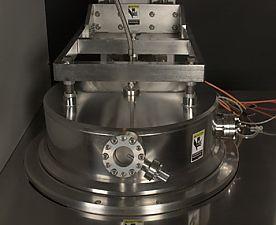

Used SAMCO PD-200D #9155559 for sale

URL successfully copied!

Tap to zoom

ID: 9155559

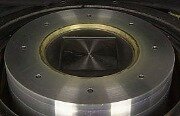

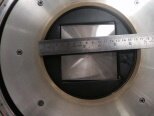

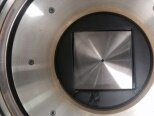

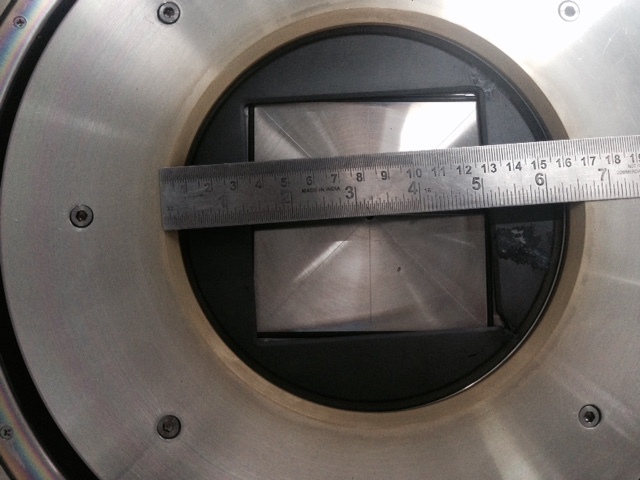

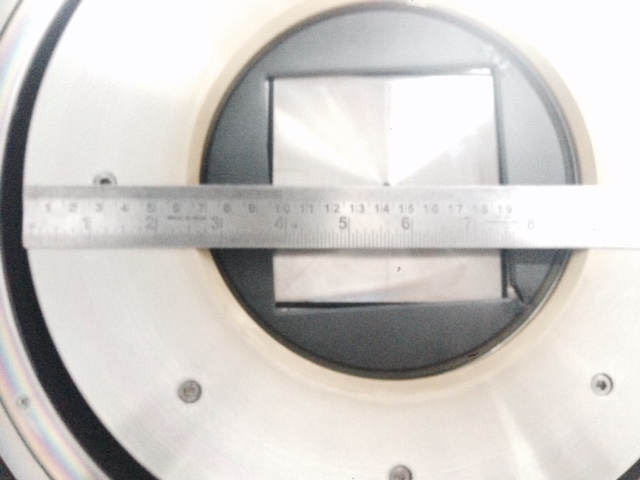

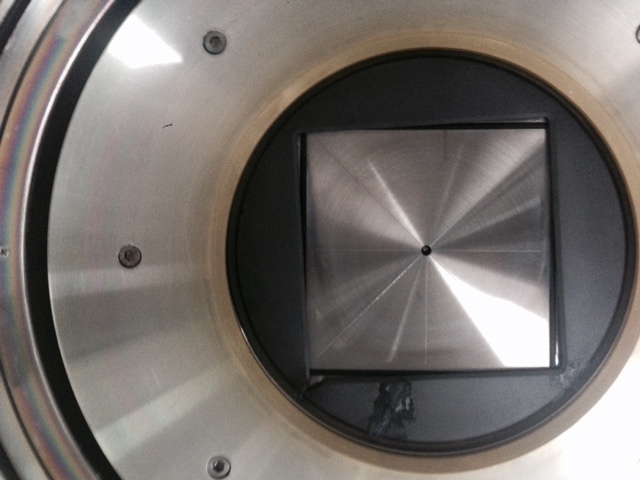

Wafer Size: 8"

Vintage: 1996

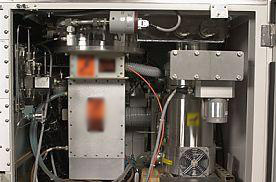

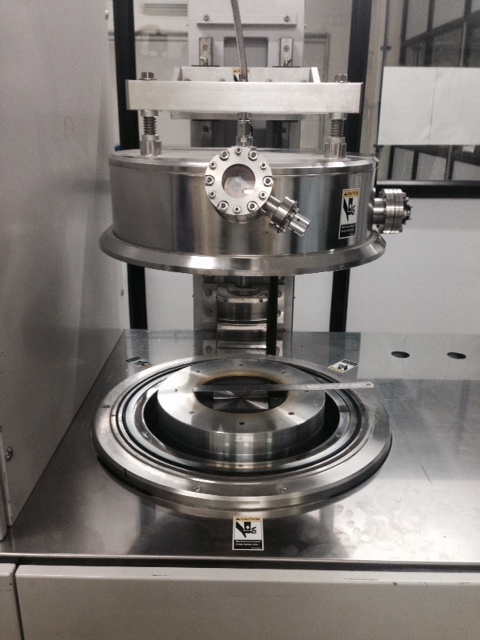

Automated ion assisted PVCVD systems, 8"

Etching and deposition of Carbon films

DLC Deposition rate: 20-30um per hour

Anisotropic etch rate: 0.25u per min

Active substrate temperature control

Compound turbo main chamber

Auto chamber lift

Xinix 1014 Endpoint detector

Chemical series Osaka TG-713M 600 lps

(3) MFC Gas lines

Luxtron 712 Fluroptic thermometer

Sierra 5000 Gas leak detector

Techware TC-111 process controller

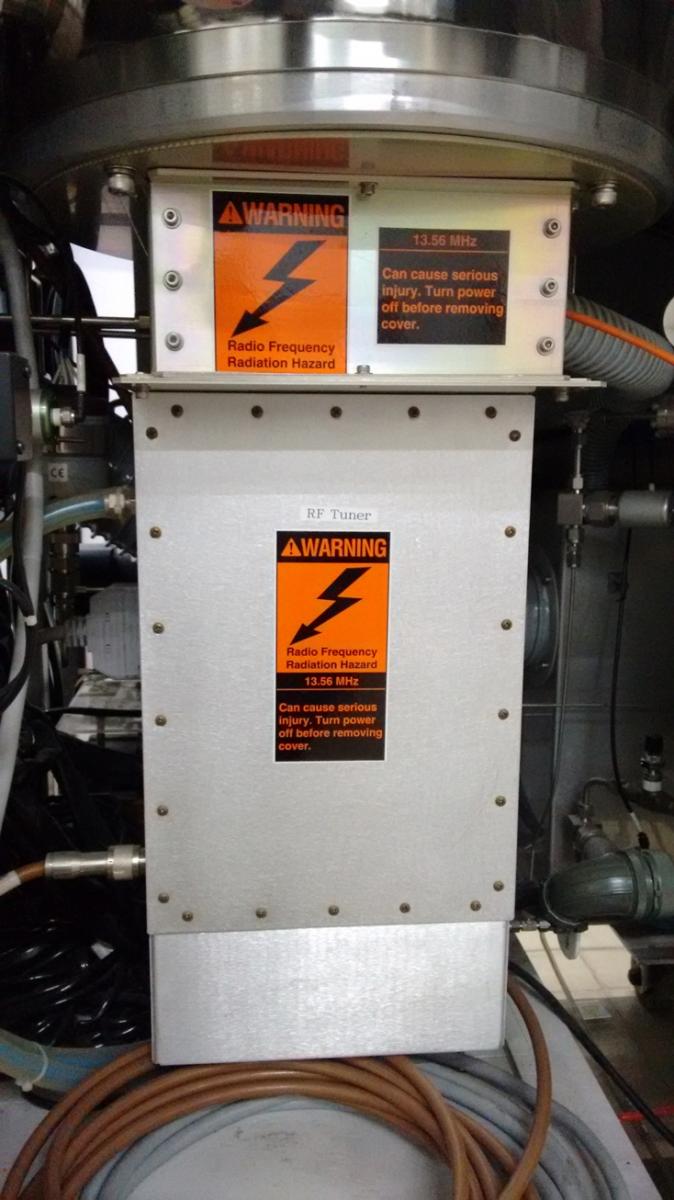

13.5 6MHz solid state generator

Iwatsu SG-4101 RF power pulse generator

Komatsu DR 621 Isothermal bath temperature controller

Luxtron 712 Fluoroptic thermometer

Luxtron 1015 End point controller

Mitsubishi NF-SF Pressure lugs for circuit breaker

Baratron type 622A, 627A and 628A capacitance manometers

Neslab RTE-111D Refrigerated bath / Circulator (Chiller)

5RK90GU-AMUL Electromagnetic brake motor

TKC REX-F900 Temperature controllers for source MFC and oven

Sentry 5000 Gas monitoring system

641PM-26P1-X Adaptive pressure controller

64244-PE52-X Control gate valve

Gases: Nitrogen (N), Argon (Ar), Oxygen (O2) for etching DLC films CF4

20-1000 Watts

Power: 10.8 KVA 3Φ 208V AC

4.6 KVA 1Φ 115V AC

1996 vintage.

SAMCO PD-200D etcher/asher is a reliable and cutting-edge mass-fabrication equipment well-suited to high-volume production of fine-tuned parts. This system is comprised of a high-performance AMEC robotic arm with an integrated etching tool, a microprocessor-controlled acid vapor generation chamber, and a main body unit with built-in safety features. The AMEC robotic arm is designed to accurately and reliably handle all of the etching processes, such as wafer surface scraping, cutting grooves, holes, ridges and fine-tuned shapes. Its design ensures that parts are precisely etched to the desired depth and shape without any undercuts or other unwanted effects. The robot's high repeatability ensures that the same part can be etched in multiple runs. The microprocessor-controlled etching chamber uses a rapid-pumping, clean-room-grade acid vapor to ensure repeatably precise etching at intervals as small as 0.2 µm. The chamber is designed with rapid acid refilling for quick restarts and for uninterrupted long-term production runs. Its design ensures that the acid vapor is released at precisely the right speed, preventing stiction of the vapor on the part, as well as hazardous oversaturation. PD-200D is designed with safety features for both the operator and the robot arm. The main body unit is a complete, water-cooled stainless steel enclosure with built-in ion and gas management systems to protect against extreme elements and contaminants. The enclosed control unit features an electrical safety certificate and continuously monitors the acid content in the etching chamber for safety purposes. A variety of safety sensors are also included to provide warning alarms or shut-down the machine for maintenance or operator needs. As a versatile, production-grade etcher/asher, SAMCO PD-200D tool is well-suited to high volume metal etching and ashing. It's reliable design ensures that fine-tuned parts can be produced with precision, repeatability, and safety.

There are no reviews yet