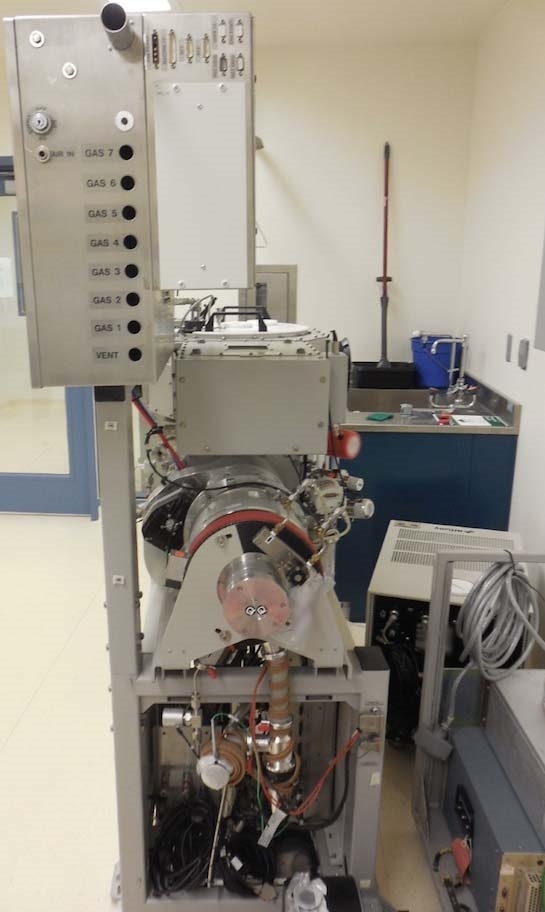

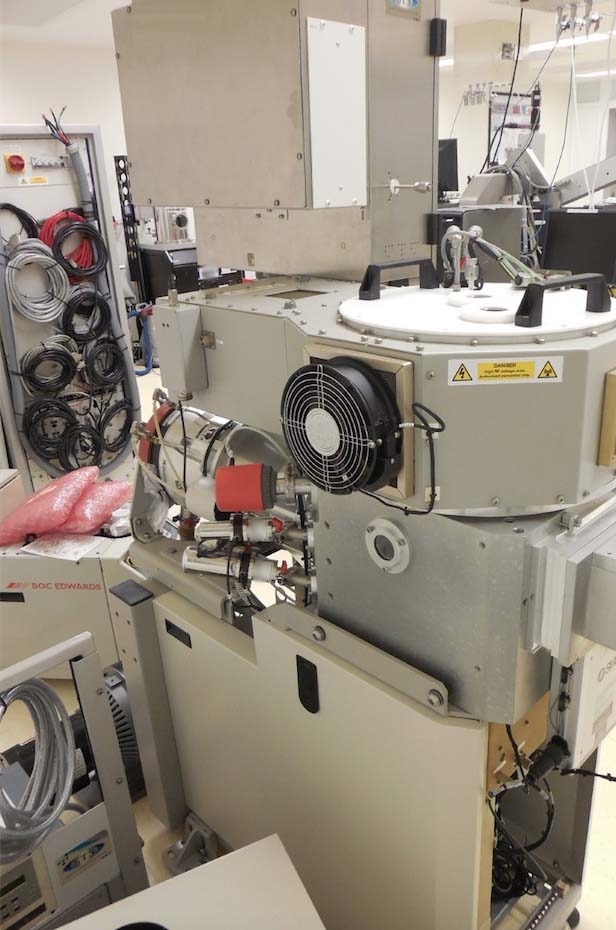

Used STS / CPX Multiplex ICP #9196059 for sale

URL successfully copied!

Tap to zoom

ID: 9196059

Vintage: 2000

DRIE Etcher

Type of load lock: Single wafer load lock

Process modules: Module 1

Module type: ASE

Process type: Polymers

Wafer handling: Direct

WTC/ ESC: WTC

Material: Silicon

Size: 100 mm

Thickness: Standard

Clamped

Pin lift

Control system / User interface:

Operating system: Windows 2000

Standard control system

Standalone VDU

Keyboard / Mouse

Vacuum load lock with single wafer loader

ICP SC160M Process chamber (MESC)

ICP 240BF Source

RF Supply / Matching unit:

ICP Source: 1 KW (13.56 MHz)

Lower electrode: 300/30 W (13.56 MHz)

Electrode temperature control (+5ºC to +40ºC)

Balun coil ICP design

Gas box and gas lines:

Gas box type: Onboard

Gas lines:

Gas MFC Size Normalized Seal Gas type

Name (sccm) (Yes/No) type (Process/Clean)

C4F8 200 Yes Viton Clean

SF6 300 Yes Viton Clean

O2 100 No Viton Clean

Ar 50 No Viton Clean/Process

CHF3 100 No Viton Clean/Process

CF4 100 No Viton Clean/Process

CO2 100 No Viton Clean/Process

Chillers and cooling circuit:

Lower electrode chiller: Affinity RWA-012

Pumps and pumping lines:

Turbo pump: LEYBOLD MAG900

Chamber backing pump: EDWARDS iH80 (M)

Load lock pump: VARIAN TS600

Power and electronics:

System voltage supply: 208 V, 60 Hz

2000 vintage.

STS / CPX Multiplex ICP is a type of etching and ashing equipment used to produce a wide variety of complex patterns on substrates such as silicon, polyimide, and quartz. The system combines ion-beam etching and chemical-assisted etching/ashing techniques to provide high production rates, improved process control, and repeatable products. STS Multiplex ICP is equipped with a proprietary High Energy Plasma Source (HEPS) and advanced substrate positioning unit for full substrate motion control. The machine is capable of processing up to 4-inch and 6-inch (200mm x 150 mm) substrates and features a process window up to 12″ with both high- and low- dielectric layers. It has a high resolution of down to 100nm, which enables it to provide finer line widths, clear vias, and better shadowing than traditional etching/ashing processes. An integrated gas delivery tool allows for precise etching and ashing with the addition of several gases, including nitrogen, chlorine, and fluorine. CPX Multiplex ICP features low electrical consumption for improved operation safety and costs. This asset also uses an advanced filtration model to prevent any hazardous fumes and particles from spreading throughout the production environment. By taking advantage of the improved process control and substrate motion capability, this etching/ashing equipment allows for higher throughput rates and more consistent process results. With its high energy plasma source, Multiplex ICP is also able to process a variety of material types including silicon, polyimide, and quartz. Additionally, it can also process extremely thick layers up to 100 µm. STS / CPX Multiplex ICP has further improved on etching/ashing performance through the addition of a proprietary process sequence that includes various steps, from scrubbing (which removes particles from the surface) to etching (which is used for creating patterns in the material) and ashing (which is used to remove excess material). It also has an adjustable bias power system for improved process tuning and precise results. Overall, STS Multiplex ICP is an advanced etching and ashing unit suitable for production and research operations. It features improved process control and throughput rates, a high resolution for better shadowing and patterning, low electrical consumption for improved safety, and a proprietary process sequence to ensure repeatable results.

There are no reviews yet