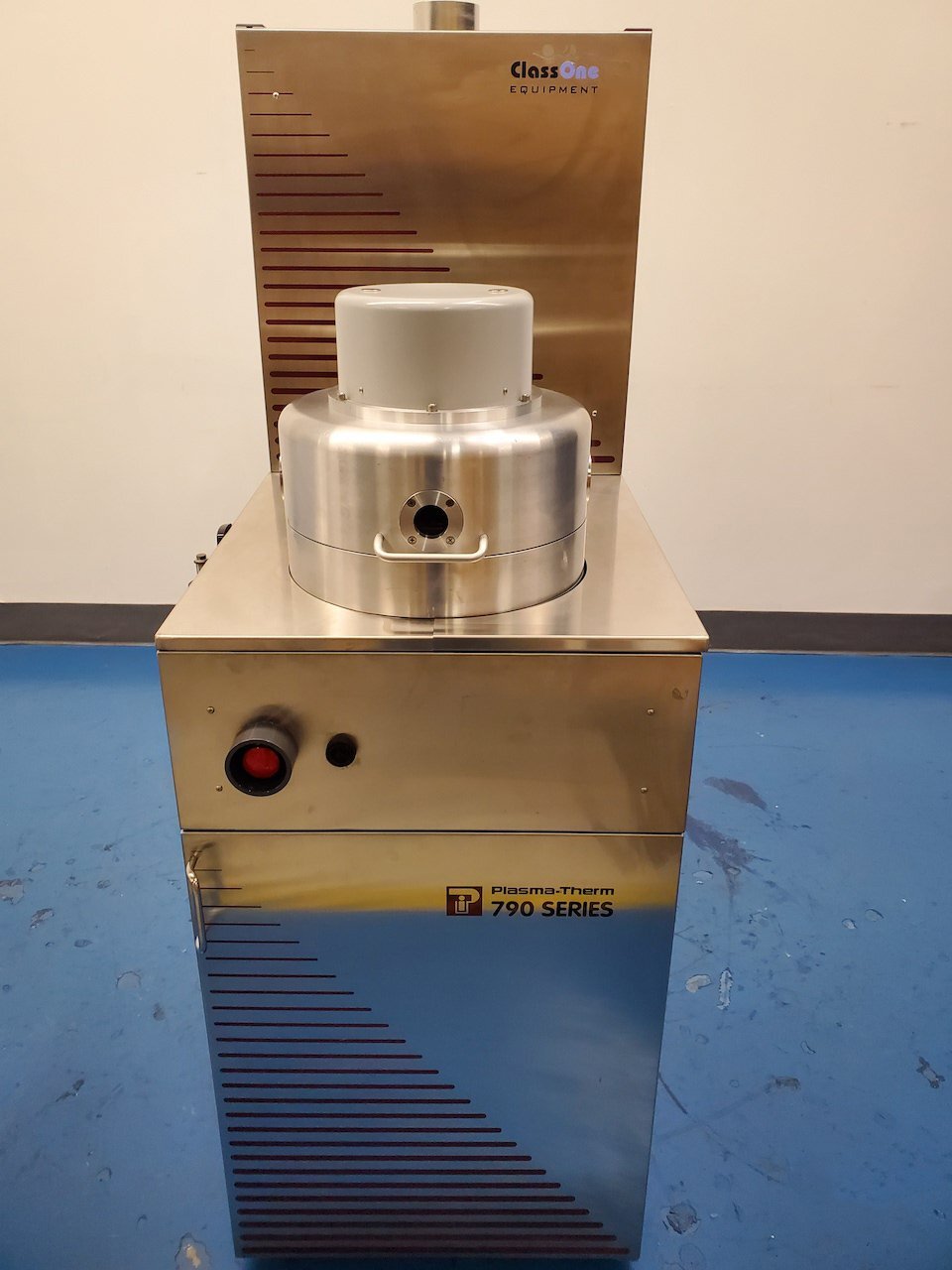

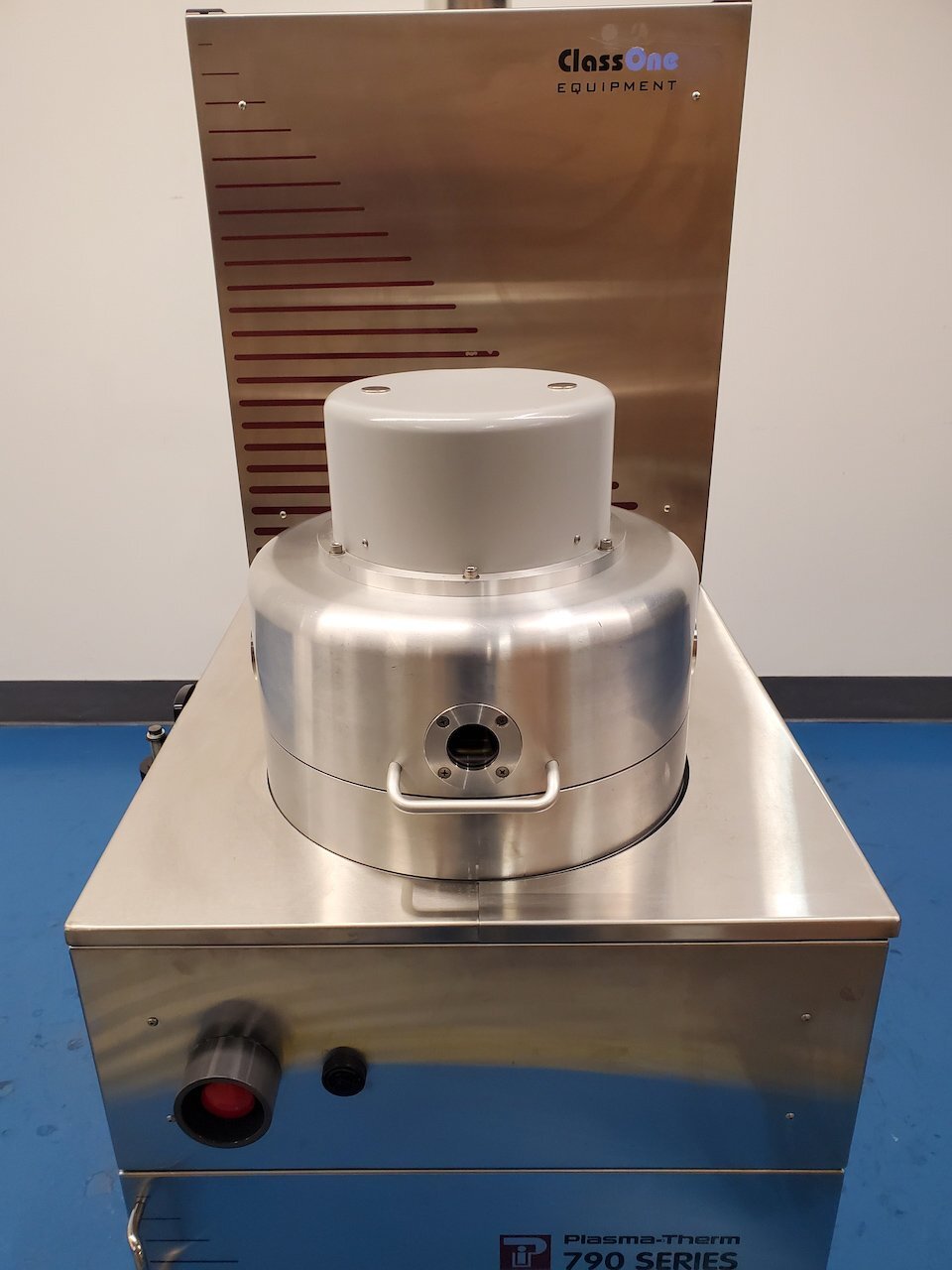

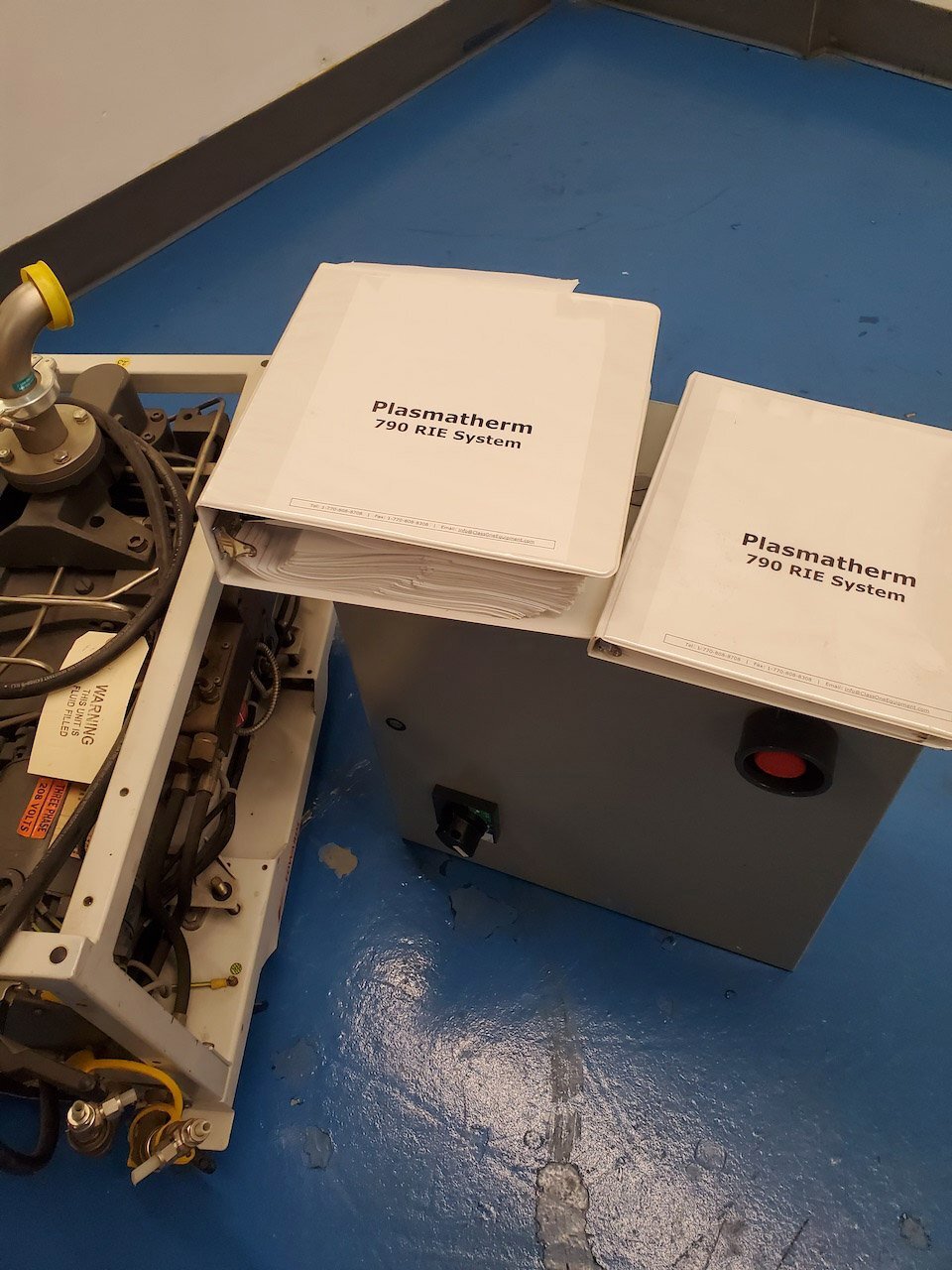

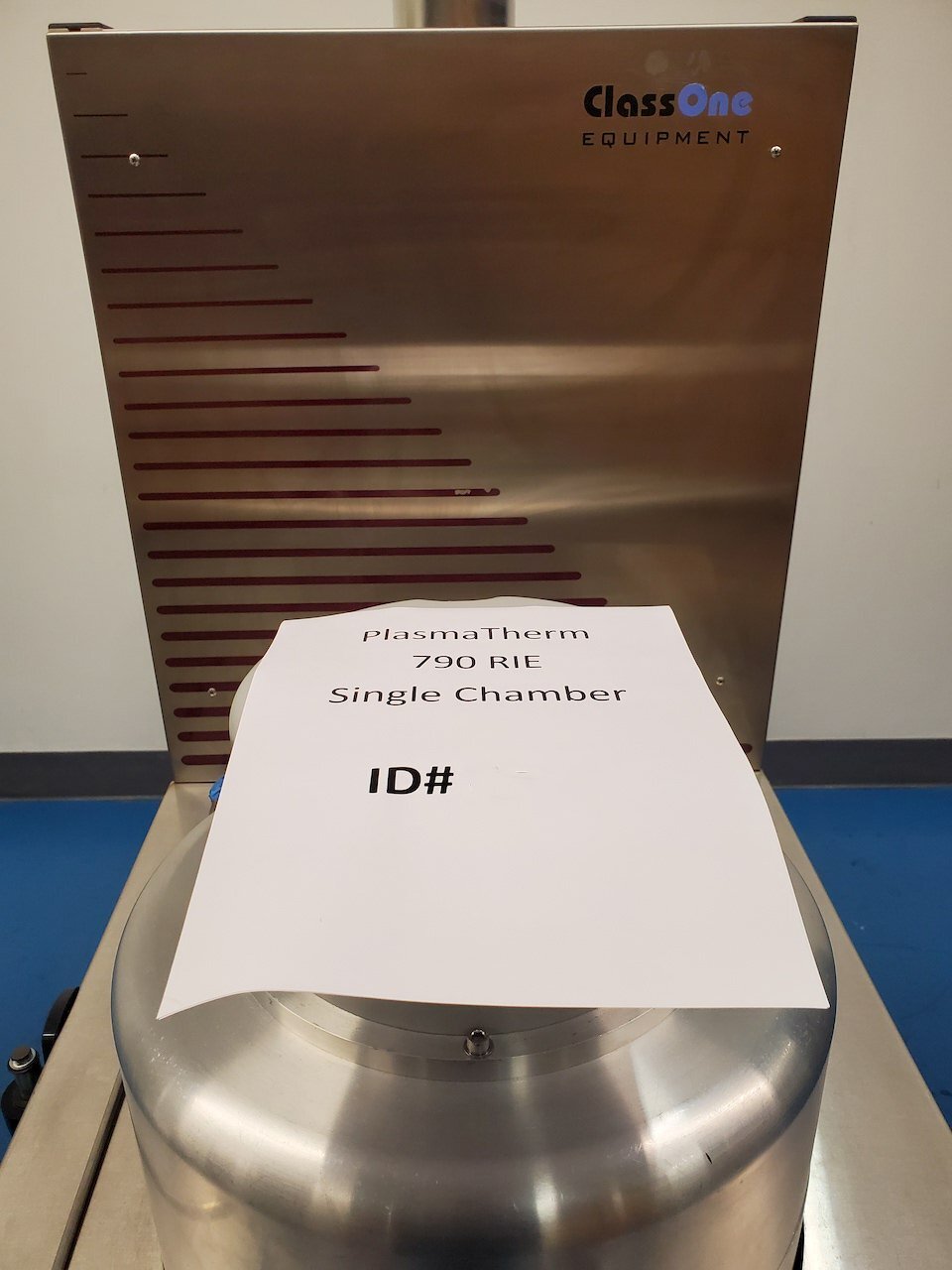

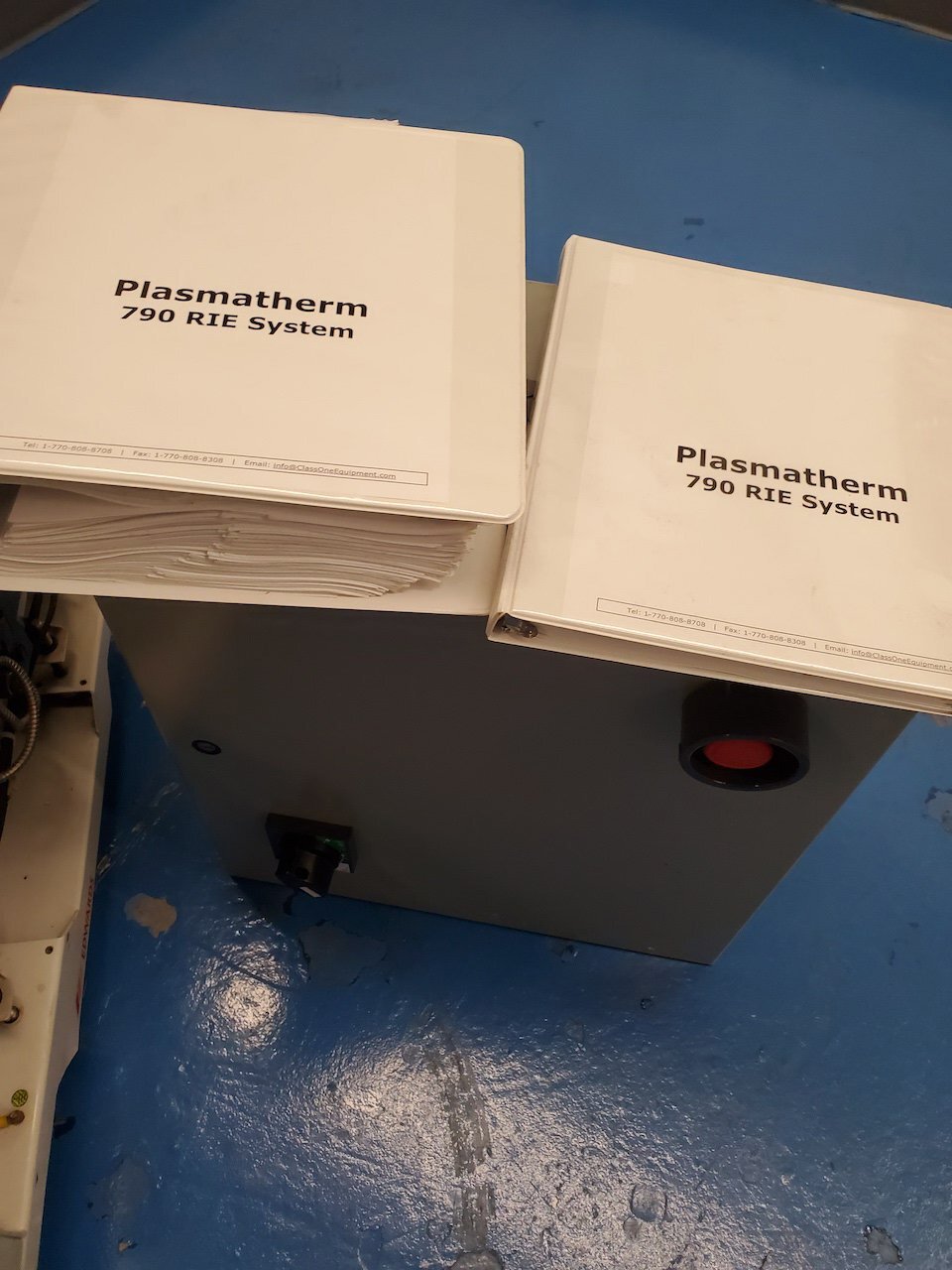

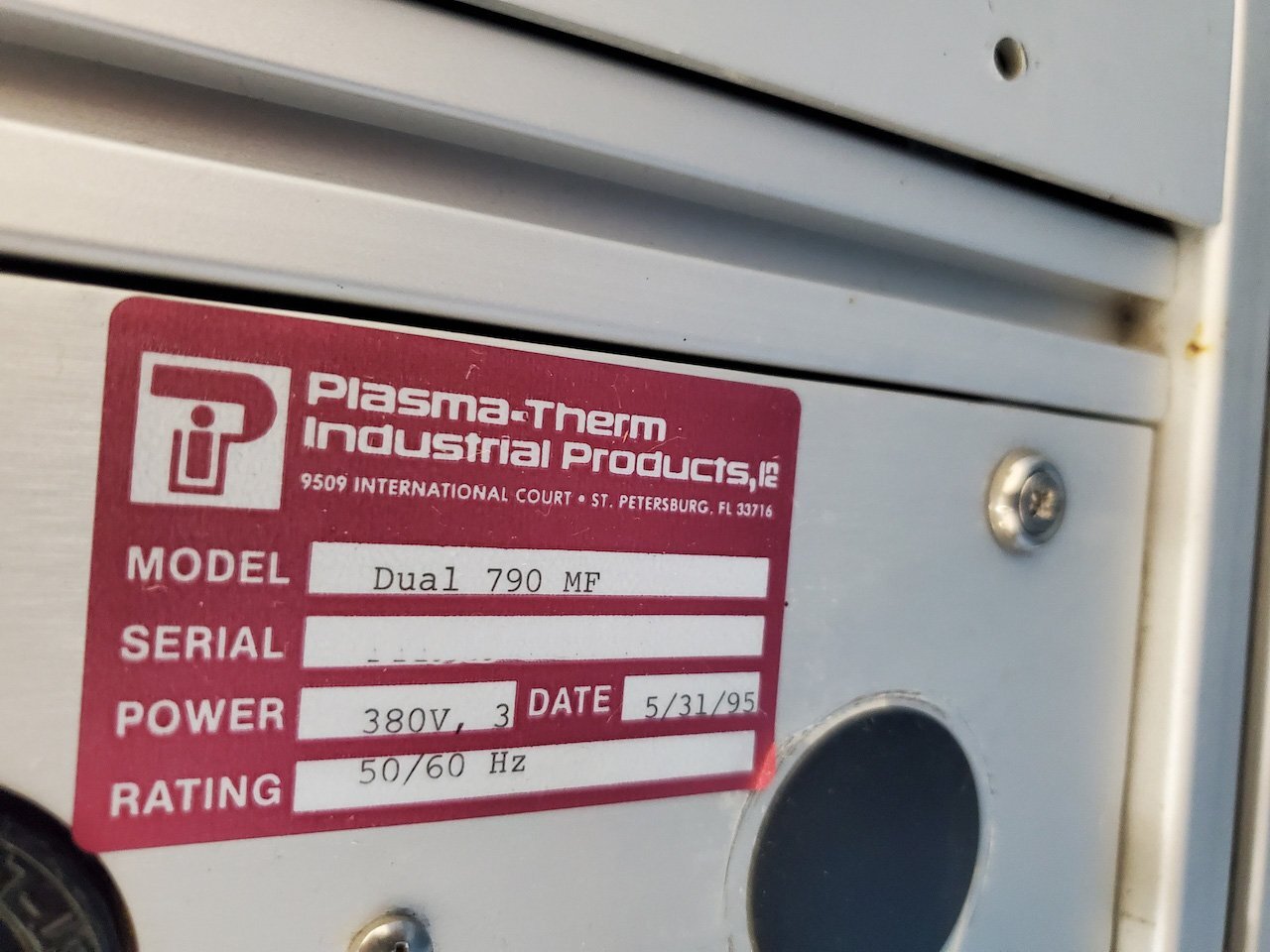

Used PLASMATHERM / UNAXIS 790 #9350317 for sale

URL successfully copied!

Tap to zoom

ID: 9350317

Wafer Size: 8"

Reactive Ion Etcher (RIE), 8"

Non load-locked single chamber RIE

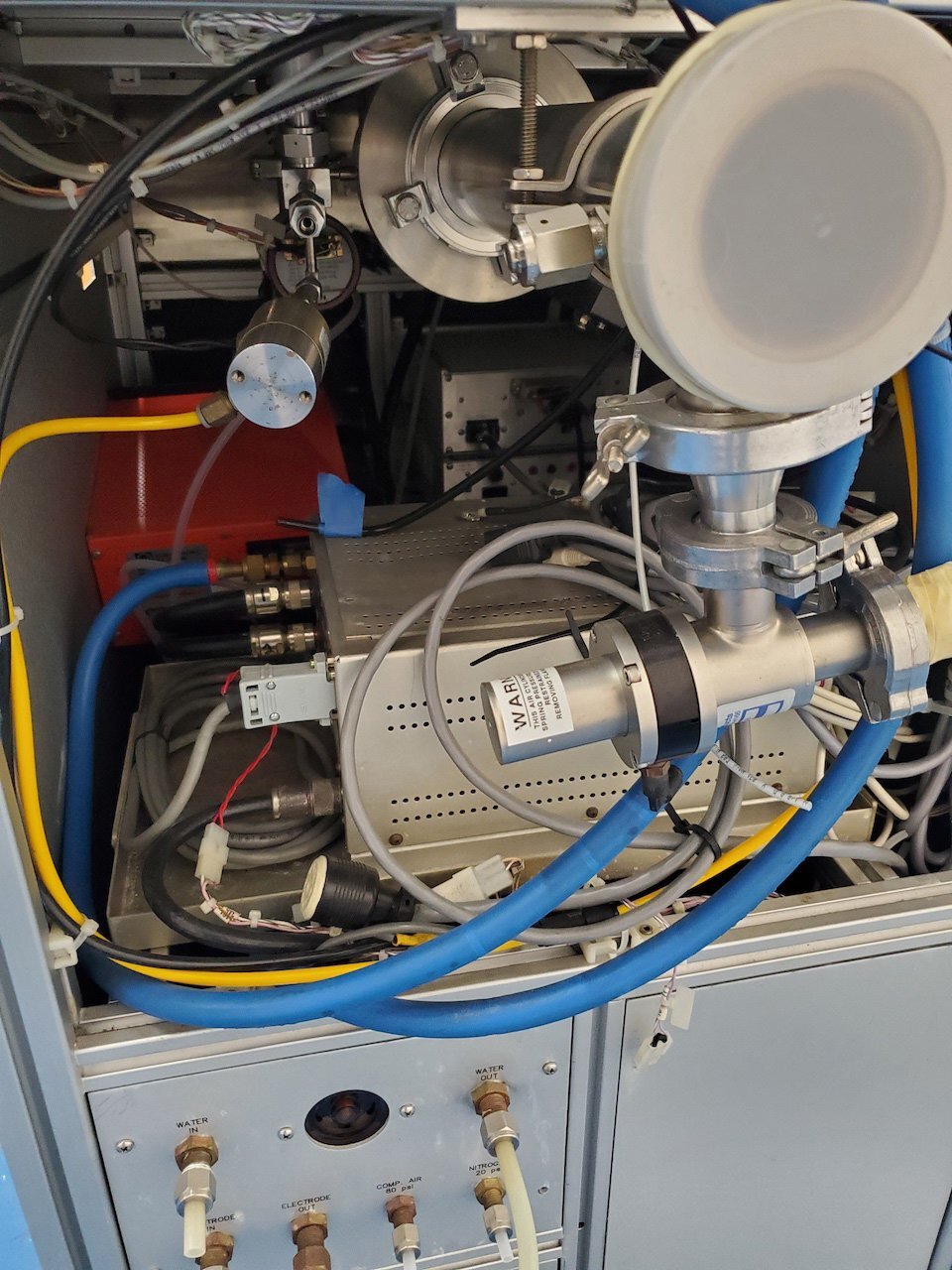

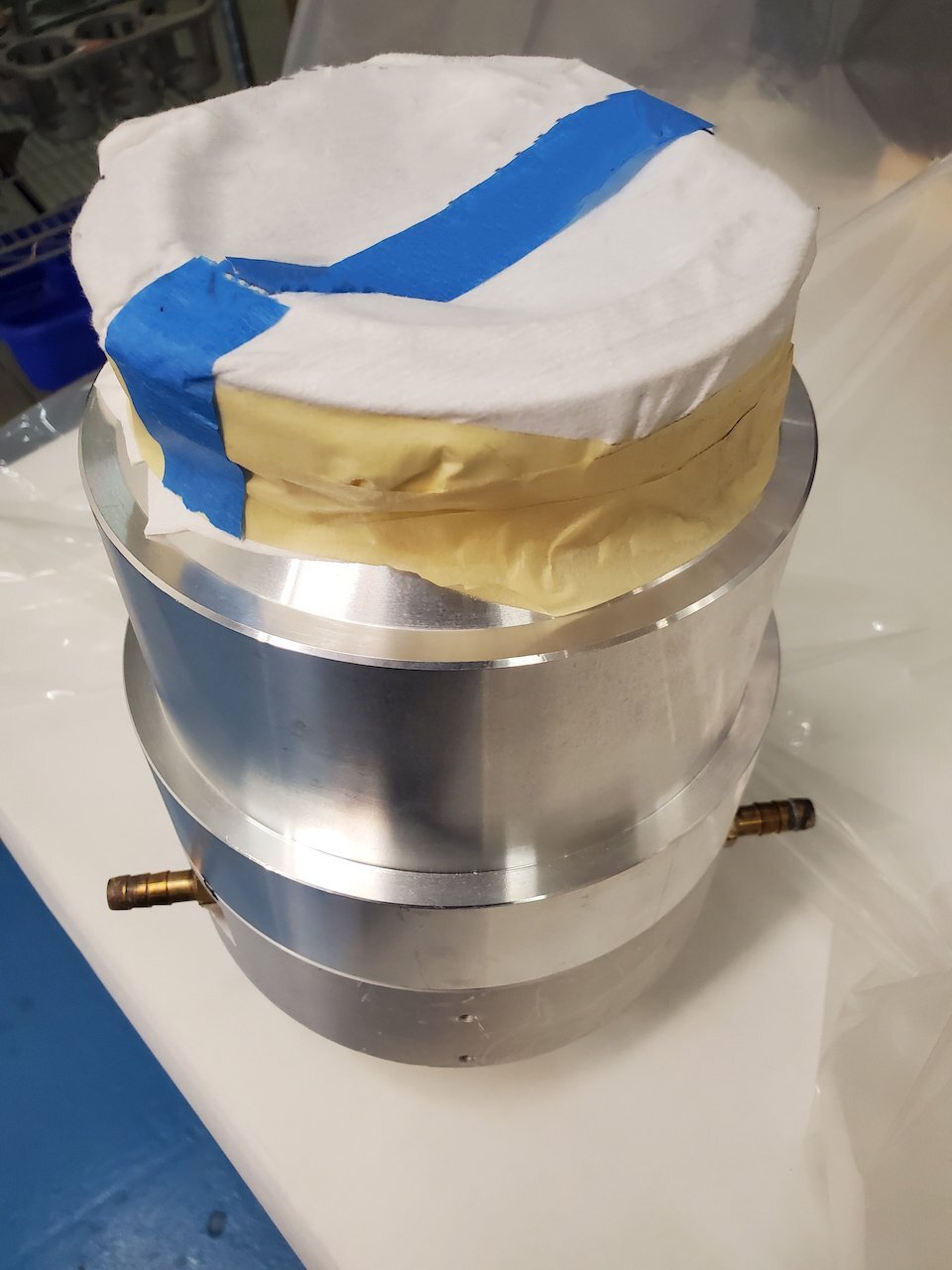

Electrode: 240 mm Diameter

System setup to process: Diameter InP wafers, 2"

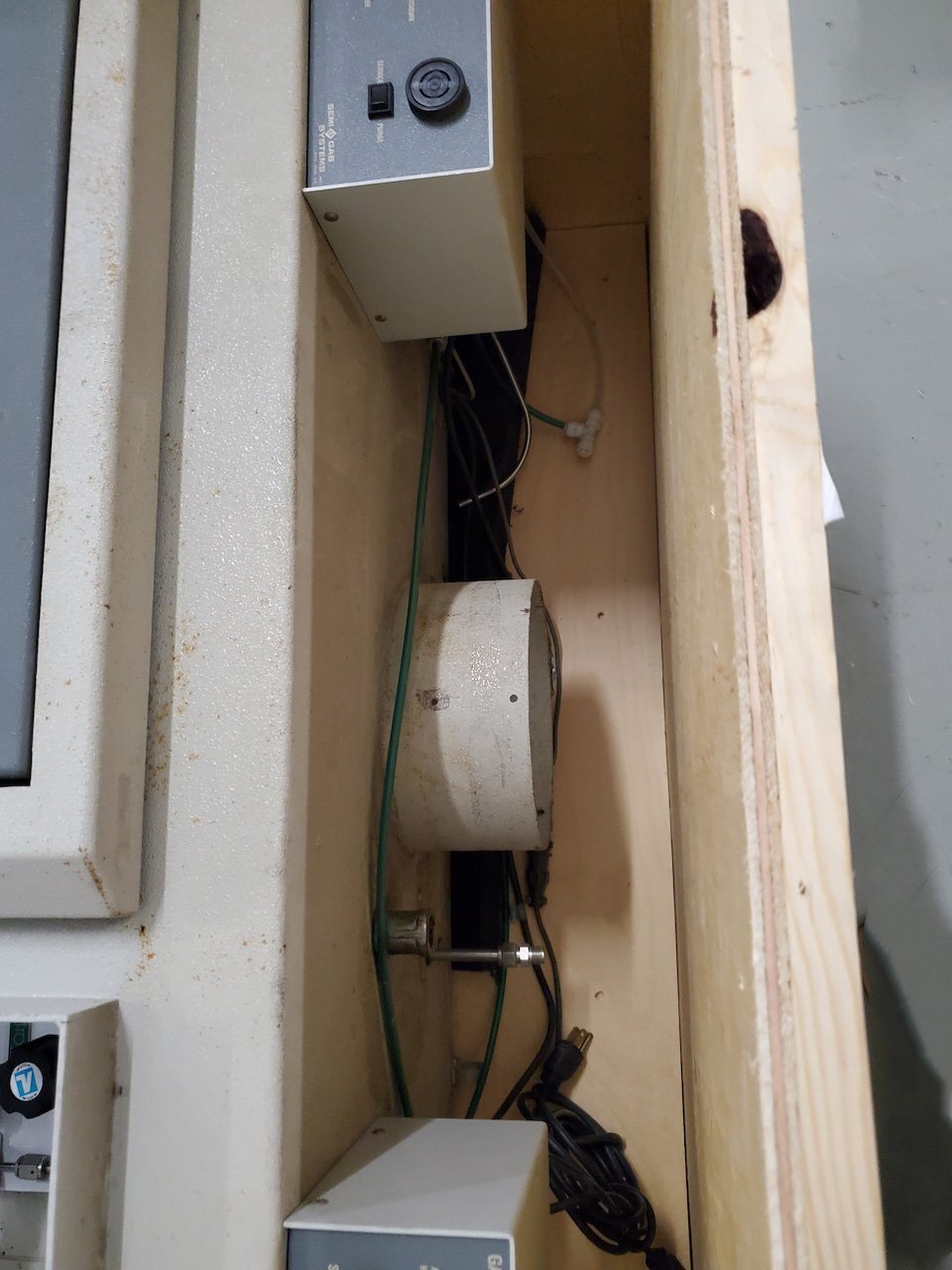

RFPP RF Generator, 500 W

RF Match: 500 W

AMN Power supply

ION Gauge controller type: 290

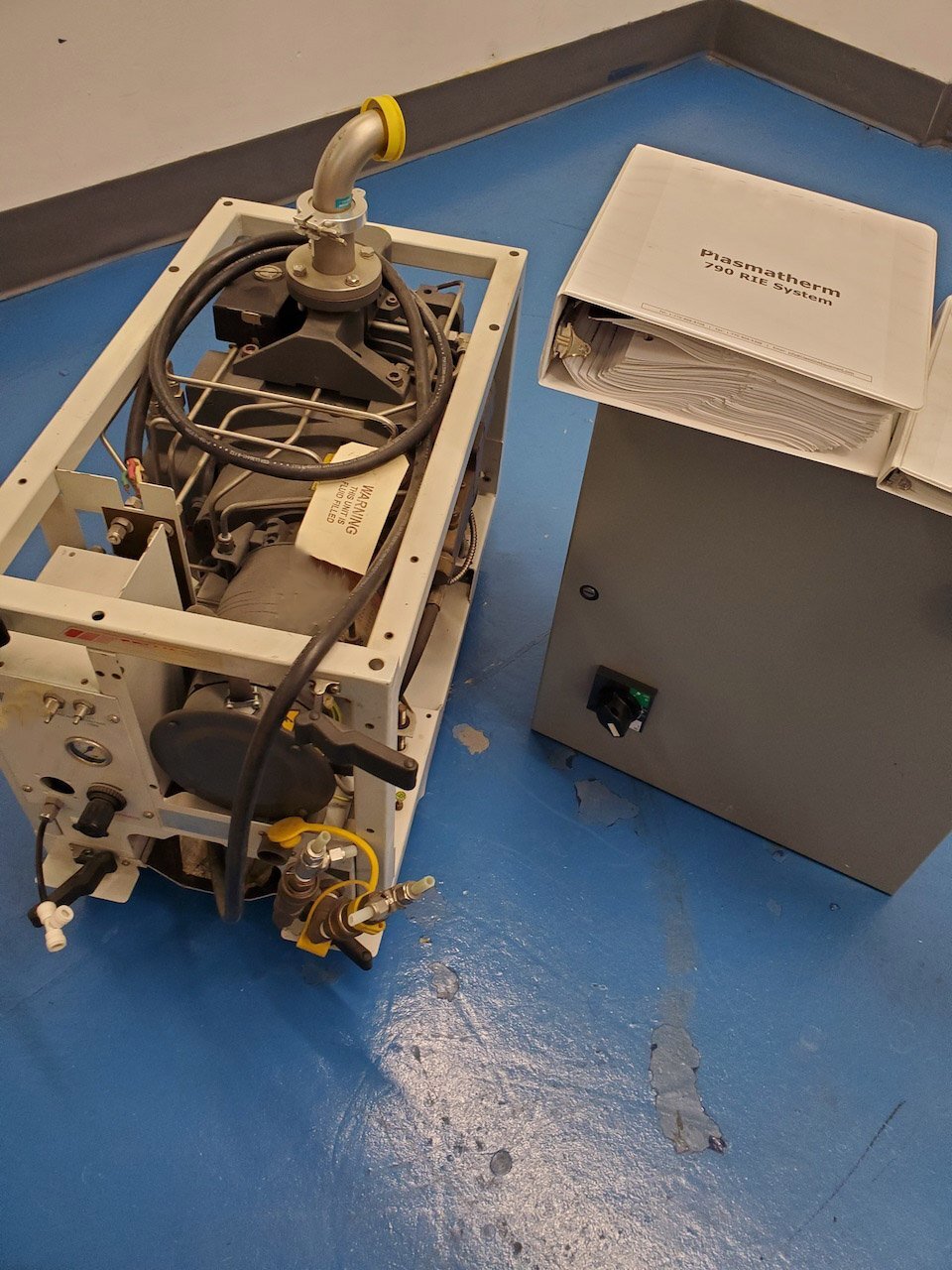

LEYBOLD 361C Turbo pump

LEYBOLD NT 150 / 360 Controller

LEYBOLD NT 150 / 360 Controller (Spare parts)

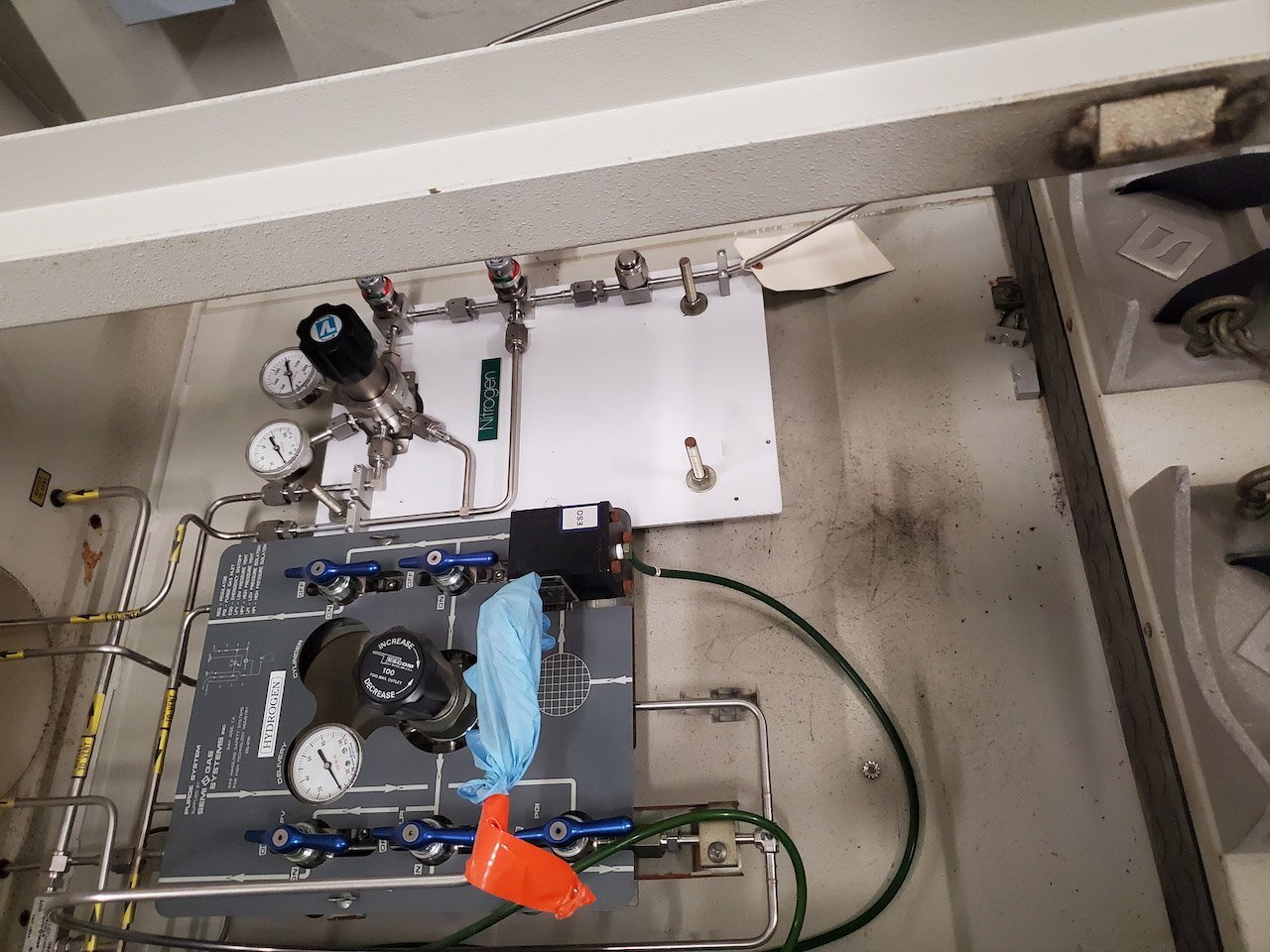

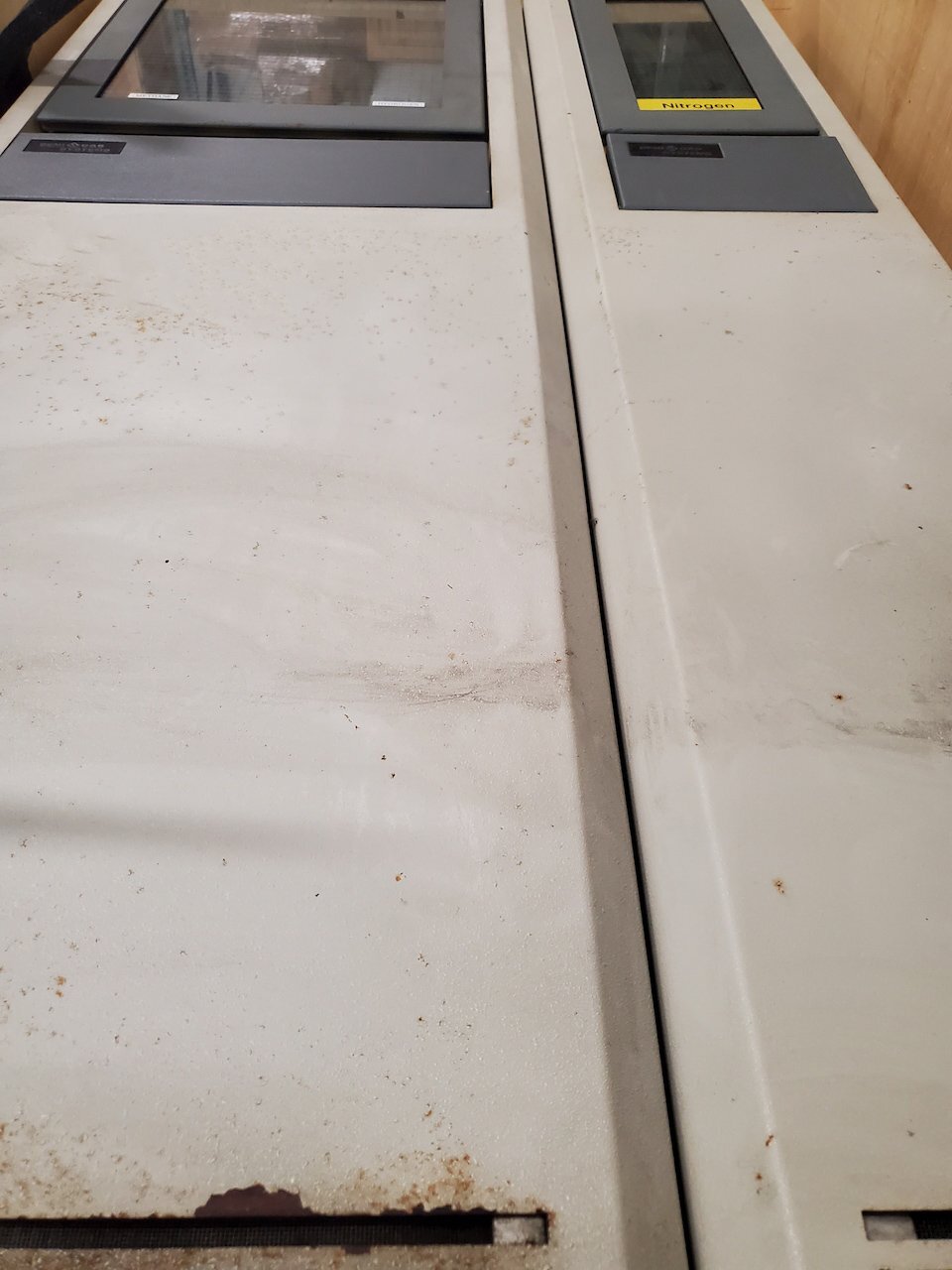

MKS 1160B Mass Flow Controller (MFC)

EDWARDS QDP40 Dry pump

Manual

1995 vintage.

PLASMATHERM / UNAXIS 790 is an advanced etcher and asher for use in the production of semiconductor devices. This unit is a fully automated, high-throughput equipment which offers both plasma etching and wet ashing capabilities. UNAXIS 790 utilizes a fully enclosed load-lock chamber and robotic transfer arm to ensure the highest levels of performance and repeatability. The automated process ensures safe, consistent etching and ashing results with a maximum sample throughput of 60 wafers per hour. PLASMATHERM 790 is ideal for the production of active devices, including MOSFETs, CMOS, Read/Write Memories, SRAMs, and DRAMs. The system's plasma etching process is based on a ternary gas mixture composed of Silane (SiH4) oxygen, and hydrogen, and is regulated by an automated pressure control unit. Using this process, 790 can etch and clean various complex layers of modern semiconductor devices. The capabilities of PLASMATHERM / UNAXIS 790 also include substrate and spot etching, selectivity controls, and high solution utilization and temperature control for uniform etching. The ashing process of UNAXIS 790 is based on a wet process that utilizes HF gas and oxygen. This process is controlled by an automated pressure control machine which utilizes electrochemical ashing to remove organic deposition material from the substrates. The tool's efficient and accurate ashing process reduces organic particle contamination. PLASMATHERM 790 is supplied with a host of process-oriented features that help to improve process times and productivity. These features include an adjustable gas pressure asset which allows for the combination of plasma etching and wet ashing. The embedded software helps users monitor the various etching and ashing parameters, while also providing log data collection and analysis functions. These features allow the user to precisely monitor and adjust the process parameters to achieve bespoke process results. In conclusion, 790 is an advanced etcher and asher for semiconductor device production. Featuring an automated process, the model offers high throughput and improved productivity. The unit's Plasma etching procedure creates complex device layers with precision and accuracy while its wet ashing process removes organic deposition material. The equipment also comes with a host of process-oriented features, providing users with detailed and repeatable process performance.

There are no reviews yet