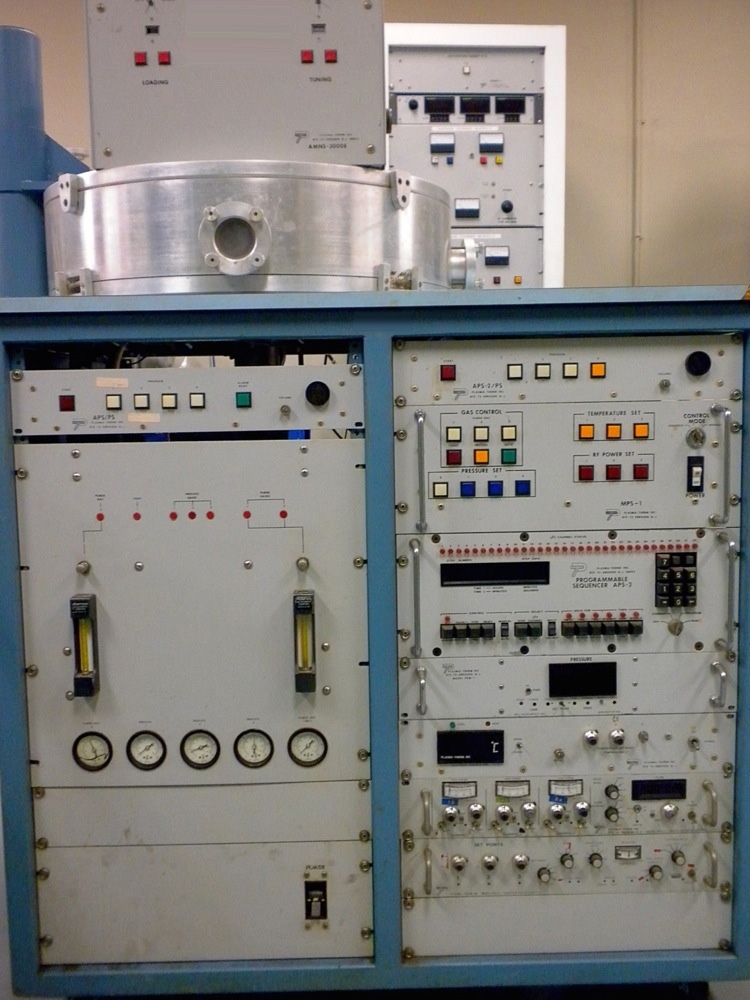

Used PLASMATHERM PK 24 #140728 for sale

URL successfully copied!

Tap to zoom

ID: 140728

Plasma etch system

For implementing dry etching techniques

Dielectric & metals

Pumping system:

Corrosion resistant pump: 40 DFM

Oil filtration system

Chamber / Fixture:

26" Diameter x 5" high Al ring

Al substrate: 26" Diameter

RF Top electrode: 22" Diameter

Electrodes designed for temperature control

Spacing: 1/8" to 2"

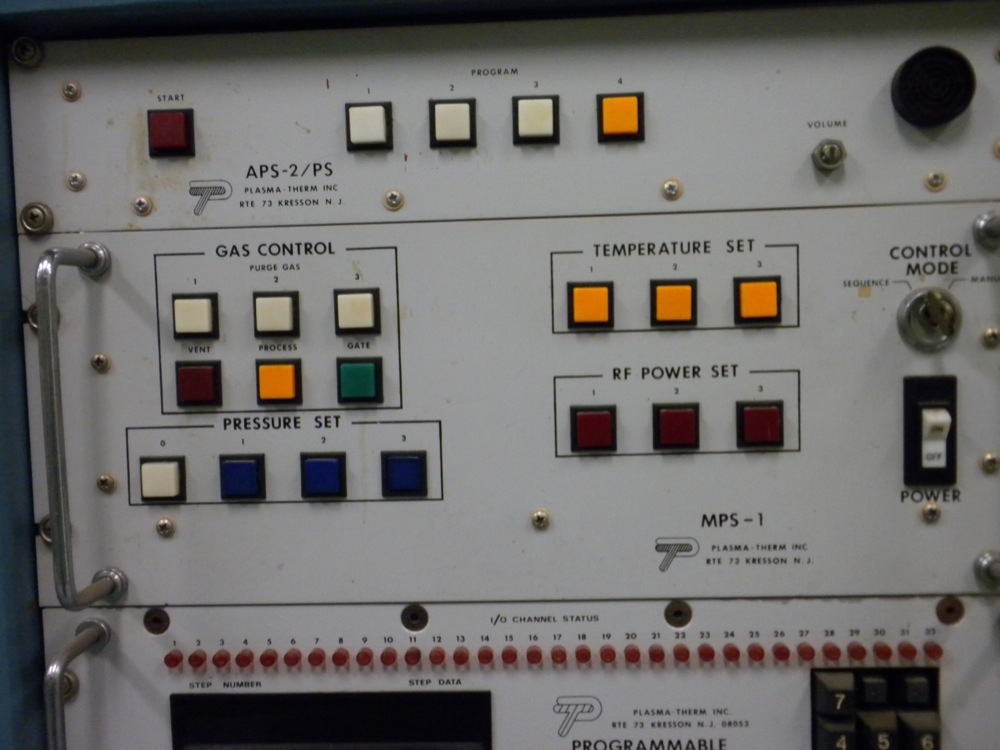

Auto tuning

Matching network box

Cabinet

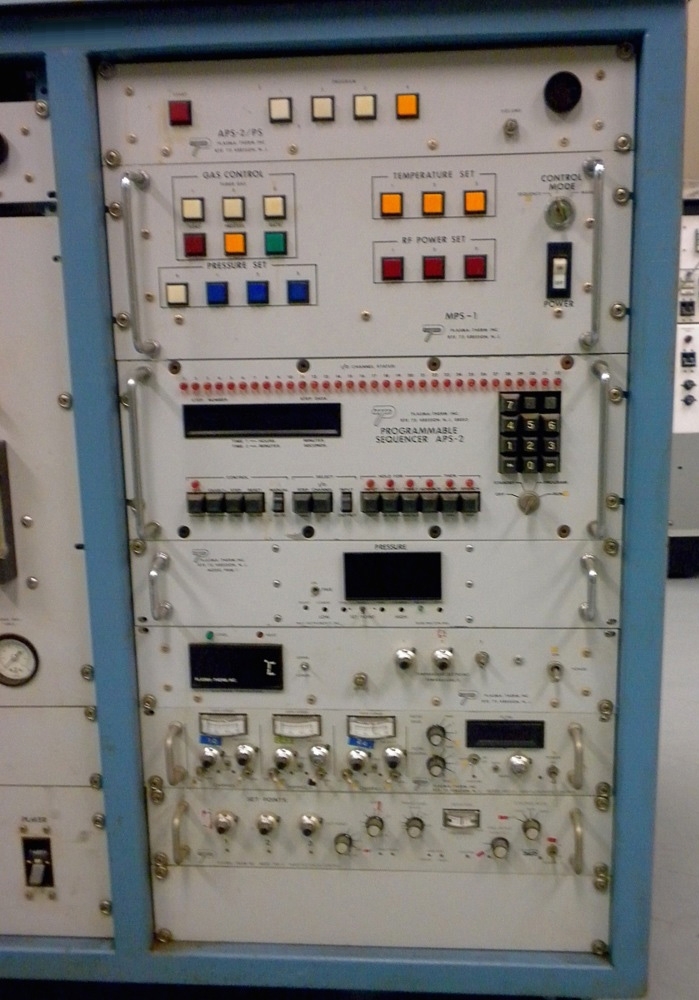

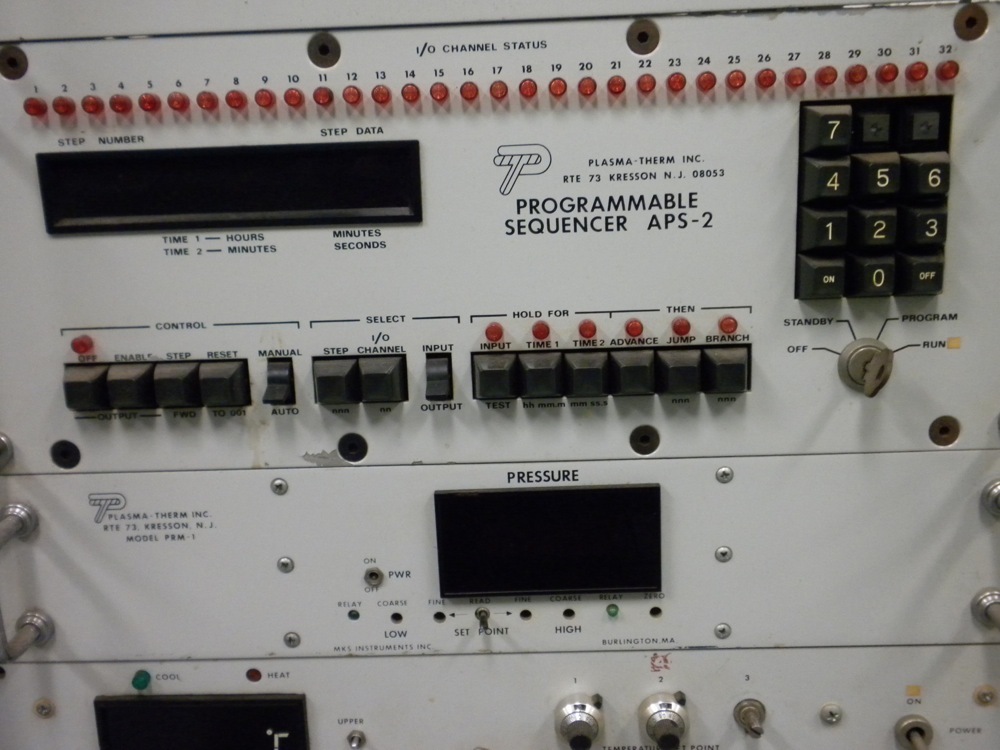

Pressure monitor & control:

Capacitance manometer

Digital readout

Throttle valve & controller

Missing pumps:

Mechanical pump

Pump (Turbo molecular / Diffusion)

Gas inputs:

(3) Process gases: Mass flow control

(2) Purge gases: Rotometer

Flowmeter ranges:

0 - 10 SCCM

0 - 100 SCCM

0 - 1000 SCCM

RF Power: 13.56 MHz, 3 kW

Documentation included.

PLASMATHERM PK 24 is a precision etching/ashing equipment designed for both laboratory and industrial applications. With an oxygen-rich plasma, this system is capable of producing grooves, recesses, and surface structures on substrates such as metals, ceramics and glass materials. The integrated software provides easy-to-use parameters for etching and ashing. The supplied tools like milling tools, drill bits, and laser cutting tools are highly efficient, offering long-life and greater precision. Moreover, PK 24 allows for easy and friendly operation with direct data access, parameter control, automated processes and machine integration. The unit includes Dual-Vortex plasma sources, a unique, patented technology with a one turn timing feature. The advanced Vortex Reactor technology allows for uniform etching and ashing of substrates, guaranteeing products of high-quality with fast cycle times. The built-in blower helps reduce etch and ashing time, offering constant, stable plasma for high for excellent product consistency. PLASMATHERM PK 24 also provides economic gas management and low cost consumables. Its gas monitoring machine allows for automatic gas delivery, ensuring a safe and reliable operation. The supply container is modular and openable to allow easy changing of consumables and usage of different gasses. PK 24 has a medium-sized chamber, with a working area of 245 x 245 mm, offering great flexibility for a wide variety of applications. Compared to alternative etching and ashing systems, PLASMATHERM PK 24 features a large working area and process area, making it suitable for larger substrates. PK 24 is designed for safety and reliability. The chamber and other components are designed for a clean and dust-free working environment, as well as for temperature and gas stability, providing consistent performance in industrial operations. Furthermore, the tool's top cover and liquid cooling asset solve the problem of condensation inside the chamber. PLASMATHERM PK 24 is easy to use and maintain, allowing operators to access all necessary data and control parameters. Its easy to read control and diagnostics panel is designed for maximum efficiency and reliability. Moreover, all the necessary safety equipment and safety features, such as probes and sensors, are integrated to prevent any accidents in the work area. As a result, PK 24 offers excellent security and a secure working environment.

There are no reviews yet