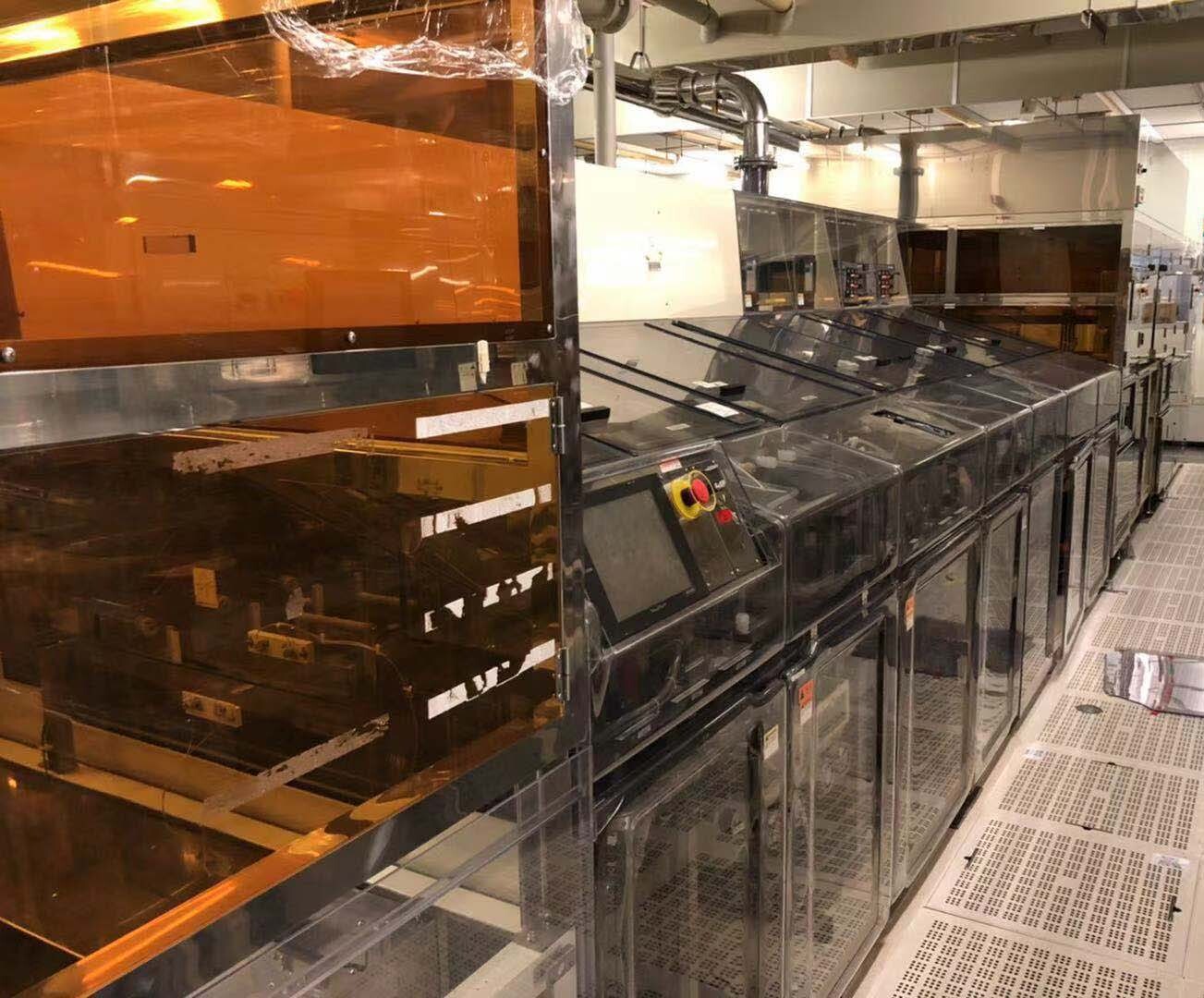

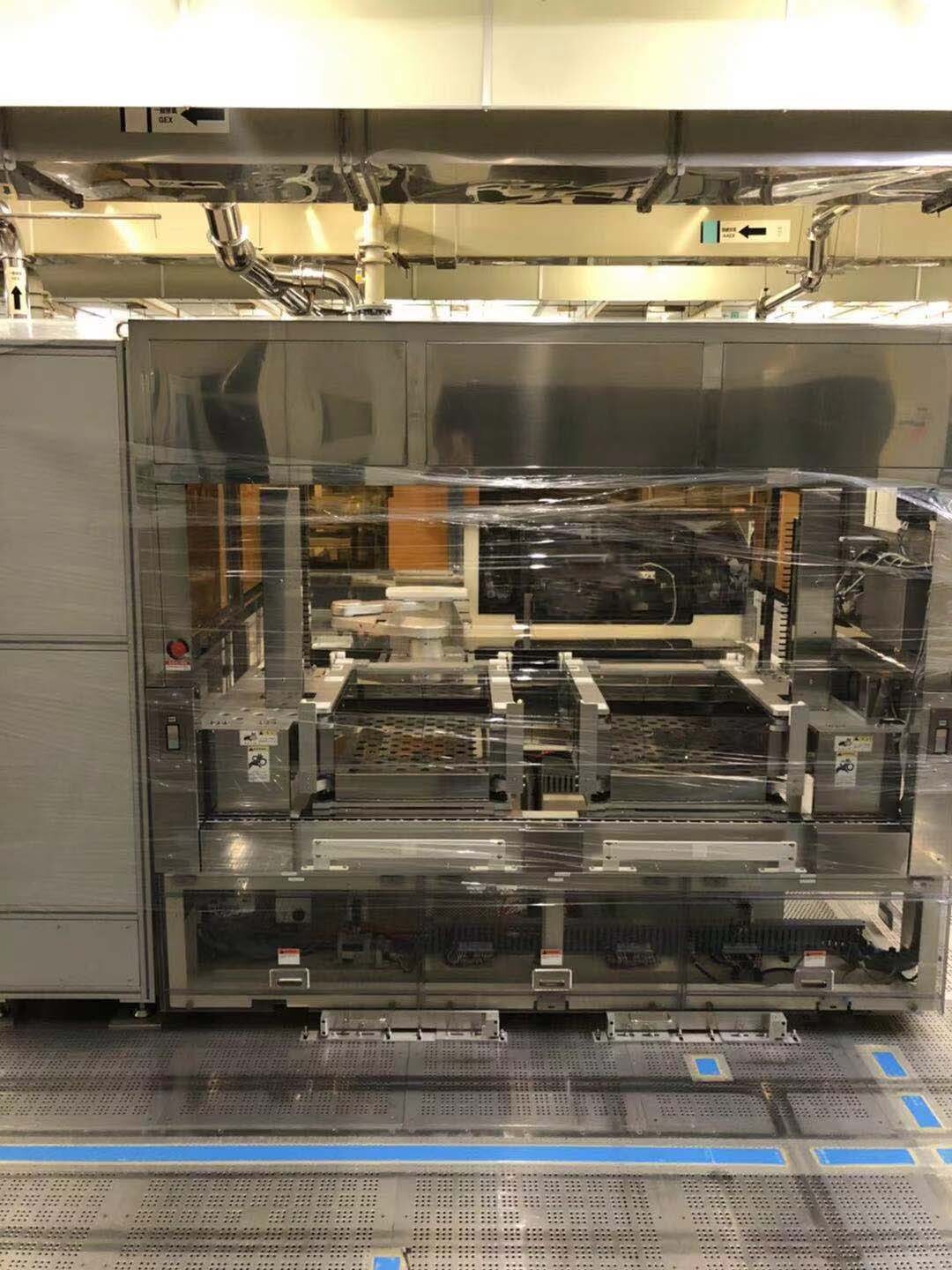

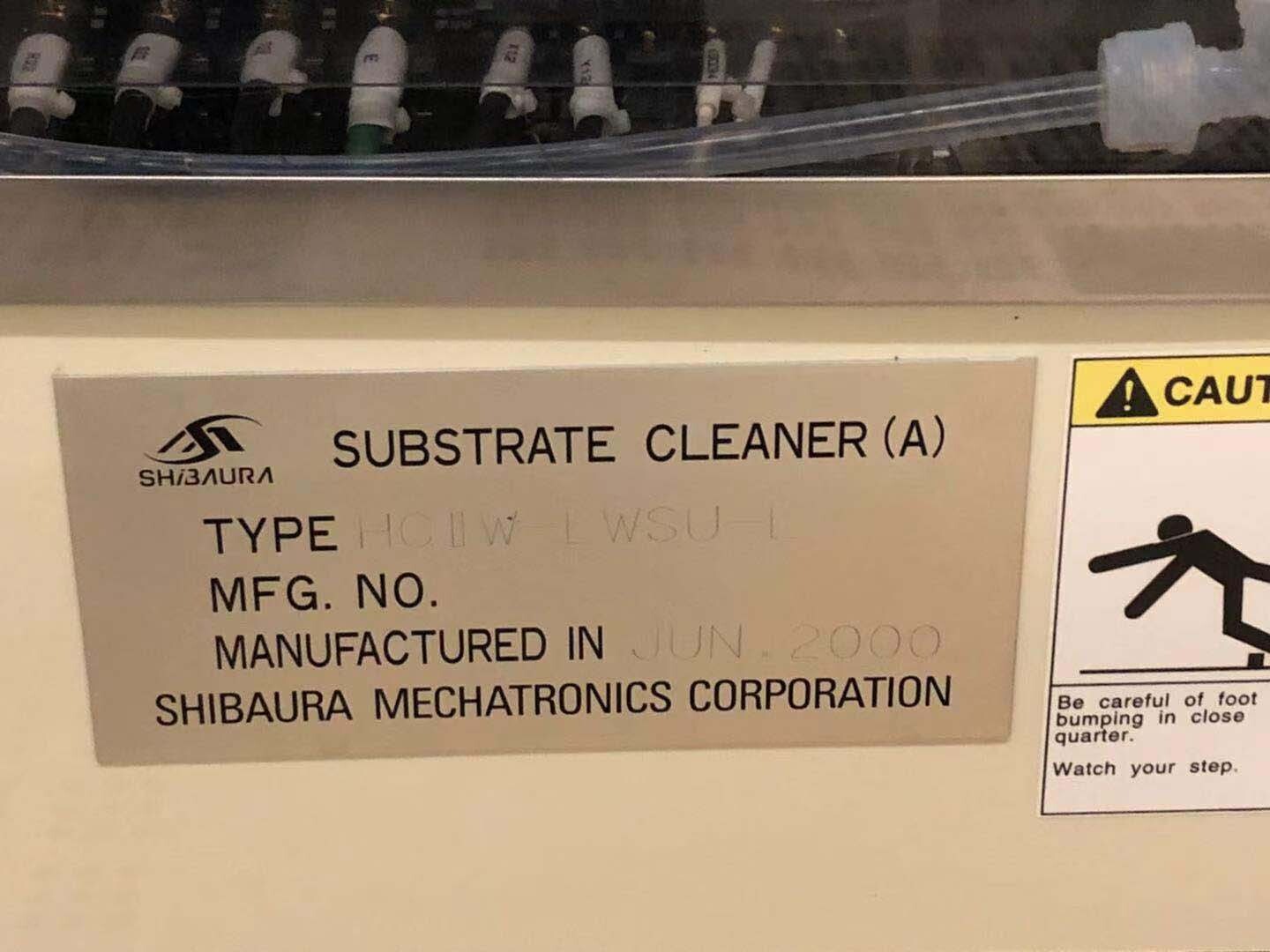

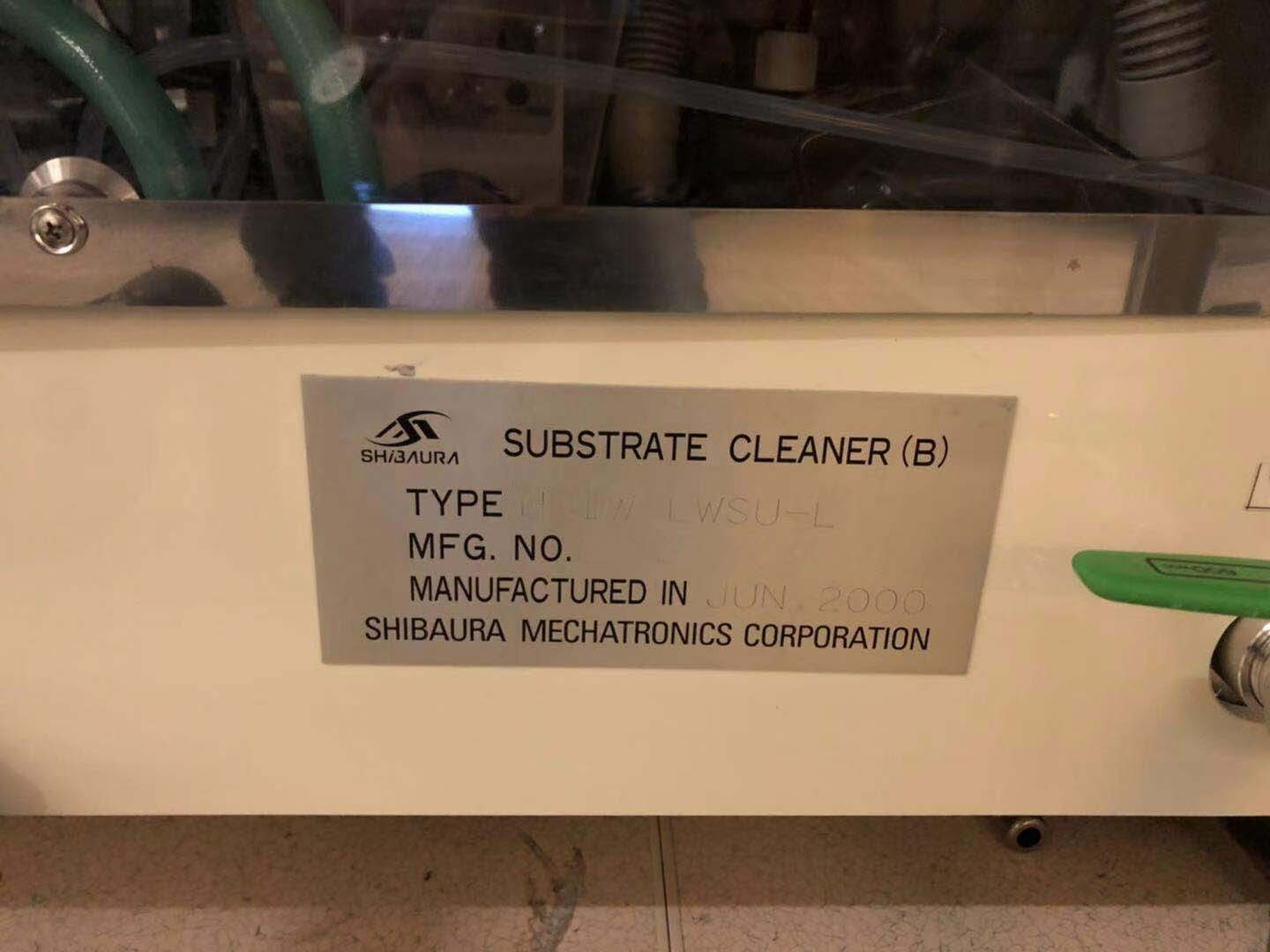

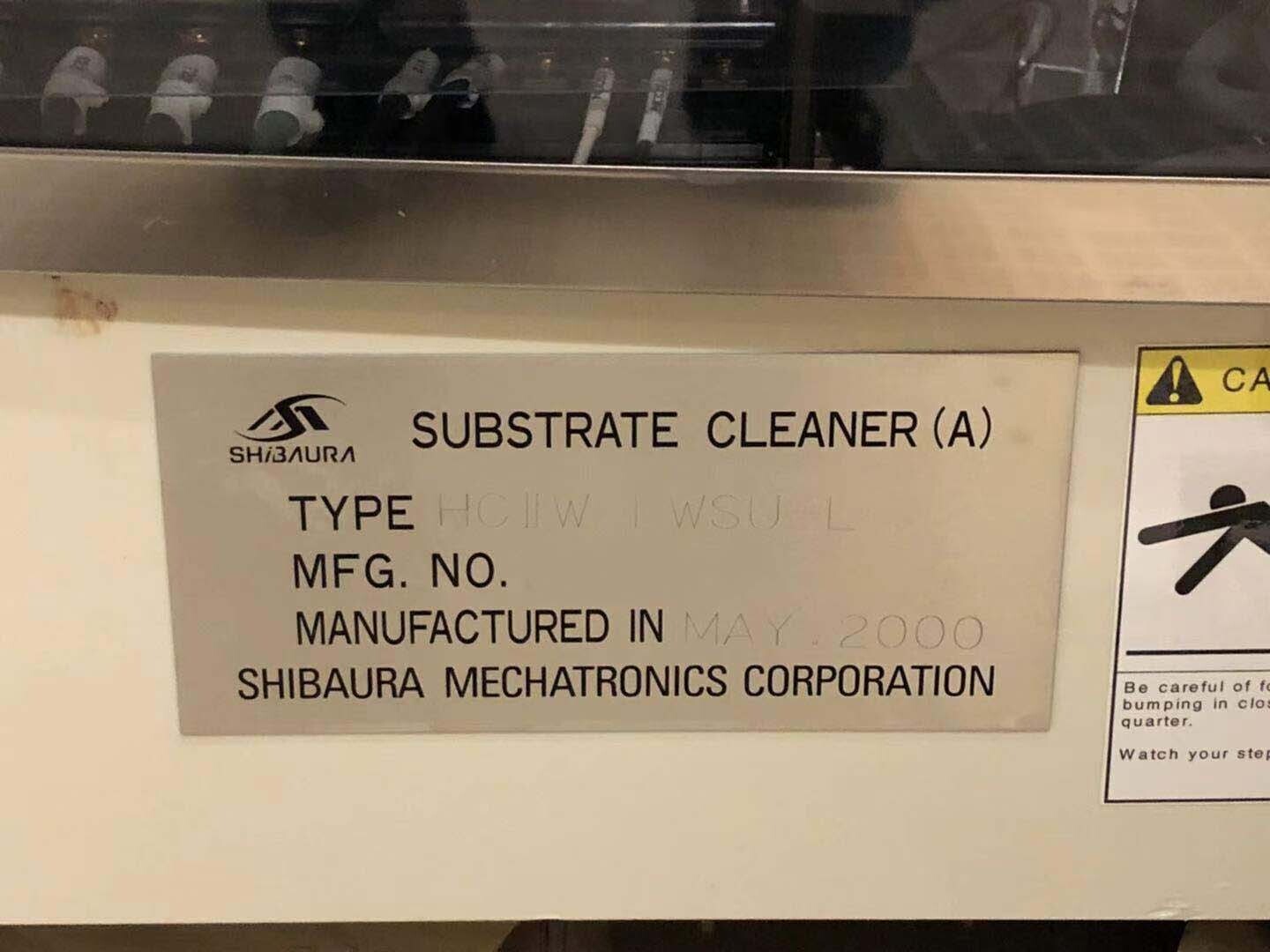

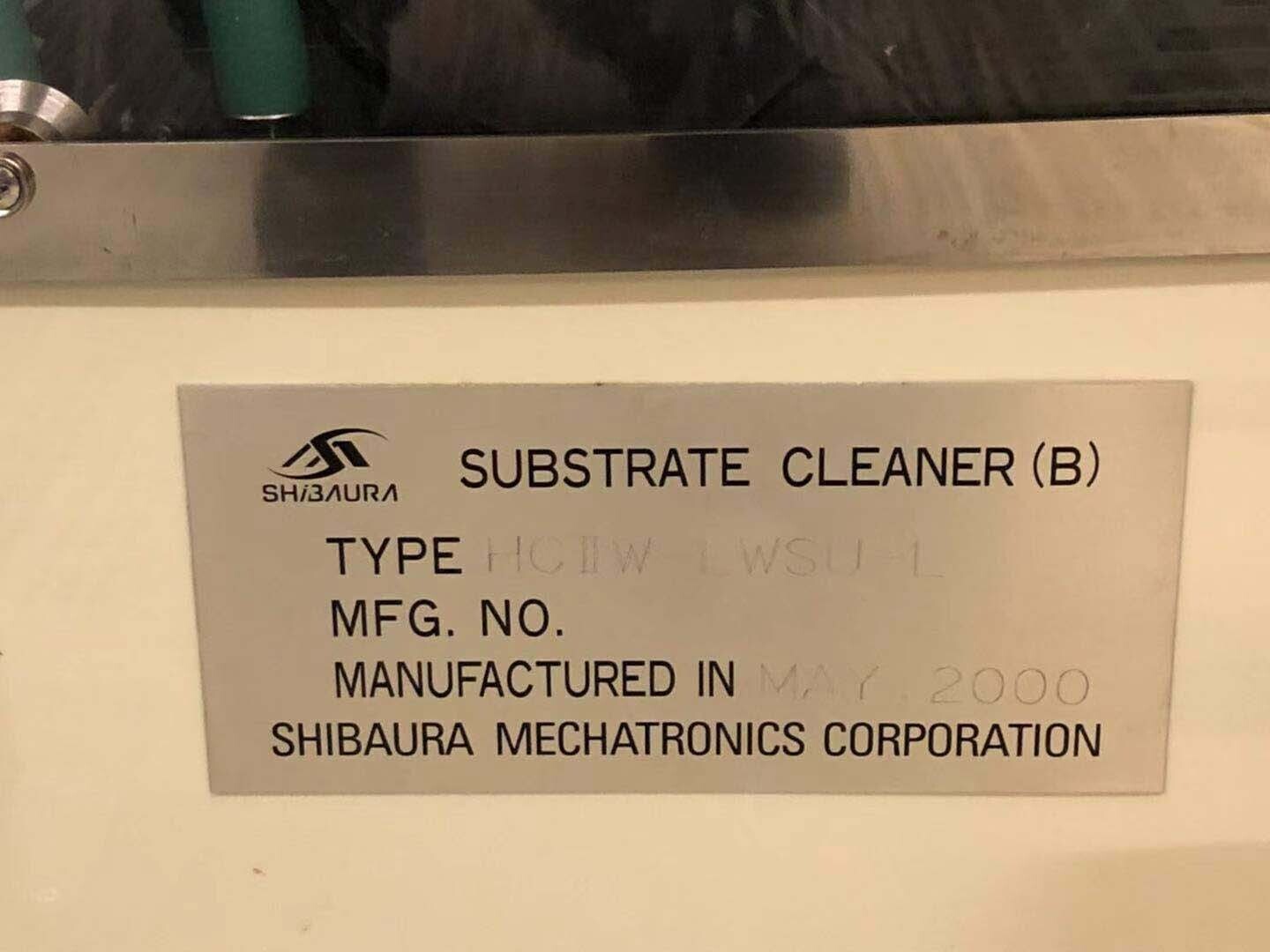

Used SHIBAURA HCIIW-I-WSU-L #9382336 for sale

URL successfully copied!

Tap to zoom

SHIBAURA HCIIW-I-WSU-L is a plasma etch/etch equipment that uses dry reactive ion etching (RIE) technology. This etcher system is built with a hybrid chamber, high-frequency power supply, and a chlorine gas supply. The hybrid etcher combines the benefits of a PECVD (Plasma-Enhanced Chemical Vapor Deposition) and RIE etcher. The hybrid etcher allows for the deposition of protective coatings and then the etching of underlying material. The PECVD process utilizes plasmas formed by the high-frequency power supply to etch micro-structures onto various substrates such as plastics, metals, or glass. On the other hand, the RIE process utilizes medical grade Cl2 (chlorine gas) to etch/etch materials down to sub-micron level. The RIE process is ideal for photomask patterns, integrated circuit designs, and more. HCIIW-I-WSU-L utilizes a unique pressure control unit to maintain the required etching rate and pressure inside the reaction chamber. The vacuum chamber is designed to be capable of pressures from pressure from 2×10^-2 Torr to133 mTorr with a maximum temperature of 200 °C. The machine can reach a base etching rate of up to 500 Angstroms/minute on a wide range of materials including silicon, quartz, and other dielectric materials. The etching process is controlled by proprietary embedded software, allowing manual and automatic controls depending on the user's needs. Additionally, the embedded software allows for multiple etching recipes to be written and stored. The etching recipe can be optimized by the user and adjusted to match the desired etch pattern, etching rate, and repeatability. SHIBAURA HCIIW-I-WSU-L tool is a versatile asset ideal for both rapid prototyping and mass production. It is ideal for integrated circuit design, photomask fabrication, and other high-tech applications requiring precise etching/etching results. This etcher model is reliable, precise, and easy to use.

There are no reviews yet