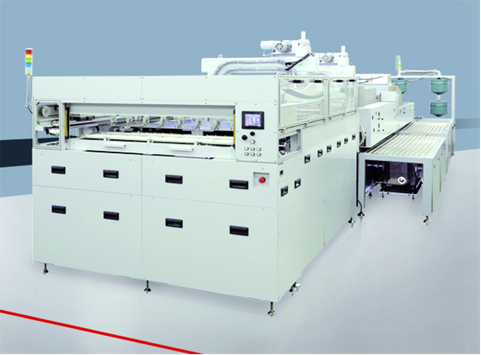

Used SCHMID Blue 1100 #9006876 for sale

URL successfully copied!

Tap to zoom

ID: 9006876

Wafer Size: 6"

Vintage: 2010

PECVD System

Direct plasma source

370-440 kHz

88 wafer per tray, 1100 wafer per hr (based on 6" wafer)

N2 SiH4, NH3 gases

Vacuum supply and gas supply system included

Abatement excluded

PLC controlled, including recipe management

Currently installed

2010 vintage.

SCHMID Blue 1100 is a chemical etching and ashing machine that is used in semiconductor manufacturing. It is an efficient, reliable and cost-effective solution for substrates ranging from 4" wafers, metal, and MEMS, to advanced 3-D patterns. The machine is equipped with a unique technology called 'Smart Chip Matching', allowing chips or devices to be perfectly mated to each other, achieving higher throughput and better yield rates. Blue 1100 is built with an all-steel frame designed to enable optimal flow and maximum performance. The frame ensures a stable configuration even during high-temperature operations, and is also designed for easy maintenance. The chamber is designed to give an even etching effect and has been approved for cleanroom operation, meeting IEC 61672-3 standards. It has also been tested to withstand the modulation of temperature range from -10°C to +54°C. The machine is powered by an advanced intelligent processing system, designed for processing with high speeds while maintaining excellent yields. It is fitted with PID temperature controllers, enabling you to run at higher temperatures and minimizing temperature fluctuations. It also has various input/output card, a thermal printer, a three-way valve for rapid thermal cycling, and other dedicated components for precision etching and ashing. The machine has an advanced cooling system, allowing optimal process temperatures. In addition, a cooling water design runs all the way around the chamber, ensuring that the substrates remain steady during long process times and high temperatures. SCHMID Blue 1100 also features intelligent software for optimizing cycles, increased accuracy and safety. It can also be operated remotely, offering flexibility in production, with users able to switch from one type of product to another quickly. Overall, Blue 1100 is an ideal etcher and asher for semiconductor production. It is feature-rich, robust, and designed for cleanroom operation. It can process large substrate wafers with much higher yields and less variable processes, allowing for efficient and cost-effective semiconductor production.

There are no reviews yet