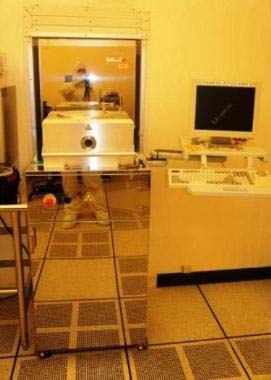

Used PLASMATHERM / UNAXIS 790 #9081010 for sale

URL successfully copied!

Tap to zoom

ID: 9081010

Wafer Size: 8"

Vintage: 2003

Reactive Ion Etcher (RIE), 8"

Manual load

Non-load lock system

RF Power supply with matching network

RF 600 W Power supply

LEYBOLD 361C Turbo pump with NT20 controller

Gas distribution panel consisting of (4) MFCs per process side

2003 vintage.

PLASMATHERM / UNAXIS 790 is a high precision, high throughput plasma etcher / asher designed for multi-user applications. It features a compact and robust design that can be used with both standard photolithography and ultra-precise patterning techniques. The equipment utilizes advanced vacuum technology, a low velocity, high pressure plasma, and a closed cross section chamber to achieve consistent results with excellent etching or ashing performance. With a chamber volume of 550 liters, the system is capable of accommodating up to four 8" wafer cassettes. UNAXIS 790 incorporates a reliable, user-friendly, and efficient user interface. Separate process control modules are provided for each of the chamber components, along with optional software for adjusting key parameters (such as etch time and pressure) and monitoring the process. A memory function allows for easy recall of previously saved processes and parameters. The unit is equipped with two independently interchangeable plasma sources, including a high-pressure RF source for etching and an oxygen asher source for etching and post-processing applications. In addition, PLASMATHERM 790 includes advanced process control features such as automatic process control (APC) and automatic gas control (AGC). With both of these features, the machine can maintain process repeatability and accuracy by making necessary adjustments while the user is running a process. The tool also includes a dual stage turbo pump capable of reaching base pressures down to 5 x 10-6 to 10-7 torr, which ensures a high quality, low particulate contamination plasma chamber environment. The chamber's integrated gas distribution asset ensures a uniform etch or ashing rate with minimal workload nonuniformities. 790's choice of etching/ ashing gases (Ar, O2, Cl2, CF4, CHF3, etc.), its adjustable pressure range (20-150 mTorr) and its ability to perform either positive or negative etch makes it an ideal etcher / asher for a wide variety of applications. To reduce operating costs, the model includes a GasClean programmable gas blend equipment, which allows for the automatic and remotely controlled passage of gas blends. This reduces the amount of manual intervention required and the resulting redundancies in gas usage, while the built-in gas recycle feature further reduces gas costs. With an advanced safety system and thermal insulation, PLASMATHERM / UNAXIS 790 is designed to provide optimal unit performances with high process repeatability and a clean and safe working environment.

There are no reviews yet