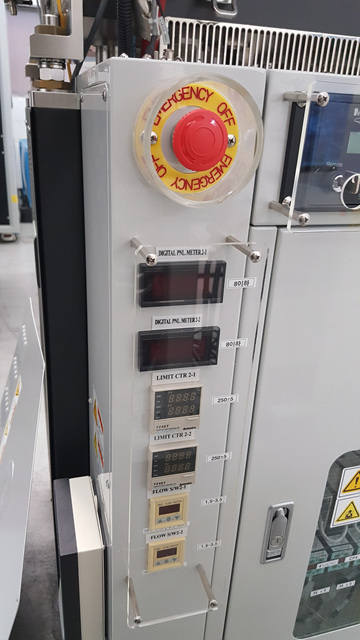

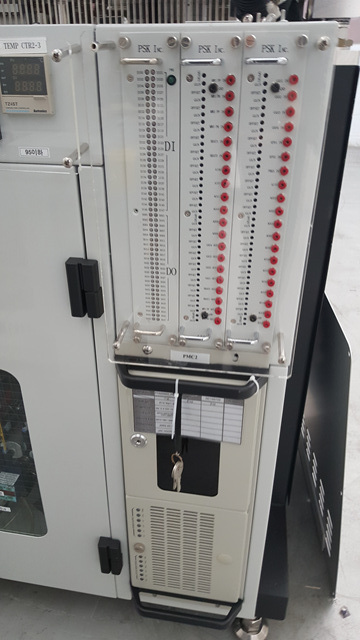

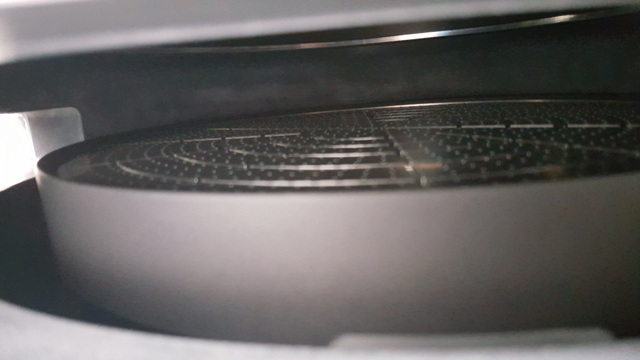

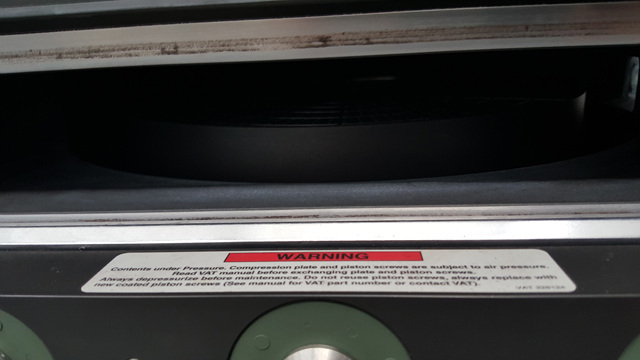

Used PSK TERA 21 #9133786 for sale

URL successfully copied!

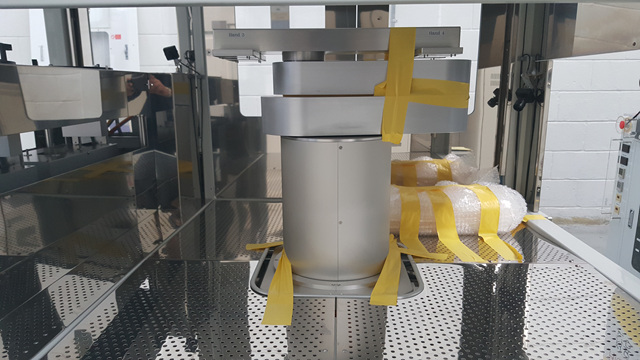

Tap to zoom

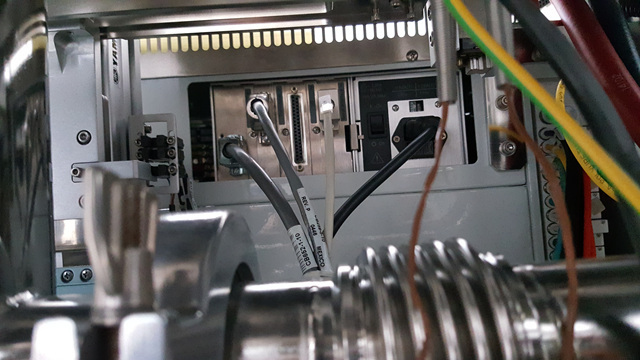

ID: 9133786

Asher, 12"

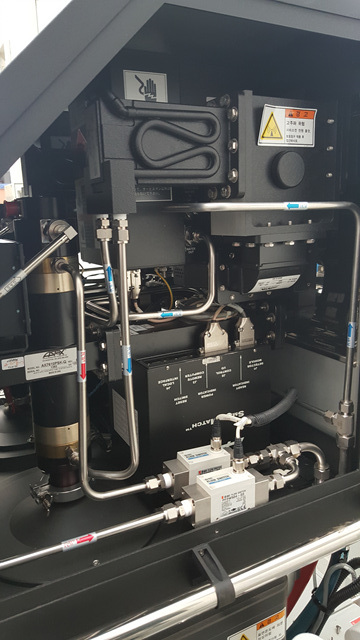

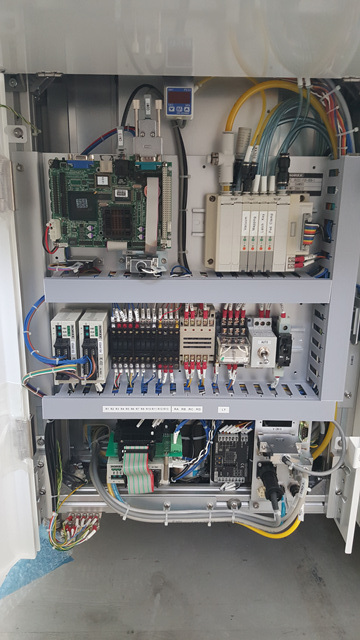

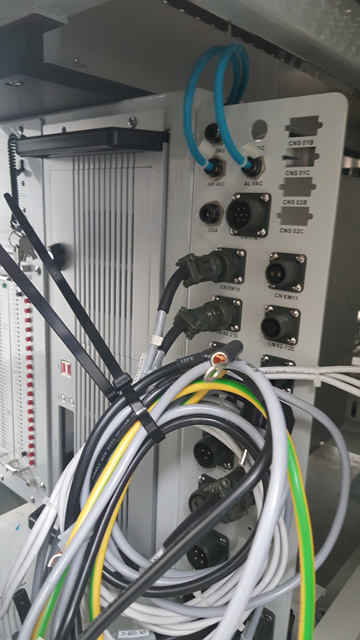

Electrical Configuration:

Main Power: 30 208VAC 250A 60Hz

UPS Power: 10 208VAC 100A 60Hz

Wafer Size: 12-inch Wafer

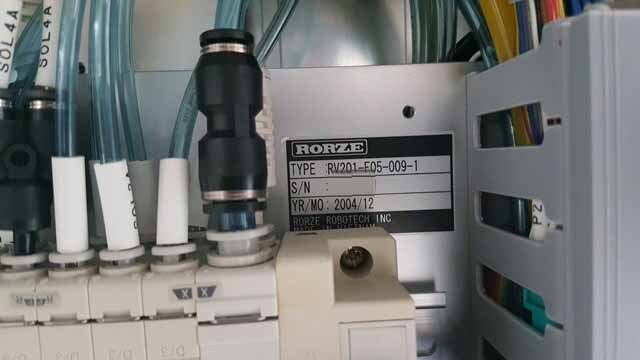

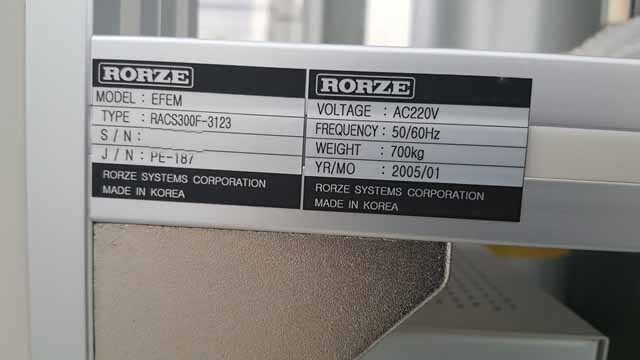

Loadport Maker / Model : Rorze / RV201-F05-009-1

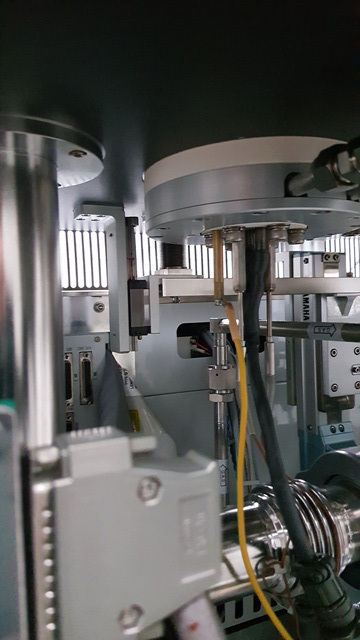

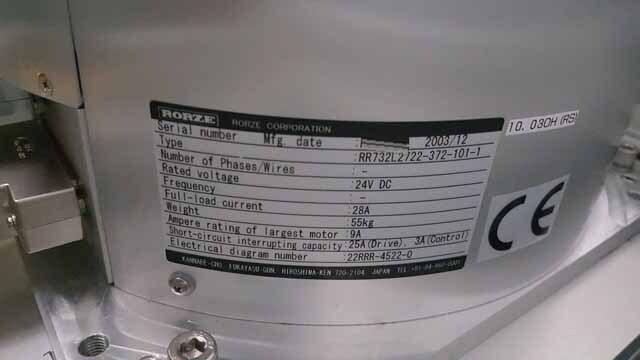

FI Robot Maker / Model: RORZE / RR732L2722-372-101-1

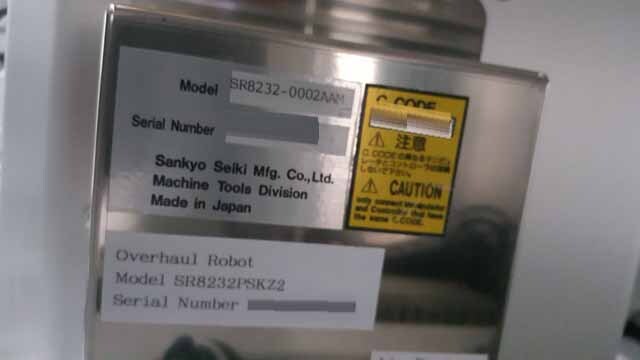

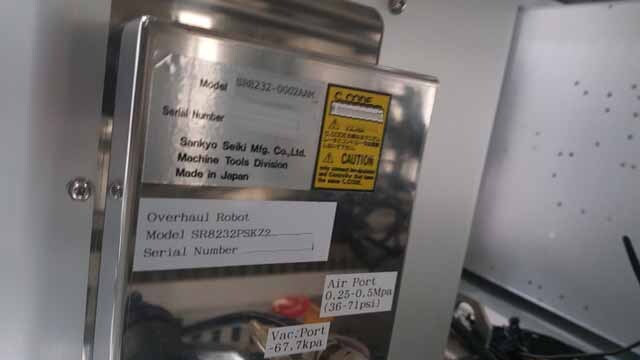

TM Robot Maker / Model :Sankyo/SR8232-0002AAM

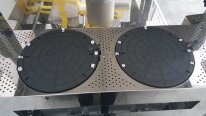

Cooling Station: 2 Stage

Dual Aligner

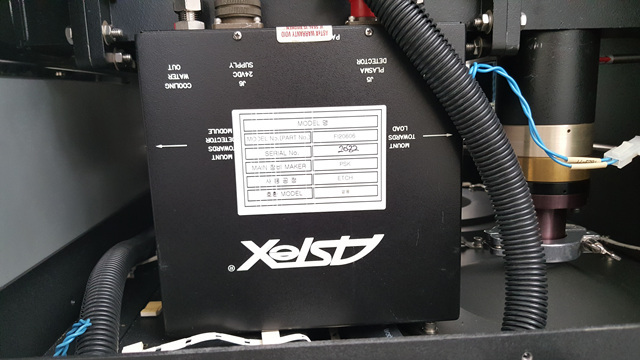

Model Items Maker

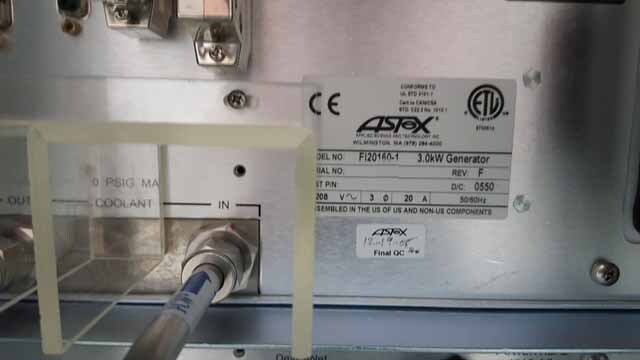

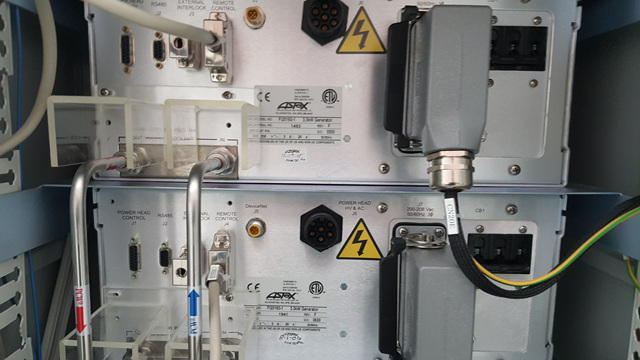

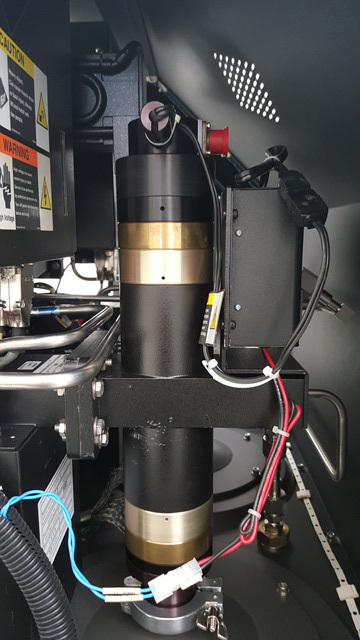

FI20160-1 M/W Generator MKS

AX7610PSK-Q Applicator MKS

FI20162-1 Magnetron Head MKS

FI20606 Smart Matcher MKS

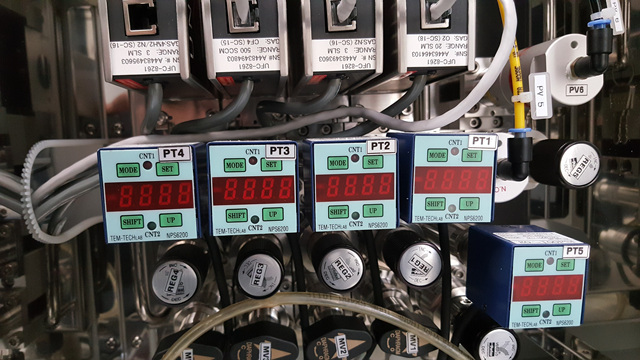

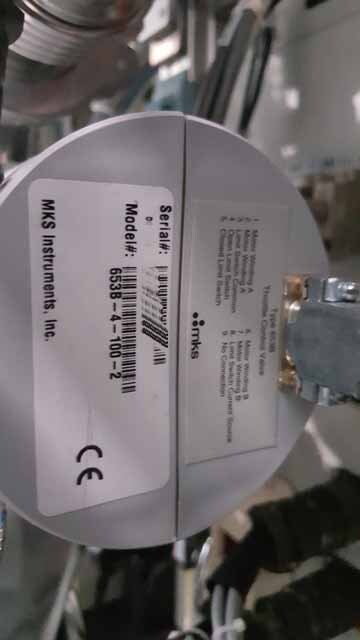

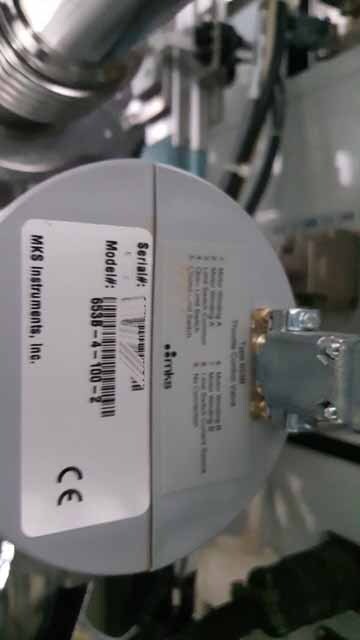

626A02TBE Chamber Manometer MKS

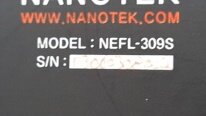

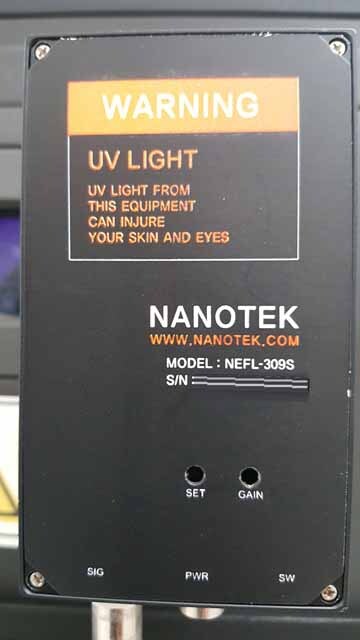

NEFL-309S EPD NANOTEK

600 Series APC Contoller MKS

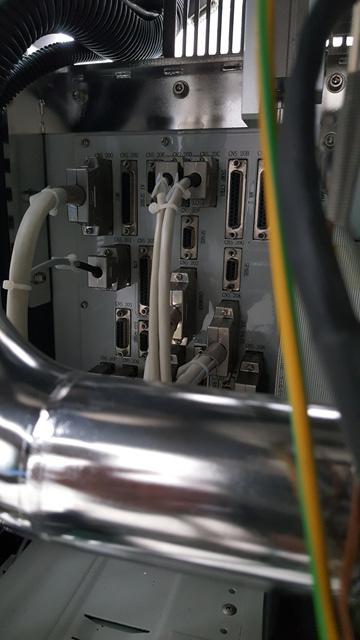

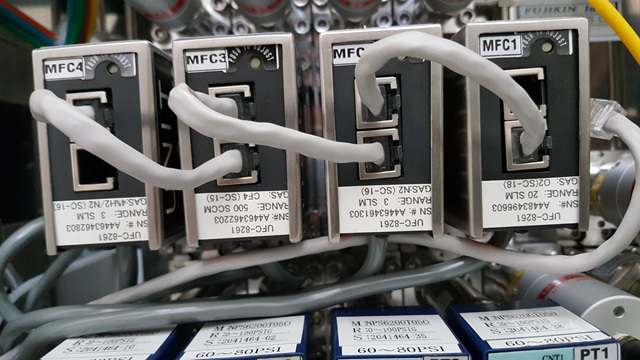

UFC-8261 Gas1 UNIT

UFC-8261 Gas2 UNIT

UFC-8261 Gas3 UNIT

UFC-8261 Gas4 UNIT

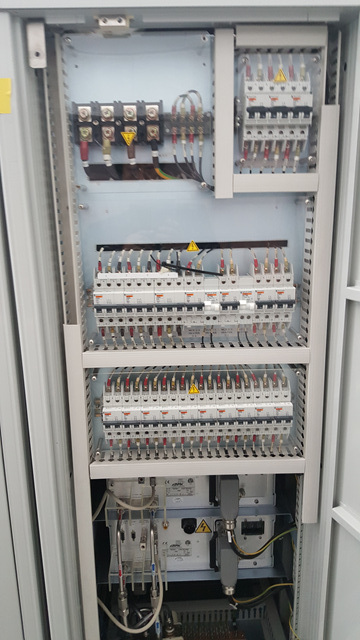

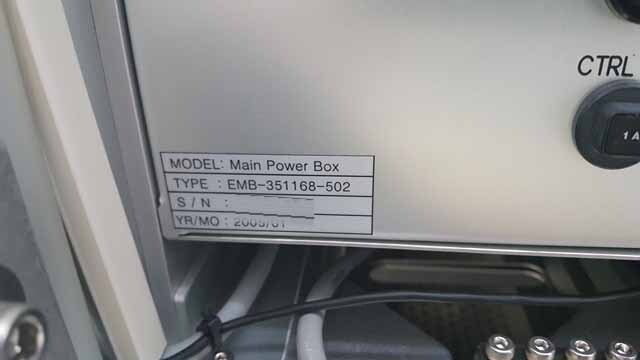

AC Power Rack:

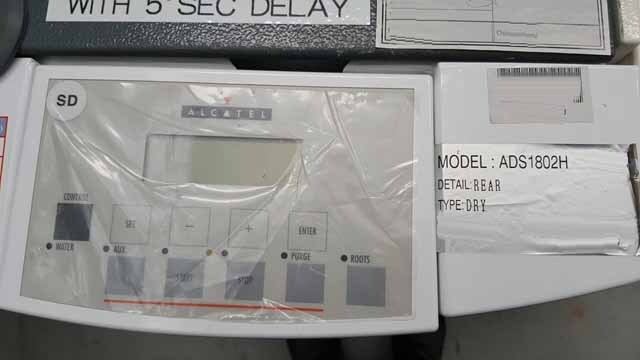

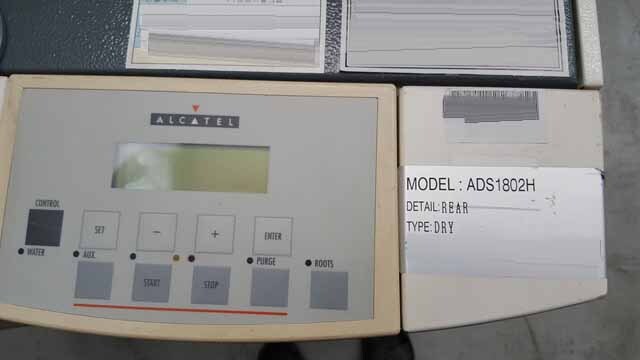

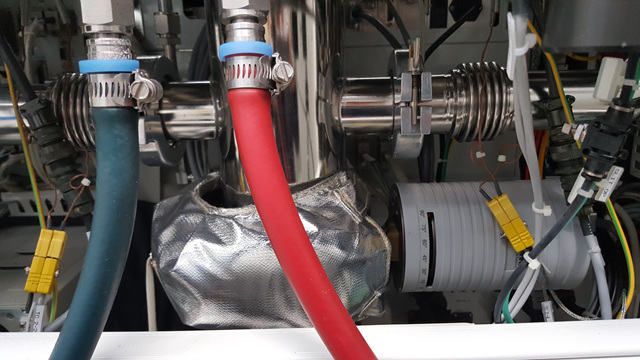

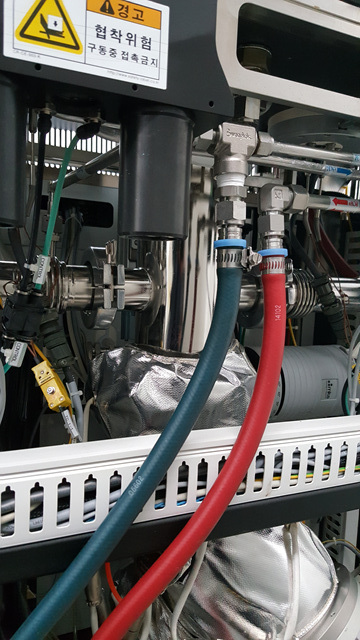

Pump Maker/ Model : ALCATEL / ADS1802H

Pump Rack : ALCATEL

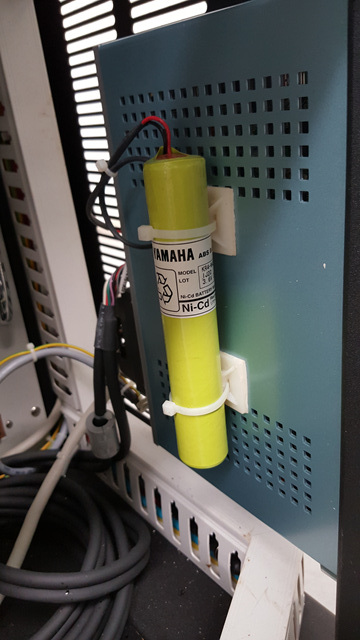

2005 vintage.

PSK TERA 21 is an advanced etcher / asher which is designed to perform superficial mechanical action on various substrates. It combines a modern design with economical handling and fast processing time. The unit is equipped with an adjustable rotary speed control and permanent magnetic chuck, giving it the capability to handle diverse substrate sizes and shapes. The powerful motor of TERA 21 etcher / asher has a maximal speed of 75K RPM and the precise speed control allows for precise and controlled operations. The installation of a PC-controlled DC circuit creates an additional level of adaptation, as it is possible to adjust the cutting depth, substrate feed rate and cutting head speed separately from one another. The PC utility software allows saved programs to be recalled for multiple operations, which helps to increase process efficiency. The etcher / asher features two cutting settings and different interchangeable cutting heads, which are made of very resistant materials. This allows for a high degree of material removal as well as surface processing. The heat generated during the cutting process is dissipated by efficient cooling system, therefore avoiding thermal damage to the substrate. An additional advantage of the etcher / asher is that it can be used for machining multiple substrates with different features in various directions. This makes the device suitable for a variety of surface treatments in order to create competitive parts or devices. PSK TERA 21 is highly versatile in its application and is suited for a range of intricate works and automated parts, such as those used in automotive, aerospace, medical device and general engineering sectors. With its combined time and cost efficiency features, the etcher / asher is an efficient choice for majority of metal processing applications.

There are no reviews yet