Used PLASMATHERM / UNAXIS SLR 740 #9276449 for sale

URL successfully copied!

Tap to zoom

ID: 9276449

Wafer Size: 8"

Vintage: 1999

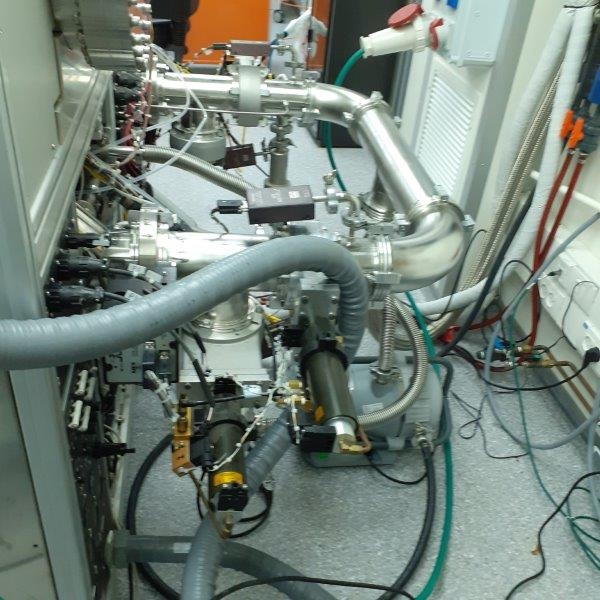

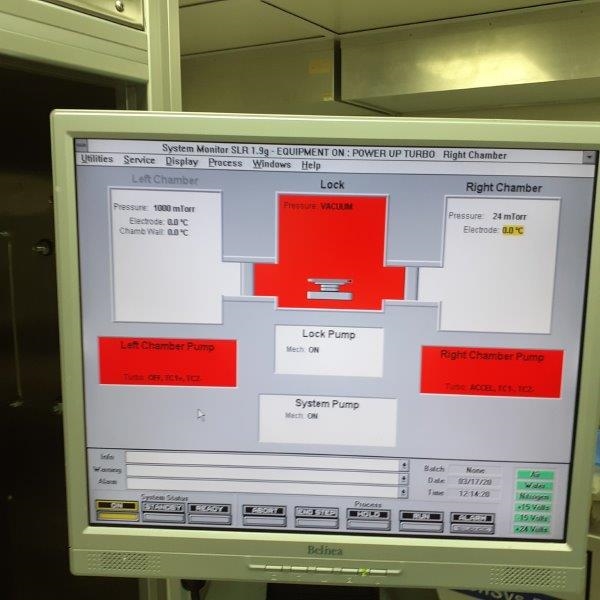

Reactive Ion Etcher (RIE), 8"

Dual chamber

PC Controlled

Operating system: Windows

No ICP

LH Chamber:

Low vacuum

RH Chamber:

EDWARDS Turbo Molecular Pump (TMP)

With adjustable top electrode gap

High vacuum

Electrodes, 8"

Plasma etch power

Load lock

Automatic loader and unloader arm, 3"-8"

(8) Gas channels

Left chamber:

Make / Model / Gases / Scale

MKS / 1479A / AR / 100

MKS / 1479A / CHF3 / 100

MKS / 1479A / C2F6 / 100

MKS / 1479A / CF41 / 100

MKS / 1479A / SF6 / 50

MKS / 1479A / HE / 100

MKS / 1479A / O2 / 10

MKS / 1479A / O2 / 100

Right chamber:

Make / Model / Gases / Scale

MKS / 1479A / CF-41 / 100

MKS / 1479A / SF6 / 50

MKS / 1479A / HE / 100

MKS / 1479A / CHF3 / 100

MKS / 1479A / C2F6 / 100

MKS / 1479A / O2 / 10

MKS / 1479A / O2 / 100

MKS / 1479A / AR / 100

Does not include:

(2) Chillers

Backing / Roughing pump

Load lock pump

Power supply: 400 V, 50 Hz, 3-Phase

1999 vintage.

PLASMATHERM / UNAXIS SLR 740 is an etcher/asher that is used in the fabrication of semiconductor devices. It is designed for the accurate milling and deposition of thin films on wafer surfaces. The device is specifically intended for the fast and precise etching of the masks used in the production of semiconductor devices. UNAXIS SLR 740 has a 4-inch by 2.5-inch (10 cm by 6.25 cm) size for compatibility with the equipment used in typical production lines. This etcher has a maximum pressure of 700 mTorr and a maximum process temperature of 450°C. It is capable of depositing material at rates up to 500μm/sec and can etch at a depth of up to 5μm/min. The process is ultra clean and controlled, using a plasma based equipment to ensure uniform deposition. This system has an advanced built-in safety unit which protects the operator from hazardous gases or particles. The device has a touch-screen control panel and a user-friendly menu-based interface for easy programming. It can store up to 26 recipes, allowing for specific processes to be done on demand. The device also features an autofocus optics machine to ensure accuracy, and comes with an integrated vision tool to ensure the processes are done correctly. The device has a slurry flush asset that enables the removal of contaminates at the end of the process. It is equipped with a built-in cooling model that minimizes process downtime. A vacuum exhaust equipment is also included to ensure the process is done safely. The chamber of PLASMATHERM SLR 740 is equipped with a gas shower system with 3-zone flow control. This allows for precise control of the etching process and further improves process repeatability. The gas shower unit is monitored by a series of temperature probes, ensuring no temperature fluctuations occur during the process. Furthermore, the device is certificate as an antistatic devices and is also designed with a radiation safety machine. Overall, SLR 740 is an effective, reliable, and accurate etcher/asher device that is suitable for use in the fabrication of semiconductor devices. It offers a wide range of features and an efficient design that make it the perfect choice for any semiconductor production line.

There are no reviews yet