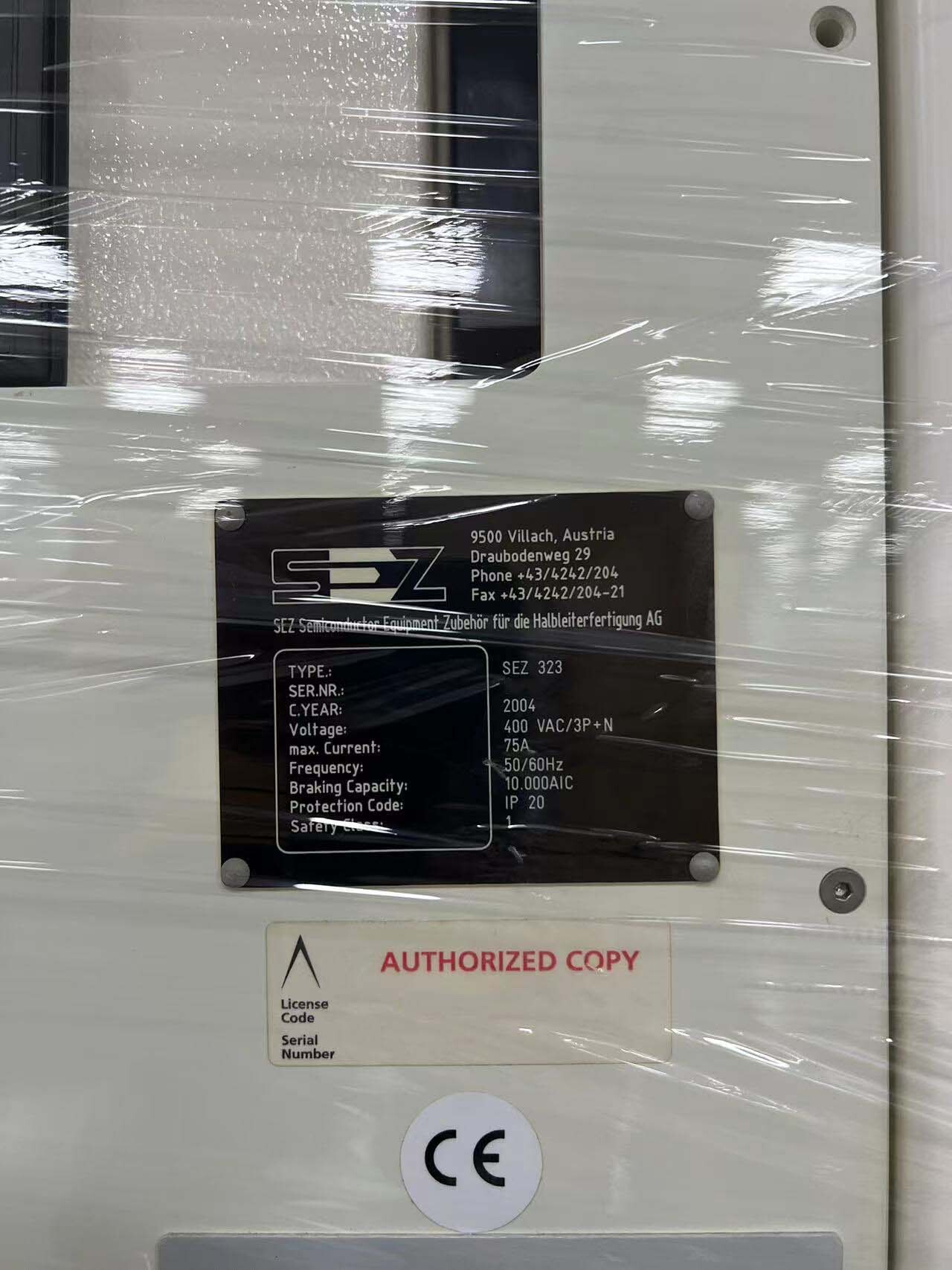

Used SEZ / LAM RESEARCH 323 #293632547 for sale

URL successfully copied!

Tap to zoom

ID: 293632547

Wafer Size: 12"

Vintage: 2004

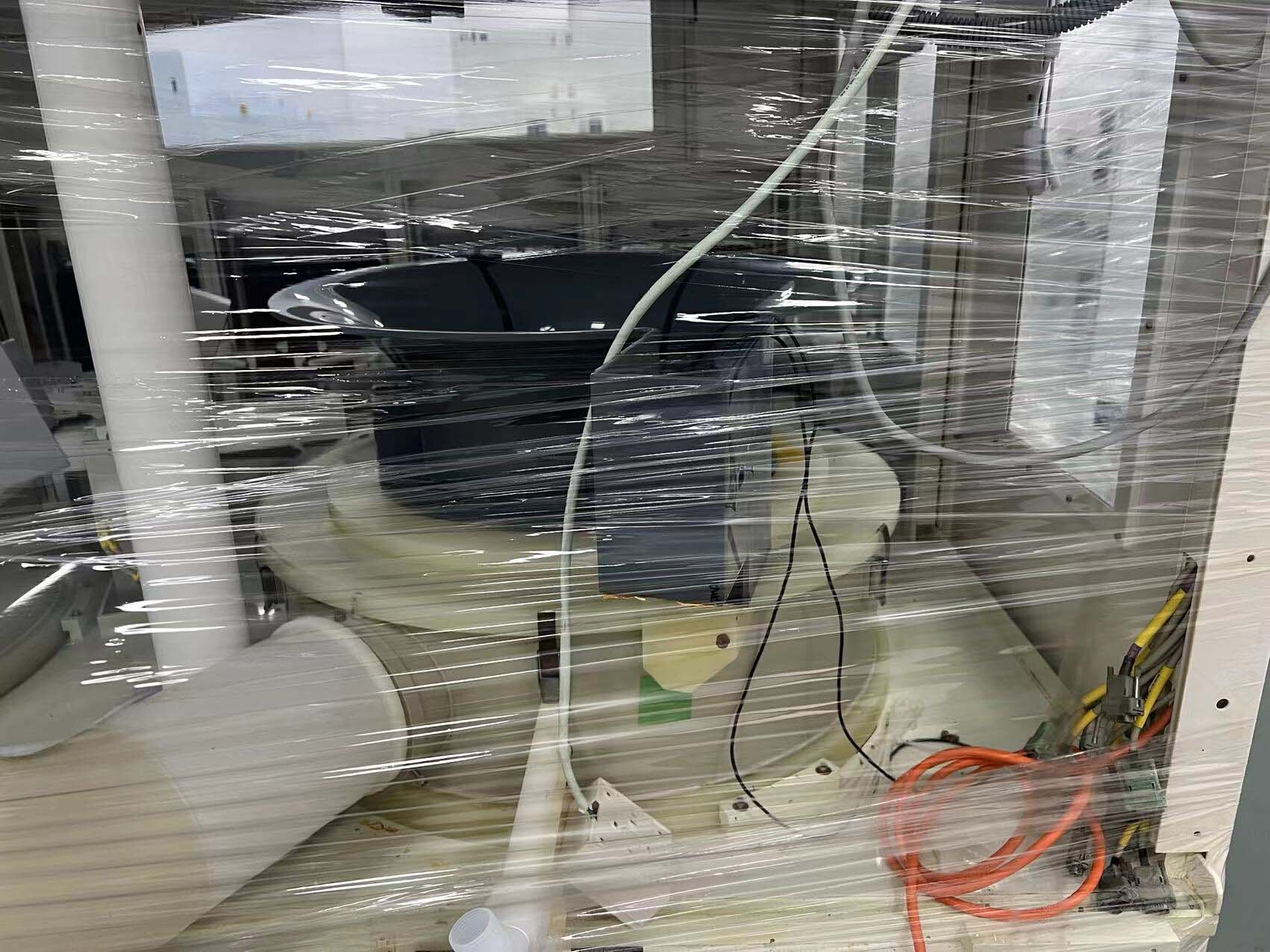

Spin processor, 12"

Controller

Carrier station block, (4) FOUP

Process block

AC Power box

(2) Etchers

CDU

Temperature Control Unit (TCU)

Solvent supply system: (2) Tank auto supply systems with CSS

Direct drain

Heater tank

(4) SLQ-QT500 Flow meters

2004 vintage.

SEZ / LAM RESEARCH 323 is a type of etching and ashing tool that enables high quality selective etching and ashing of compound material layers. This tool produces highly accurate and repeatable results, allowing for selective removal of different materials in complex layers by chemical etching and plasma ashing. SEZ 323 features a compact, robust design, making it suitable for applications where space is limited. The etching and ashing process can be completed using various gases, including oxygen, argon, sulfur hexafluoride, and ammonia. Control of these gases is achieved through the use of pressure and flow controllers, as well as an advanced vacuum system. The tool also allows users to select between a range of etching and ashing parameters, such as temperature, pressure, and power. LAM RESEARCH 323 is designed to enable high-precision etching and ashing processes. The digital process program enables users to set up etching and ashing processes based on their desired results, while the computer touchscreen and graphical user interface provide an intuitive approach to operation. The tool also includes built-in safeguards that automatically shut down the machine if pre-set parameters are exceeded. This etcher / asher also features a working area of 4 inches, making it suitable for small-scale projects. The chamber is made from robust steel for improved reliability and performance. 323 also features an integrated cooling system that uses the surrounding environment to cool the electronic assembly and the reaction chamber. SEZ / LAM RESEARCH 323 etching and ashing tool offers a durable and high precision solution for selective removal of materials. It is a great choice for many industries, such as the semiconductor and ceramic industries, where high quality results are needed to produce finished products.

There are no reviews yet