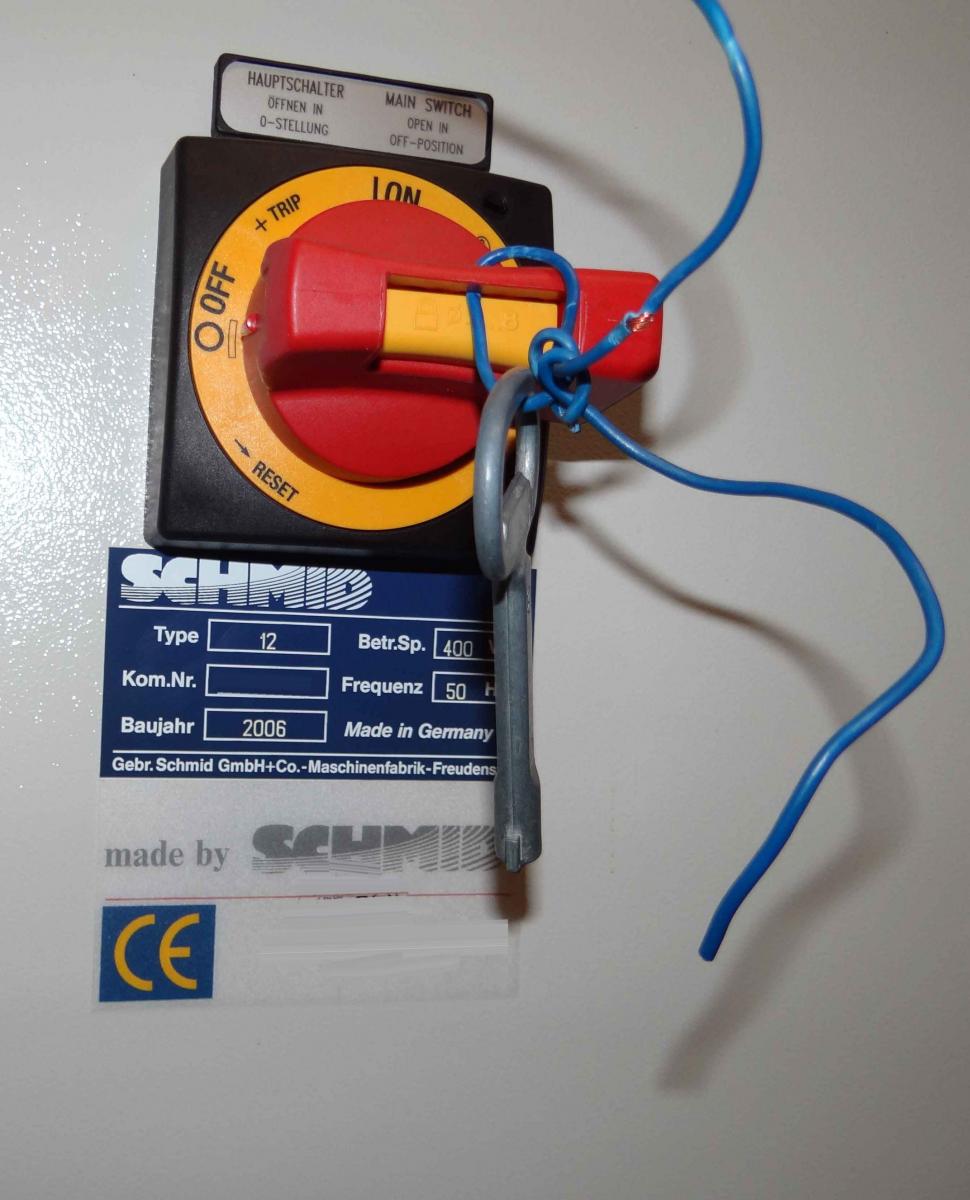

Used SCHMID Combi Line #9012747 for sale

URL successfully copied!

Tap to zoom

ID: 9012747

Vintage: 2006

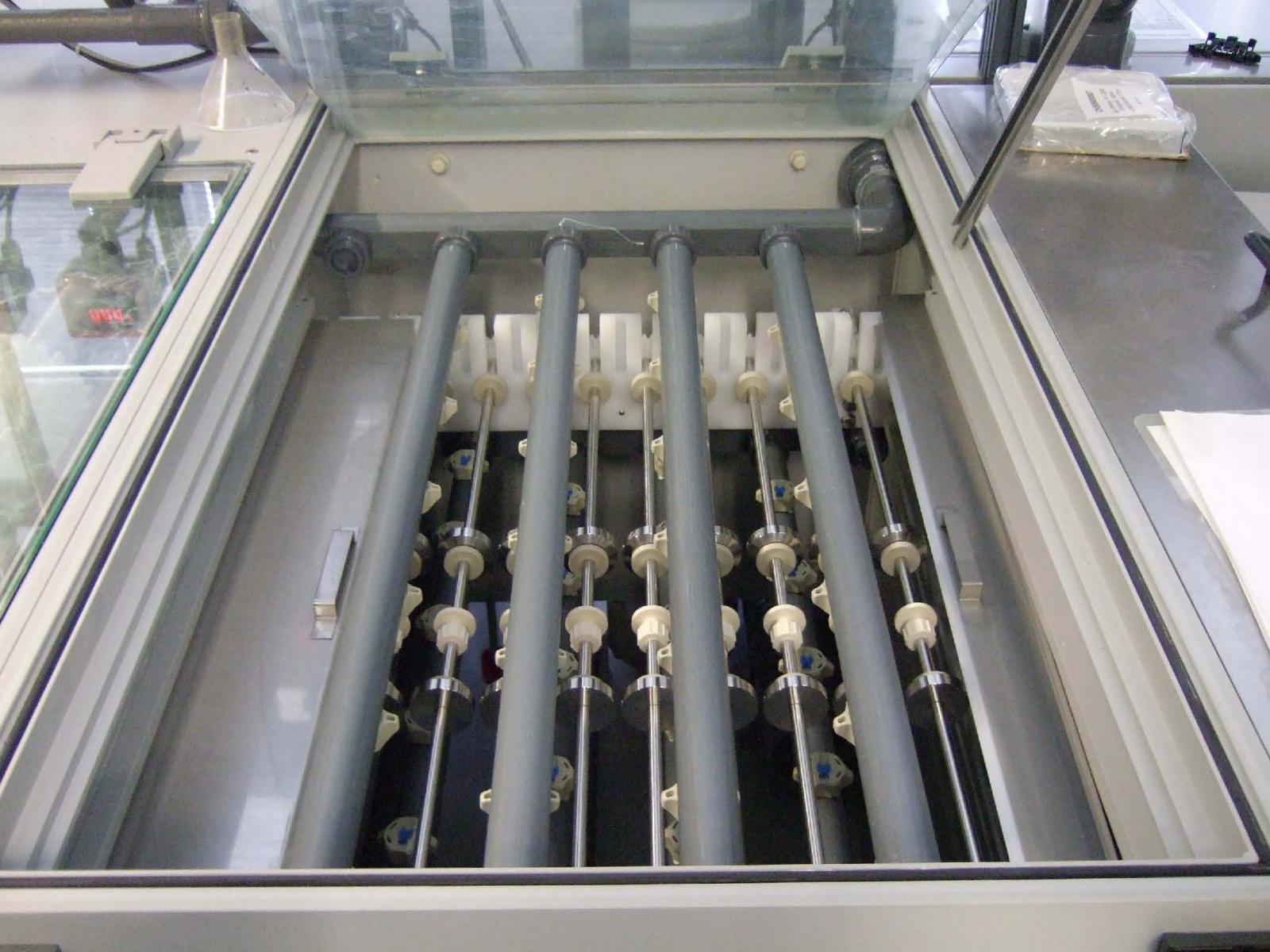

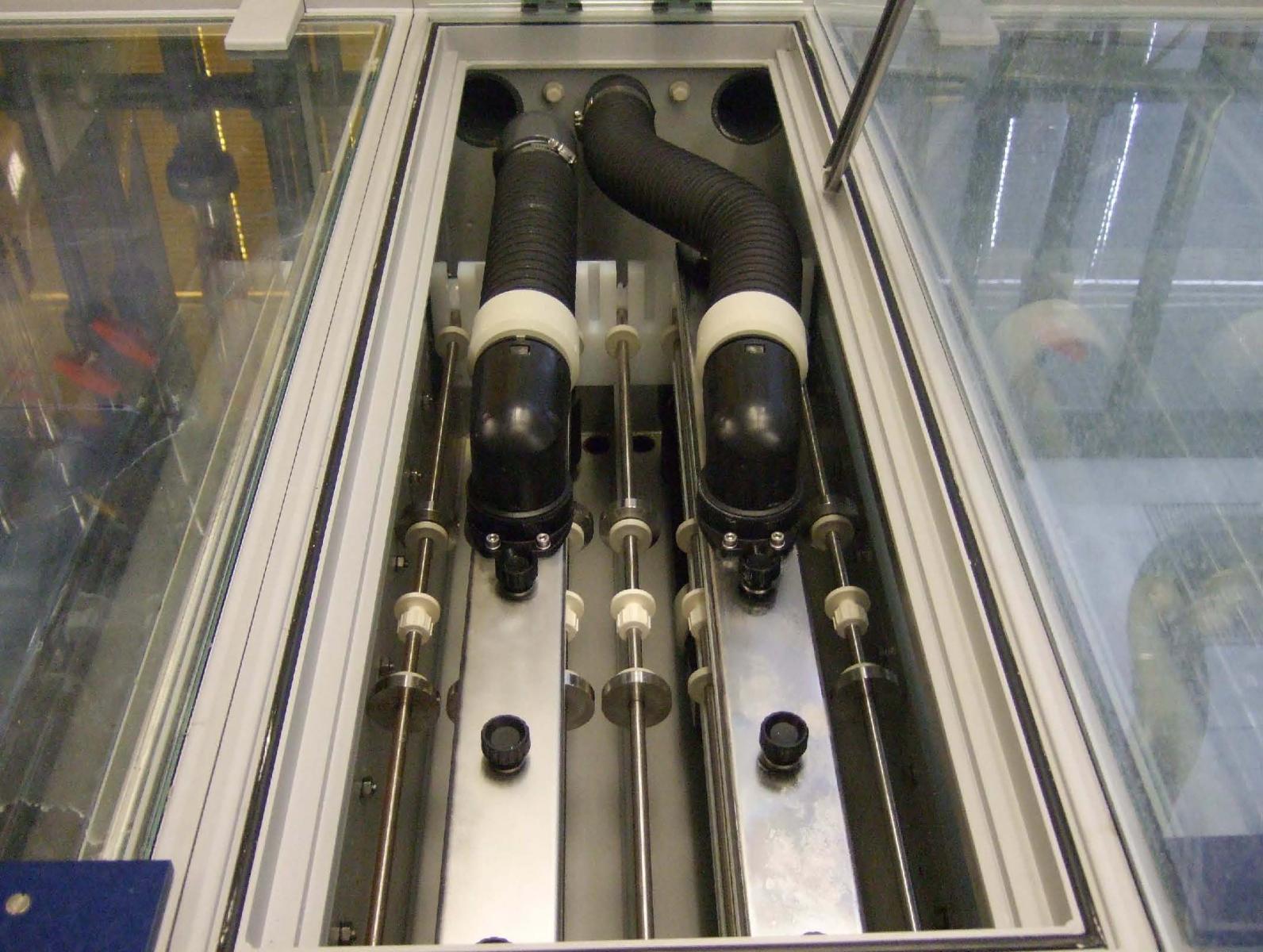

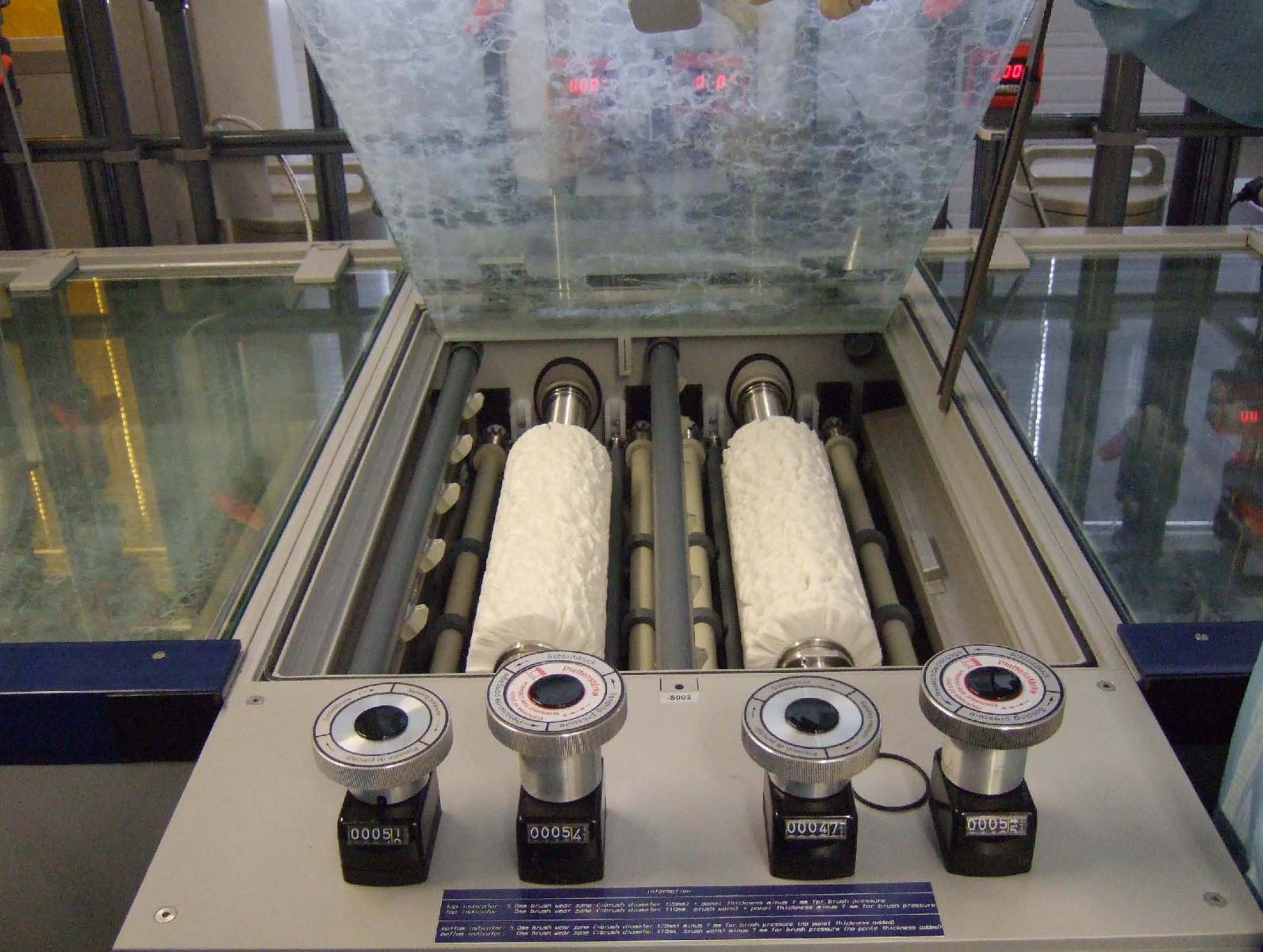

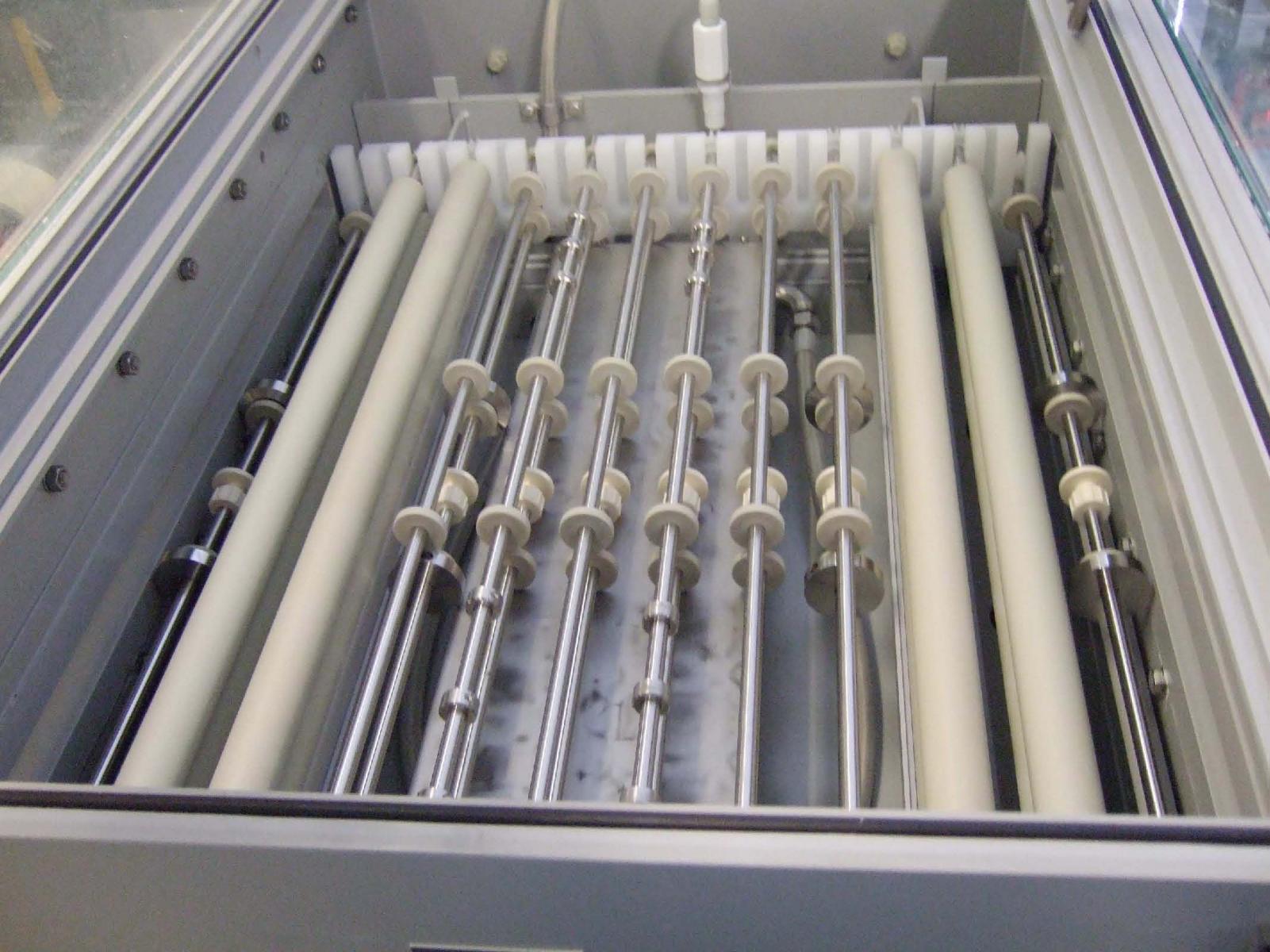

Substrate cleaning system

Operating elements: Right to left

Material cleaned / Glass substrates:

Maximum: 300 x 300 mm

Minimum: 150 x 150 mm

Glass thickness maximum: 1.1 mm

Glass thickness minimum: 0.4 mm

Cleaning capacity max: 20 m² / h at 100% load

Dimensions: 5000 mm long

Volume in m³: Ca 8 m³

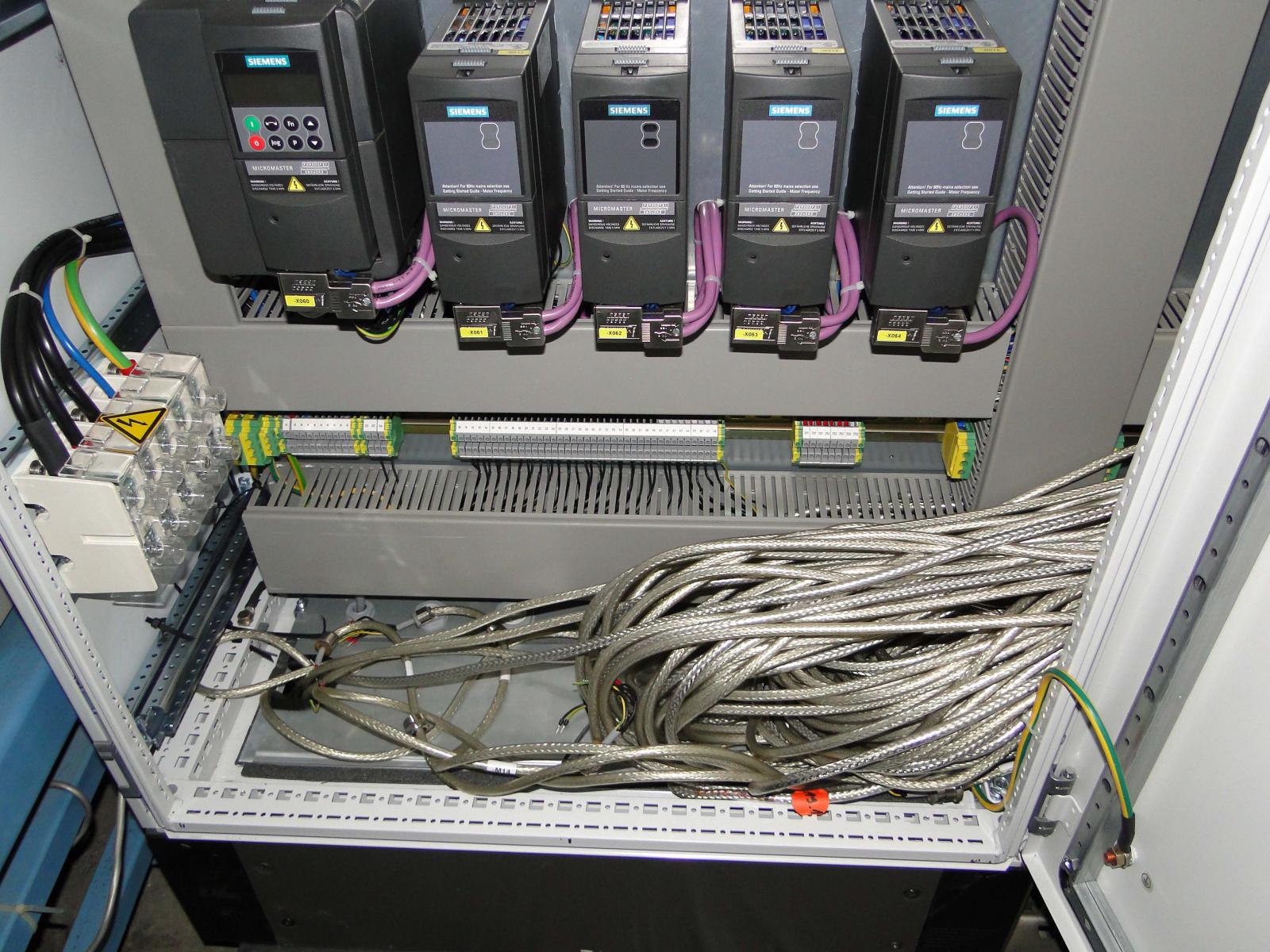

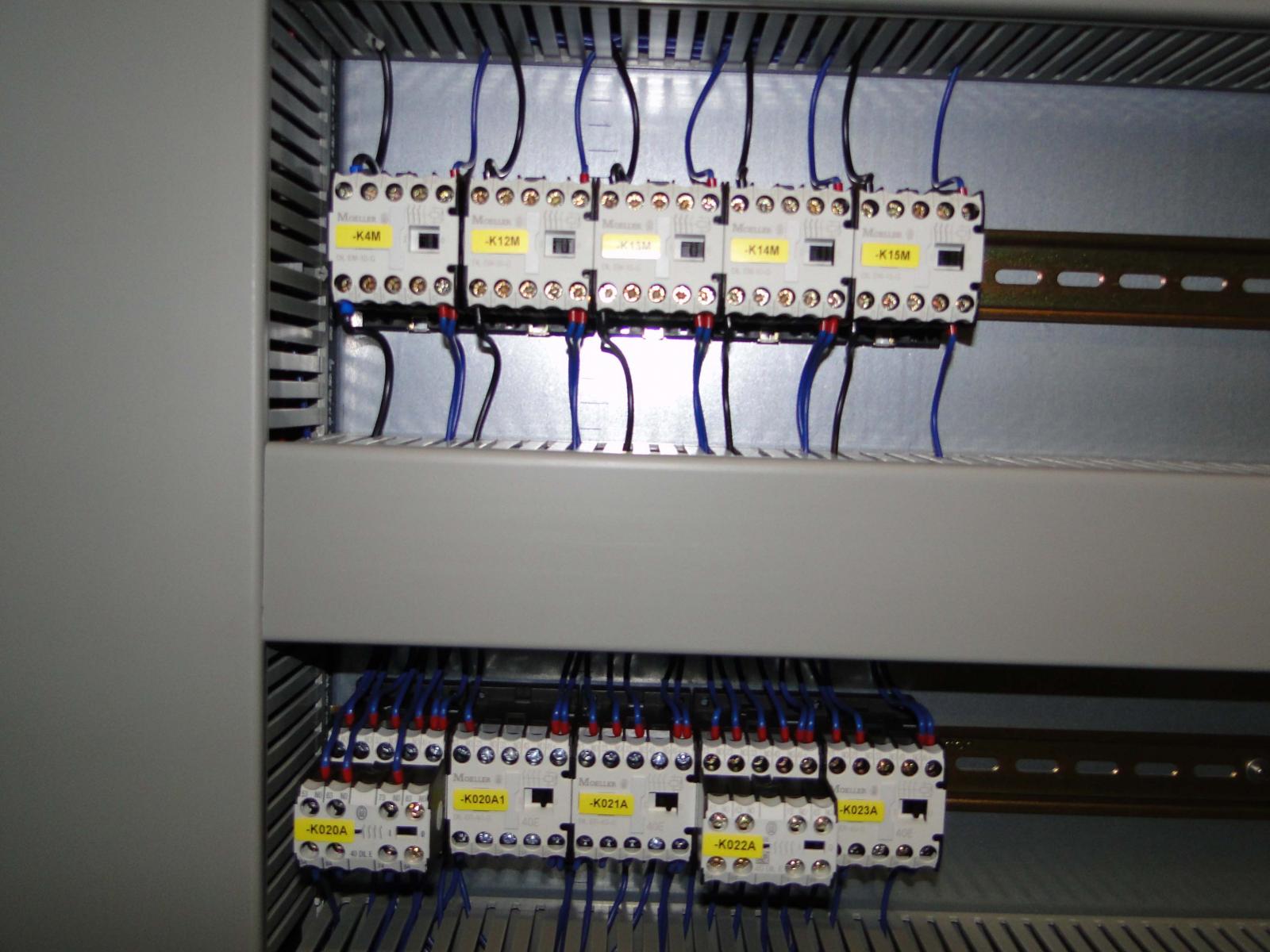

Remote control cabinet

VE- Ultrapure water with 0.5 μS / cm

Water consumption: 150 l/h of deionized water in operation

Without operation:

Water consumption: 3 to 5 l/h through bypass

Feed rate approx: 0.5 to 1.0 m / min

Working range feed: 0.2 to 6.0 m / min

Electrical connections:

400 V, 50 Hz, 3 Phase

Control voltage: 24 VDC

Power consumption: 21.6 kW

2006 vintage.

SCHMID Combi Line is a multi-functional etcher/asher designed to mark metals, metals alloys, and other areas requiring efficient and accurate mark-making. Combi Line is well suited to marking various medical components, medical implants, and other medical hardware. This machine operates with a biphasic process consisting of dry etching and wet ashing. The dry etching process used by SCHMID Combi Line creates a precise, long-lasting mark with the help of a powerful, German-made, hermetically-sealed laser head. The laser head has an adjustable output power from 1 - 200 watts, providing users with a wide range of laser etching capabilities. The material being marked is exposed to a laser beam with a wavelength of 360 - 540 nanometers, and an ideal beam diameter of 0.4 - 1 mm. The output of the laser can be controlled by several parameters, including beam power, speed, focus, and pulse frequency. The laser can also be adjusted to etch any desired height or depth. The wet ashing process employed by Combi Line is a high-precision technique using a combination of ultrasonic baths and chemical etching solutions. The etching solution is heated to a temperature of approximately 150 degrees Celsius, and then sprayed onto the workpiece. The etchant solution will then go to work on the material's surface. The ultrasonic baths act to agitate the etchant solution, creating tiny bubbles on the surface of the material. These bubbles act to break down the surface layer of the material and the exposed material is further etched away. The etching process can be adjusted to etch any desired depth or height and can be used to produce both engraved and raised lettering. SCHMID Combi Line is a robust, versatile etcher/asher, and is designed to stand up to the demands of industrial production. This machine is equipped with the latest control and diagnostic components, allowing for quick, efficient operation. Combi Line has a compact design, allowing for easy installation in a limited factory space. It is also designed for full automation, featuring automated loading and unloading, as well as automated laser and wet ashing processes. SCHMID Combi Line is a reliable, durable machine and is the ideal choice for reliable mark-making applications. It ensures accurate, long-lasting marking to produce the highest quality marks.

There are no reviews yet