Used SEZ / LAM RESEARCH RST 201-8/6 #9399478 for sale

URL successfully copied!

Tap to zoom

ID: 9399478

Spin etcher

Missing parts:

ECO Left and right

Chuck

Elevator

Spindle

Dispenser

Power panel on the left side

Heat exchanger

Pump in CDS

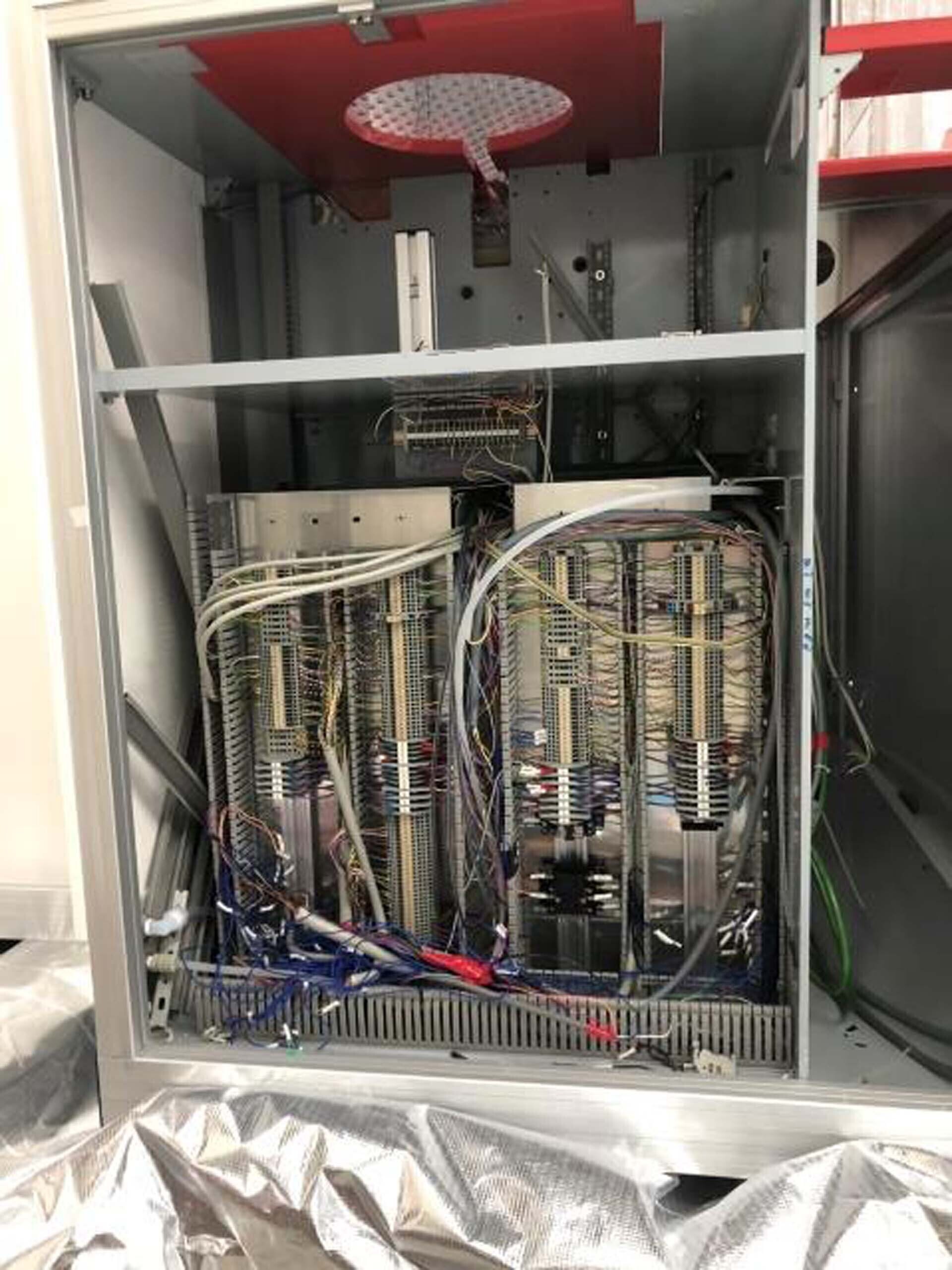

Boards in CDS host

Valve in CDS

Filter in CDS

PC Board

N2 Arm

DI Arm

Suckback module.

SEZ RST 201-8/6 is an advanced etch/asher equipment designed to perform a variety of etching, ashing, and cleaning processes. This system is ideal for applications that require high precision and repeatability. The RST201-8/6 includes a vacuum chamber, a primary source for process gas, a control unit for the vacuum chamber, a controller for the main source, and a series of sputtering sources for highly selective etching. The vacuum machine is an integral part of the overall performance of LAM RESEARCH RST201-8/6. The tool is capable of maintaining an operating vacuum level of 10-4 Torr at a maximum pressure of 0.6 Torr. This ensures that process conditions remain consistent over time, ensuring better performance and process repeatability. The primary gas source consists of four gas inlets, allowing for the introduction of either SiH4, CHF3, O2 or N2. This gives the asset the capability to etch, asher or clean materials in a variety of processes. To ensure a full range of performance, the RST201-8/6 features a series of twelve sputtering sources that are capable of delivering uniform power to a wide area of the substrate. The control model of the RST201-8/6 is based on Labview software and programming. This programming enables the equipment to precisely control process parameters and other settings in order to provide the best process results possible. The programming also allows for fully automated startup and shutdown procedures. The RST201-8/6 from SEZ / LAM RESEARCH is a highly versatile etch/asher system that is ideal for a wide range of applications. The vacuum unit provides high reliability and repeatability while the control machine enables the fine tuning of process parameters to obtain the optimal performance. In combination with the primary gas source and the sputtering sources, this tool provides the best etching and cleaning performance available in the industry.

There are no reviews yet