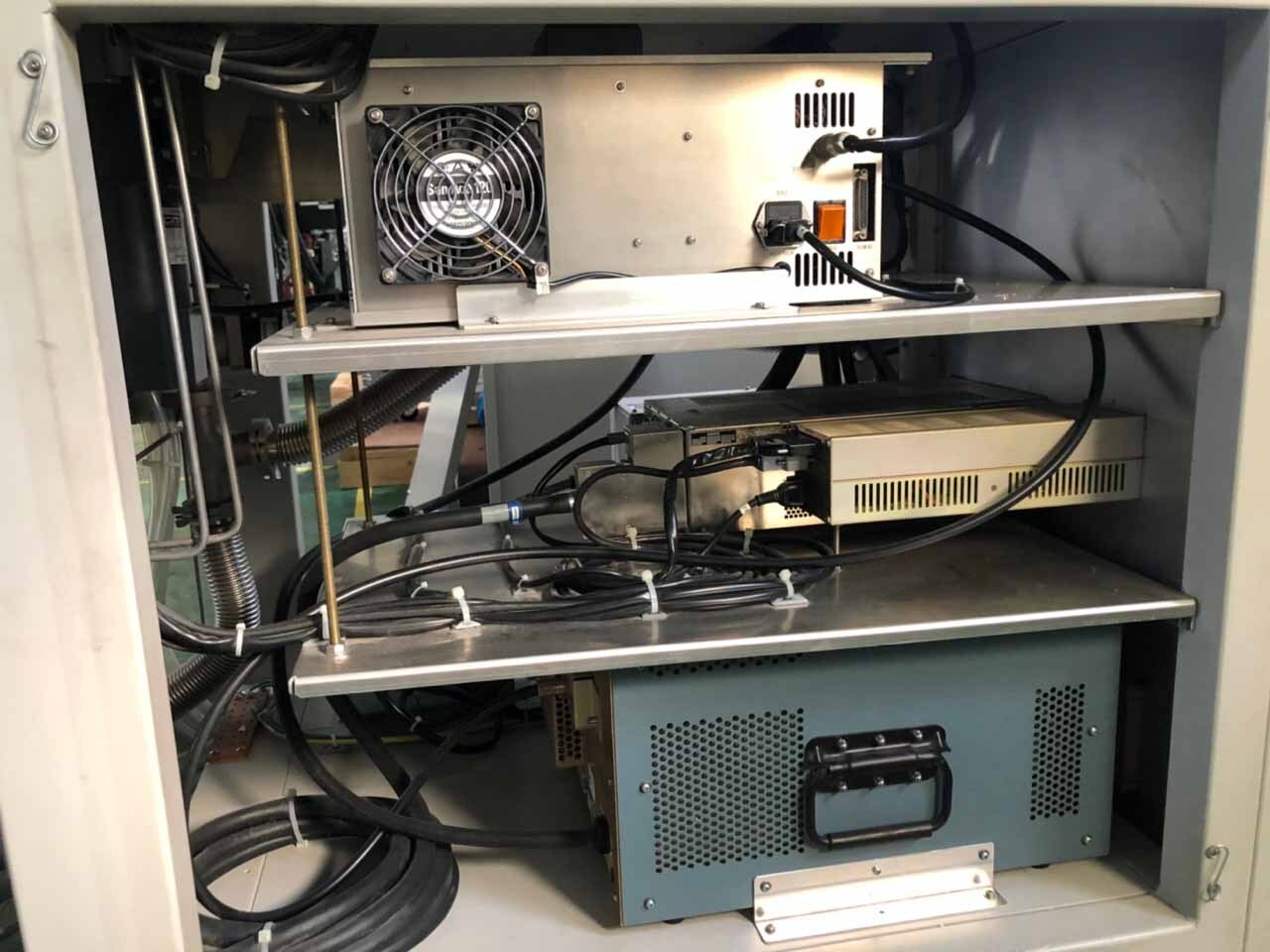

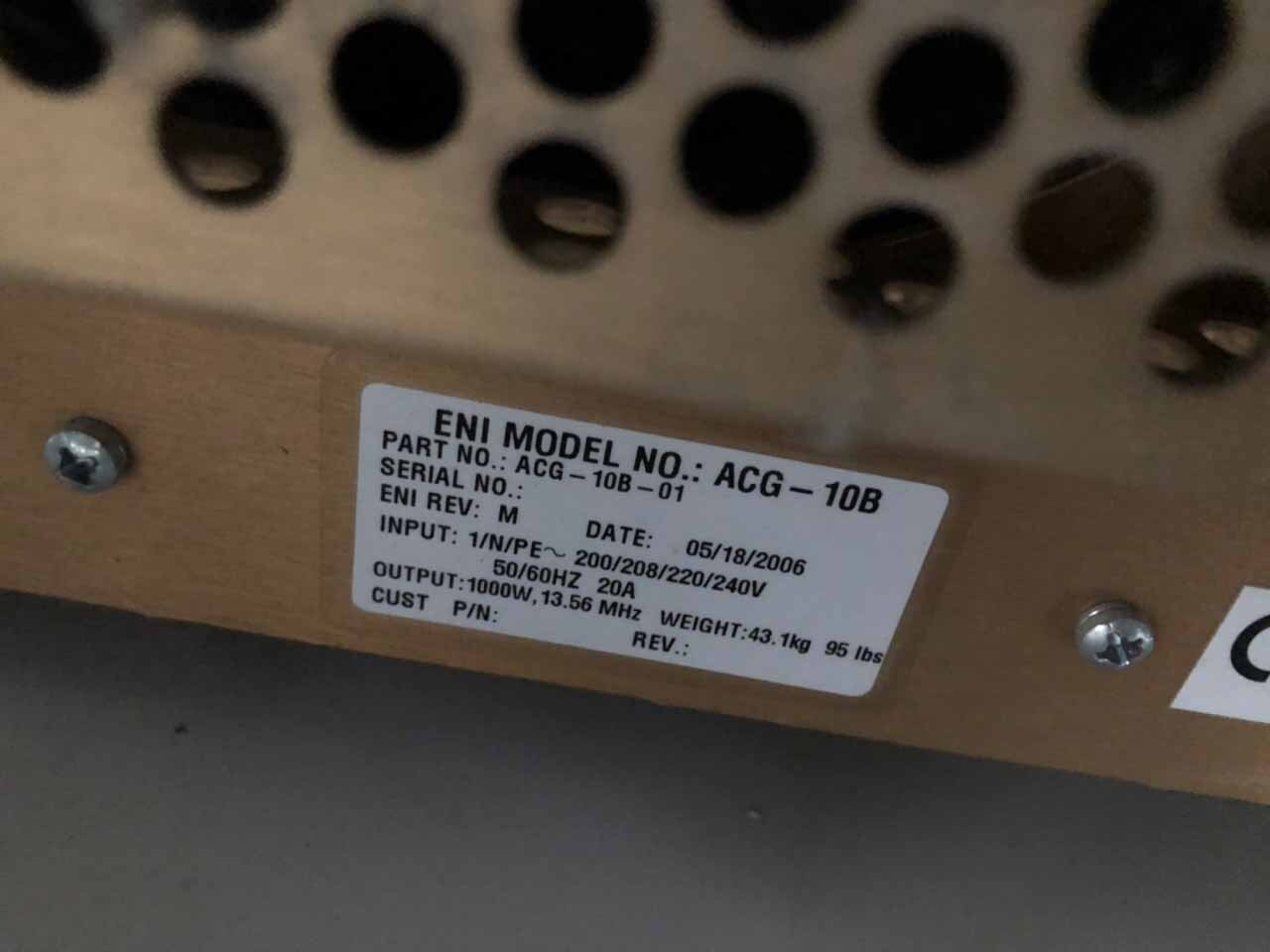

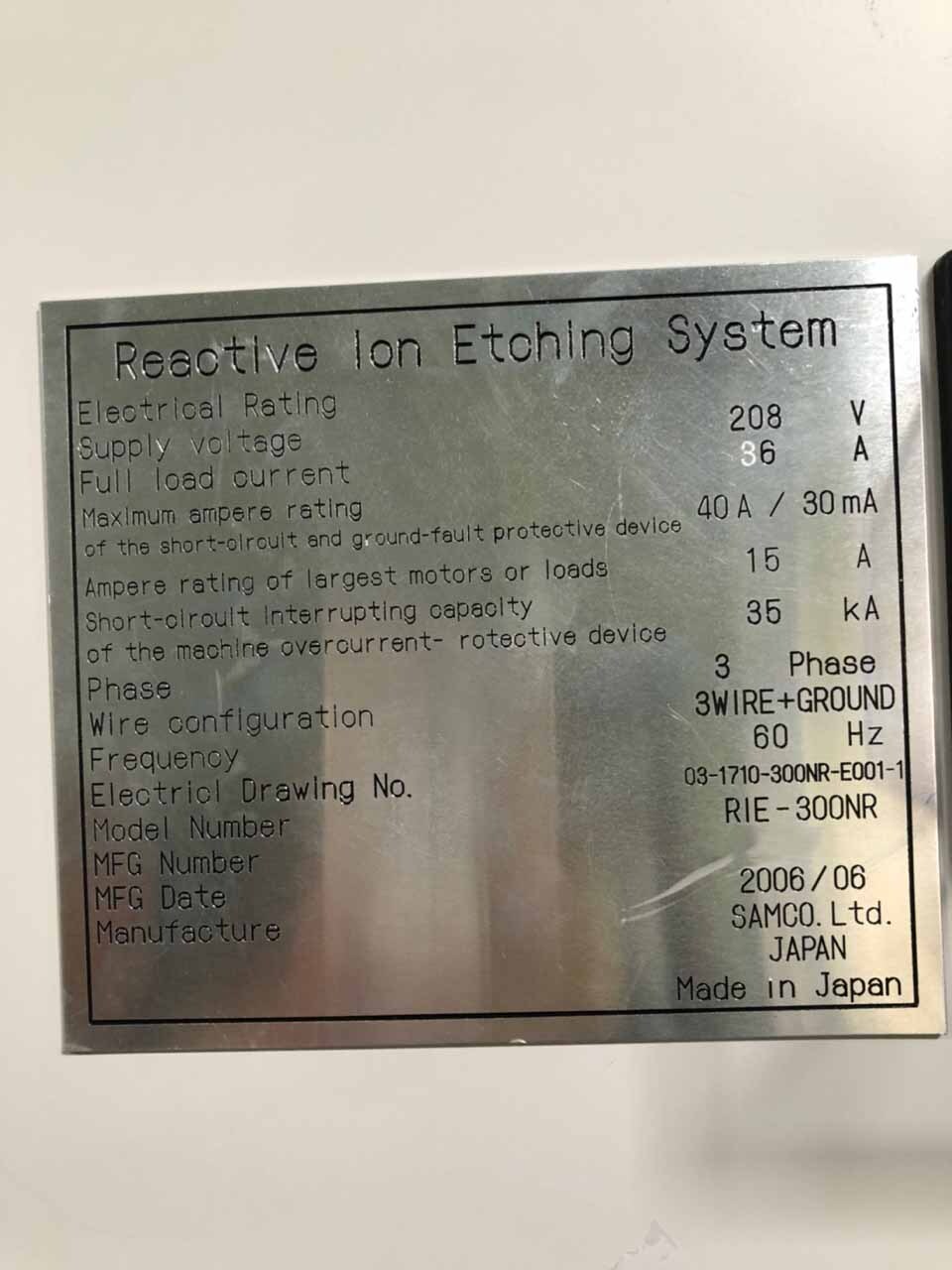

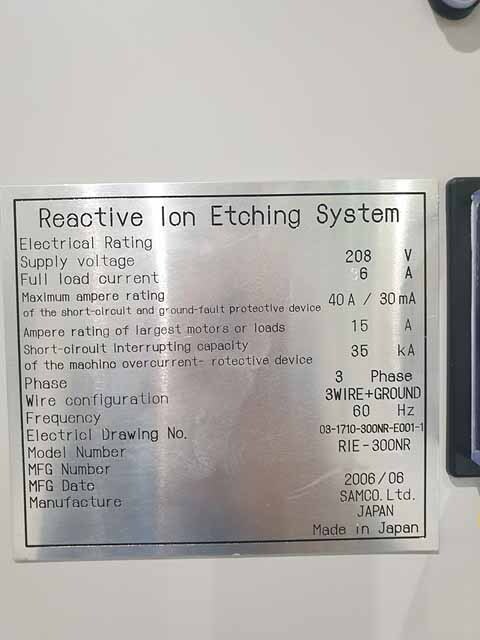

Used SAMCO RIE-300NR #9402475 for sale

URL successfully copied!

Tap to zoom

ID: 9402475

Wafer Size: 12"

Vintage: 2006

Reactive Ion Etcher (RIE), 12"

2006 vintage.

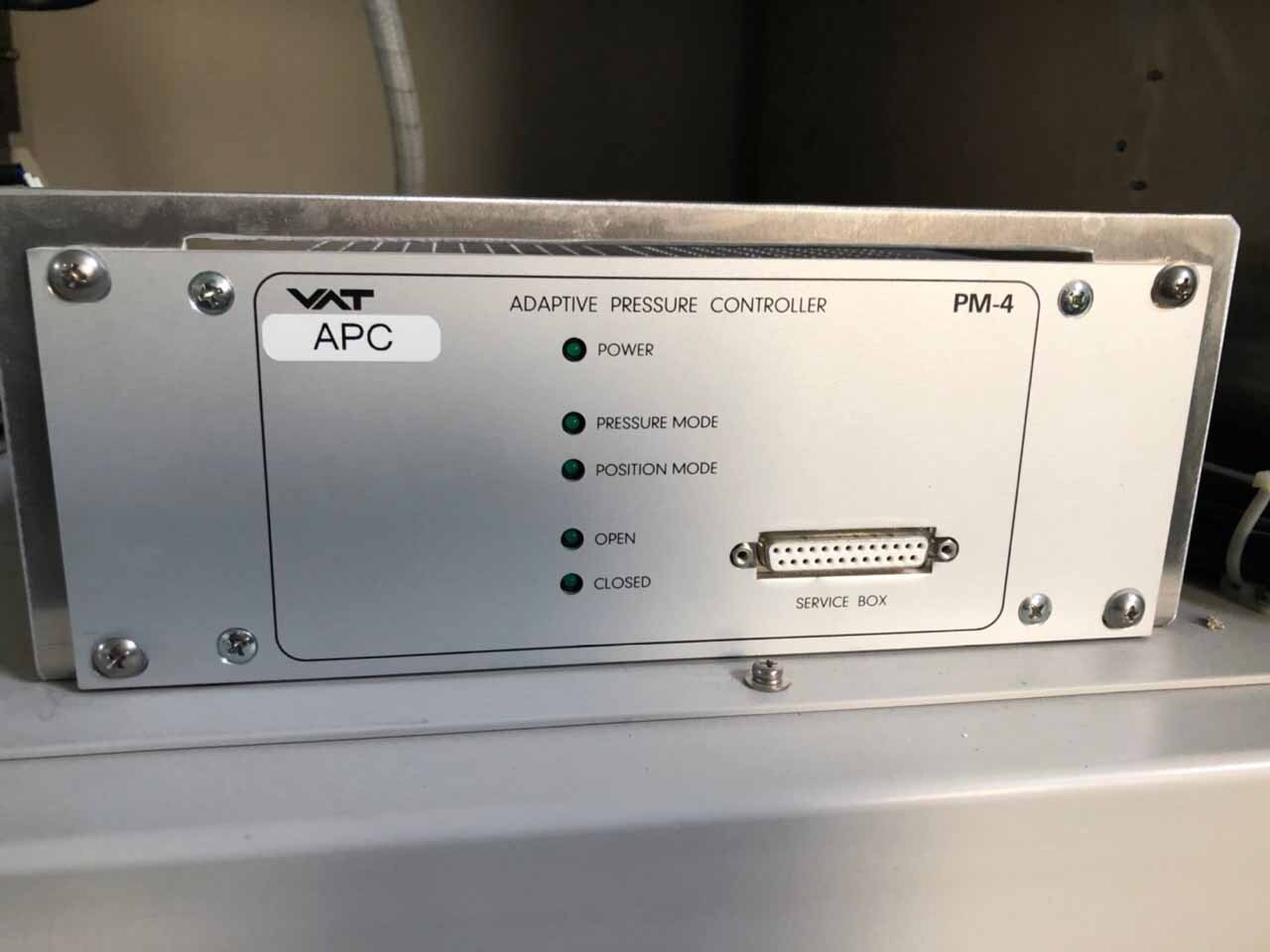

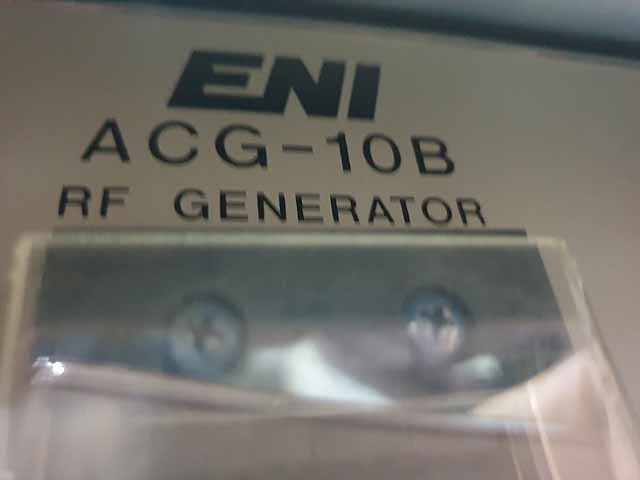

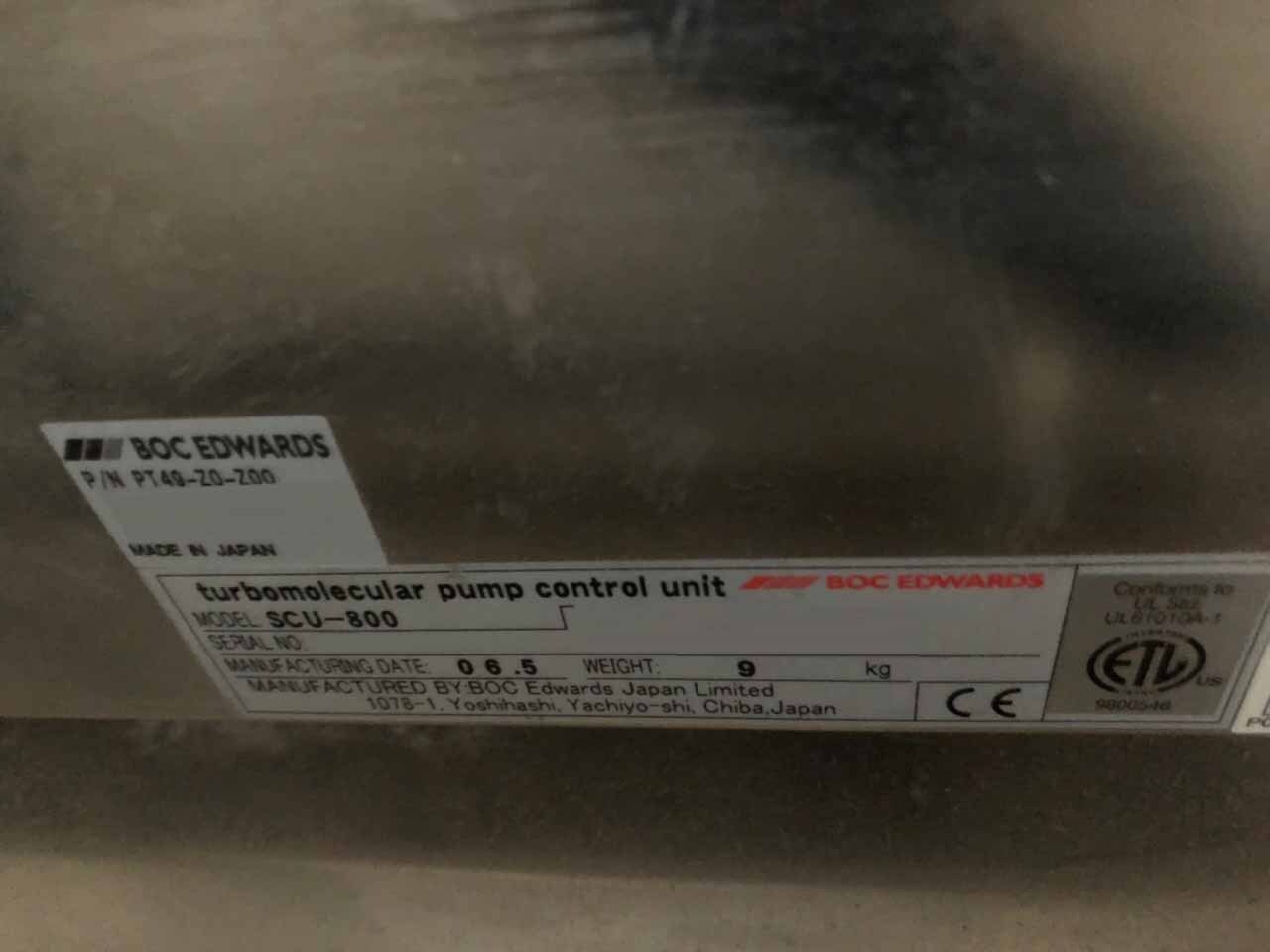

SAMCO RIE-300NR is a reliable Reactive Ion Etcher (RIE) designed for etching a wide variety of substrates including quartz, silicon, ceramics, metals, and polymers. It offers excellent process stability, repeatability and uniformity. SAMCO RIE 300 NR is capable of etching features down to 0.2um in a variety of materials. This makes it suitable for precision etching applications, such as microelectronics, optoelectronics, and MEMS. RIE-300NR is equipped with a small footprint, low-cost console and is supported by a large platform. It includes up to five process chambers with different types of cells, such as high-throughput barrels, wave-guide chambers and linear cells. It also features a number of advanced capabilities including high-temperature operation, pressure/flow control, automated process sequencing, and a wide range of cooling/purging options. RIE 300 NR also offers a number of advanced features, such as high-end process monitoring, a proprietary user-friendly touch screen control panel and software, programmable recipes and recipes sharing, a web-browser interface, and advanced process sequencer. This allows users to configure the machine to their needs and ensure reliable, repeatable and consistent etching scenarios. SAMCO RIE-300NR features a wide range of process gases, providing flexibility and optimized process control. Gases such as Cl2, O2, Ar, BCl3, N2, and SF6 can be used in a variety of flow and pressure settings to optimize etch results. The gas delivery system is capable of insuring best precision and control with a minimum degree of downtime. SAMCO RIE 300 NR is also available with an optional vacuum pump that can be used to reduce the breakdown voltage when etching thin films. This makes it suitable for thin film applications and ensures reliable and repeatable etch results. RIE-300NR is the perfect tool for the etch application for a variety of materials including semi-conductors, ceramics, glass and polymers. It provides superior process control, reliable operation and outstanding repeatability, and is ideal for precision research and engineering applications.

There are no reviews yet