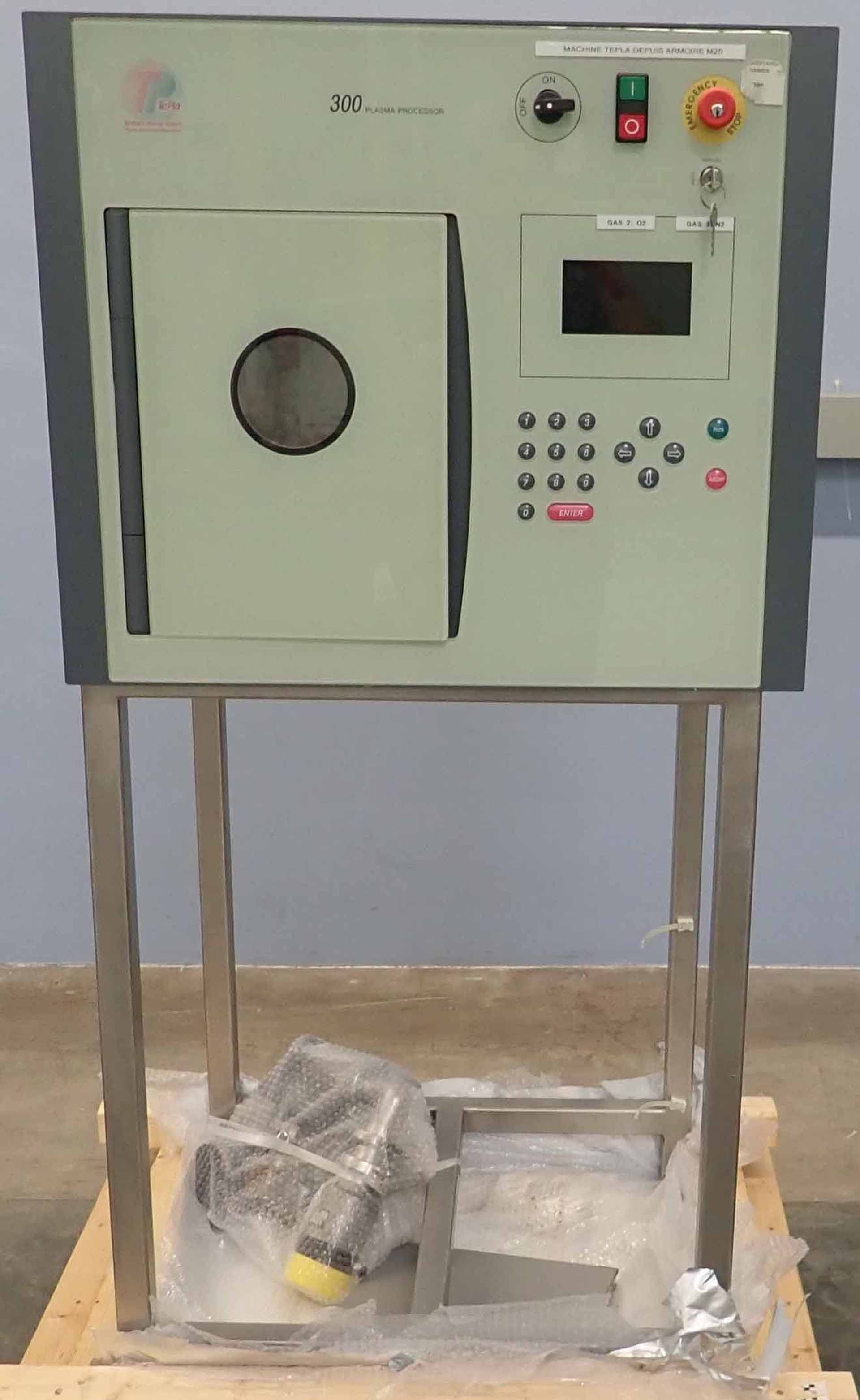

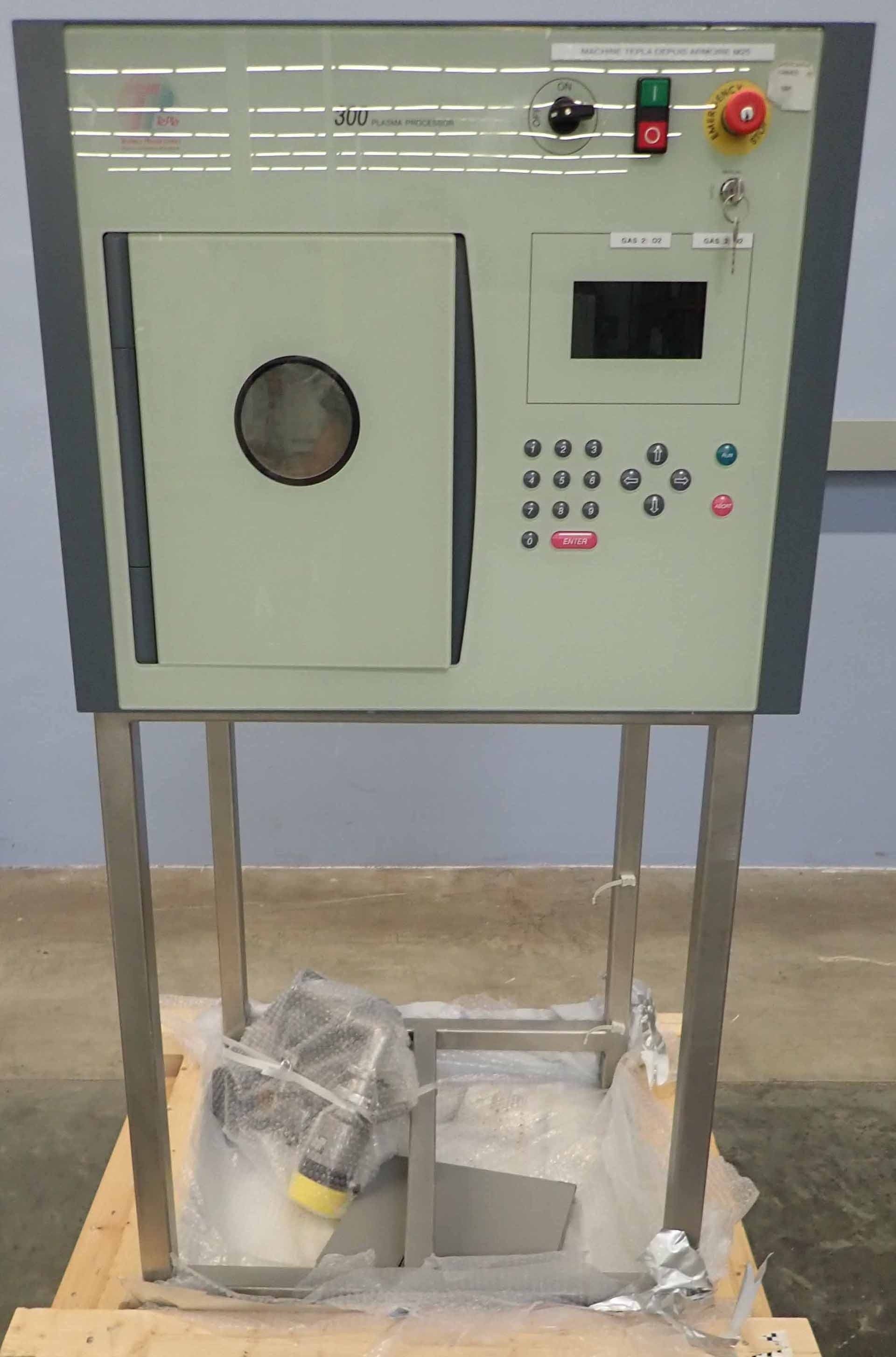

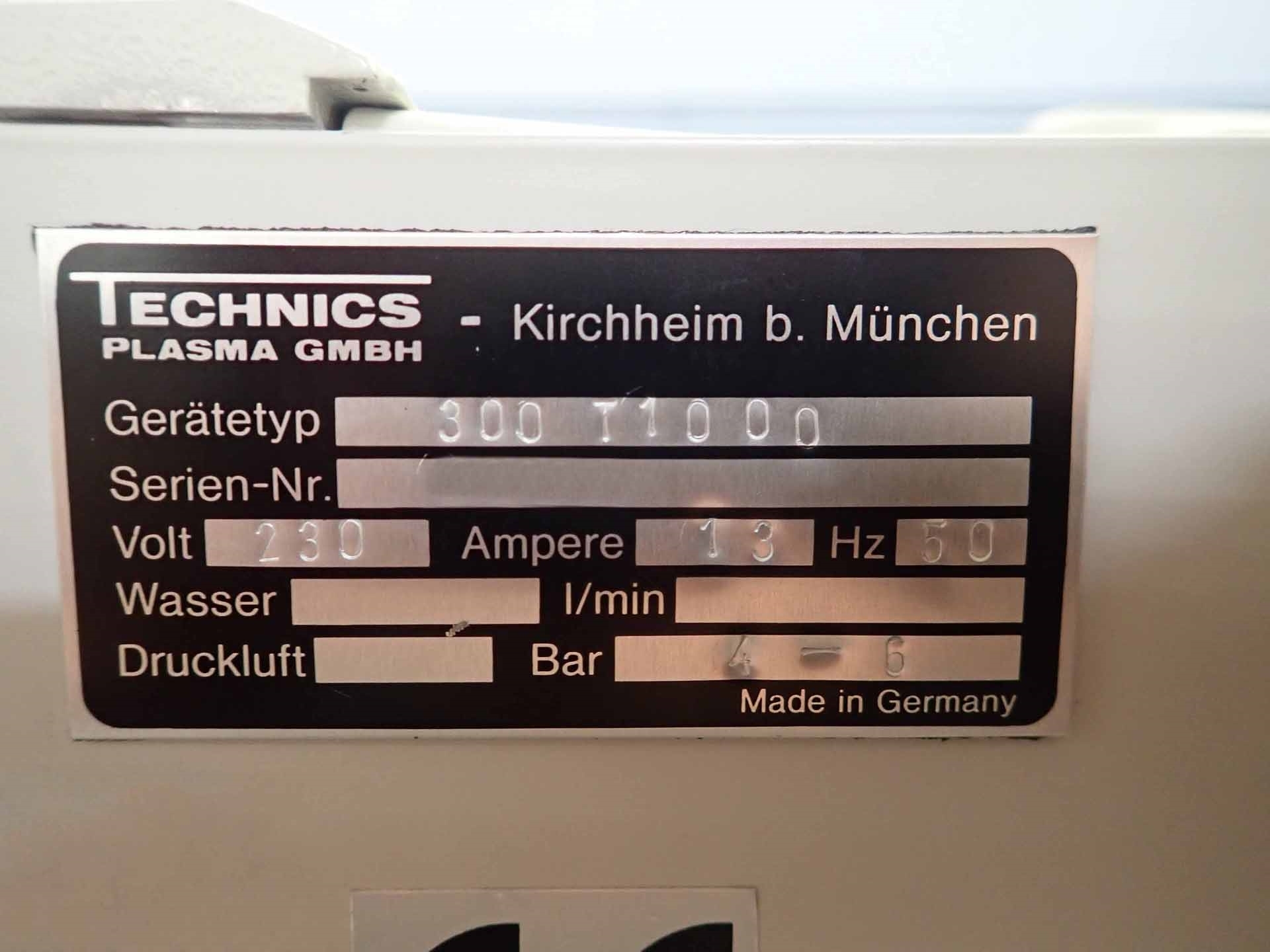

Used PVA TEPLA / TECHNICS 300 TL1000 #9247548 for sale

URL successfully copied!

Tap to zoom

ID: 9247548

Plasma asher

Running hours: 2,065

CE Marked

Power supply: 230 V, 50 Hz, 13 Amps.

PVA TEPLA / TECHNICS 300 TL1000 Asher is a high-performance etcher designed for industrial use. It is a gas-controlled, single wafer and batch processing equipment that is suitable for all semiconductor applications. The asher uses a combination of chemical and physical processes to etch patterns and structures in a wide variety of substrates. The gas used is a combination of oxygen and a volatile organic vapour which is mixed with inert nitrogen gas. The chamber pressure is maintained at a constant level to ensure repeatable and accurate process results. TECHNICS 300 TL1000 Asher is equipped with a variety of features to ensure consistent quality and reliability. It is capable of producing etching or etching sputtering rates of over 100 nm/min with a maximum throughput of 30 wafers per hour. Additionally, the asher is able to handle substrates of different sizes, shapes, and types. The user interface provides a clear view of the status and parameter settings, as well as comprehensive real-time process monitoring. The gas supply system of PVA TEPLA 300 TL1000 Asher is designed to provide a stable and repeatable dosage rate for the gases. All gases are stored in chambers where the gas concentration and flow rates are precisely controlled. Even distribution of the gas mixture is maintained through multiple gas inlets to ensure uniform etching or sputtering rates across the entire substrate. 300 TL1000 Asher is equipped with a number of safety features to protect personnel and equipment. The unit has a door interlock which prevents the access to the chamber when the machine is in operation. An advanced fire suppressant tool ensures that hazardous situations are prevented. Additionally, the entire asset is tested and certified for CE safety compliance. PVA TEPLA / TECHNICS 300 TL1000 Asher is also equipped with a variety of process control options to ensure uniform etching or sputtering rates with minimal variation. Temperature, pressure, and other variables can be monitored and controlled with an ultra-precise feedback loop. The heating model is designed to prevent the chamber walls from becoming too hot, reducing reaction time and ensuring uniform process results. In conclusion, TECHNICS 300 TL1000 Asher is a reliable and efficient etcher / asher suited for the most demanding semiconductor applications. Its high throughput rate and easy to use interface allow for consistent and repeatable process results. It is equipped with comprehensive safety features and process control options to ensure safety and accuracy.

There are no reviews yet