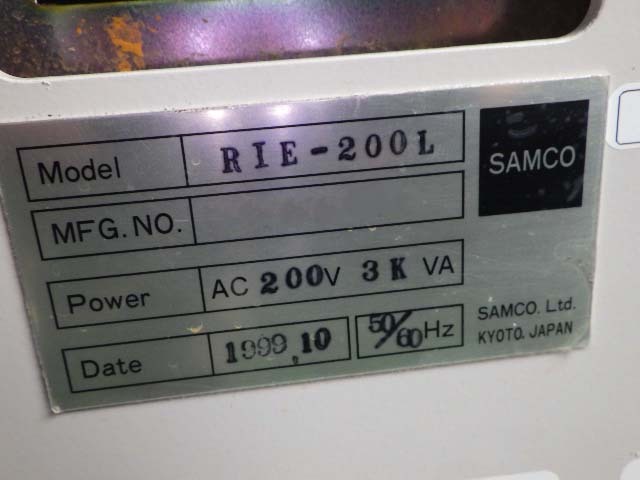

Used SAMCO RIE-200NL #293638507 for sale

URL successfully copied!

Tap to zoom

ID: 293638507

Vintage: 1999

Reactive Ion Etcher (RIE)

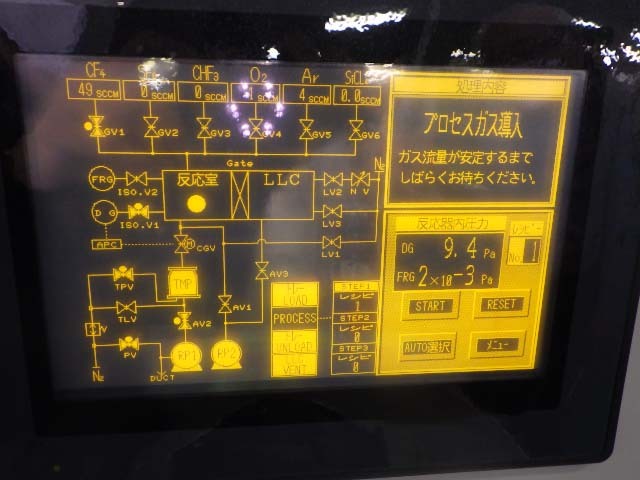

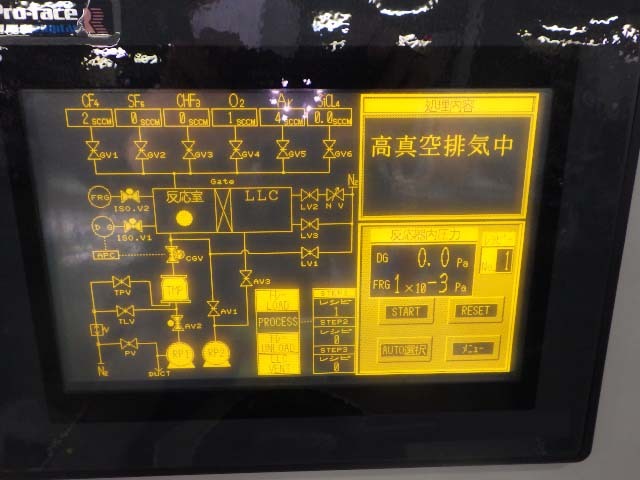

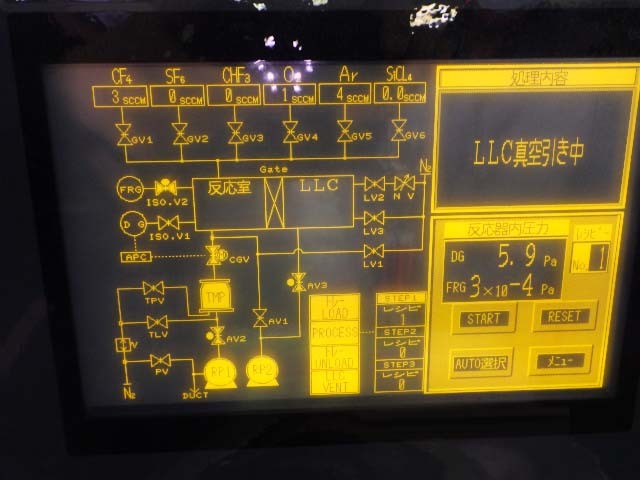

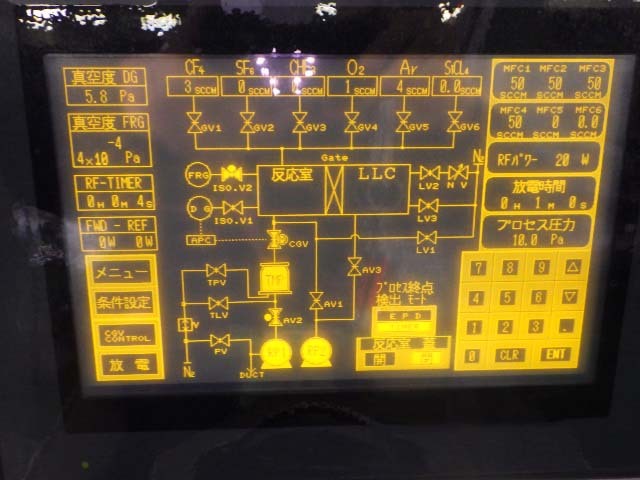

High frequency power supply: 13.56 MHz, maximum 300 W Crystal

Oscillation control solid state type

Impendence auto-matching

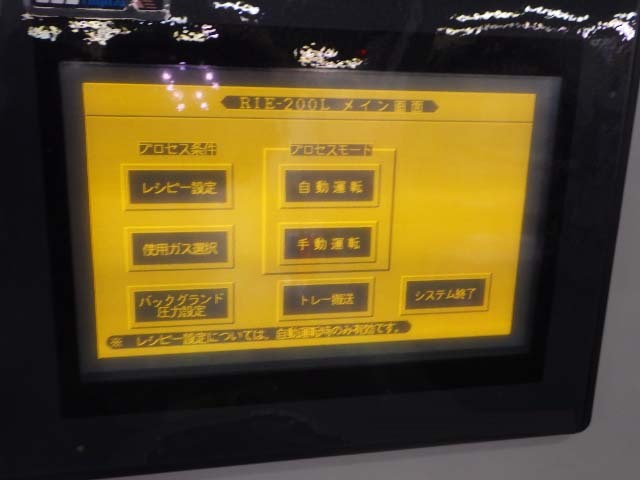

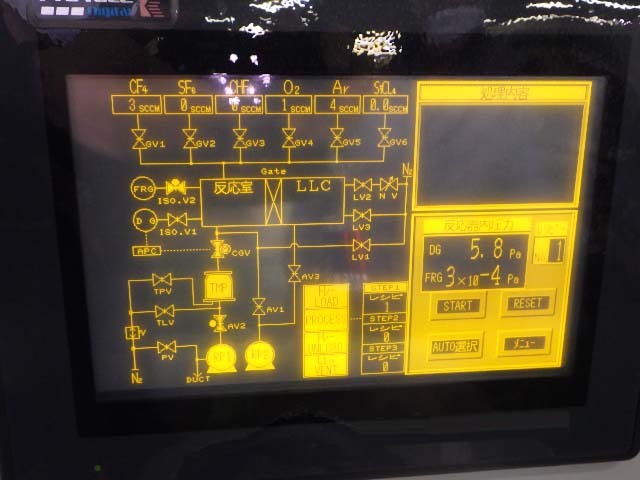

Digital display in the touch panel

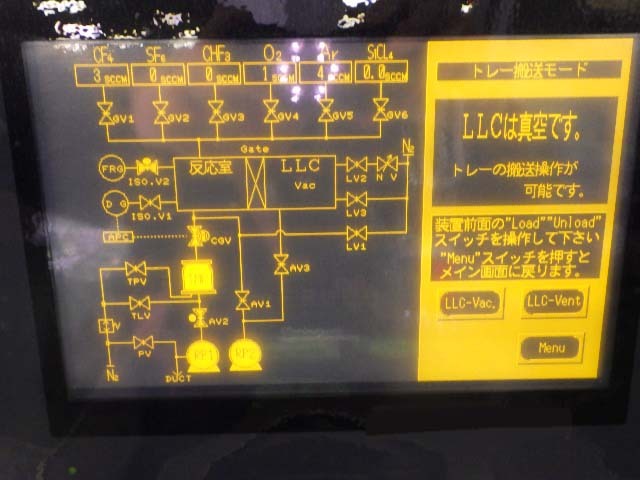

Compound molecular pump

Type: N2 Purge line with auto leak line auxiliary

Direct connection type (rotary pump): 208 liters/min

Automatic pressure control valve, 4"

Perot seal air operated valve

SUS316 Piping

Pipe connection joint: 1/4" VCR Welded

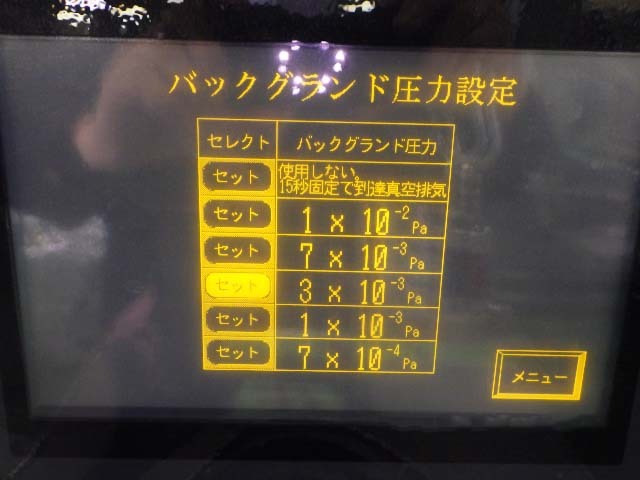

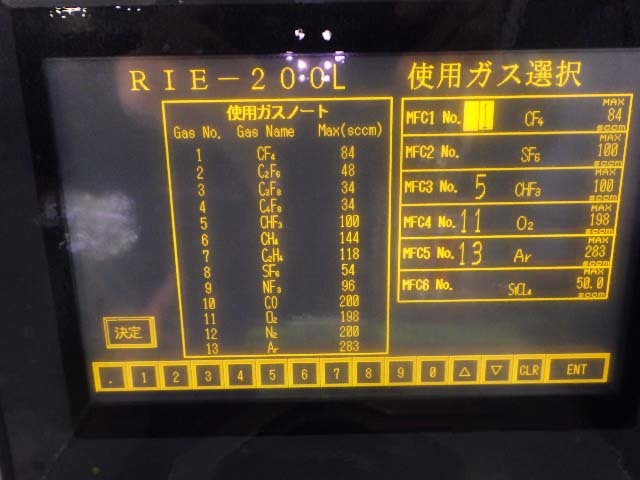

Mass flow controller:

MFC Line / Gas / Flow

MFC 1 / SiCi4 / 50 SCCM

MFC 2 / CF4 / 100 SCCM

MFC 3 / SF6 / 100 SCCM

MFC 4 / SF6 / 100 SCCM

MFC 5 / O2 / 100 SCCM

1999 vintage.

SAMCO RIE-200NL is a reactive ion etcher/asher for a wide range of surface preparation and etching operations. It is a versatile equipment that can be used to accomplish a variety of applications from small batch to high precision etching. This etcher/asher is designed to provide good process repeatability and excellent feature resolution in order to produce consistent, high-quality results. It is suitable for any type of material, such as polysilicon, amorphous silicon, glass, and metal. This system is based on a double chamber design, with the etching chamber and the ashing chamber connected together by a single pump and set of sensors. This allows the user to switch between etching and ashing with just a few clicks. The main chamber is equipped with a remote plasma source, which can be placed in any position to optimize the etching process. The etching chamber is further equipped with a cylindrical glass window, a bellows vacuum seal, and a cooling jacket for stabilizing and controlling the temperature of the process. Inside the etching chamber, RIE-200NL utilizes etching gases to break down and deposit material from the surface of the substrate. The etching process can be optimized using various parameters such as etch rate, selectivity, inductivity and layer thickness. The unit is capable of producing high-density sub-micron features with excellent repeatability, making it ideal for high-precision applications. SAMCO RIE-200NL can also be further enhanced with additional accessories such as shadow masks, liners and spacers, as well as secondary processing capabilities such as heating and cooling. The ashing chamber is used to remove carbon and dust particles, and is designed with a built-in plasma source to ensure optimum particle removal. Both etching and ashing processes can be monitored and controlled using an on-board computer, as well as from a remote location. In addition, all parts can be easily accessed for maintenance and repair work. The machine also includes an optional real-time, non-contact temperature monitoring tool for further process optimization. Overall, RIE-200NL is an effective and reliable etcher/asher that offers excellent precision and repeatability. It is capable of producing high-end results with great precision and efficiency, making it an ideal choice for a wide range of surface preparation and etching operations.

There are no reviews yet