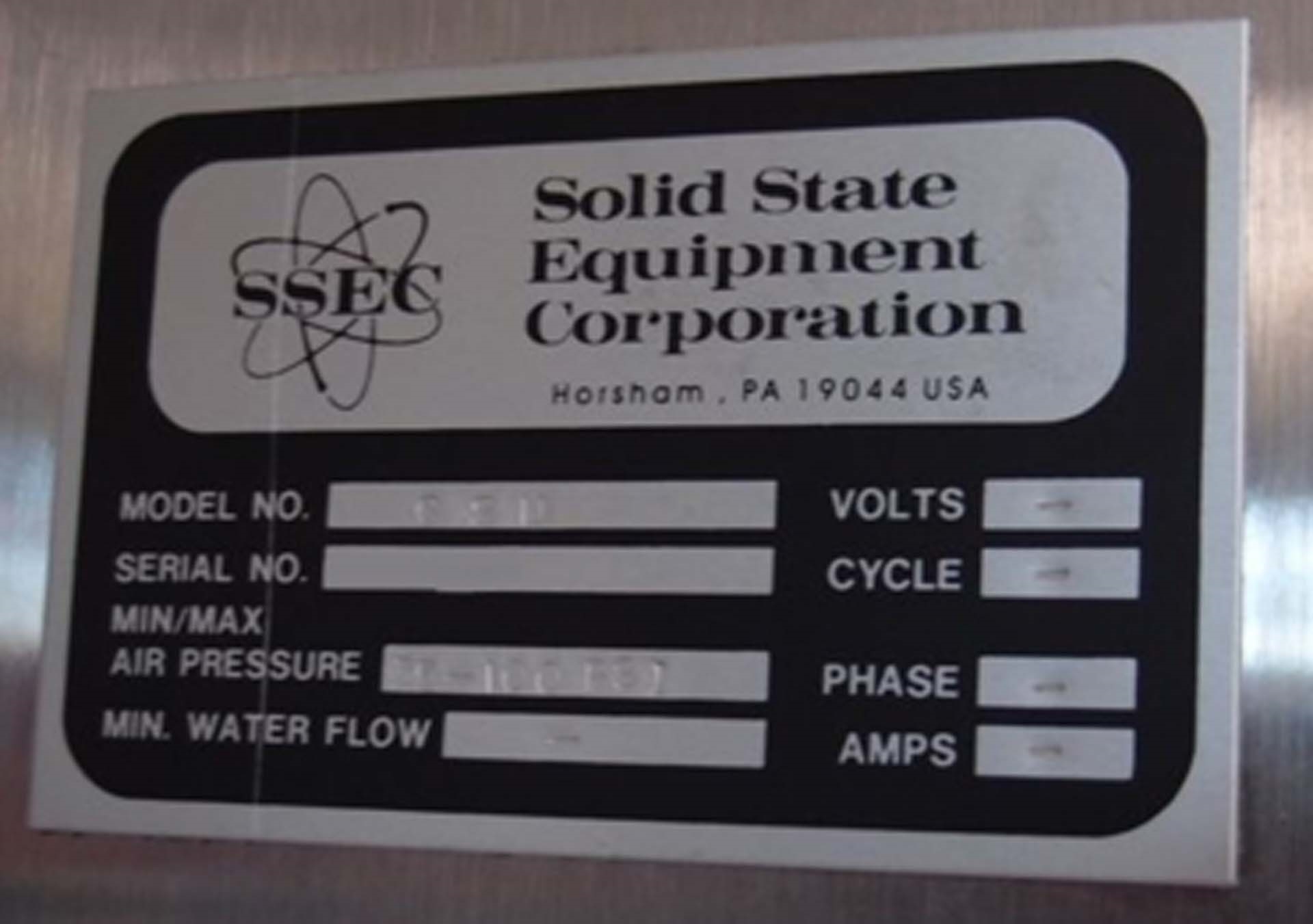

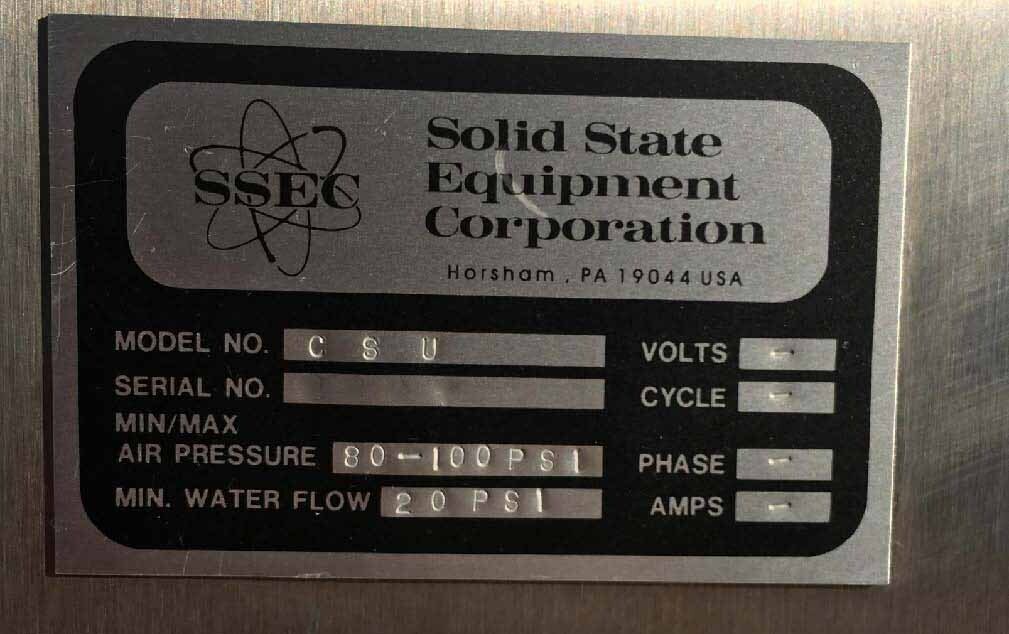

Used SSEC Evergreen Series II 203 #9260711 for sale

URL successfully copied!

Tap to zoom

ID: 9260711

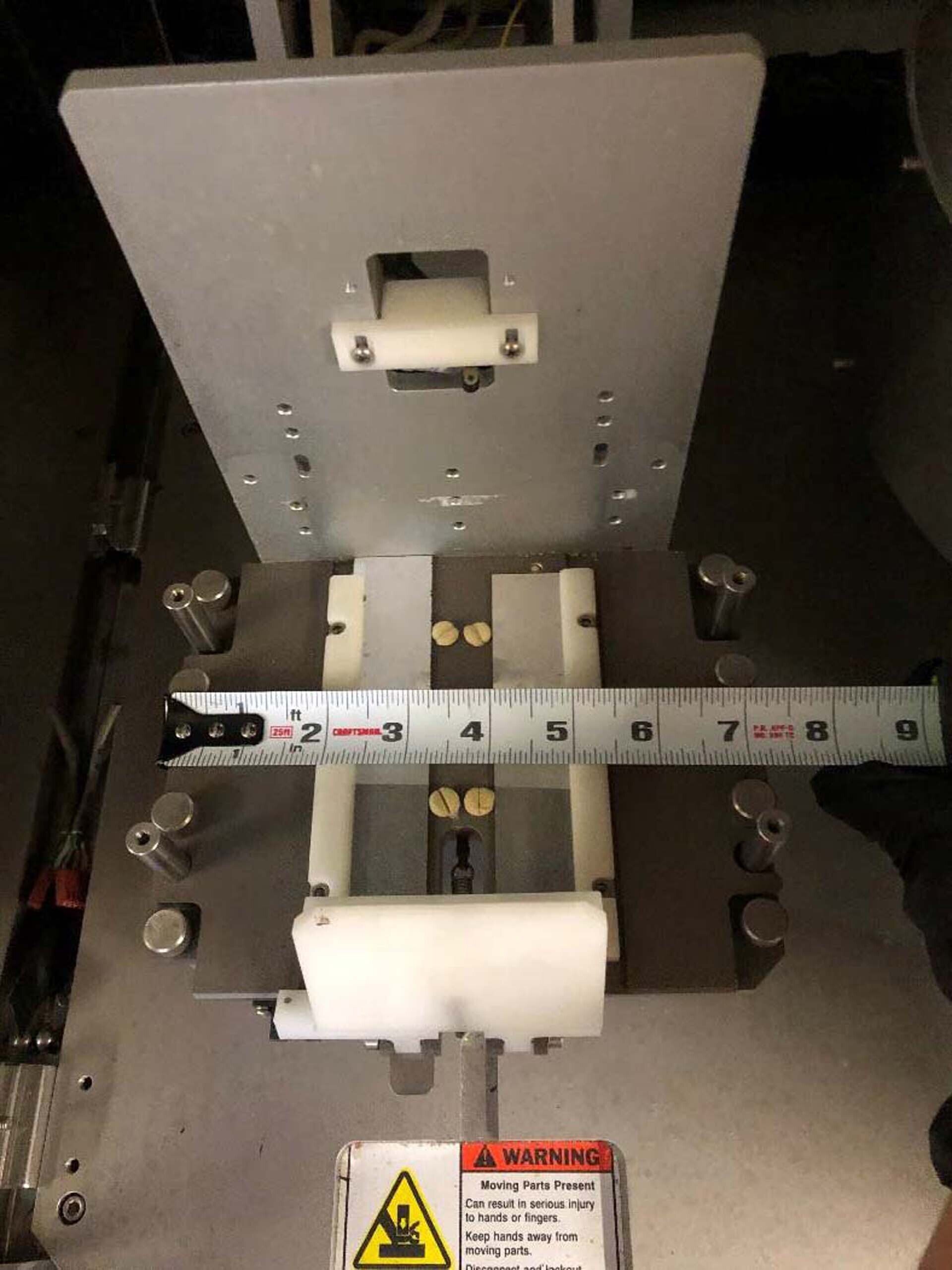

Wafer Size: 6"

Photoresist wafer etchers, 6"

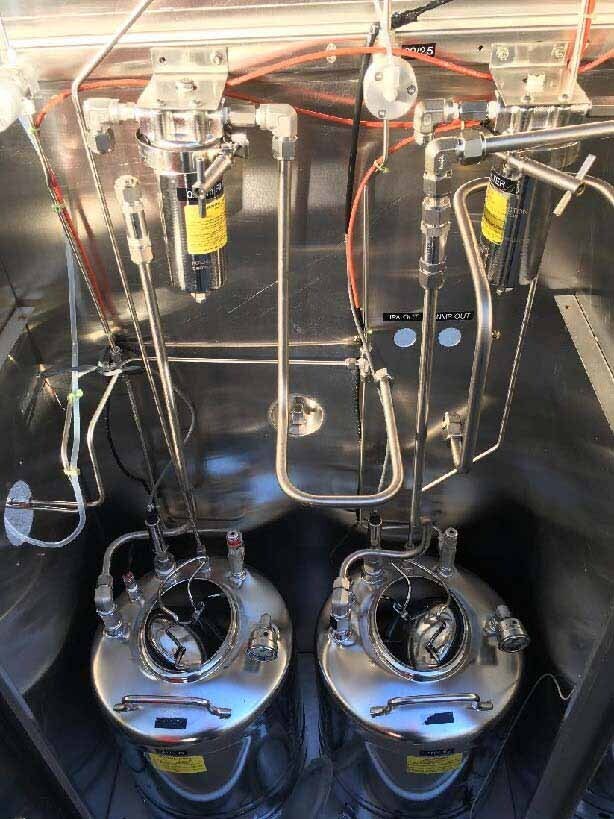

Chemical storage

Wafer transfer cabinet

Transfer cabinet

Stainless steel

Recirculating chillers

With (2) pumps / LG HPC Coolers.

SSEC Evergreen Series II 203 is an etcher / asher designed for integrated processing of customer wafers. This device is meant to provide a cost-effective solution for wafer applications such as pattern transfer, etching, thin film deposition, and metrology, enabling high throughput wafer fabrication. The Series II 203 is based on the reliable and durable Evergreen Series II platform, and additionally features a high-precision wafer handling system to ensure seamless and efficient processing of customer wafers. The Series II 203 makes use of direct-drive technology to achieve greater accuracy and production quality. This high-performance, resource-efficient etcher / asher uses accurate and precise integrated motion controls and direct-drive technology to provide optimal quality and reproducibility in the processing of customer wafers. Also, the device utilizes an advanced pre-heated vapor deposition and etching (PPVE) process, which enables the production of extremely thin and densely packed features on customer wafers. The Series II 203 is equipped with a reliable 10-position robot-controlled wafer handling system, making the processing of multiple wafers a breeze. Additionally, it features an effective Flow Panel Interface Management System (FPI-MS), which allows for the continuous monitoring and analysis of the process activities in real-time. This feature enables quick and automatic wafer program tuning for specific customer requirements. The device has a durable stainless steel chamber, with a vacuum rating of up to 10+5 torr. Additionally, it comes with an integrated quartz window and embedded sensors for temperature monitoring. The Series II 203 also comes with a range of exclusive technologies to ensure the highest quality and uniformity of the materials being processed. These technologies include carrier gas, process drift, wafer lot optimization, and an advanced data logging feature. In terms of safety, the Series II 203 is equipped with a host of advanced safety features. It makes use of interlocks, anti-collision systems, and fail-safe mechanisms to keep personnel and wafers safe. Lastly, the device is designed with a range of user-friendly interfaces and controls to make the operation and maintenance of the device easy and hassle-free.

There are no reviews yet