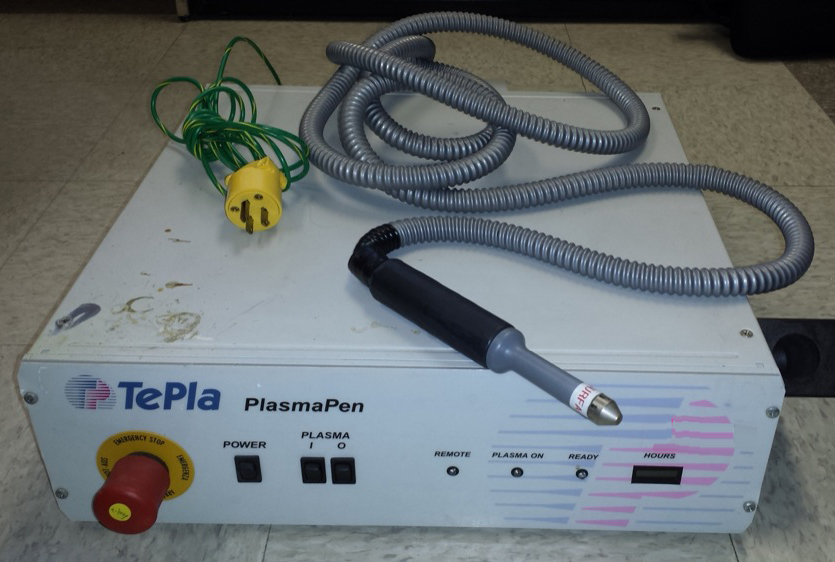

Used PVA TEPLA / TECHNICS PlasmaPen #9056655 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

PVA TEPLA / TECHNICS PlasmaPen is an electrochemical etching and ashing equipment designed to deliver high accuracy and precision in the fabrication and etching of micro-components. It offers an automated solution for small to large scale production and can be used for a variety of processes such as planarization, etching, cleaning, and sputtering. The system consists of a vacuum chamber, a control unit, a power supply, and an etching/deposition electrode. The vacuum chamber is made up of a high-vacuum chamber, and an exhaust chamber. The high-vacuum space is separated from the exhaust chamber by a heat shield, which prevents heat transfer from the exhaust to the etching/sputtering chamber while maintaining overall chamber integrity. The chamber is then filled with a noble gas such as Argon, Xenon, or Helium to ensure adequate pressure and temperature stability. The approach taken with this unit is that pressure and temperature can be precisely measured in order to maximize etching and sputtering accuracy. The control unit is used to precisely control the various components of the machine. This includes the power supply, chamber pressures, gas composition, and the deposition and etching parameters. In addition, it can monitor and analyze the etching process so that the tool can be adjusted for optimal performance. The power supply can be adjusted and configured to apply different voltages to the substrate for etching and deposition. This is essential since the voltages are responsible for controlling the etching and deposition rates. An electrochemical process is used for the deposition of the desired material, which then initiates the etching process. This is why the power supply is so important in this asset, as it can be used to adjust the voltages to precisely control the rate at which the material is deposited and etched. The etching/deposition is performed by an electrode, which is machined to meet the customer's exact specifications. This allows it to achieve the most accurate etching/deposition rates and accuracy. The etching/deposition process is highly reliable and accurate due to the combination of precise material selection and deposition, heat/pressure control, and low-power options configured by the control unit. The accuracy and precision of this model make it an ideal choice for small to large scale production. TECHNICS PlasmaPen is a powerful etching and ashing equipment designed to provide high-precision micro-component fabrication. Its comprehensive approach towards pressure and temperature control, automated power supply, and accurately machined electrode makes it an ideal choice for accurate deposition and etching of delicate components.

There are no reviews yet