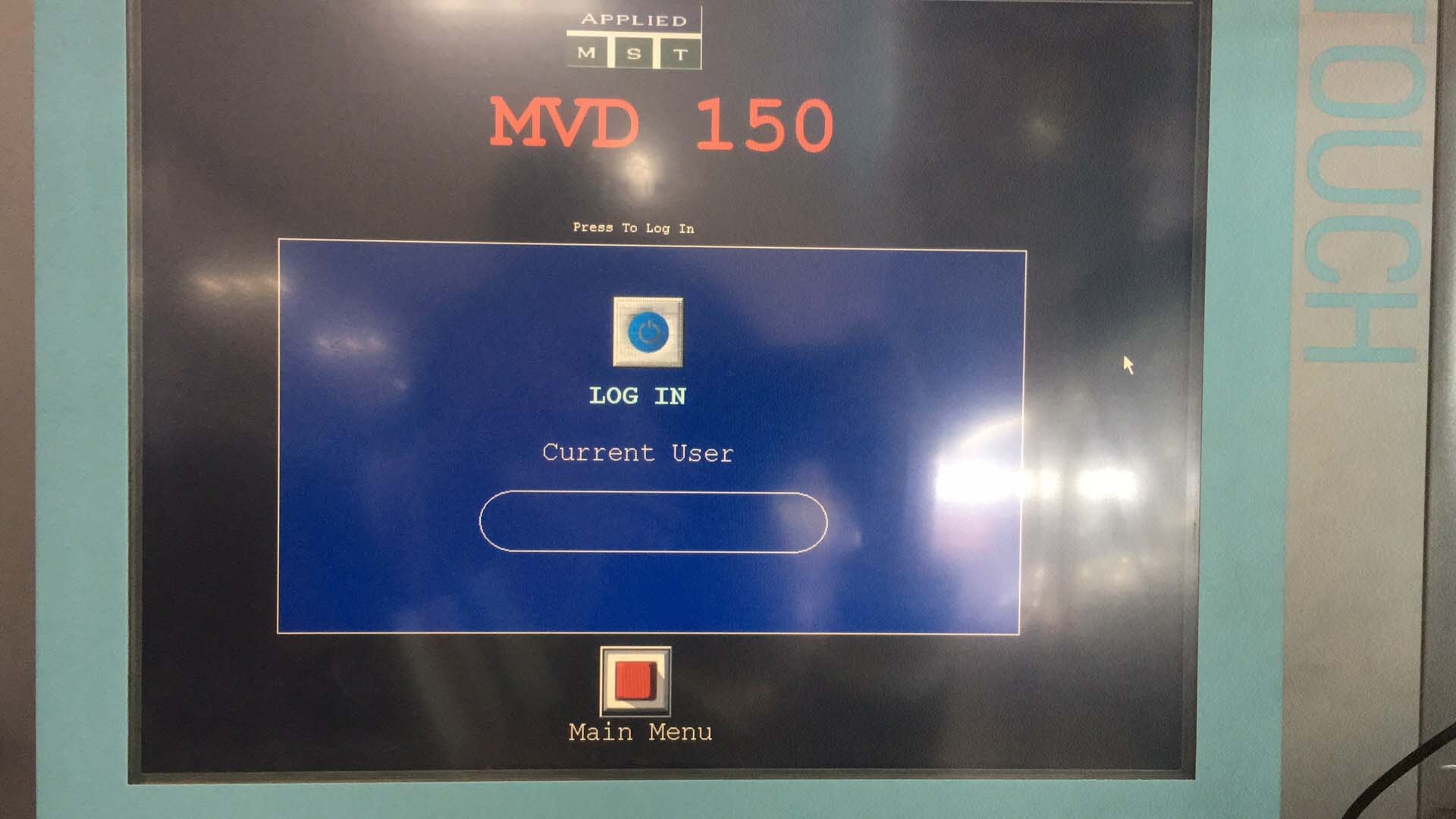

Used SPTS MVD150 #9280194 for sale

URL successfully copied!

Tap to zoom

SPTS MVD150 is an advanced etching and ashing equipment designed for a range of applications including MEMS, photonic, and 3D integration fabrication. Using radio frequency (RF) technology at frequencies of 25 MHz and 130 MHz, it provides highly selective and precise removal of materials for patterning, over a wide range of temperature-controlled process temperatures ranging from -50˚C to 1000˚C. Key features of the system include an unparalleled chamber size of 300x300x150mm, a vacuum unit with a high gas flow of up to 1000slm, a magnetic and mass flow controller for precise flow rate control, and a remote substrate technology for long-duration processing. The machine offers advanced process control, including computer control of the process parameters. It is capable of continuous feedback and monitoring through a range of sensors and monitors, ensuring tight control of critical wafer temperature, pressure, and positioning. Additionally, multiple process control parameters, such as chamber pressure, RF power, and etching depth, can be programmed and optimized to yield superior results. The tool is also equipped with a suite of etching and ashing chemistry delivery systems, providing the versatile ability to choose the chemical needed for precisely engineered etch and ashing. It has been optimized to work with an extensive range of process chemistries to optimize the process for specific material combinations. Furthermore, the asset has been tested and qualified to meet a wide variety of industry standards, allowing it to meet strict quality and safety requirements. It is designed for optimal repeatability, cleanliness, and low-cost-of-ownership with certifications such as ANSI/RIA NIST-2011, ISO 9001:2015, Pacific Council Chambers (PCC) compliant, and SEMI S2 compliant. Its low-pressure mode (LPV) allows for consistent and precise operation during ashing processes, helping to reduce process and statistical variation. Finally, the model also has a range of support for production scale etching and ashing, including a protocol library, a remote monitoring equipment, and automated loading/unloading systems. MVD150 etching system is an ideal choice for engineers and manufacturers looking for a powerful and precise etching and ashing unit that can handle a wide Variety of materials and processes. It offers a cutting-edge approach to etch/ash production, allowing consistent and repeatable results while saving time, resources and money.

There are no reviews yet