Used SAMCO RIE-200NL #293621510 for sale

URL successfully copied!

Tap to zoom

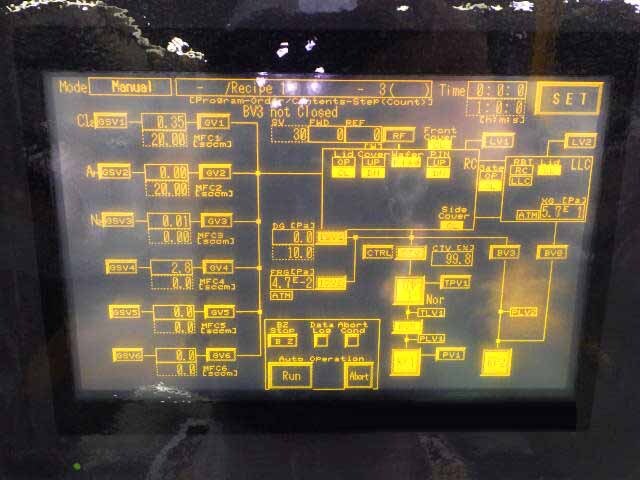

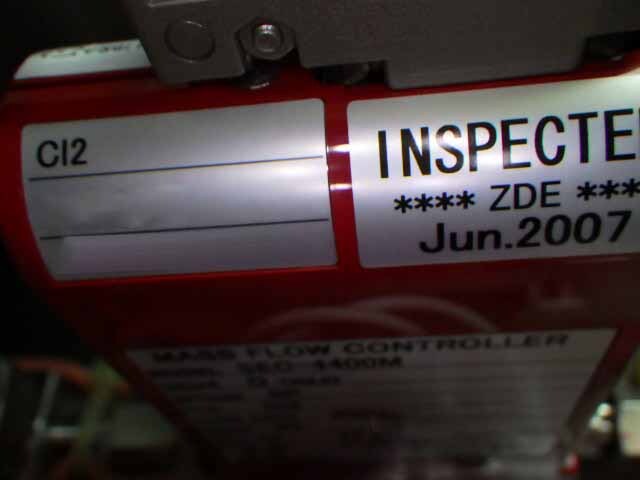

SAMCO RIE-200NL is an etching and ashing equipment designed and manufactured by SAMCO Technologies. This system is designed for a variety of etching and ashing applications, such as electronics, semiconductors, and optoelectronics. RIE-200NL utilizes an inductively coupled plasma (ICP) etch process, which offers advantages over traditional etching processes such as deep anisotropic etching and an extremely low temperature process. This allows the user to control the etching rate, adjust the energy, and modify process parameters to achieve the desired result. The unit is equipped with an advanced controller that provides versatile functions for controlling the etching process and operation parameters. It also includes a self-diagnostic function that checks machine performance and diagnostics that can be remotely accessed. SAMCO RIE-200NL features a gas inlet manifold with four independent gas channels, allowing theetcher to select the optimal gas mixture. The process chamber is made from stainless steel and quartz, providing excellent temperature and pressure control. The chamber also features removable side walls, making it possible to process large wafers and multiple substrate configurations. RIE-200NL is designed with a highly efficient dual frequency microwave generator, which maintains low internal temperatures and minimizes particle contamination. It also offers user programmability, allowing the user to easily customize process parameters and recipes. The user can also monitor in-situ wafer temperature. The optional baseplate allows for rapid recipe customization and helps minimize cross contamination. It is also compatible with a wide range of etch chemistries, including halogen-based etching, sulfur-based etching, and both chlorine and fluorine-based etching. SAMCO RIE-200NL etcher/asher is an ideal tool for research and development of advanced etching and ashing processes. With its versatile functionality, high precision and ease of use, it is suitable for a wide range of applications including semiconductor, optoelectronic, microelectronic, and other industries requiring etching and ashing processes.

There are no reviews yet