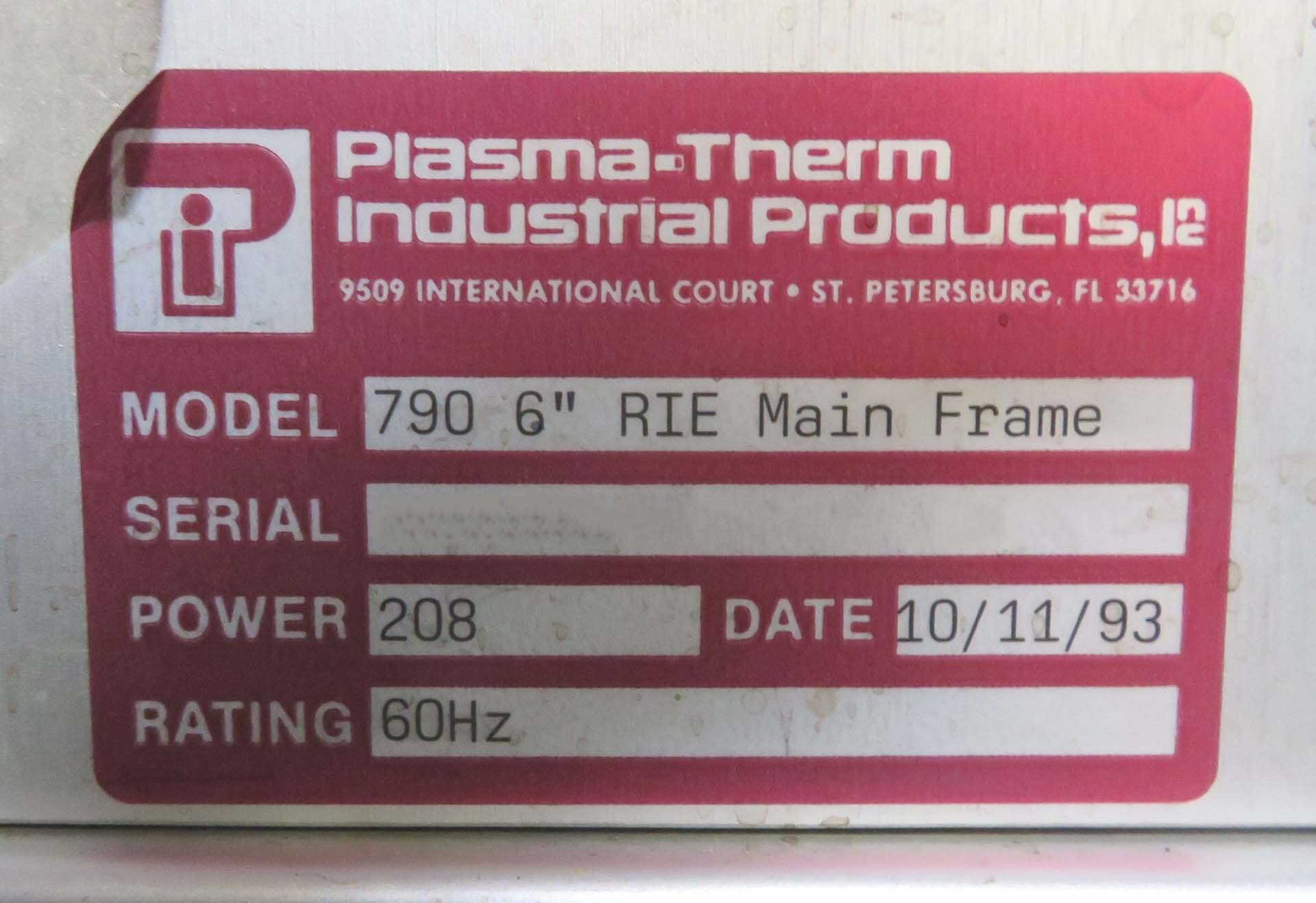

Used PLASMATHERM 790 #293636673 for sale

URL successfully copied!

Tap to zoom

ID: 293636673

Wafer Size: 6"

Vintage: 1993

Reactive Ion Etcher (RIE), 6", parts system

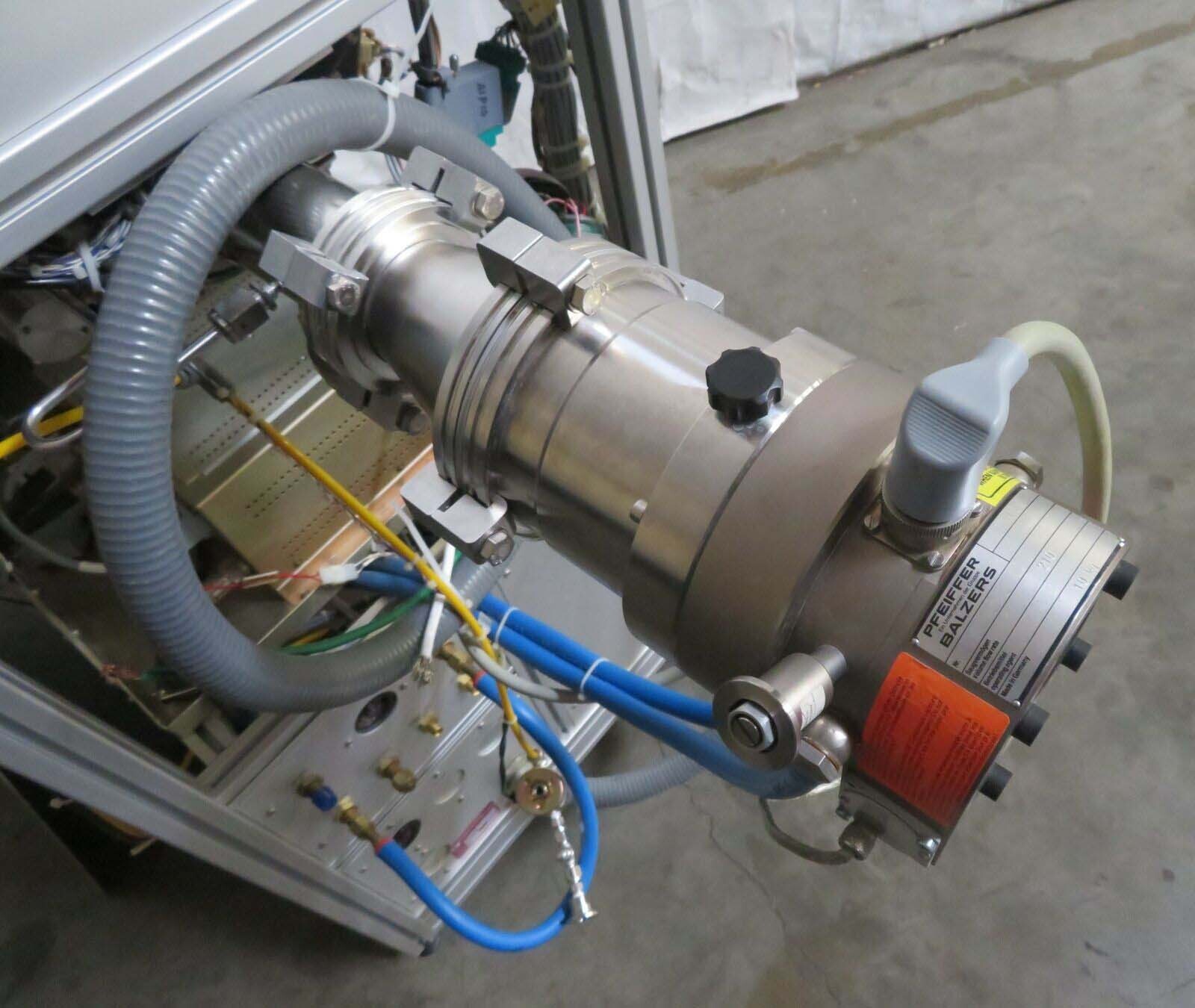

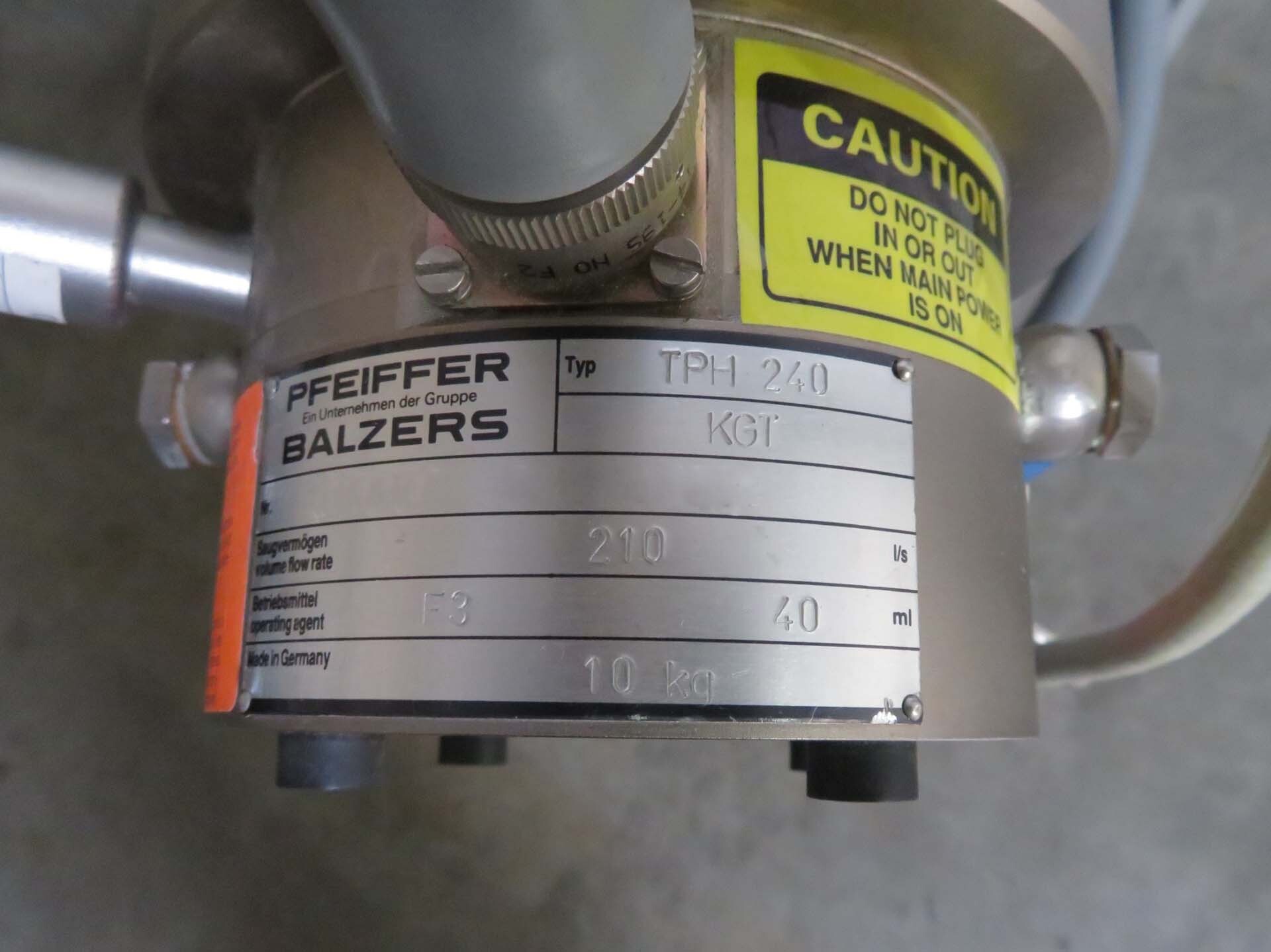

PFEIFFER / BALZERS TPH240 Turbo vacuum pump with TCP 380

MKS 153 Control valve

AM-5 Auto matching network

(4) Mass Flow Controllers (MFC)

(2) Floppy disks

AMN-PS2A RF Controller

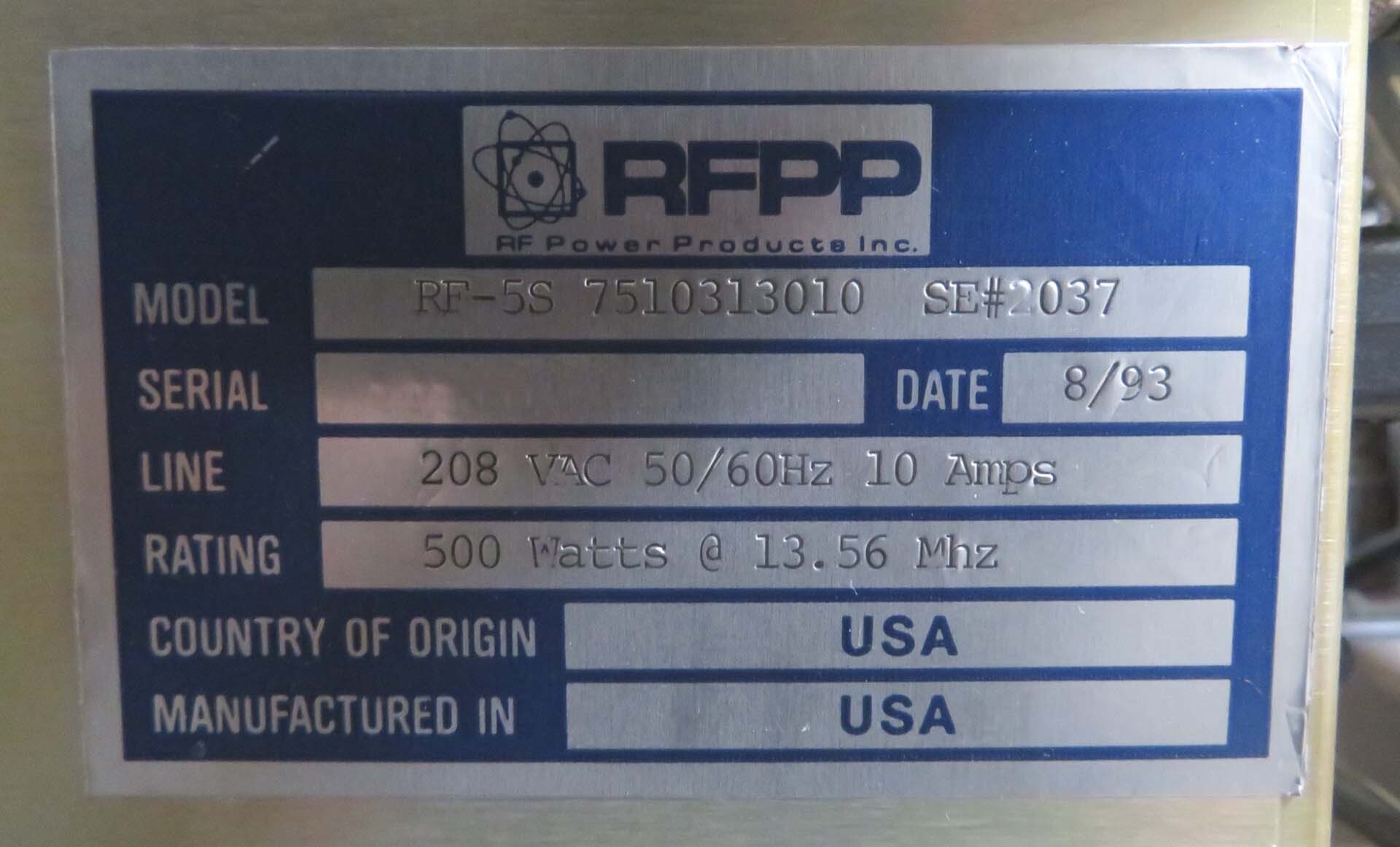

RFPP RF-5S RF Power supply (500W, 13.56 MHz)

Power supply: 500 W, 13.56 MHz, 208 VAC, 60 Hz

1993 vintage.

PLASMATHERM 790 is a high-performance etcher or asher specifically designed for the clean, efficient, and cost-effective production of printed circuit boards. The equipment offers both extreme accuracy and reliability, thanks to its advanced technological features. It is a highly reliable, robust and maintenance-friendly plasma asher system, perfect for fine feature process control, with repeatable results. The unit consists of an insulated stainless steel reaction chamber, a high-frequency source, a gas flow machine and an automated multi-tool plasma source. The reaction chamber is heated to ensure proper thermal management of the heated reaction gas. The chamber is equipped with an advanced vacuum tool which is able to monitor the process pressures and temperature in real-time. The high frequency source produces up to 40,000 Watts of power for etching of object surfaces and materials. This power is also used to heat the reaction chamber and create a vacuum environment. A number of plasma tuned multi-tool sources are available for the asset to provide a range of plasma parameters for improved etching uniformity. The specialized gas nozzle model enables precise adjustment of the etch process parameters, like power, flow, speed, and pressure. The nozzles are capable of forming uniform, high-quality etches over the entire surface area. The reaction chamber design makes it possible to control the position of the nozzles and tune the process parameters, allowing the equipment to be used for various etching applications, such as printed circuit boards. 790 has various safety features, including an automatic shut-off system, which prevents further use of the unit in the event of excessive temperature and pressure. It also features an Emergency Stop button, which stops the machine and prevents any further work in order to protect operator safety. The tool also has a wide range of software and control options, like intelligent user interfaces, to enable the user to configure their own etching process. The asset is compatible with a range of computer-aided design (CAD) packages, allowing for efficient integration into an existing production line. In conclusion, PLASMATHERM 790 is an advanced, reliable and compact etching model, offering highly repeatable results and great flexibility. It is a perfect choice for cost-effective, high accuracy production of printed circuit boards.

There are no reviews yet