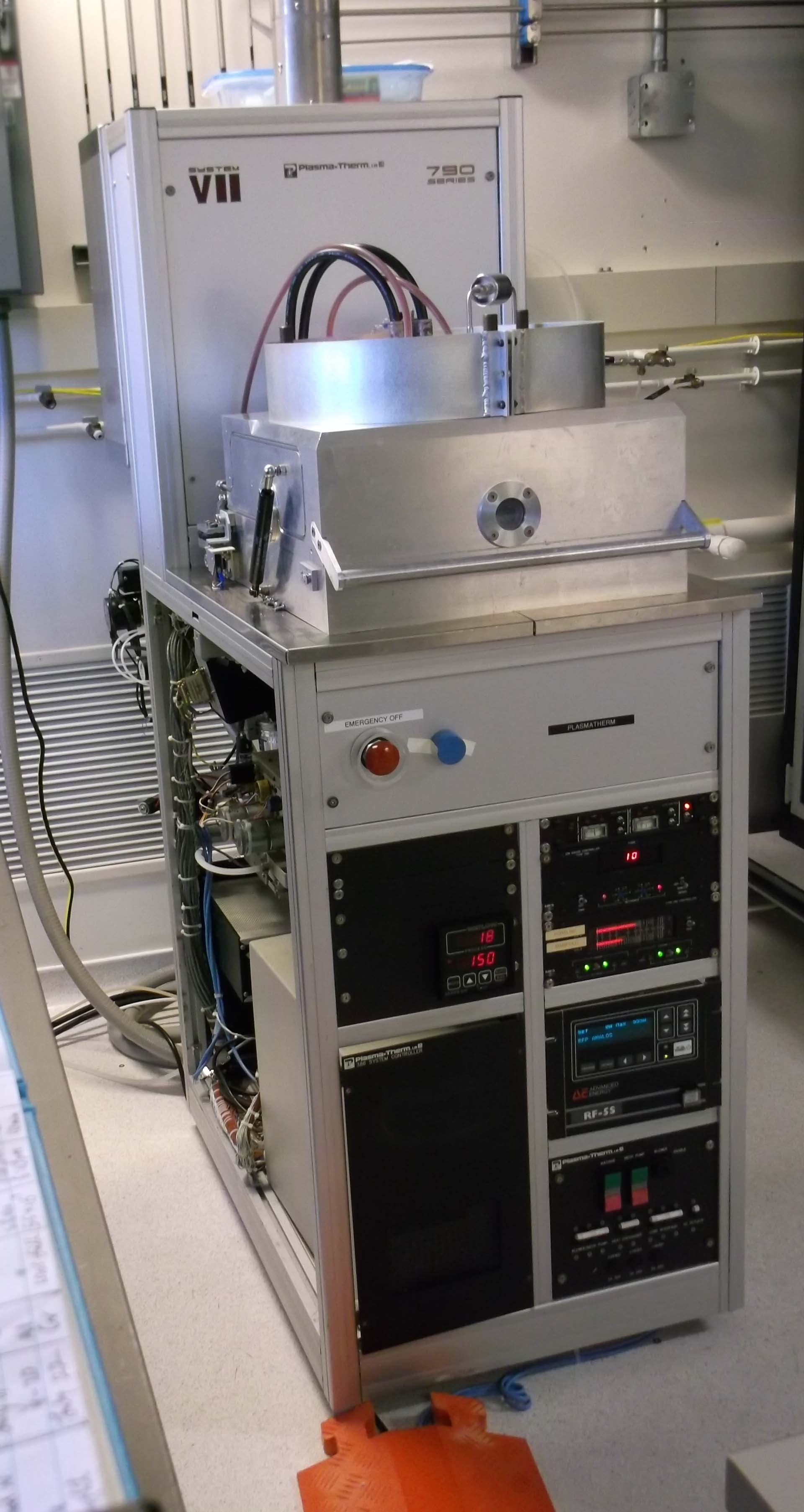

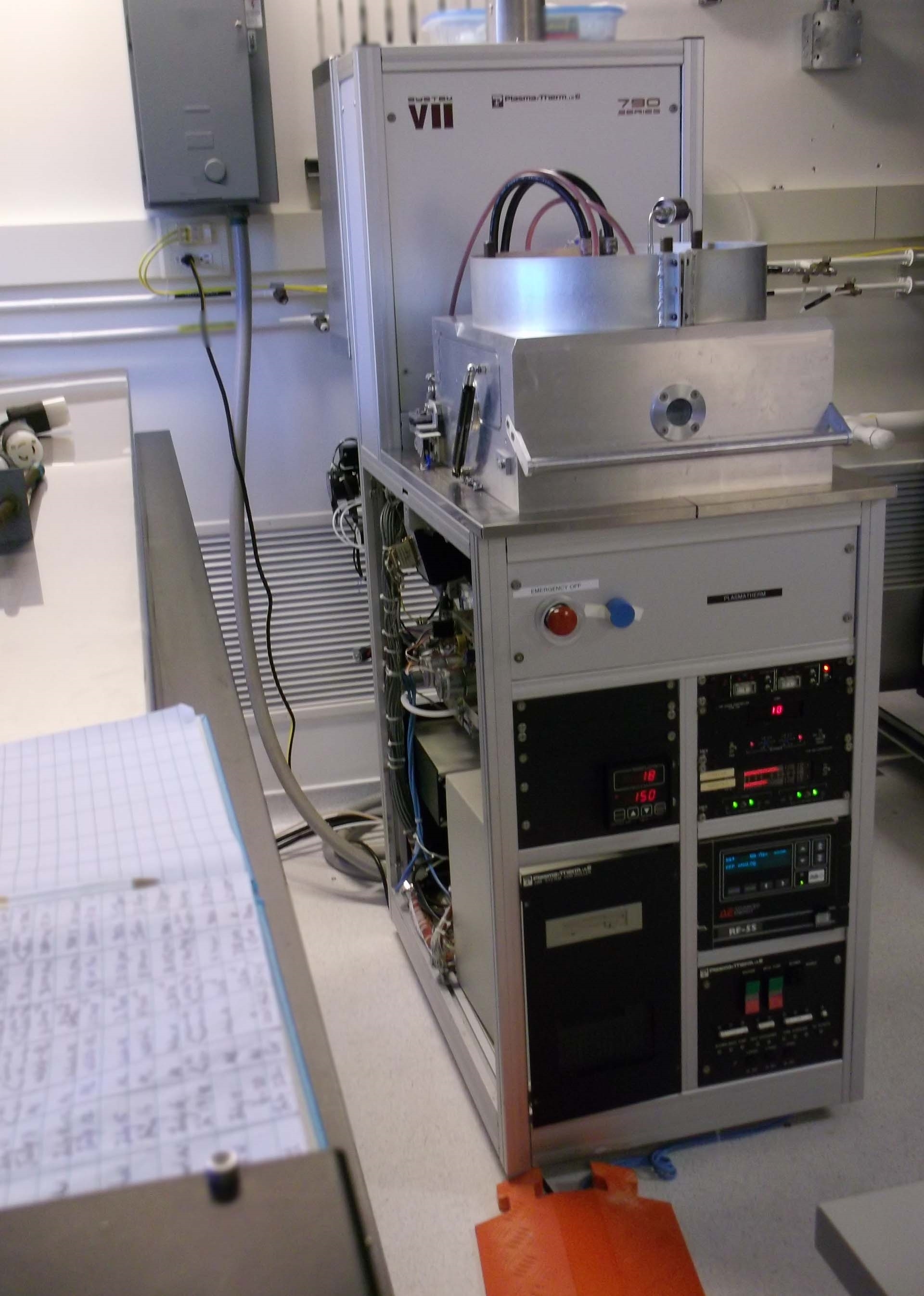

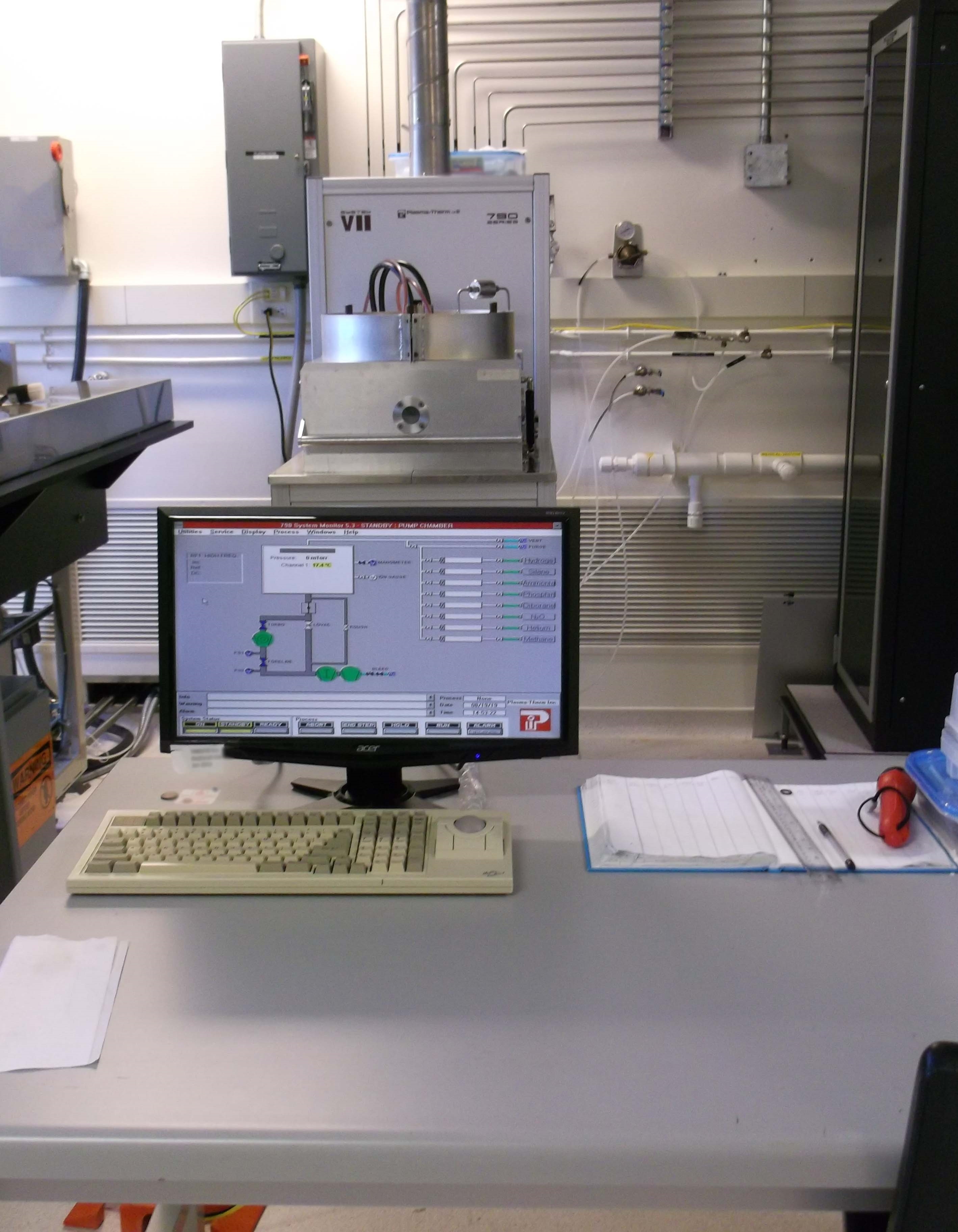

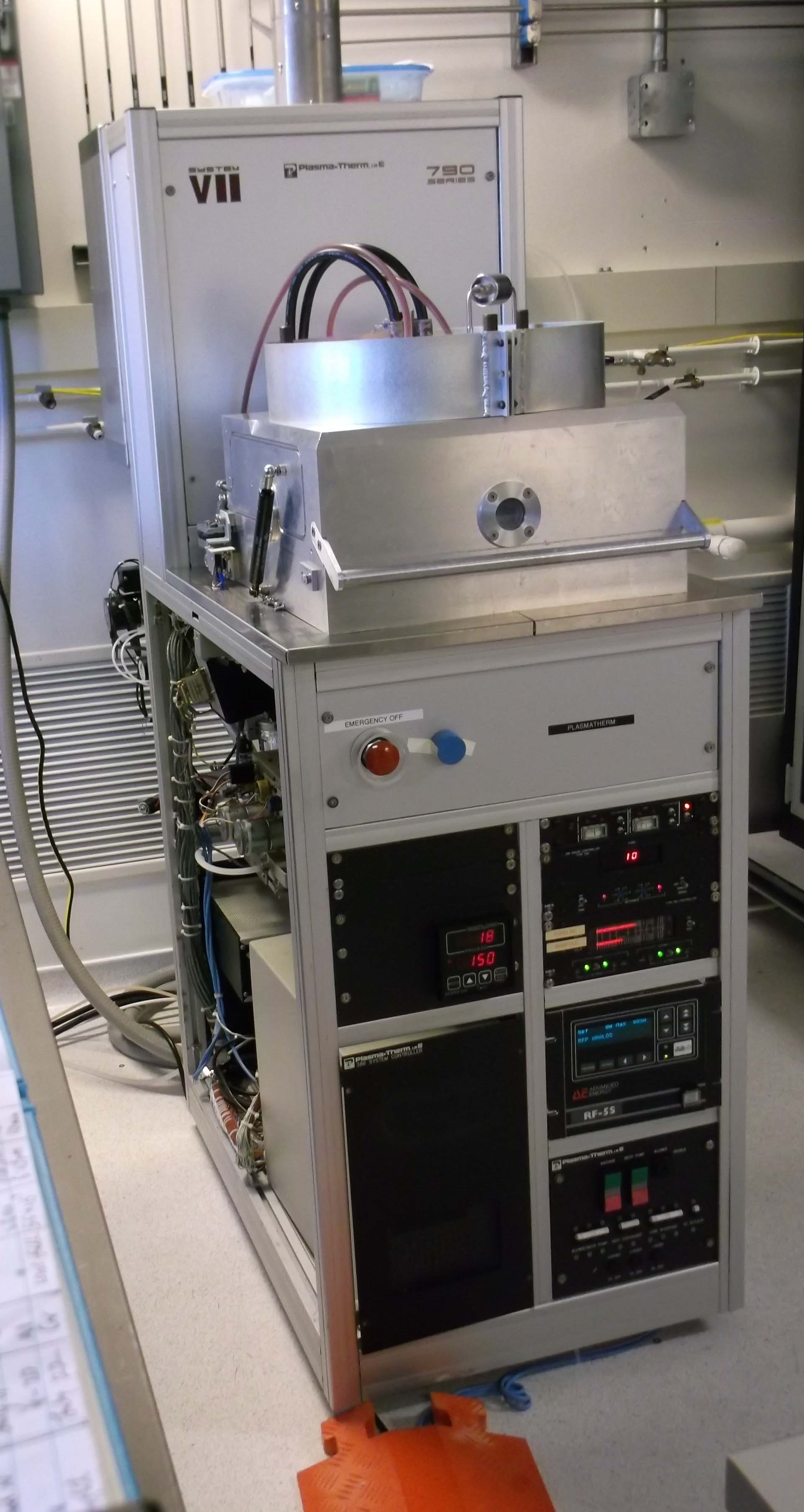

Used PLASMATHERM 790 #9260193 for sale

URL successfully copied!

Tap to zoom

ID: 9260193

Vintage: 1993

PECVD System

Operating system: Windows 3.1

RF Plasma

ADVANCED ENERGY RF 5S Power supply

Power output: 500 W at 13.56 MHz

Max pressure: 900 mT

Deposited materials:

Amorphous

Nanocrystalline Si deposition

Si3N4

SiO2 films

Gases:

CF4 / O2

CH4 / 10 sccm

He / 500 sccm

N2O / 100 sccm

B2H6 / 10 sccm

PH3 / 10 sccm

NH3 / 500 sccm

SiH4 / 50 sccm

H2 / 10000 sccm

N2 Needle valve

1993 vintage.

PLASMATHERM 790 is an Etcher/Asher, specifically a technology that uses plasma to etch, clean, and activate on a wide variety of materials including metals, semiconductors, and polymers. The unit features a variety of etching and ashing options including reactive ion etching (RIE), a chemical vapor deposition (CVD) process, and a dry-release equipment. The system is equipped with two sources of high-powered RF energy, allowing for higher throughput rates and flexibility of application when compared to other etching systems. PLASMATHERM includes RF surface strikes as well as multiple configuration options, including auto-center and auto-scan. The unit includes a 6.4" IDLF (Chamber Desiccator Lid), a fully-loaded bake station, and direct-to-voltex power supply for powerful etching and ashing requirements. The 6.4" IDLF can process up to 2.7 nm per second, with a maximum rail speed of 30 nm per minute. PLASMATHERM also comes with an integrated temperature monitor and control unit. The temperature control and monitor unit is based on two readings, one for each of the two power supplies used. This allows users to regulate the temperature of the plasma chamber in order to optimize processing results. 790 uses a advanced ECOALD-motorized stage for precise motion control during high-volume processes. This motion-control machine uses an internal controller to monitor stage movement, allowing for more aggressive thanmechanical stability. The carbon fiber and steel construction of the stage ensure stability during aggressive high-volume processing. The tool also includes temperature monitoring and control up to 1000°C. PLASMATHERM 790 has an in-built control unit monitoring asset and a built-in diagnostics unit. This feature allows users to test their process and make adjustments or trouble-shooting as needed. PLASMATHERM also has a variety of safety features to protect users from harm during operation. The model is designed to automatically shut off power in the event of gas or voltage fluctuations, as well as blast protection to protect personnel from an accidental pressure increase. The equipment also includes a built-in quartz window cleaner, protecting the porcelain. 790 is an advanced, automated Etcher/Asher designed for high-volume operations. It is equipped with a variety of features, including advanced motion control, temperature control, and blast protection. The unit is capable of etching a variety of materials with high precision and accuracy, allowing users to optimize processes for specific jobs. The built-in safety features further ensure user safety during operation.

There are no reviews yet