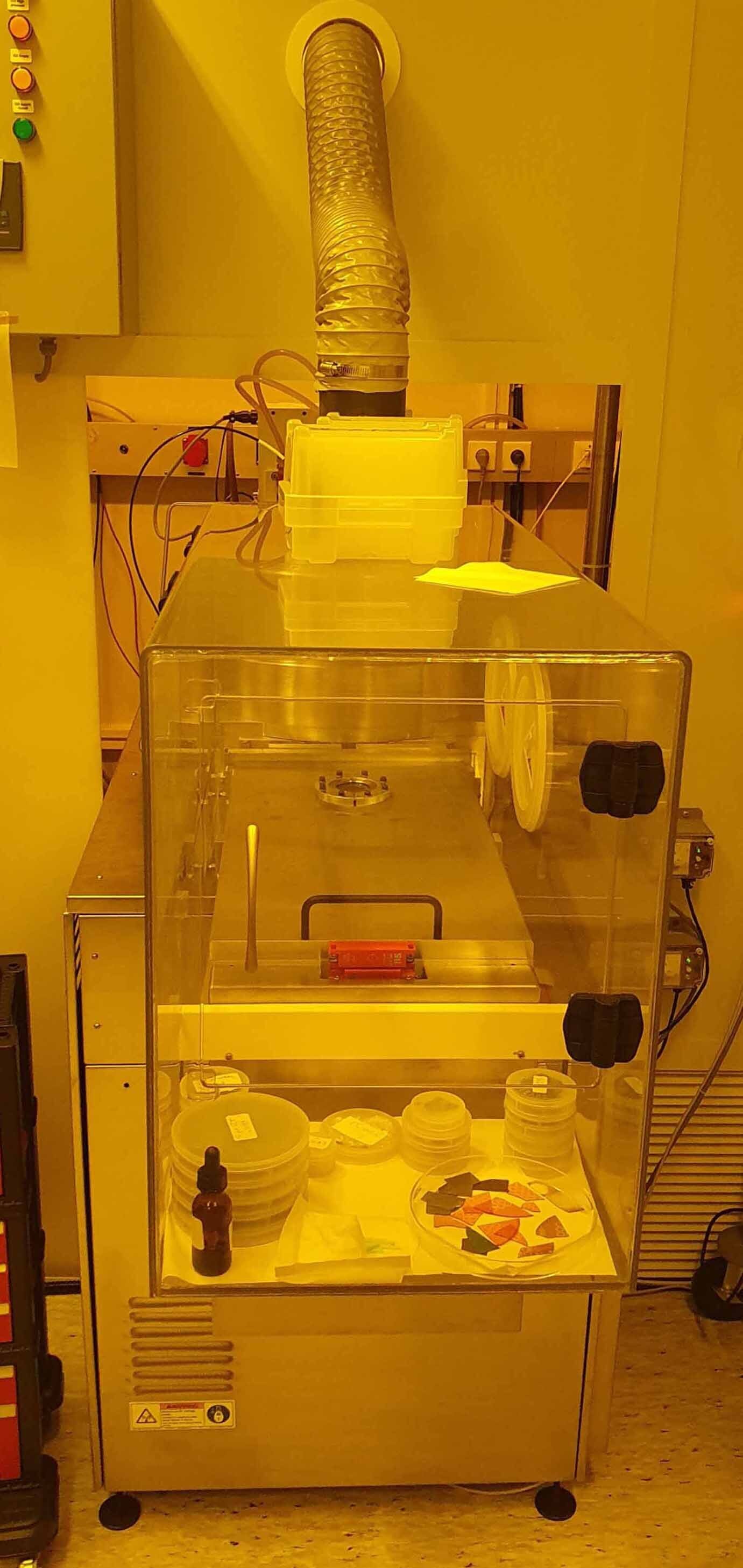

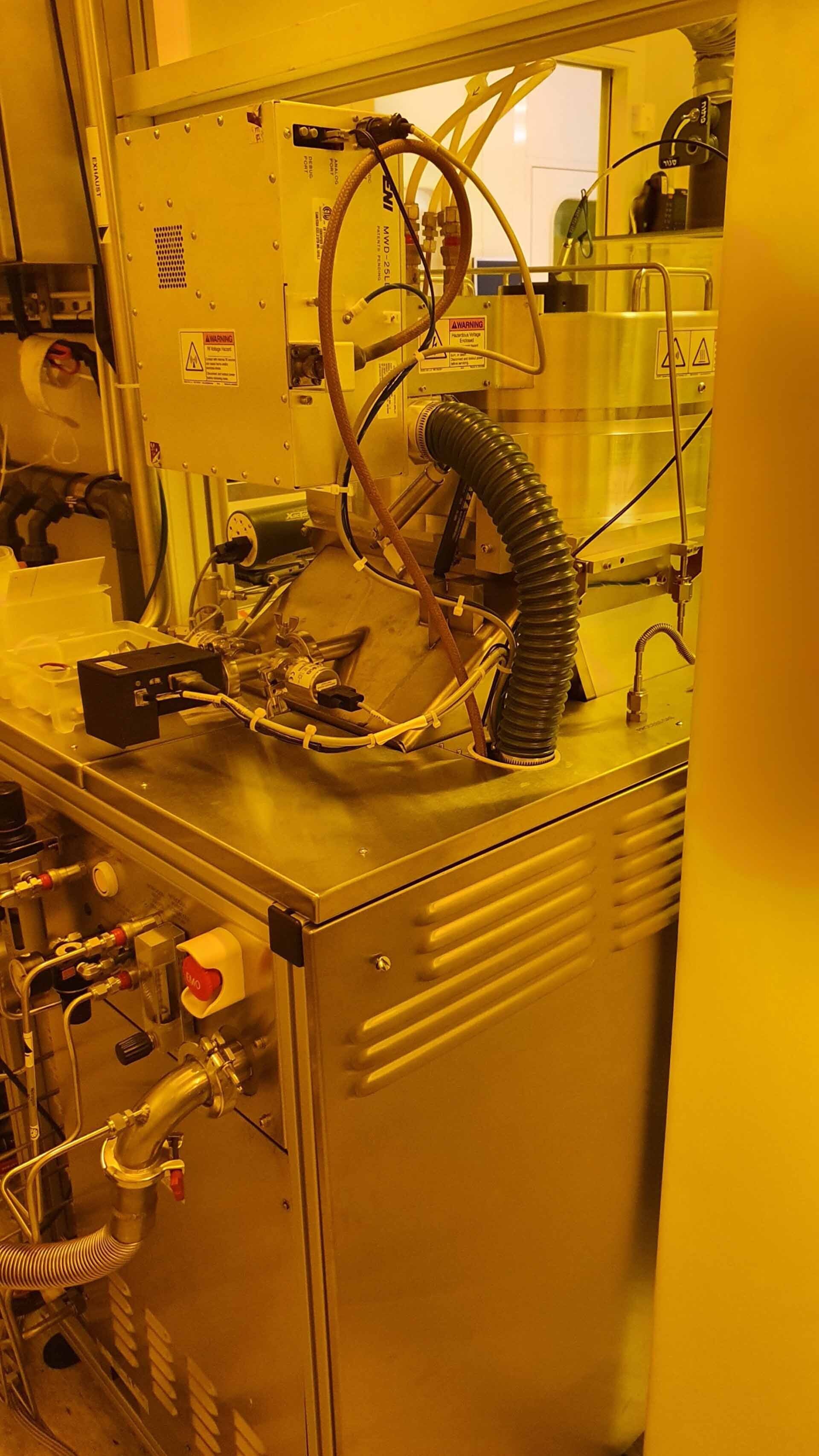

Used PLASMATHERM / UNAXIS Shuttleline #9351989 for sale

URL successfully copied!

Tap to zoom

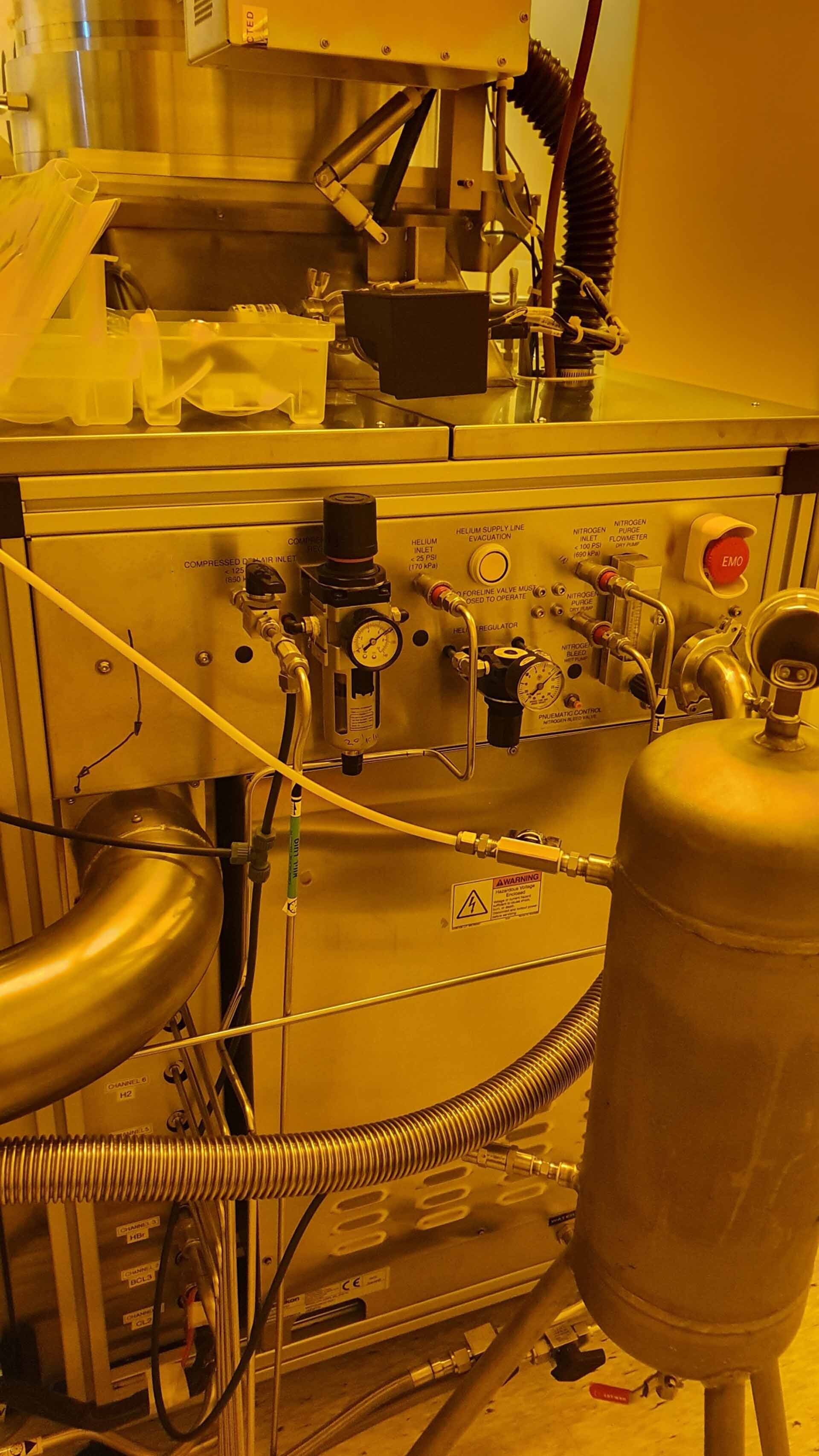

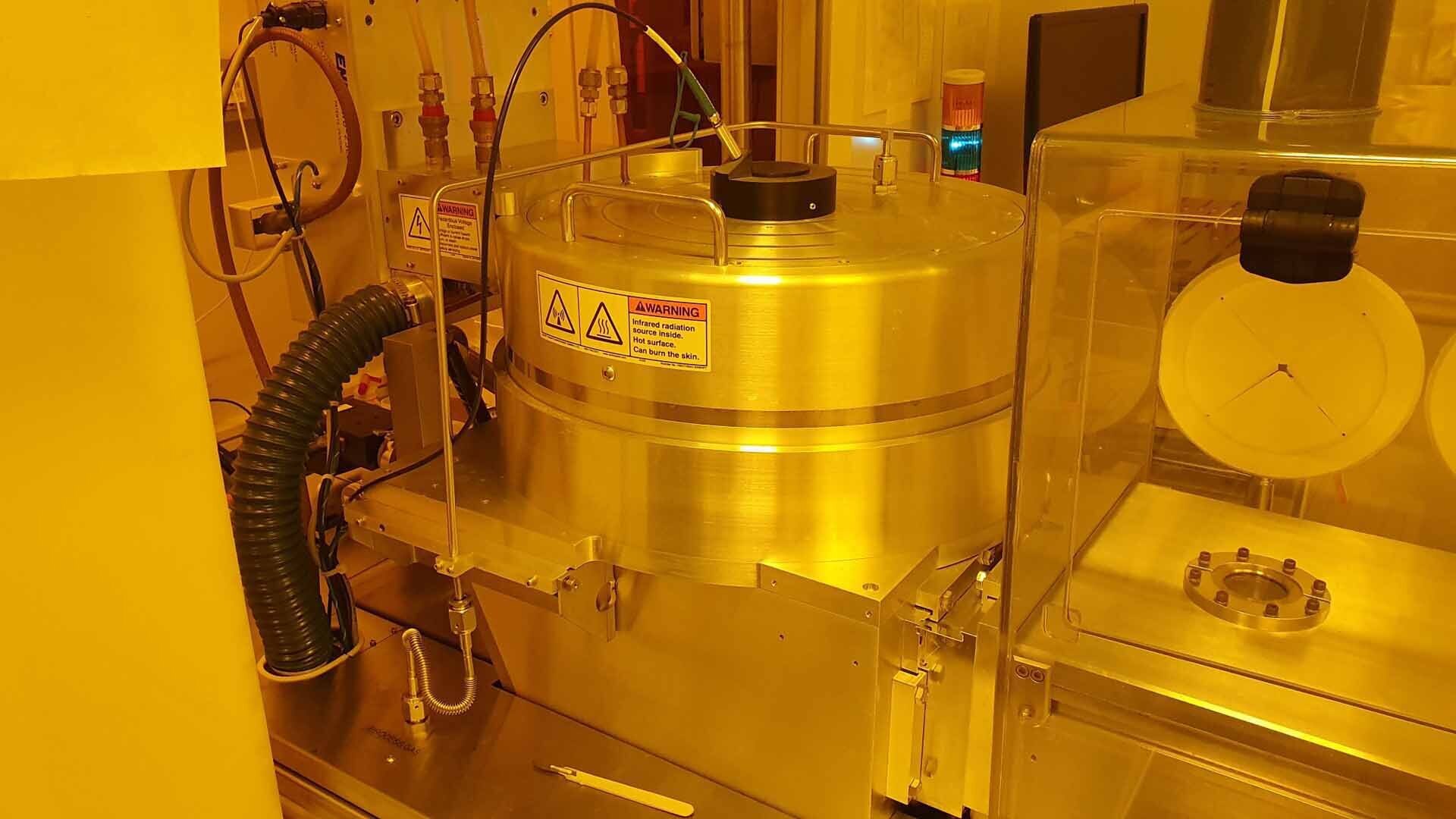

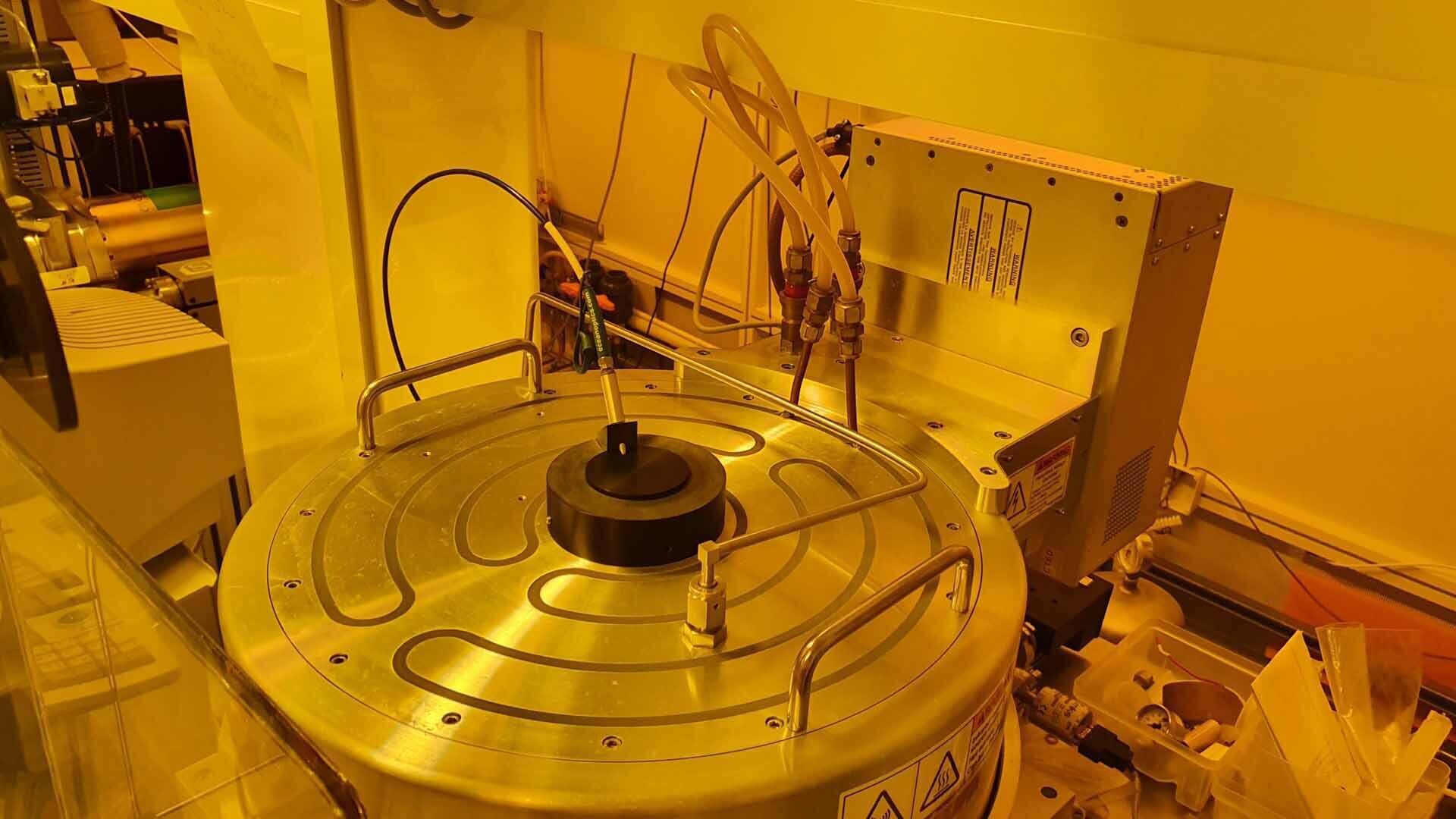

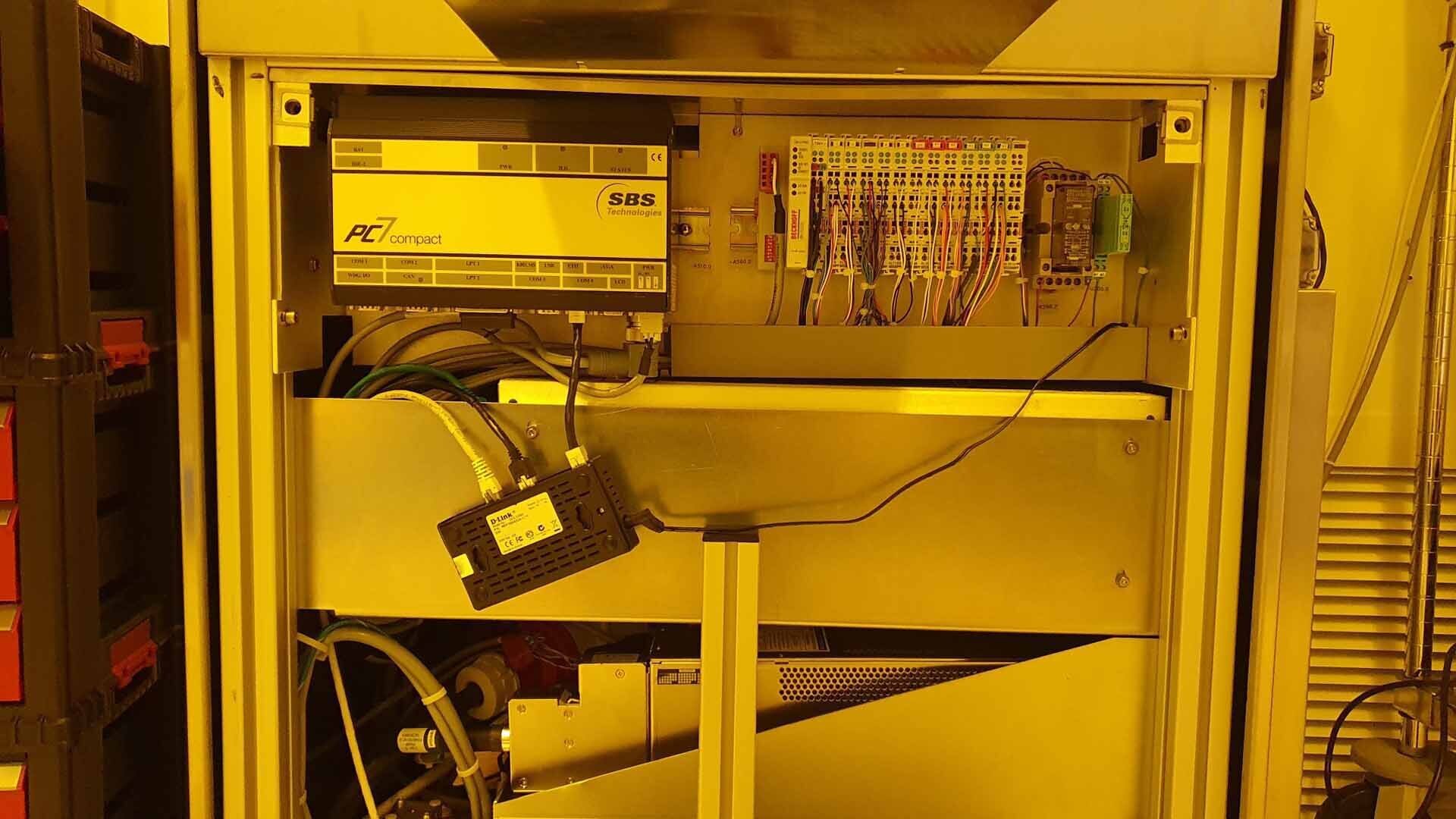

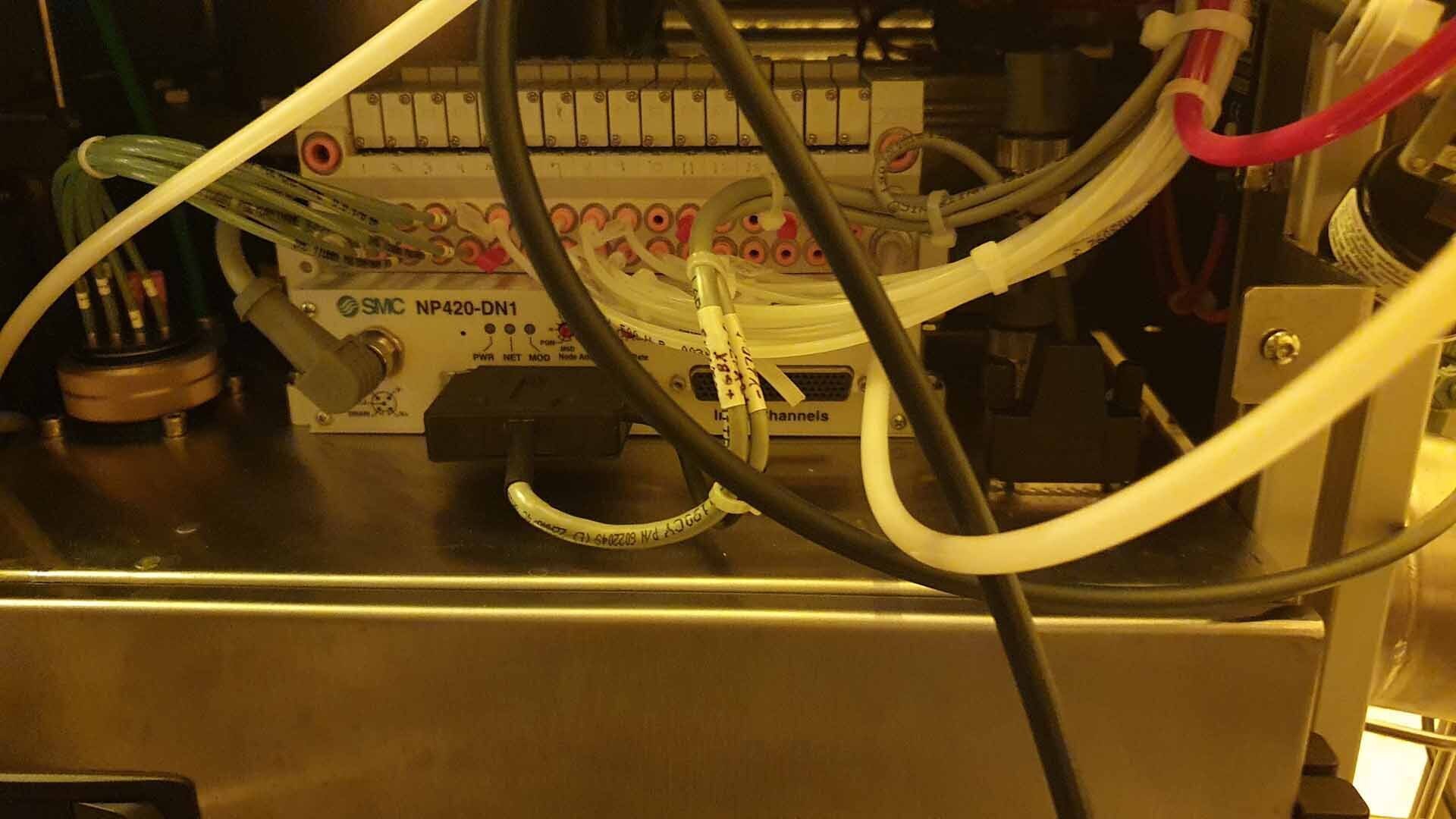

PLASMATHERM / UNAXIS Shuttleline is an innovative wet etcher/asher for use in the microelectronics and nanotechnology industries. UNAXIS Shuttleline features a single-source, low-cost wafer-processing platform, enabling simultaneous processing of up to 20 wafers, with selectable etching/ashing recipes. It is designed as a self-contained unit that includes single-wafer pre-clean and post-clean stations, as well as optional batch dip pre-clean and post-clean systems that can be upgraded for increased throughput. The process chambers feature high temperature options up to 250 degrees Celsius, static or dynamic chambers for different etching/ashing recipes, and the ability to monitor process events with in-situ process control. PLASMATHERM Shuttleline is designed to process a wide range of wafer sizes and materials, with the capability to process up to 150mm wafer sizes. Shuttleline also features "anti-lock chambers" to reduce processing time and improve throughput. Moreover, PLASMATHERM / UNAXIS Shuttleline is equipped with a recipe management equipment, for storing and recalling user-defined recipes, as well as a built-in data acquisition and analysis system, which is capable of capturing lamination process images for later analysis. In addition to its advanced features, UNAXIS Shuttleline is designed with a combination of flexibility and ease-of-use, featuring interchangeable wafer carriers and automated diagnostics for quick and easy maintenance. Furthermore, the unit is equipped with a full suite of safety features, including an emergency pressure shutoff machine and an automatic water shutoff valve, to prevent possible hazardous material releases and equipment damage. Finally, PLASMATHERM Shuttleline's open architecture allows for easy integration with other systems, for custom applications. Overall, Shuttleline wet etcher/asher is an incredibly advanced and reliable piece of etching/ashing equipment that is perfect for microelectronics and nanotechnology industries. Its combination of flexibility, safety, cost-effectiveness, and ease-of-use makes it the perfect choice for any etching/ashing job.

There are no reviews yet