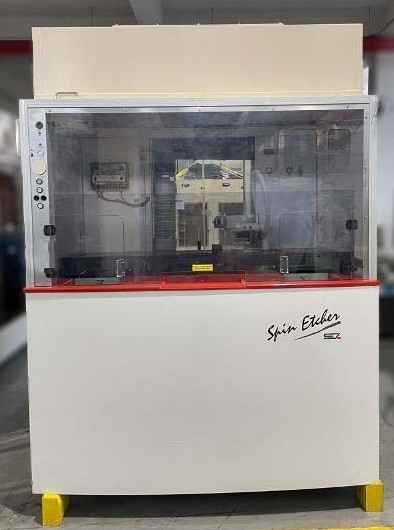

Used SEZ / LAM RESEARCH RST 201 #9394221 for sale

URL successfully copied!

Tap to zoom

ID: 9394221

Wafer Size: 8"

Vintage: 1996

Spin etcher, 8"

Process: Poly SiO2

Medium 2:

Chemical

(2) PILLAR PE-10MA Pumps

Heat exchanger: 1.6 kW / 80 CC Chilled water

Mixing type: Base chemical to level, spike secondary with dosing pump

Dosing pump size: 10 ml

Filter housing

Medium 3:

Chemical

(2) PILLAR PE-10MA Pumps

Heat exchanger: 1.7 kW / 80 CC Chilled water

Mixing type: Base chemical to level, spike secondary with dosing pump

Dosing pump size: 10 ml

No filter housing

N2 Flow: SCCM Monitored

Dispense:

Suck back: (2) Stages-valve to suck back valve, 3/8"

Medium 2: Analog flow monitor

Medium 3: Analog flow monitor

HMI: Rear

Static bar

Chuck type: Bernoulli (Standard)

(6) Spare parts

System safety equipment:

EMO Switch type: Turn to release EMO

EMO Guard ring

Chemical delivery options

Gem interface

CDS Unit

SUB Unit and spare part

Facilities:

N2

CDA

UPW

Exhaust

Vacuum

Power requirements:

Remote power module

Line voltage: 400V VAC Platform

Line frequency: 60 Hz

UPS: Computer

1996 vintage.

SEZ / LAM RESEARCH RST 201 is an etcher/asher that is used for subtractive chemical processes in the manufacturing of semiconductor devices. It is a reliable, high-performance platform used for precision etching of various materials such as Si, SiO2, SiN, Polyimide, and Metal. SEZ RST 201 features an automatic chemical source container management equipment, a large work envelope of 660 x 940 mm, and a user-friendly color graphical user interface (GUI). It also comes with an integrated robot for easy loading and unloading of wafers, as well as advanced chemical analysis technology. LAM RESEARCH RST 201 utilizes a highly advanced etching process that allows for complicated geometries to be built with speed and precision. The etch process is conducted in a clean, low-pressure chamber that prevents outgassing and minimizes contamination. A gas mixing system with the ability to adjust the ratio of etching and protective gases to a specific application's needs is included. It also features variable pressure that increases the process speed, reduces contamination and wear, and increases the quality of the etch. RST 201 includes a sophisticated tool control unit, which monitors and controls key functions of the etcher/asher and monitors the process parameters during etching. This ensures that the etching process is accurately maintained and monitored to maintain the highest quality of product. A double-chamber vacuum design is also included, which provides a low vacuum pressure environment with a low base pressure and high backside pressure, further enhancing etch uniformity and productivity. SEZ / LAM RESEARCH RST 201 is capable of performing wet etching, the most common etch process used by the semiconductor industry today. It is also capable of dry etching, where chemical gasses react with the surface of the material to be etched. The machine has been designed to enable high-performance processes and enable a variety of etch patterns, including holes and slots, to be etched quickly and accurately. SEZ RST 201 is an ideal etcher/asher perfect for multi-layer etching, patterning, and even three-dimensional structures. This etcher/asher is highly customizable and can be used to create intricate patterns of various shapes and sizes. LAM RESEARCH RST 201's improved features and functions, as well as its user-friendly GUI, make it an invaluable tool for those in the semiconductor manufacturing industry.

There are no reviews yet