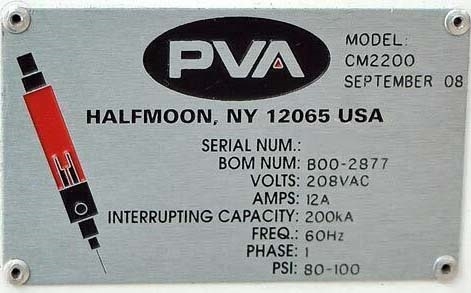

Used PVA 650 #9266554 for sale

URL successfully copied!

Tap to zoom

ID: 9266554

Vintage: 2008

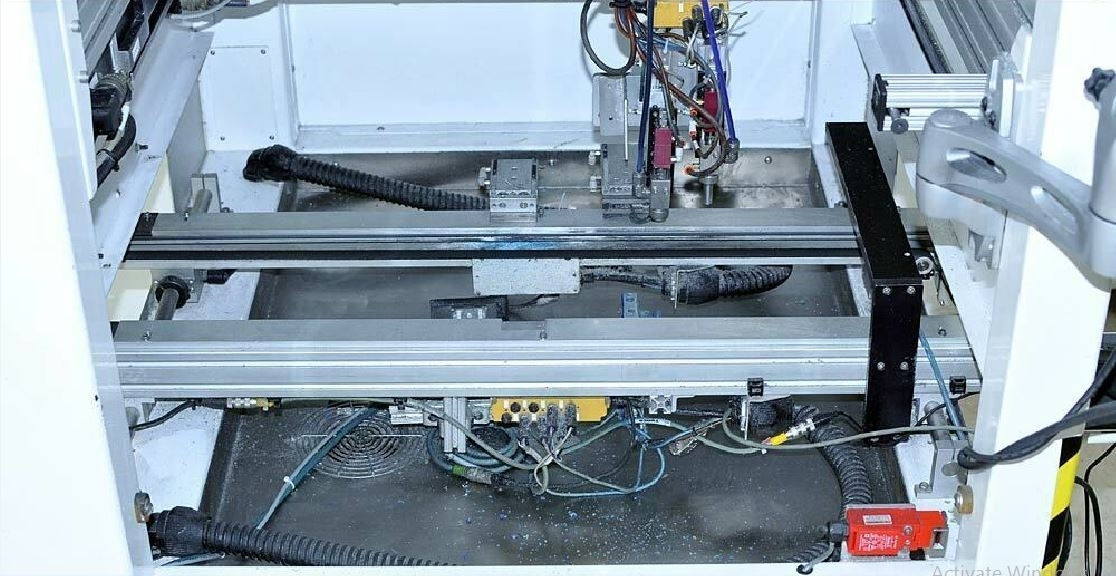

Conformal coating machine

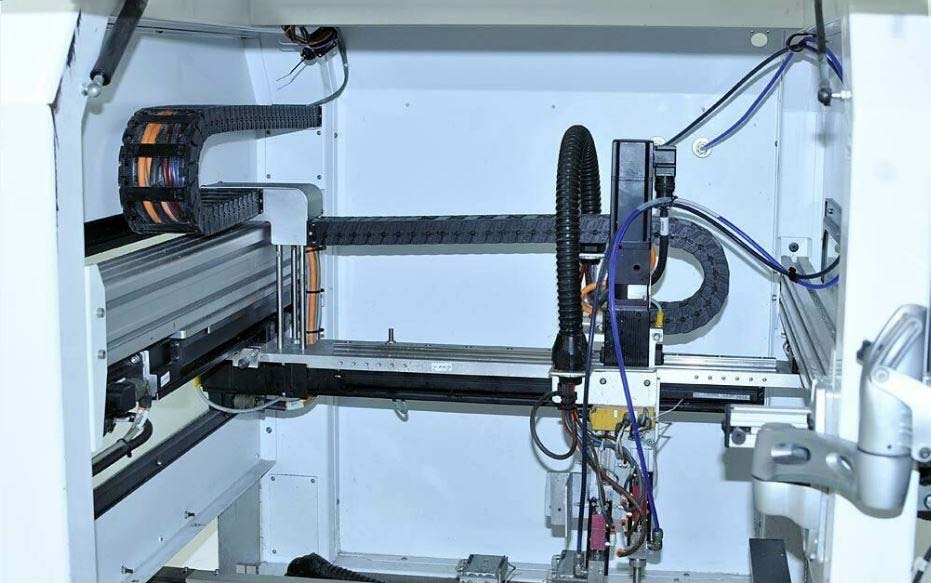

3-Axis gantry style robot work cell

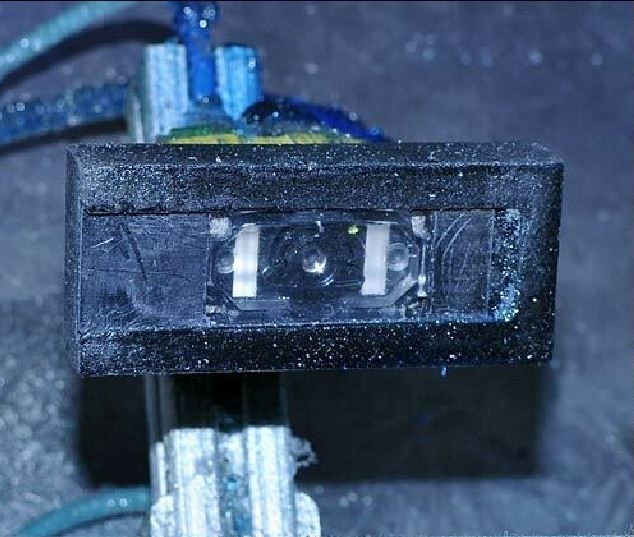

Intended for dispensing / Application

Conformal coating / Liquids

(2) Dispensing heads

Work area: 18" x 18" x 4"

Repeatability: 0.001"

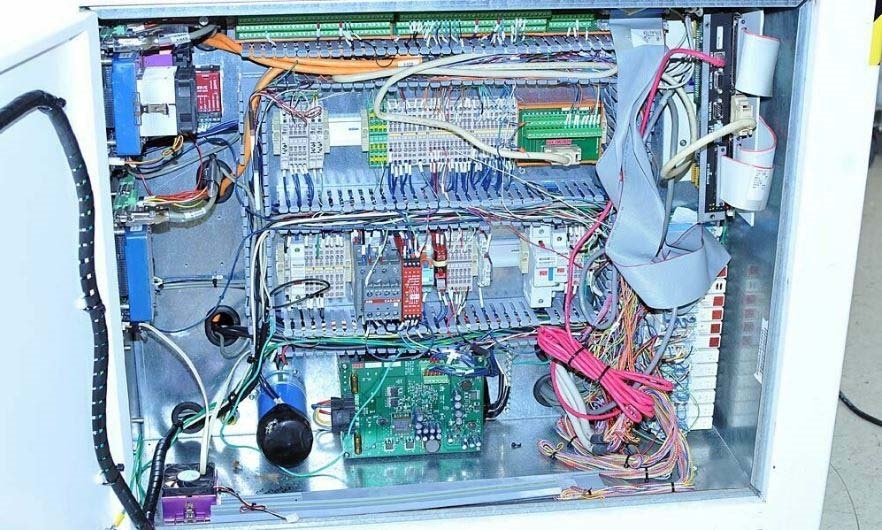

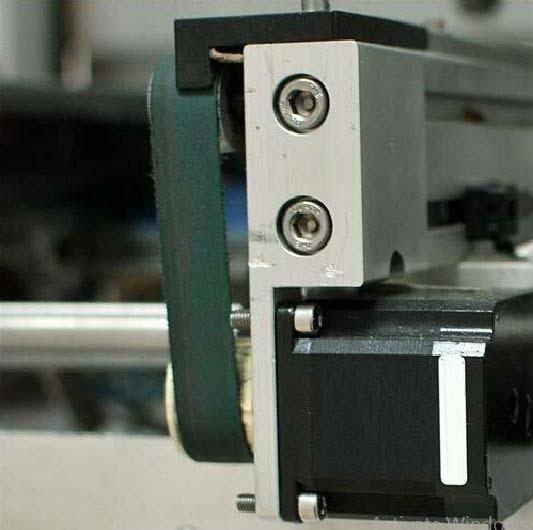

3-Axis servo motors

Silicone rubber application machine

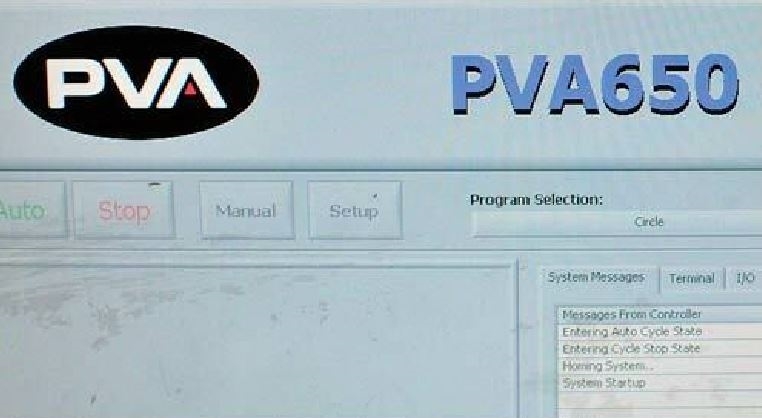

Computer programming / Control

THK SKR33 Series precision XYZ linear motion

And modules with servo motors

THK HR20 Linear motion guides X and Y axes

Galil motion controller

Open-center edge belt conveyor, 43" (Side-to-side)

Pneumatic stops conveyor

SMEMA Conveyor communications

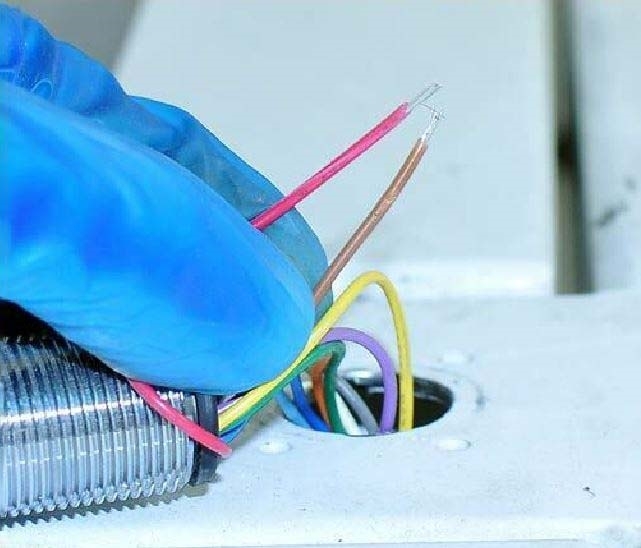

Compressed air

Computer hard drive missing

Power: 208 VAC, Single phase

2008 vintage.

PVA 650 is an advanced Reactive Ion Etch (RIE) system designed for deposition and etching of a wide range of materials, including metals, ceramics, and semiconductors. 650 is a cost-effective, highly automated etcher/asher with high-precision alignment, blazing speeds of up to 500mm/sec, and reliable results even for complex geometries. It utilizes state-of-the-art reactive ion beam etching (RIBE) technology, which produces controlled and highly repeatable etching and deposition results. The robust design of PVA 650 eliminates the need for an external particle filter, giving it a low maintenance operation with no need for frequent maintenance or cleanup. Its high-end automation features enable reliable and accurate processing in multiple directions, including perpendicular, angled, and self-aligning operations. 650 is equipped with an innovative touch-screen interface and advanced software algorithms to ensure repeated accuracy with its advanced features. Its high-speed full-axis motion drives the etching and deposition process with a maximum accuracy of 0.01μm. PVA 650 also comes with advanced process control functions, such as closed loop control, blank cycle/gap cycle, target shape/dimension process monitoring, cold wall/ hot wall effusion and substrate temperature control, which enable higher quality deposition and etching. The system is constructed from stainless steel, aluminum, and special cast-aluminum for both its frame and fixtures, providing superior durability and corrosion resistance. It is designed to meet strict safety requirements and provide a higher level of user safety. 650 is compatible with a variety of materials, including quartz, glass, and photosensitive films, and is able to process 6" and 8" substrates. It also provides superior crystal qualities and fine, complex patterns in its etching and deposition results, making it a top-of-the-line system for a variety of applications.

There are no reviews yet