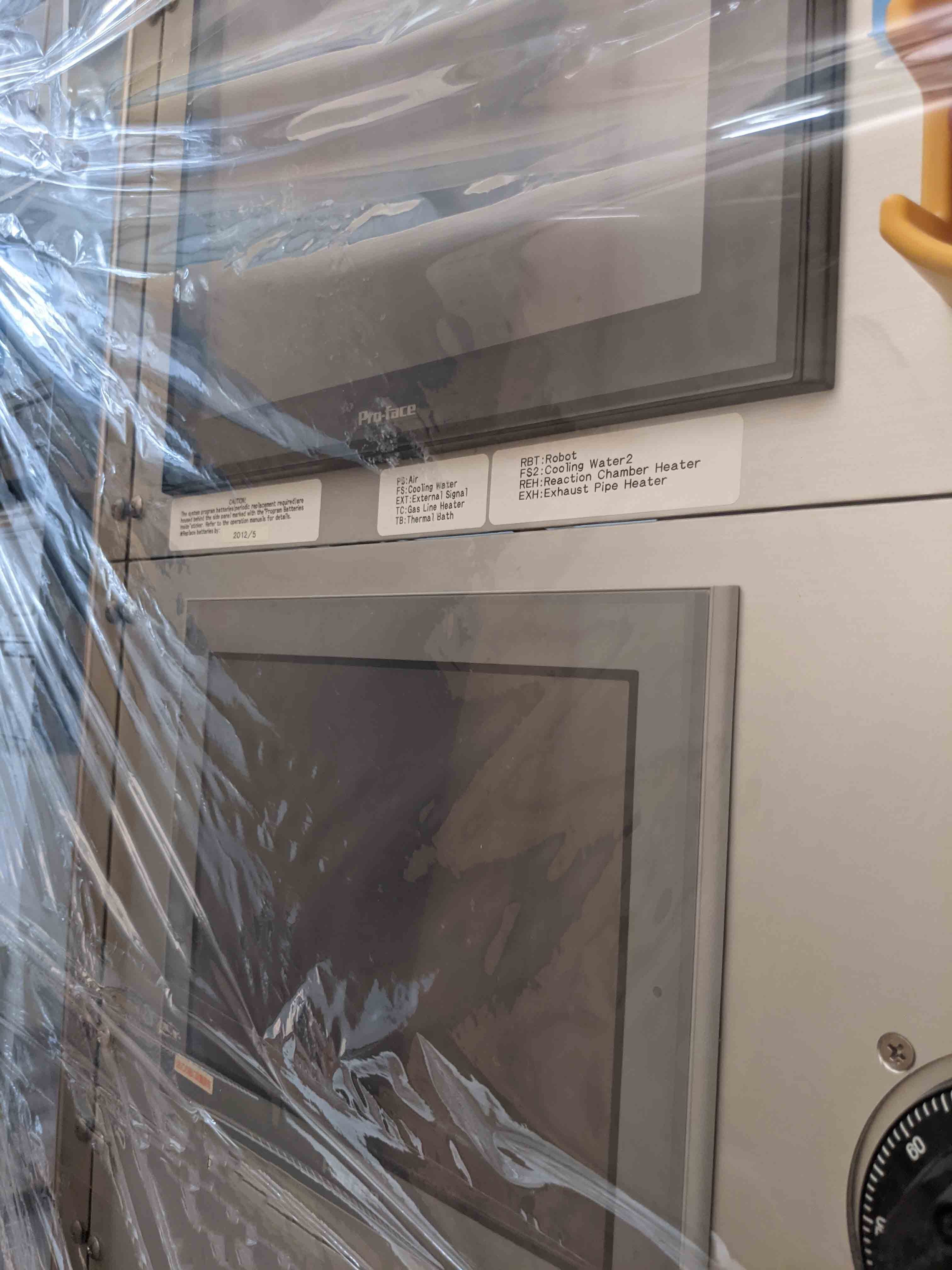

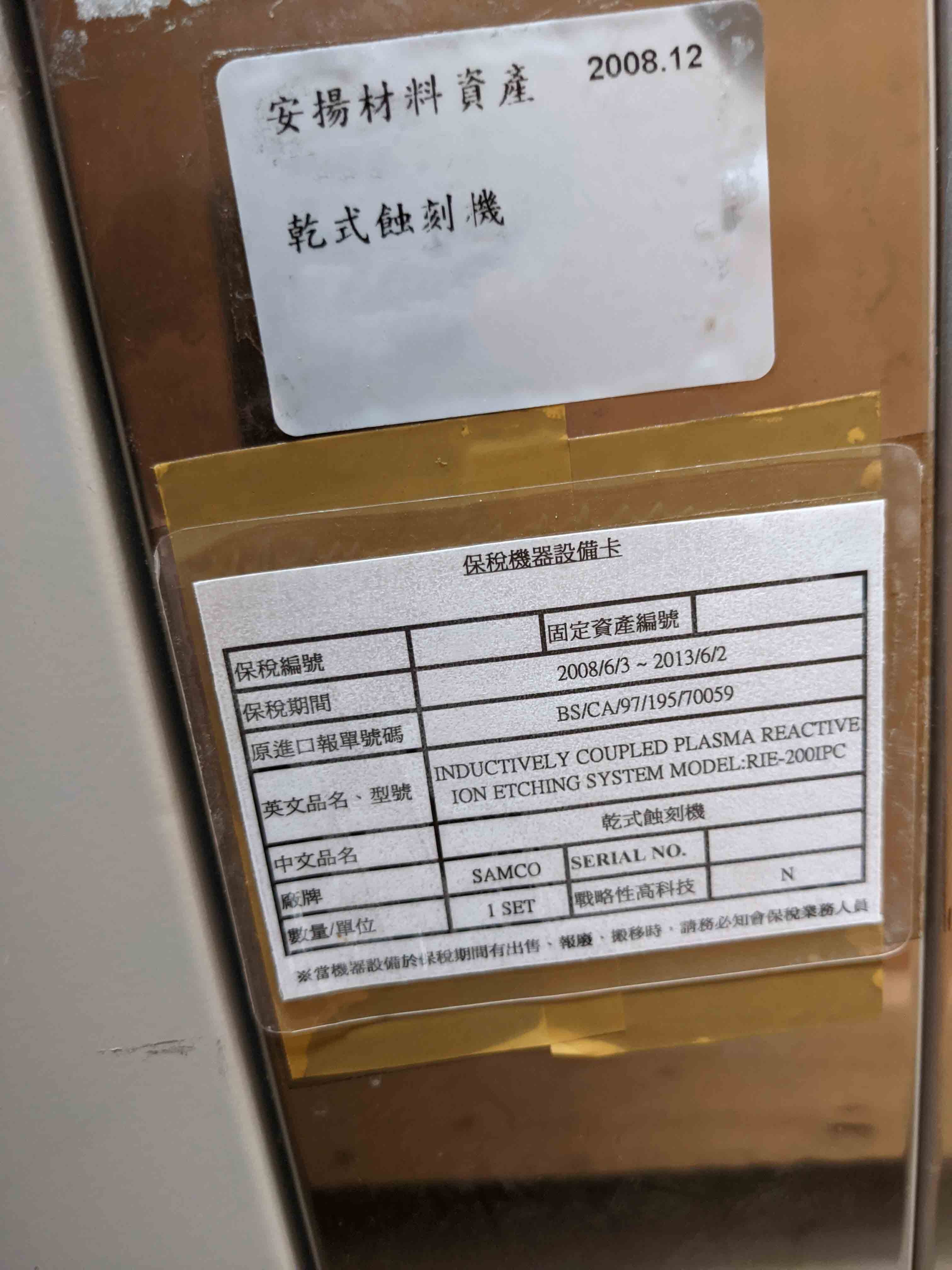

Used SAMCO RIE-212iPC #9384507 for sale

URL successfully copied!

Tap to zoom

SAMCO RIE-212iPC is a state-of-the-art plasma etcher/asher. It is suitable for both prototype and production Etch-and-Clean applications in IC fabrication processes. It is a single-chamber device with an innovative etch/clean plates concept that works with a turbulence-free linear track-and-mount system. This system allows for more efficient and uniform etching, as well as better conformality and etch uniformity. SAMCO RIE 212 IPC is equipped with an advanced E-Gun, which can create high plasma density, uniformity, and durability against different gas components. This Gun is able to maintain a high level of process stability in all etching conditions, giving the user a comprehensive, reliable etching and ashing control. The user can control both the chamber temperature and pressure, allowing for high-resolution etching. RIE-212iPC is designed for a wide variety of machining modes. It supports both dimensional and planar etching as well as laser reactive ion etching (RIE). It provides the user with excellent shape, depth and aspect-ratio control, as well as a high level of process reliability and repeatability. Not only can it etch traditional materials, but it is also able to etch hard and multi-layer protected materials such as aluminum, stainless steel and fabrics. RIE 212 IPC is extremely user-friendly. It has an intuitive control panel, which allows the user to easily modify and navigate the setup. It is capable of high speed data acquisition and analysis, as well as a quick and efficient job setup. Its modular design allows for easy integration of new components or upgrades to the device. The user can also control multiple processes simultaneously by using the integrated built-in computers. SAMCO RIE-212iPC is an advanced, user-friendly etcher/asher. With its innovative E-Gun and its linear track and mount system, it provides excellent shape, depth and aspect-ratio control, as well as high-resolution etching and ashing. It is suitable for both prototype and production etch-and-clean applications in IC fabrication processes, providing the user with both a comprehensive and reliable process control and an easy setup and operation.

There are no reviews yet