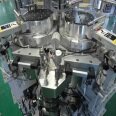

Used SHIBAURA µASH 8100 #9234515 for sale

URL successfully copied!

Tap to zoom

ID: 9234515

Wafer Size: 8"

System, 8"

(2) Chambers

Processing type: Vacuum

Mass flow controller (MFC):

Gas number / Gas name / MFC Size (SCCM)

Gas 1 / O2 / 2000

Gas 2 / O2 / 2000

Gas 3 / CF4 / 20

Gas 4 / CF4 / 20

Gauge:

MKS Baratron 626A

Range: 1.333kPa

NS FFU-222 System

DAIHEN CMC-10 Tuning control

DAIHEN SGP-10B RF Generator

DAIHEN SGM-10A Matcher.

SHIBAURA µASH 8100 is a self-contained, thermally-enhanced etching equipment designed for precise wafer patterning. This system allows for superior flexibility and performance when etching patterns onto fragile and delicate substrates. It is a complete, in-line processing etcher, working in either stand-alone or parallel batch processing mode. The unit comprises a main work platform mounted to a frame, an etching chamber containing the wafer to be etched, and a separate cooling chamber. The main work platform is equipped with unique motion-recognition technology to achieve the required pattern precision. This technology allows for the platform to detect and follow micro-patterns and maintain rigid accuracy for a variety of wafer shapes and sizes. The rectangular etching chamber is designed for uniform cooling and heating during etching process and has a special temperature control machine to regulate temperature efficiently. It allows for uniform temperature distribution and uniform etching across the entire wafer surface. The etching chamber also has electrostatic pins to precisely align wafers for high-precision patterning. ΜASH 8100 features a computerised process control tool for accurate monitoring and control of the entire etching process. This asset features a dual-channel high-sensitivity detector to detect patterns with greater precision and an intuitive graphical user interface for ease of operation. The computerised process control also offers the user additional options such as automated processing, ability to store multiple processes and the facility to switch between process menu options. The cooling chamber of SHIBAURA µASH 8100 is securely sealed, ensuring sufficient airtightness for cooling and ventilation. The entire cooling model is powered by an air-cooled blower mounted at the rear of the cooling chamber. This blower enables quick cooling or heating of the wafers prior to the etching process. ΜASH 8100 is an all-in-one, user-friendly etching equipment that is designed for comprehensive substrate patterning. Its temperature control, motion recognition and computerised process control system provides high accuracy and reliability when etching delicate and fragile substrates. Its cooling chamber protects wafers from heat damage and uniform etching across the entire Wafer surface is ensured. It is therefore ideal for applications where high precision and accuracy is required.

There are no reviews yet