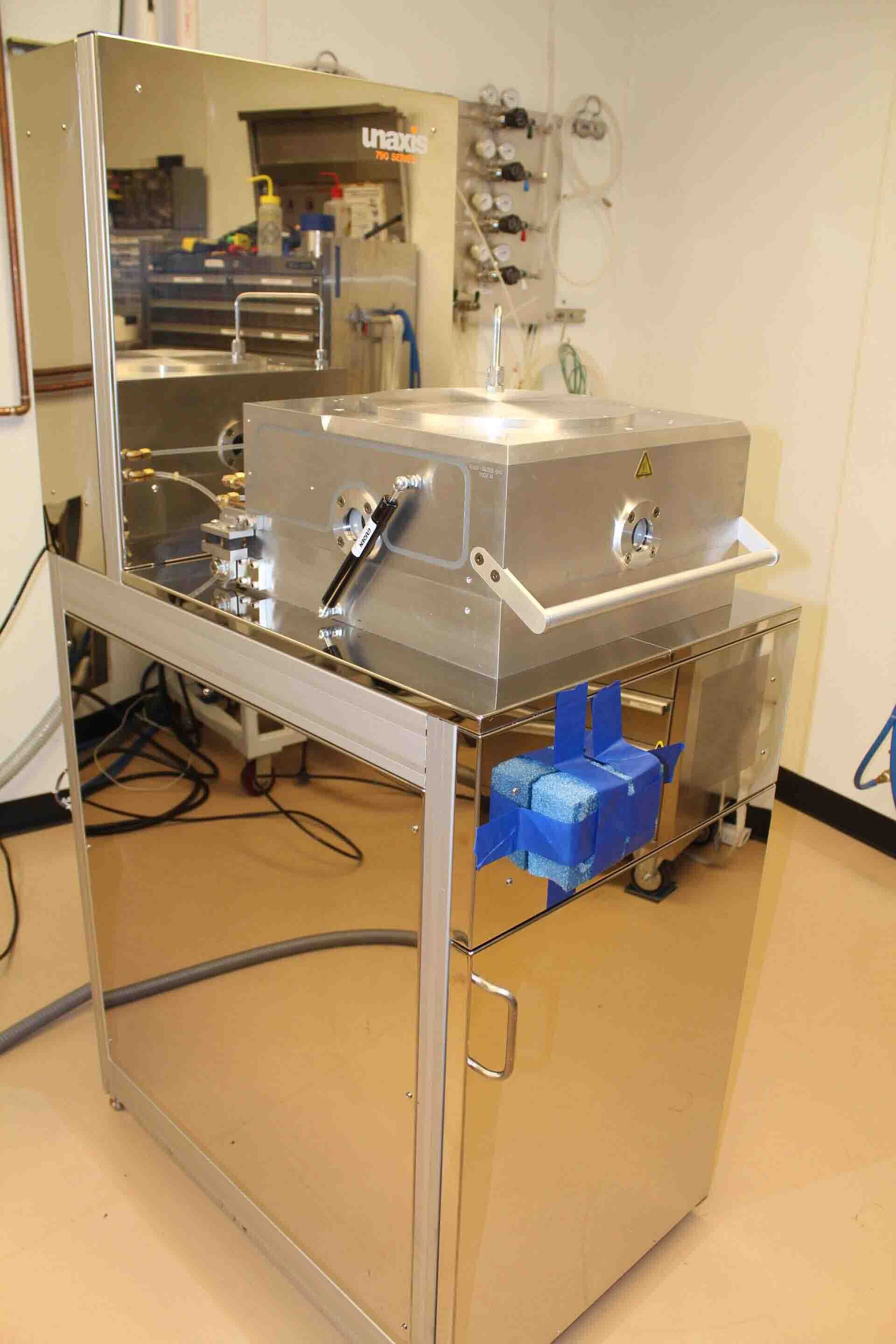

Used PLASMATHERM / UNAXIS 790 #293597269 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 293597269

Wafer Size: 2"-8"

Vintage: 2006

Reactive Ion Etcher (RIE), 2"-8"

2006 vintage.

PLASMATHERM / UNAXIS 790 is an automated etcher and asher. It is designed for etching and ashing substrates up to 150mm in diameter using radio frequency (RF) energy. It is suitable for use in a variety of applications including wafer etching, surface cleaning, lithography and microelectronic device fabrication. UNAXIS 790 features an easy-to-use interface and a fully automated process system. Its advanced process control algorithm ensures uniform etching and ashing results across the substrate surface. The chamber can be flashed with a 30W RF power source, and can also be set to a lower power level (200W) to extend the chamber life. The platen temperature can be adjusted between 100 and 400°C, and the pressure inside the chamber can be adjusted between 0.1-1.0mbar. The substrate temperature can also be monitored and adjusted. The process parameters, such as substrate deposition time, etch rate, and substrate temperature, can be set and adjusted easily. The process gases and concentrations can also be controlled, and PLASMATHERM 790 can be configured to use either dry process gases or liquid plasmas. A variety of gases and liquid combinations are available, including O2 and XeF2, H2/SF6, SF6/D2, Ar/CF4/CO2, and Ne/CO2. 790 comes with a built-in process monitoring and data collection system that records important process information, including temperature, pressure, duration, and RF power. This data can be viewed in real time, allowing quick and easy process optimization. Its multi-mode control doubles the efficiency of batch processing, resulting in a higher throughput. The built-in safety features ensure safety and compliance with applicable safety regulations. PLASMATHERM / UNAXIS 790 is a reliable and efficient etching and ashing solution for research and industry applications. Its precision process control, automated maintenance system, and advanced process monitoring and data collection capabilities ensure high-quality results with minimal operator intervention.

There are no reviews yet