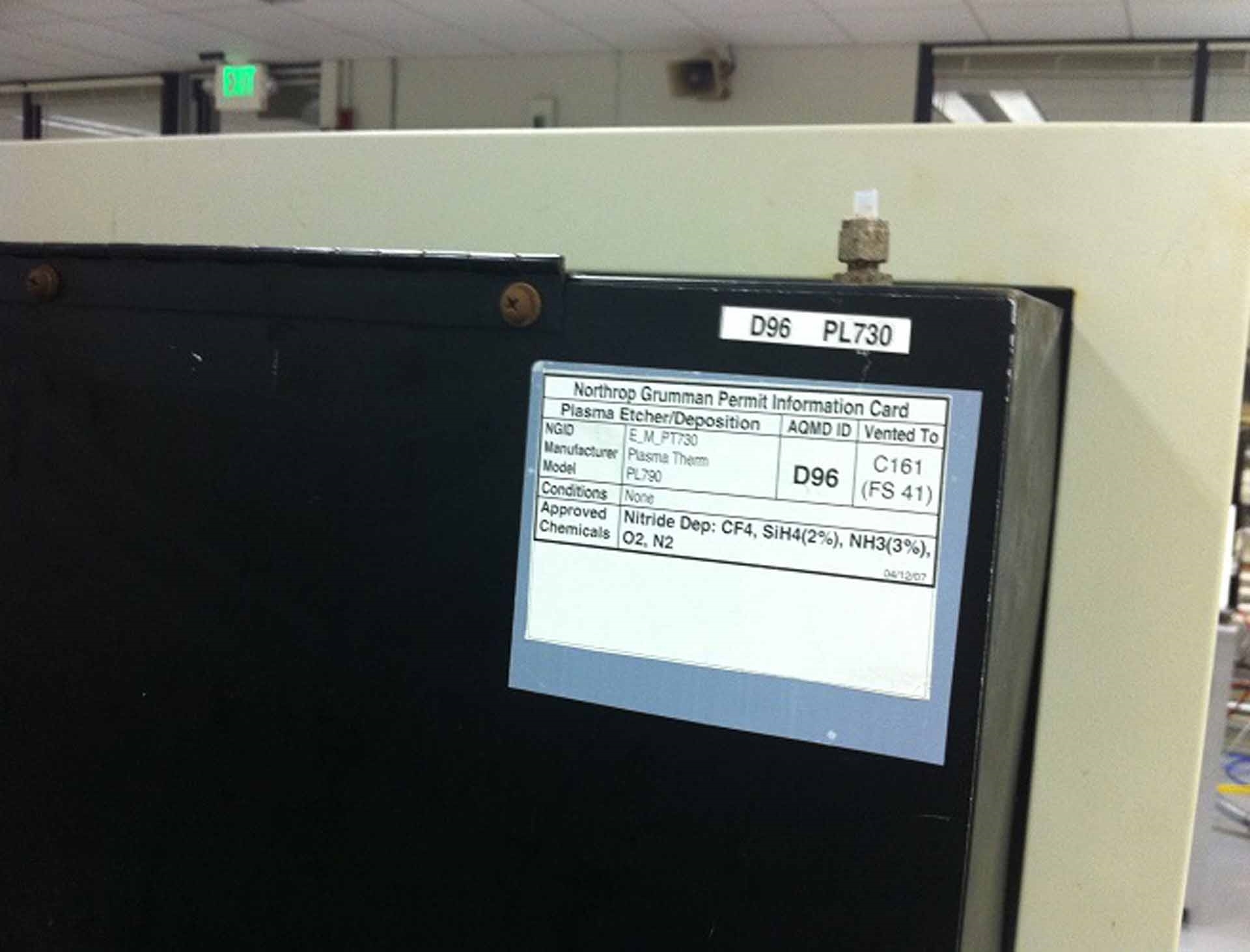

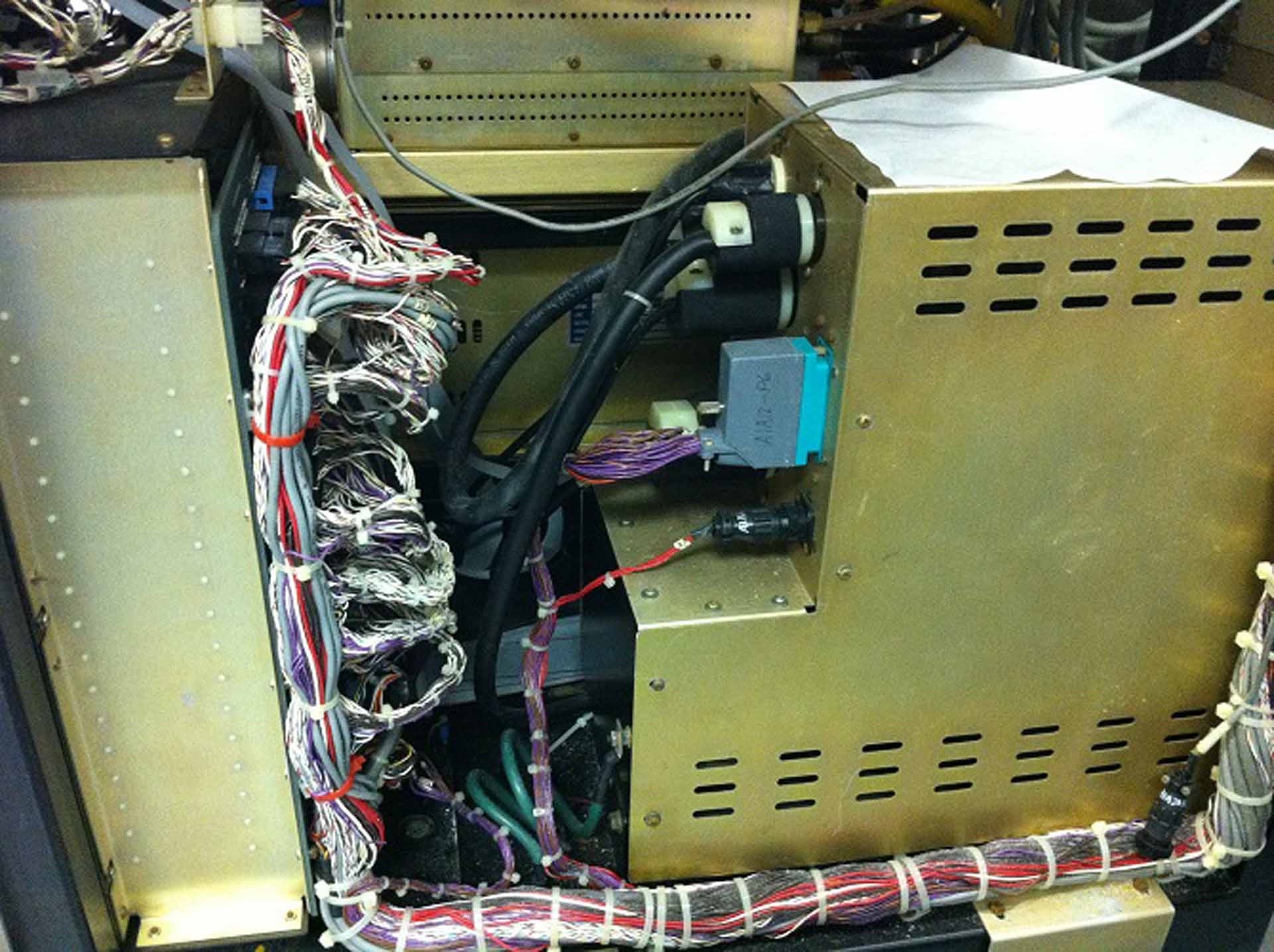

Used PLASMATHERM / UNAXIS 700 Series #9201877 for sale

URL successfully copied!

Tap to zoom

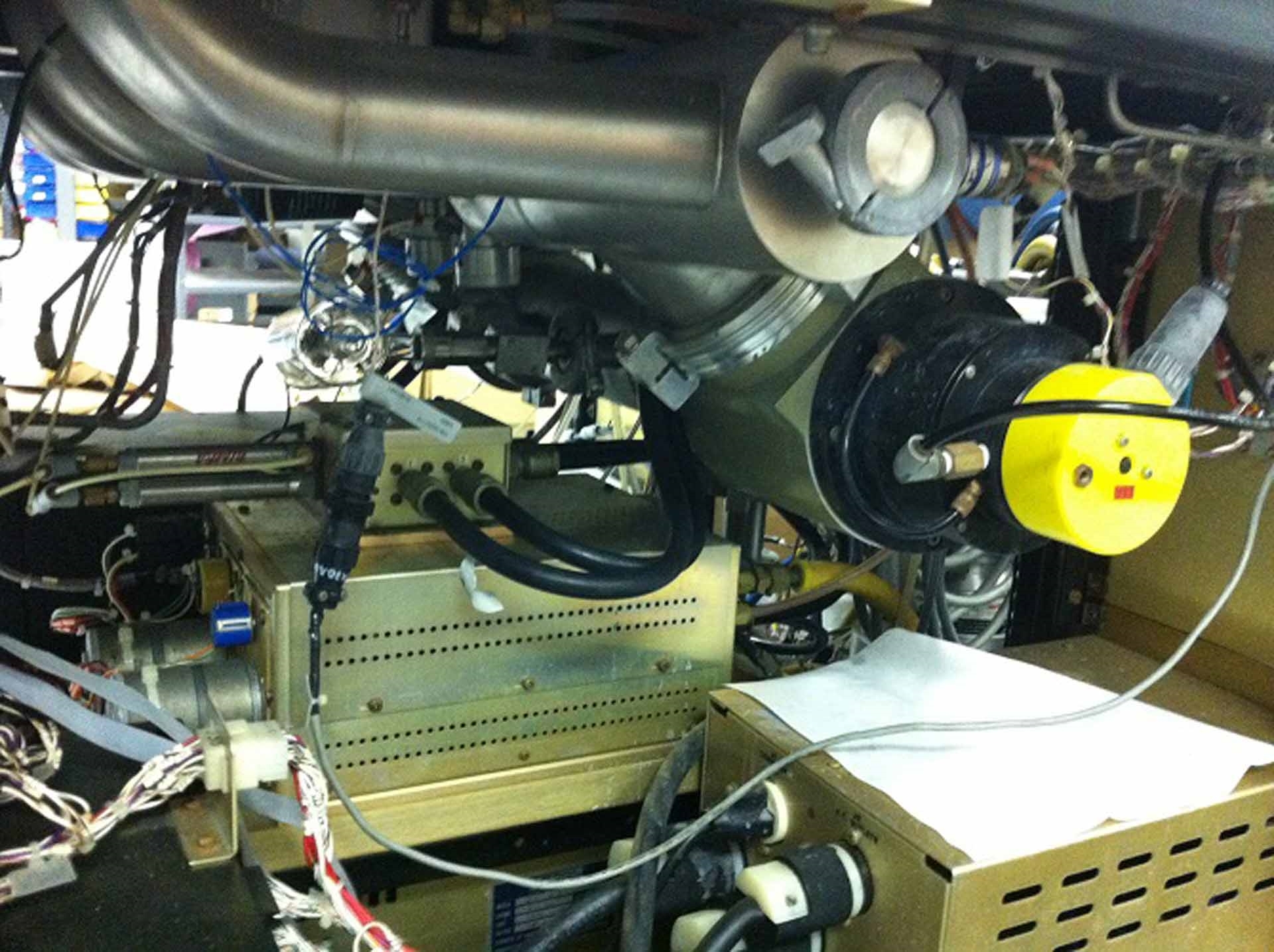

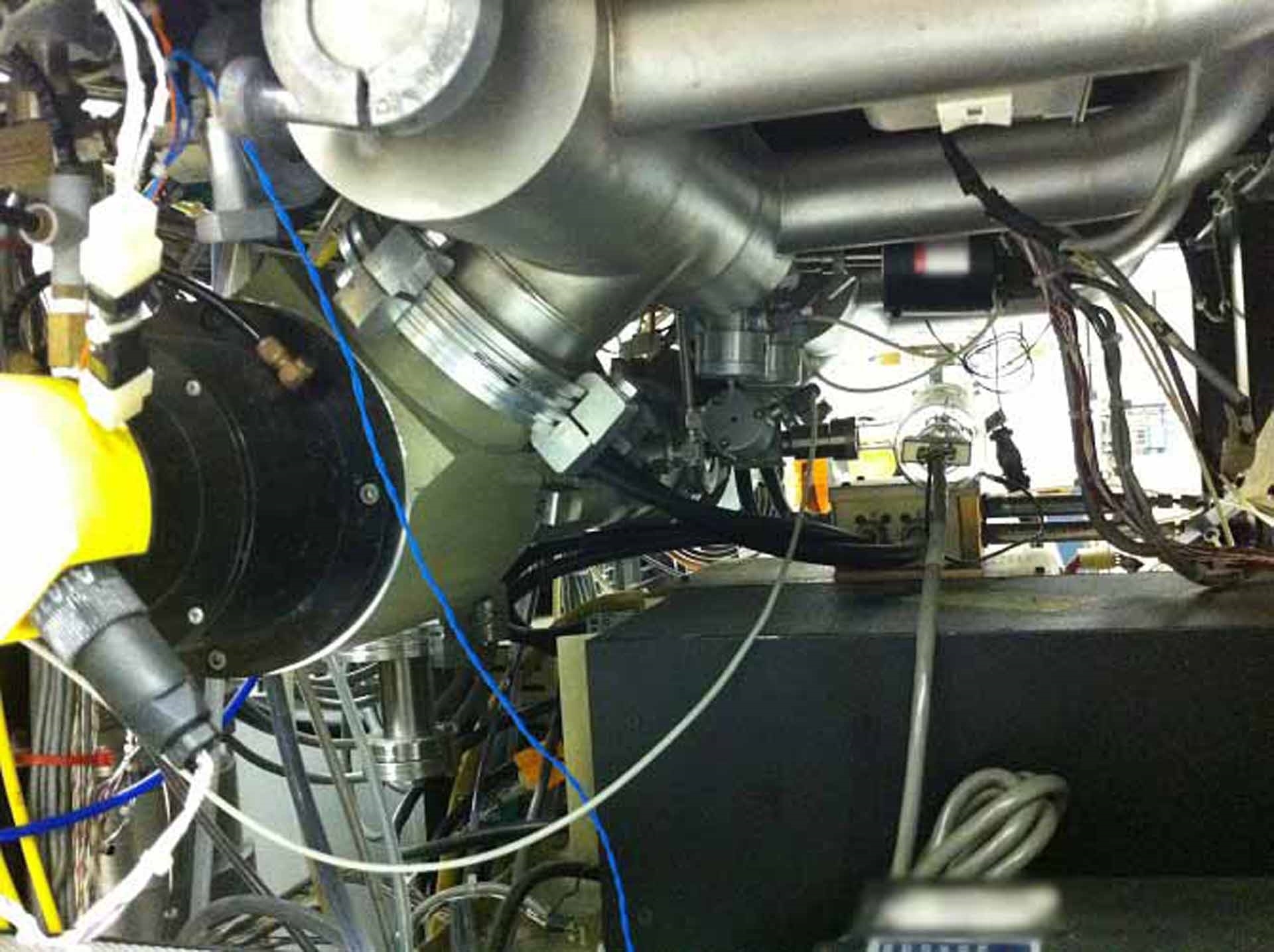

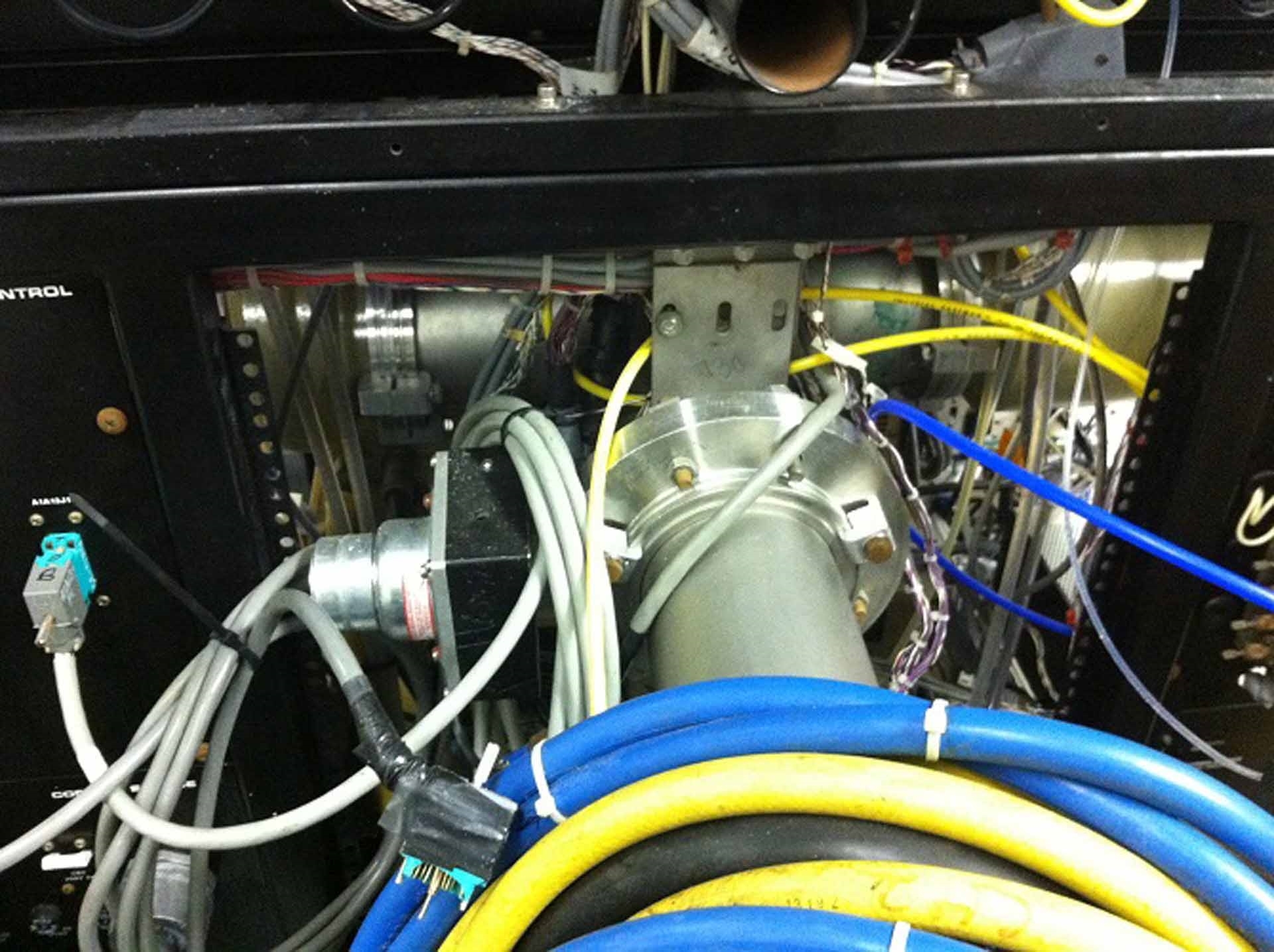

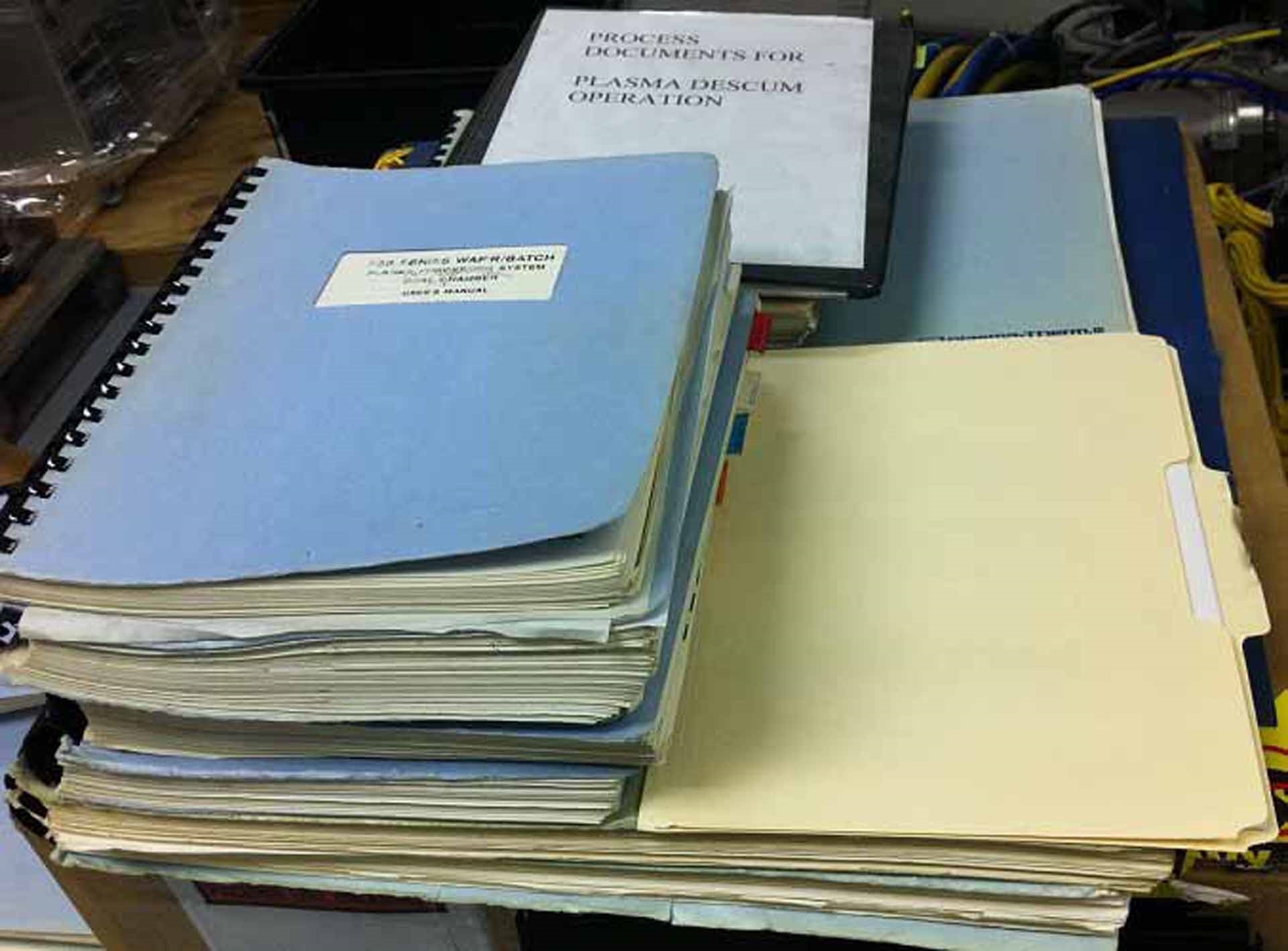

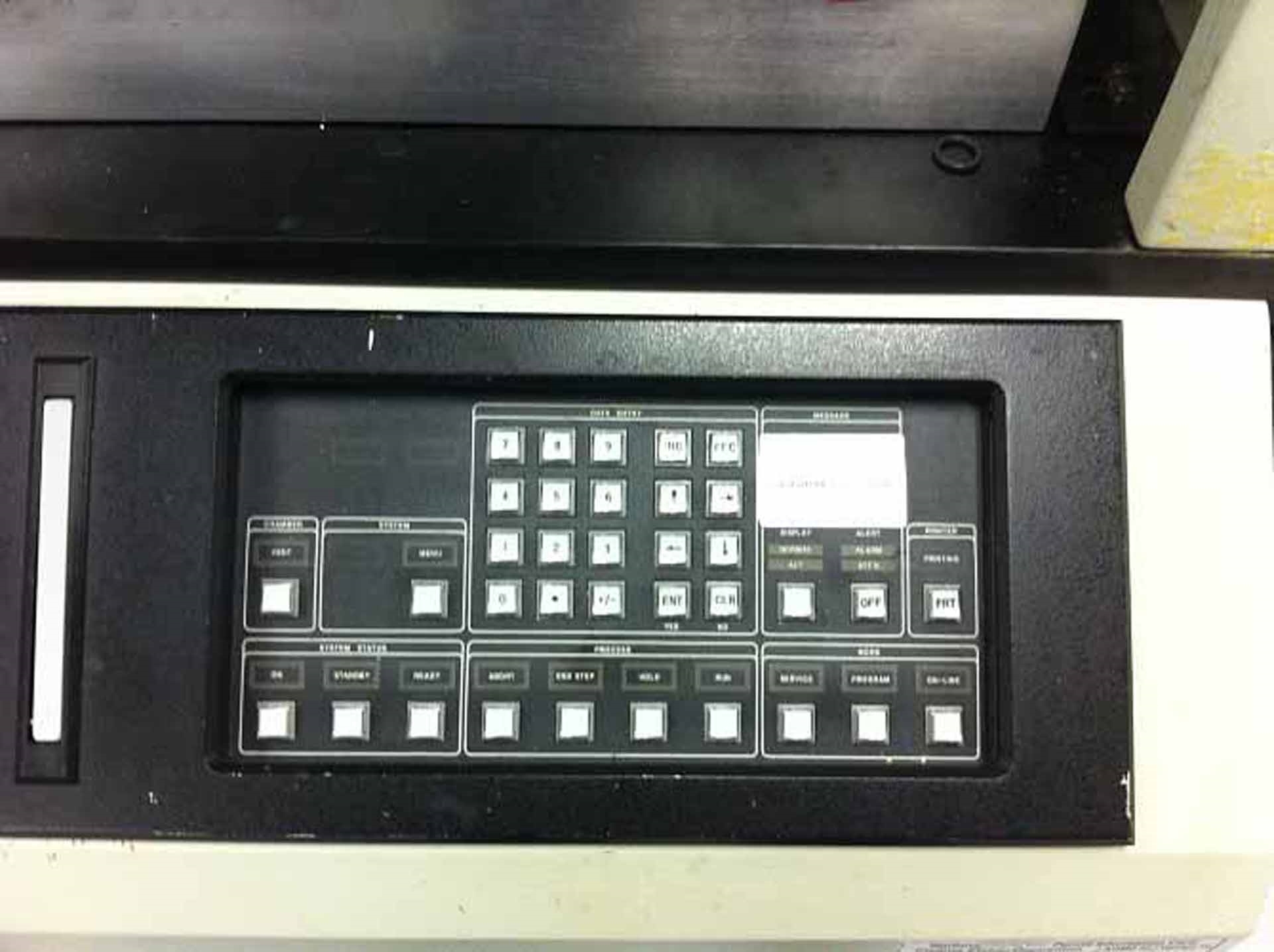

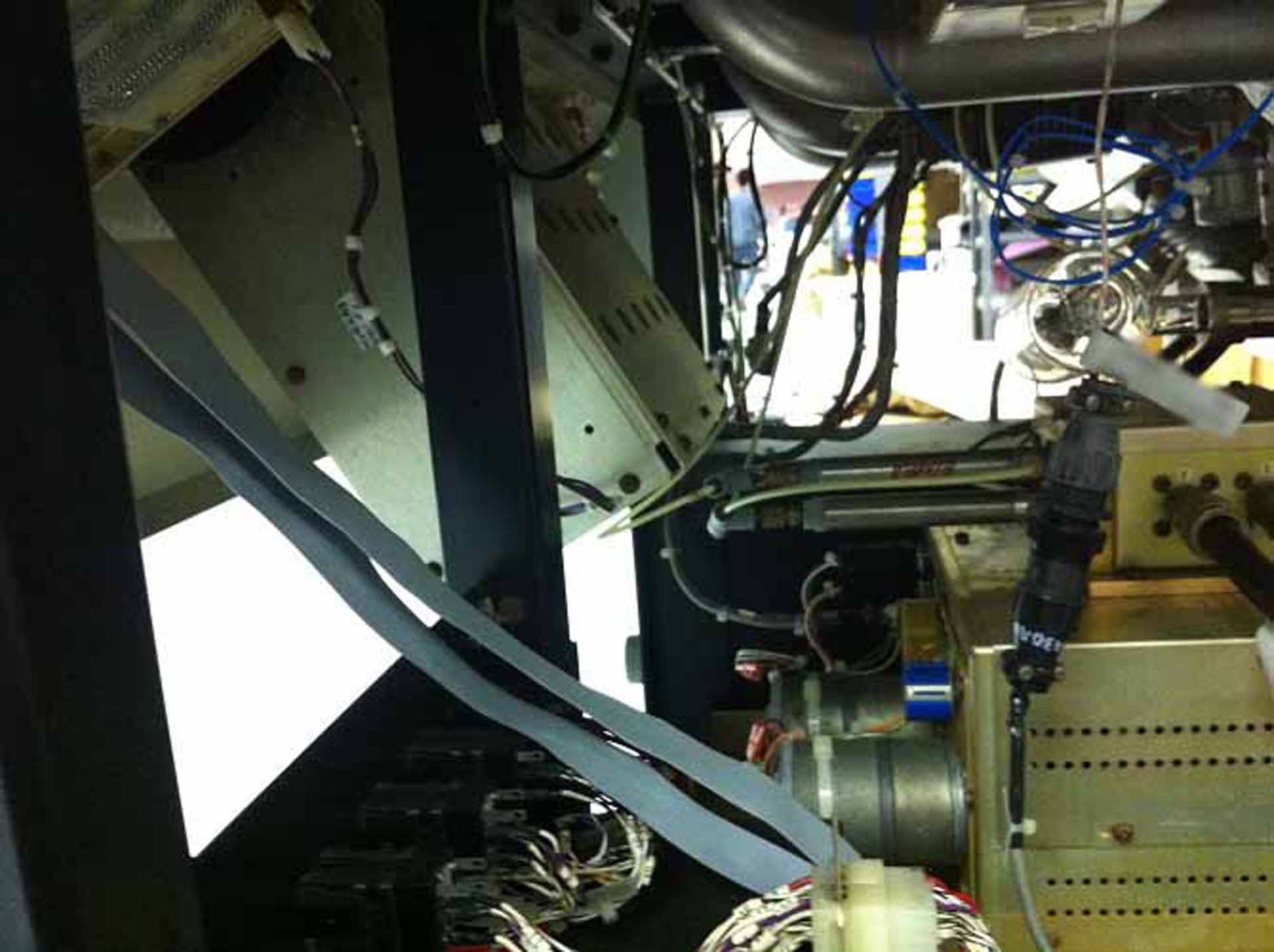

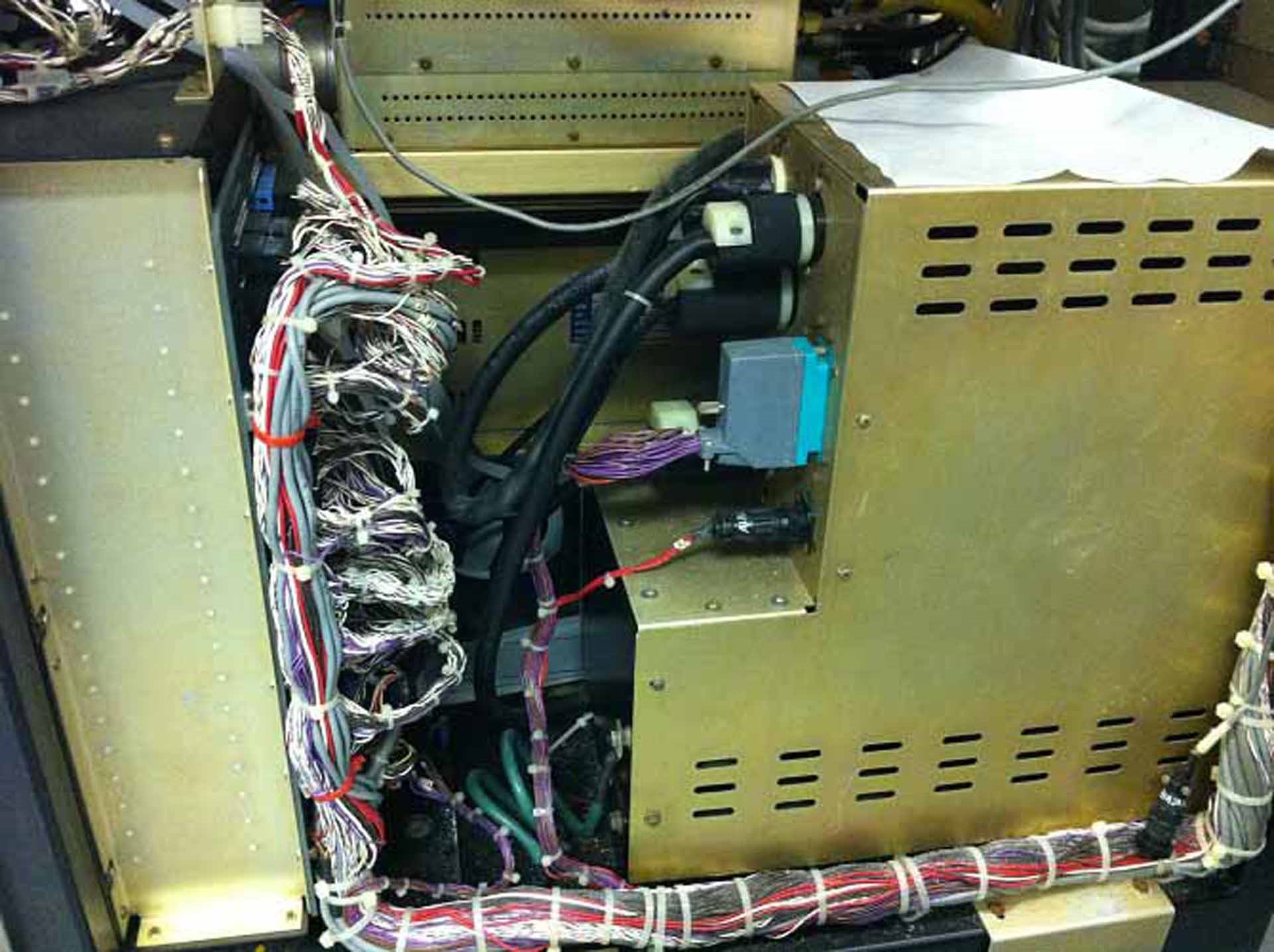

PLASMATHERM / UNAXIS 700 Series is an etcher and asher equipment designed to create a variety of electrical, mechanical, and electronic components with precise control. It is optimized for the etching of advanced materials, including copper, tungsten, and titanium. Utilizing the Vacuum Pressure Pulsing (VPP) etching technology, the system is capable of high etching efficiency levels, providing high quality results. UNAXIS 700 Series is designed to be an efficient solution for the production or research and development of electronic components. The unit provides standard process control functions based on predetermined run-times, temperatures, pressures, and gas types. It features an easy-to-use user interface that aids in process set-up and monitoring. The machine also features a multi-function process monitor, which displays all pertinent data in real-time, and allows for the adjustment of parameters during a run. It also includes process recipes, allowing for easy adjustment of all parameters simultaneously for precise control. The tool features manual control for choosing individual recipes, as well as several different preset programs, which allow for the etching of multiple components with varied results. The Automatic Recipe Optimization (ARO) feature helps to shorten etching times in order to maximize efficiency. It also assists in choosing the optimal parameters for each recipe in order to improve product quality. The Gas Blend Management (GBM) feature ensures accurate gas delivery to the etching chamber, providing consistent, high quality results. PLASMATHERM 700 Series is designed for reliable, reliable operation. The asset has been designed to ISO 9001:2015 standards and meets a variety of safety guidelines and approval standards, including CE, UL, and CSA. The model features powerful vacuum pumps to ensure clean chamber operation, and advanced thermal management techniques to protect sensitive components. The equipment is also designed to provide a low total cost of ownership, with simple maintenance protocols and a smaller footprints for easy placement within a lab or production environment. 700 Series provides users with an efficient, versatile etching and ashing system for the production and research of advanced electronic components. It features powerful control functions, easy to use user-interface, and advanced process recipes for precise operation. It is designed to provide reliable results in a cost-effective manner with minimal maintenance and a small footprint.

There are no reviews yet