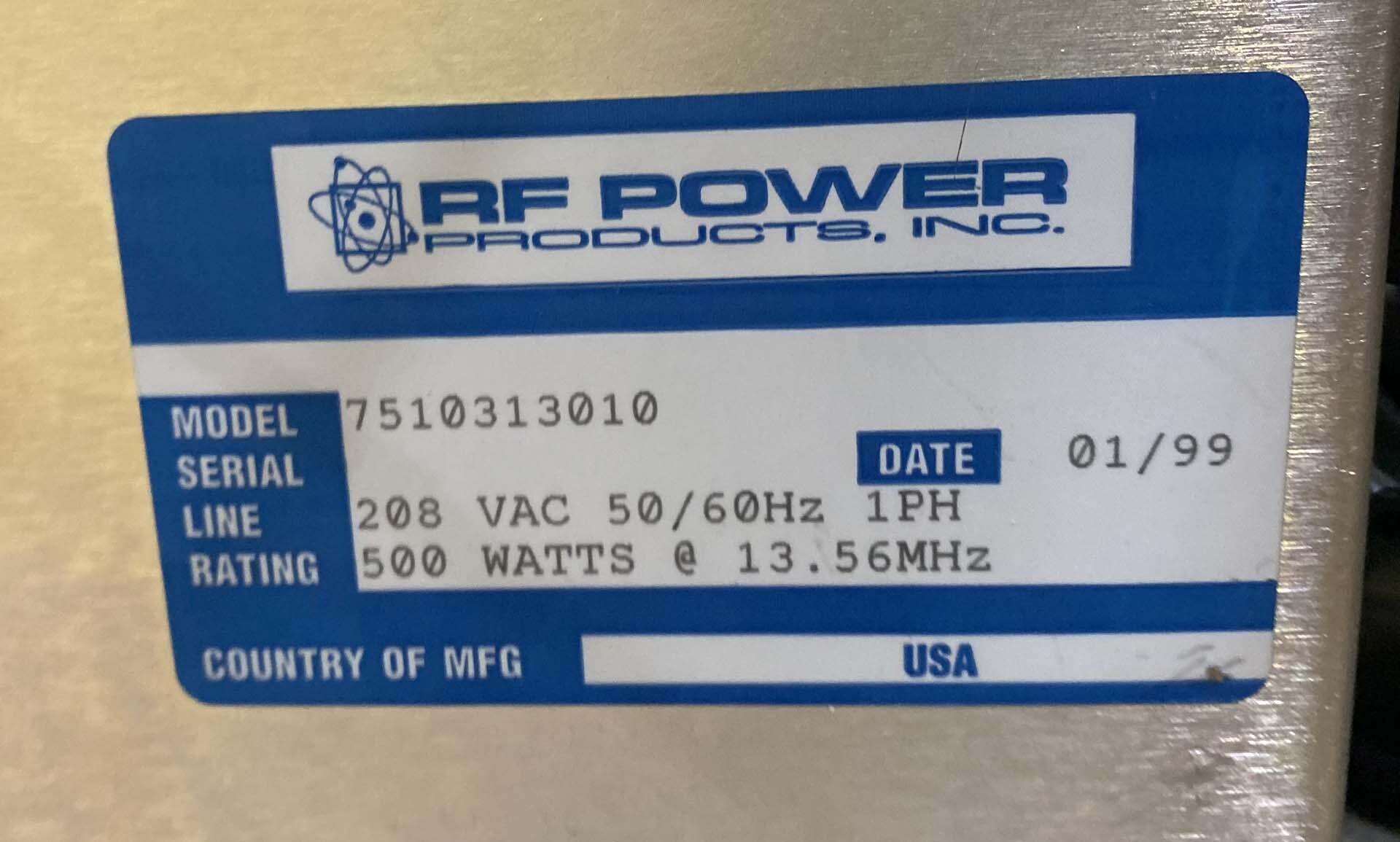

Power supply: 208 V, 60 Hz, 3 Phase

1994 vintage.

PLASMATHERM 790 Series MF is a precise and versatile etcher/asher from AIXTRON. This etcher is designed to etch and asher chips, substrates, wafers, and other thin layers of material. It features an integrated precision control equipment for accurate result. 790 Series MF is extremely precise and accurate, with an internal layer structure only 11 microns thick. This ensures that accurate etching and ashing is possible even on extremely thin substrates. The repeatability and feature size accuracy of this etcher is unmatched, with a resolution of 0.01 μm to 0.05 μm achievable. PLASMATHERM 790 Series MF is designed around the Plasma Enhanced Chemical Vapor Deposition (PECVD) process. This is a highly reliable and flexible process that allows the user to control the etch rate, selectivity, and uniformity of layers etched. This etcher is designed to precisely etch and asher charge-coupled devices (CCDs), complementary metal-oxide-semiconductor (CMOS) transistors, capacitors, inductors, integrated circuit boards, and many more thin material layers. 790 Series MF has been designed for low operating costs and minimal maintenance requirements. The etcher has an extended lifetime of operation, with zero downtime between jobs. This ensures maximum productivity and efficiency. The etcher is also easy to setup and use, with a built-in low-vibration vacuum pump for efficient process loading and unloading. This etcher can be easily integrated into any manufacturing line and system. PLASMATHERM 790 Series MF features an advanced inert gas delivery unit to ensure high quality, high productivity processes. This etcher offers complete process flexibility and reliability, with up to 4 independent process gas sources and up to 3 independently controlled gas pressure. With a gas delivery machine based on three-way and four-way solenoid valves, 790 Series MF is capable of delivering the highest-end etching and ashing results. Moreover, the etcher offers an advanced RF power supply for precise control over power management and process uniformity. Also, the advanced runtime data monitoring tool allows the etcher to monitor asset performances and provide insight into the process dynamics. This helps to optimize etching and ashing results for consistent, high-quality results.

There are no reviews yet