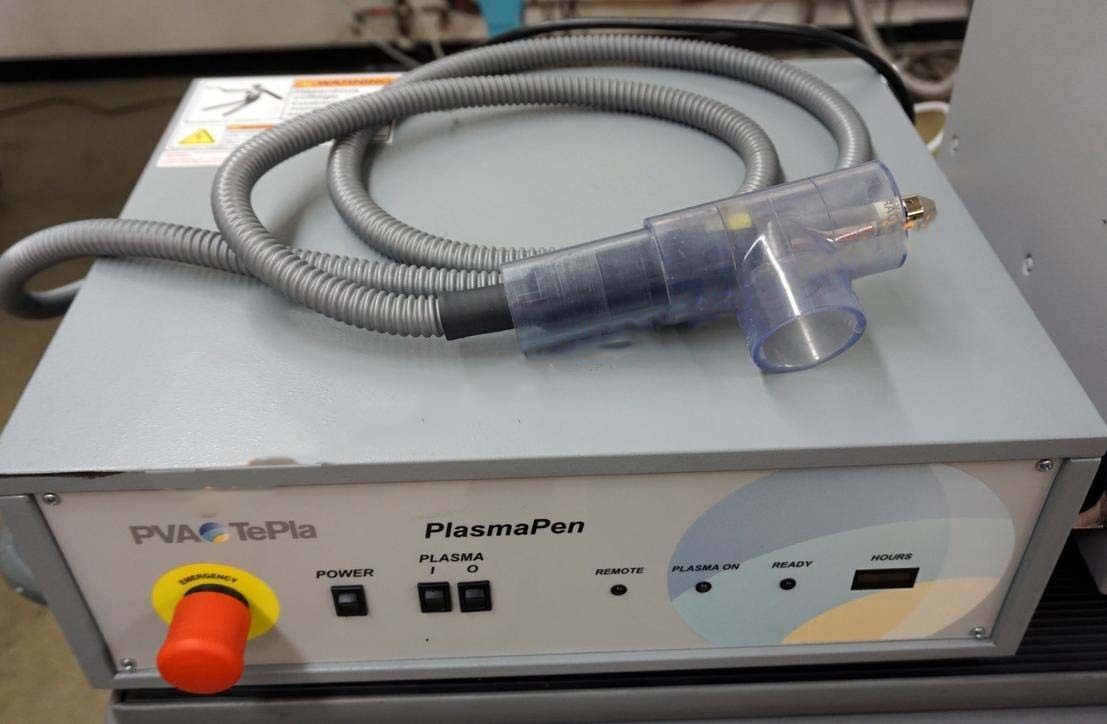

Used PVA TEPLA / TECHNICS PlasmaPen #9314747 for sale

URL successfully copied!

Tap to zoom

ID: 9314747

Cleaning system

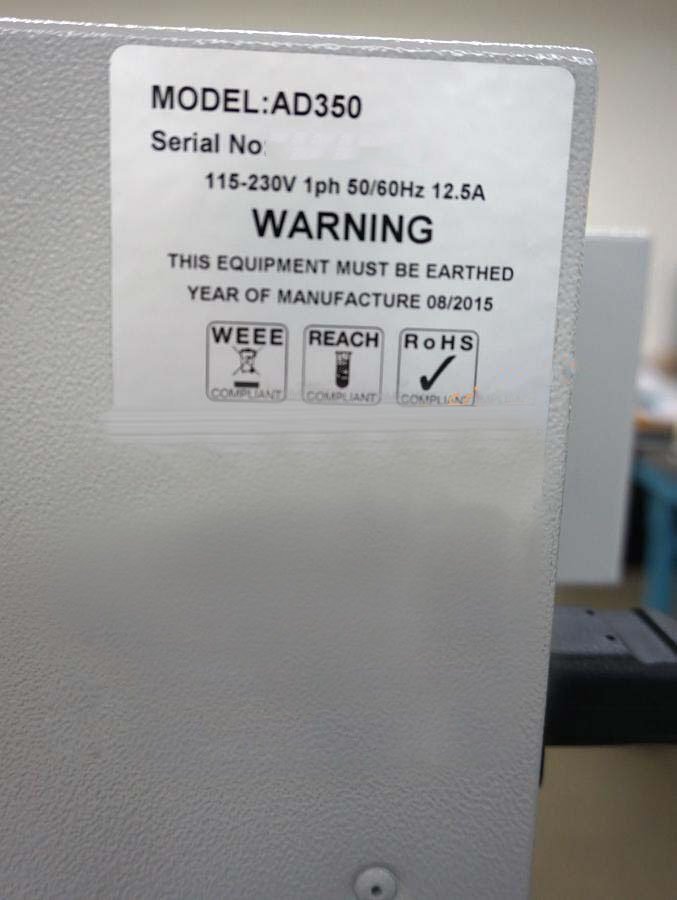

BOFA AD-350 Fume extractor

Digital flow control system

Blower with high airflow and pressure

Low cost replacement filters

Low noise levels

Filter condition indicator

Deep pleat filter technology

Advanced carbon filter

Reverse flow air

Hepa filter

17-Point sure check quality standard

Service interval: 1,500 hours (Gas dependent)

CFM 223

Compressed air: 6 bar, 88 psi

1275 liters/hour (45 cf3/h)

Other Gasses:

N2

N2/H2

O2

CO2

He

AD-350:

Voltage: 90 V - 257 V (Auto-sensing)

Cabinet construction brushed stainless steel

Powder coated mild steel

Airflow pressure: 380 m, 3 hr / 96 m bar 223 cfm / 96 m bar

Full load current: 12.5 amps, 1.1 kW

Noise level: < 60 dBA

Deep pleat pre-filter:

Surface media area: 6 m²

Filter media glass fiber

Deep pleat construction: 100 mm

With webbing spacers

Filter efficiency: 95% at 0.9 microns

Combined filter:

Hepa filter media glass fiber

Hepa media construction

Maximum pleat construction

With webbing spacers

Filter housing ZINTEC mild steel

Treated activated carbon: 9 kgs (19.8 lbs, specific blend for laser fumes)

Filter efficiency: 99.997% at 0.3 microns

Power requirements:

115-230 V, Single phase, 50/60 Hz, 4 Amps.

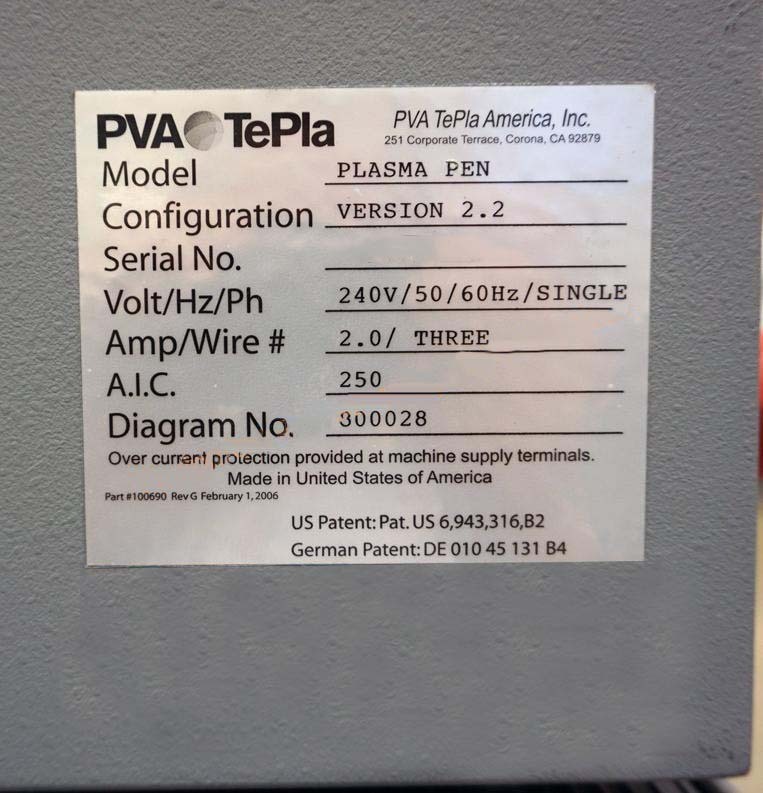

PVA TEPLA / TECHNICS PlasmaPen is a state-of-the-art etching and ashing machine specifically designed for the production of high-precision microcomponents. It is a highly flexible and capable tool suitable for creating intricate and precise patterns in a range of materials, from ferrous metals to dielectrics. This high-tech machine utilizes a narrow pulse of plasma to etch and ashing the surface layers of a variety of materials, producing intricate patterns and designs. This TECHNICS PlasmaPen operates with exceptional precision, giving the user total control over the process and allowing them to create intricate features with exceptional accuracy. PVA TEPLA PLASMA PEN features an easy-to-use control panel, making setup and operation relatively straightforward. This equipment is also environmentally friendly, using significantly less process gas than competing technologies. PVA TEPLA PlasmaPen includes various accessories to customise the etching and ashing process, including a set of multi-function electrodes, allowing the user to manipulate the plasma field and achieve high-quality etching and ashing of a variety of materials. The system also includes a variety of shielding and protection components, such as a dry unit protection and focused shield machine, ensuring safe and efficient operation. PVA TEPLA / TECHNICS PLASMA PEN is also backed by an impressive service and support network, providing the user with access to reliable technical information and advice on troubleshooting and maintenance. This efficient and reliable tool is an excellent option for any business looking to create precision microcomponents with the highest levels of accuracy and minimal waste. In conclusion, PLASMA PEN is an effective and high-tech etching and ashing machine, capable of producing intricate and precise results with exceptional accuracy. The asset is also an environmentally-friendly option, consuming less process gas than other competing technologies. With reliable service and support network, the model is an excellent choice for any business looking to produce accurate microcomponents.

There are no reviews yet