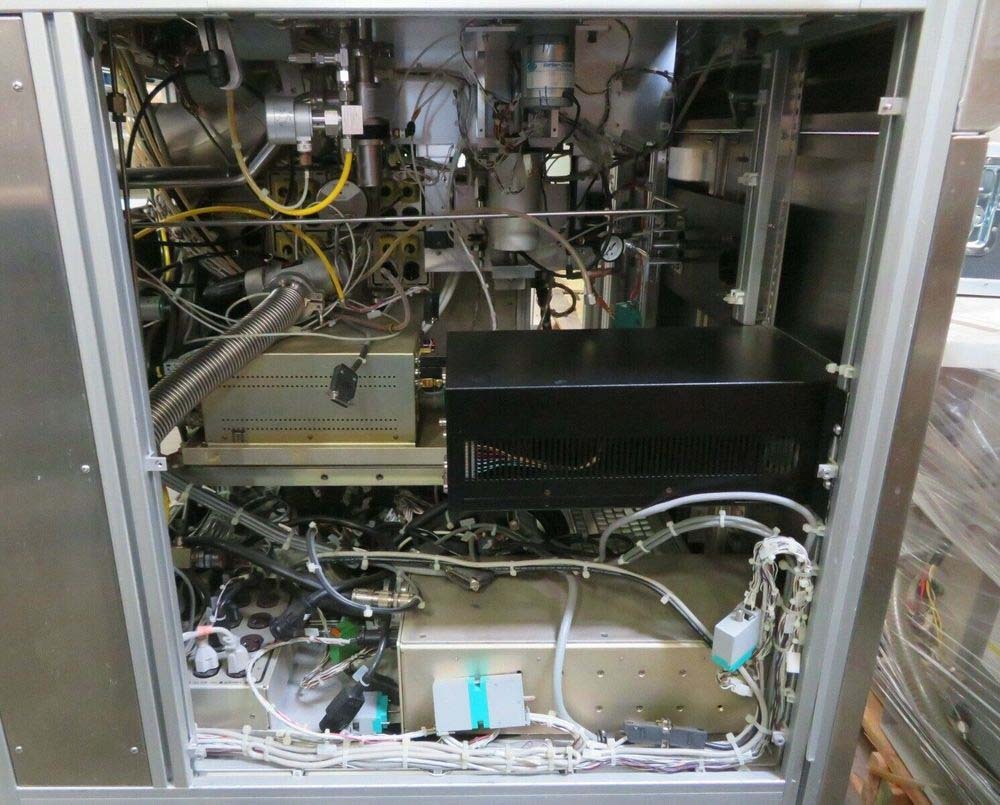

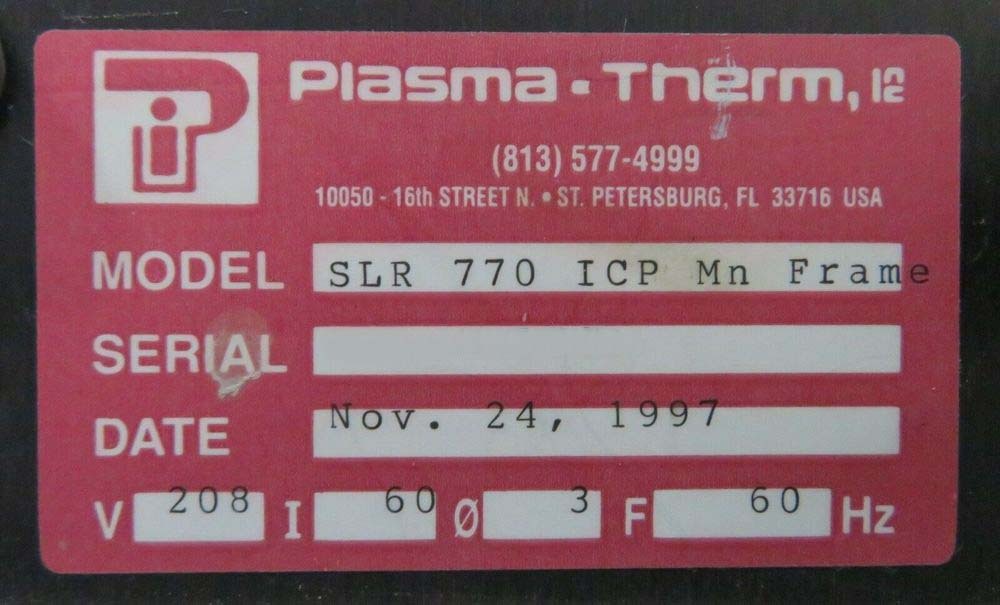

Used PLASMATHERM SLR 770 ICP #9363201 for sale

URL successfully copied!

Tap to zoom

ID: 9363201

Wafer Size: 3"-6"

Vintage: 1997

ICP Dry etcher, 3"-6"

RFPP AM-5 RF Match

ISA JOBIN YVON Sofie type LEM-1-CC controller

(4) Mass flow controllers

1997 vintage.

PLASMATHERM SLR 770 ICP is a high-precision etcher / asher designed to provide precise etching and ashing processes. It utilizes a modular platform to provide a wide range of etching and ashing processes. This etcher / asher is designed to provide a continuous, repeatable process with minimal maintenance and repeatability errors. PLASMATHERM SLR-770 ICP is a two chamber etcher / asher which utilizes a low pressure isotropic dry plasma for etching, and a high pressure dry plasma for ashing. The low pressure plasma is supplied by the plasma generator and consists of oxygen, nitrogen, and argon. The high pressure plasma uses a dry-spark pattern to generate a low voltage electrical arc, creating a vaporized vaporized ash additive. The two plasmas are then combined and stored within an isolator chamber. The burning of the material is initiated by the PC during the pre-processing phase and is continued during the etching or ashing process. As the material is etched or ashed by the combination of the two plasmas, the chamber is then purged with nitrogen to avoid any adverse reactions. SLR 770 ICP is designed to work with etch/ash-resistant materials such as semiconductor or dielectric substrates. The etcher / asher is designed to provide precise and repeatable etching and ashing processes, as well as to guarantee consistent performance. The chamber is also equipped with multiple safety features, including: high temperature shutoff, Ground Fault Interrupter (GFI), control circuitry, and high voltage isolation. The high-precision etcher / asher utilizes the most advanced VHF-Arc Plasma technology and is fully computer-controlled. This allows for a wide range of process parameters to be set and stored, including: etch and ash times, temperatures, and pressures. The process is quantified and measured using a range of sensors, such as: Quartz Oscillators, Temperature and Pressure sensors. This enables controlled and repeatable processes to be carried out across multiple substrates. The large LCD display and intuitive user interface makes SLR-770 ICP an easy machine to operate. Additionally, the machine can be equipped with a process chamber monitor camera, allowing the user to monitor the process chamber in real time. This provides an additional layer of quality assurance, ensuring that processes are performed correctly and repeating the process on subsequent substrates. Overall, the high-precision PLASMATHERM SLR 770 ICP is designed as a reliable and cost effective tool for etching and ashing processes. The modular platform, advanced VHF arc plasma technology, high voltage isolation, ease of use, and high precision makes PLASMATHERM SLR-770 ICP an attractive choice for users seeking a reliable etcher / asher solution.

There are no reviews yet