Used PLASMATHERM 790 #9113757 for sale

URL successfully copied!

Tap to zoom

ID: 9113757

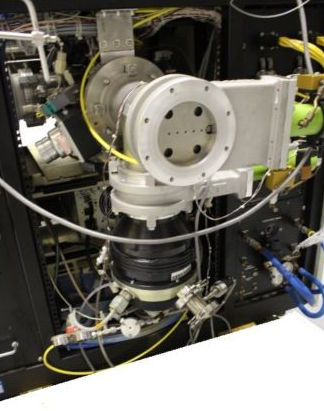

VLR RIE system

Single wafer manual load system

No load lock

Alcatel turbo with controller

Gate valve

Advanced Energy RF5S 500W RF 13.56MHz power supply

Match work and tuner

11" lower platen

13" shower head

(4) Mass flow controllers.

PLASMATHERM 790 etcher/asher is a twin, fully automated plasma etching and ashing process for the fabrication of microelectronics components on wafers. It offers flexibility and reliability in executing both etch back and ashing applications. The advanced etch back technology utilizes a high-pressure plasma source, providing high process uniformity over the wafer by delivering a uniform plasma volume over the entire wafer surface. The machine also provides a comprehensive range of etching parameters, with a broad range of different gas combinations and pressure regimes for optimal etching results. The back etch process is tailored for applications such as RIE, in which the selectivity between different materials is important. The automatic source control further ensures excellent uniformity. The in-process clean ashing is also provided with the same high efficiency and uniformity as with the back etch process. The proprietary Plasma Ashing (PA), leveraging modern low-pressure plasma technology, provides a heterogeneous thermal-plasma vaporisation of aggressive organic and inorganic materials. The thermal plasma ashing process provides clean etching of a wide range of materials - from thick dielectrics to noble metals. The system is equipped with multi-gas flow controllers, providing the opportunity to easily use reactive gas mixtures. Comprehensive interlocks with load lock chamber, robot, and substrate, ensure safe operation, and the process control software is intuitive and easy to use for initialisation and process development. An advanced endpoint detection system is incorporated into the process, which measures a specific specimen reflection and/or substrate voltage. These optical parameters make possible for complete process monitoring throughout the process. The system is available with a selection of configurations, all compatible with front/back side wafer handling robots. In summary, 790 etcher/asher offers excellent uniformity, process flexibility and repeatability, as well as automated endpoint recognition, driving cost efficiency for microelectronic components fabrication.

There are no reviews yet