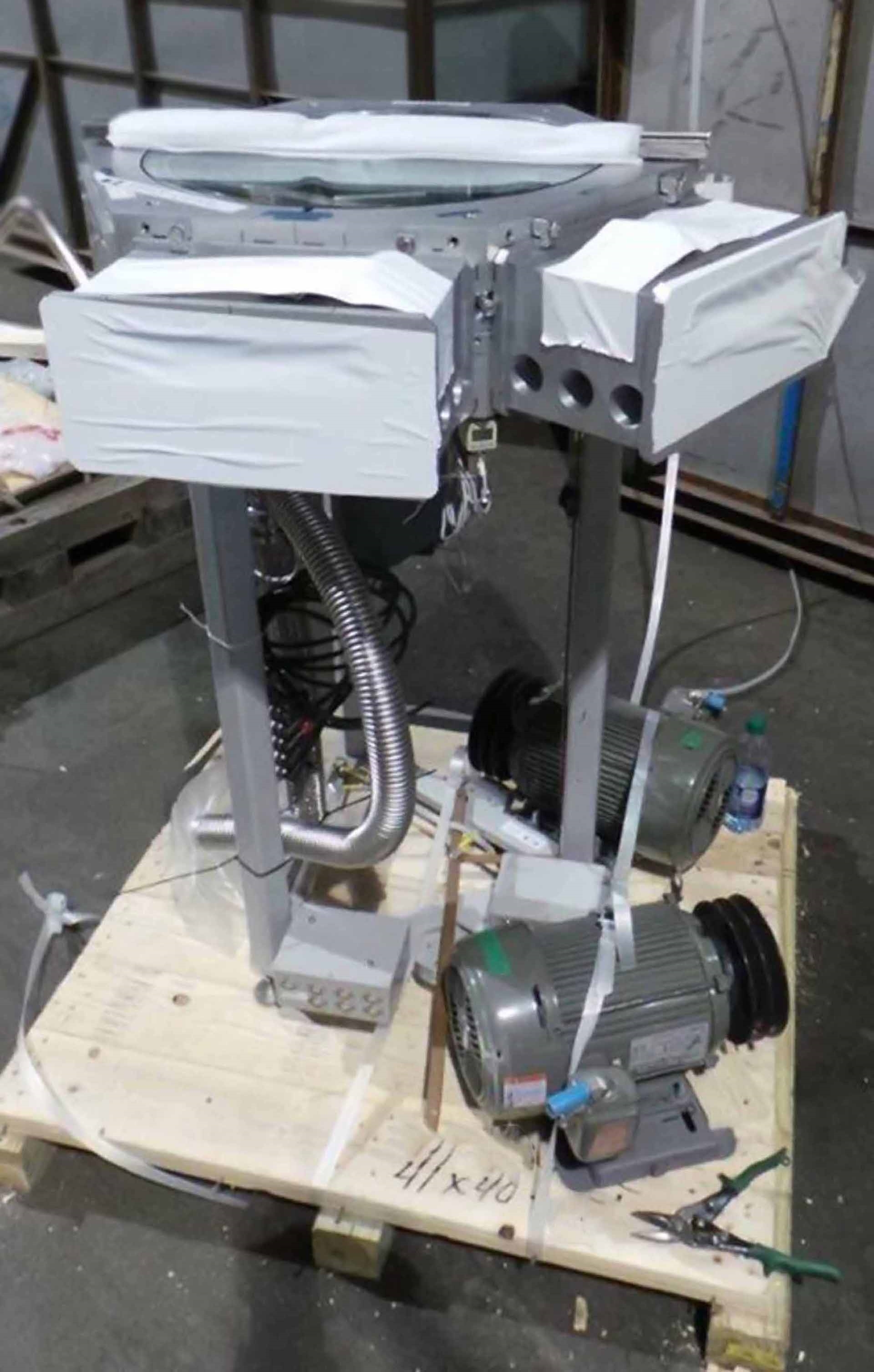

Used STS / CPX Multiplex ICP #9222691 for sale

URL successfully copied!

Tap to zoom

ID: 9222691

Wafer Size: 8"

Vintage: 1998

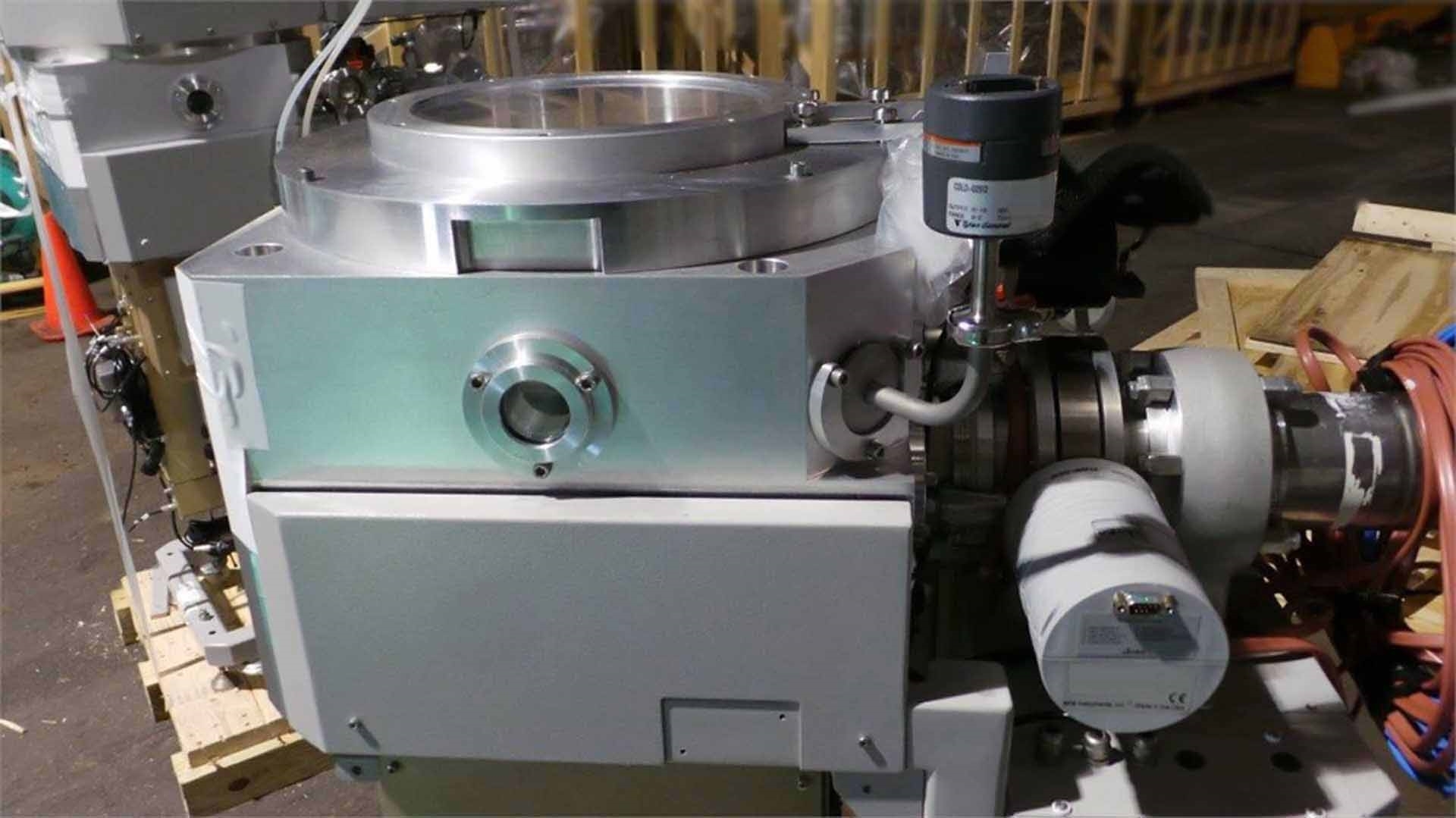

Deep silicon etcher, 8"

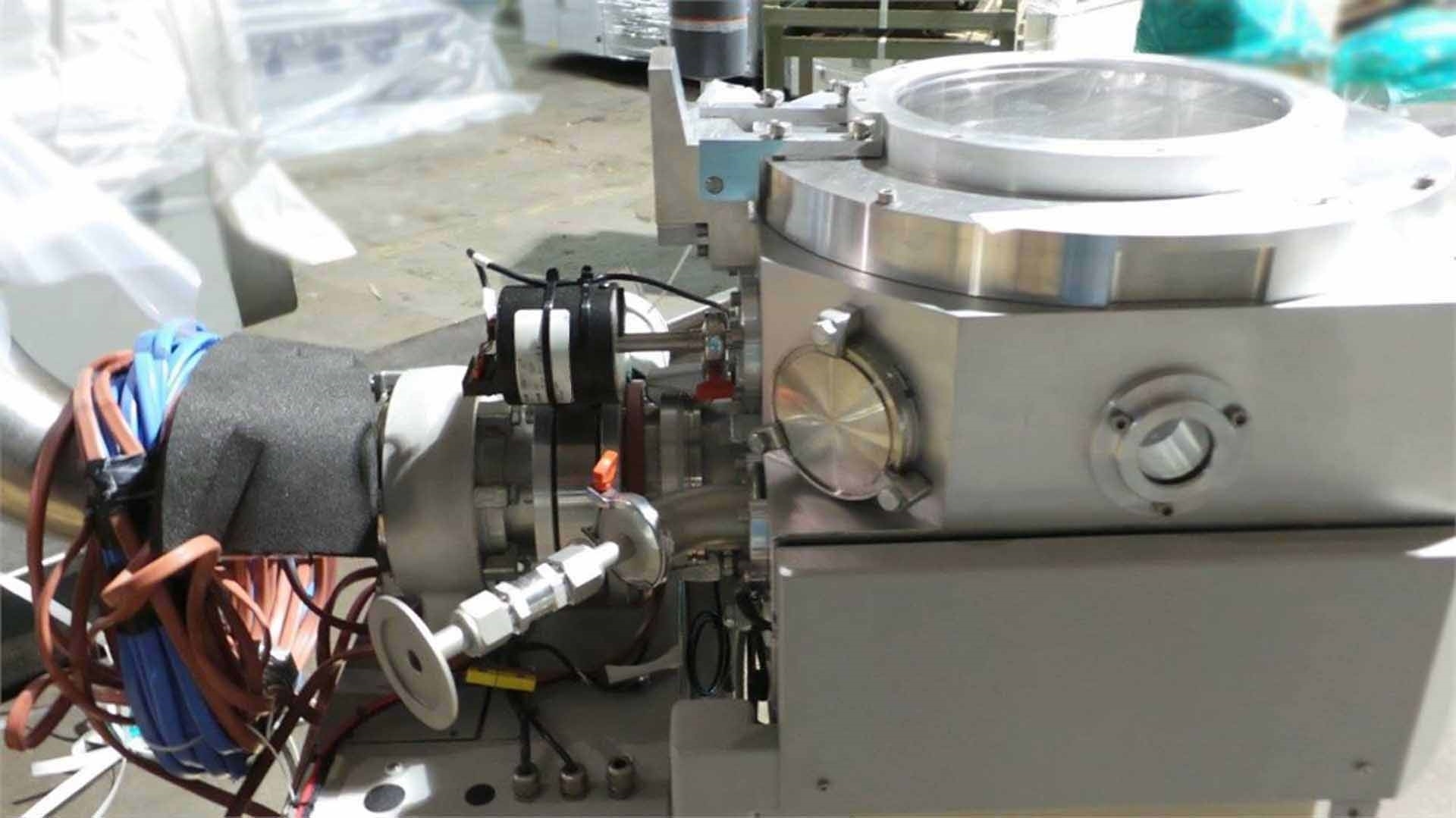

XeF2 (Xenon di-fluoride) poly silicon release etch chamber

Cfg wafer, 6"

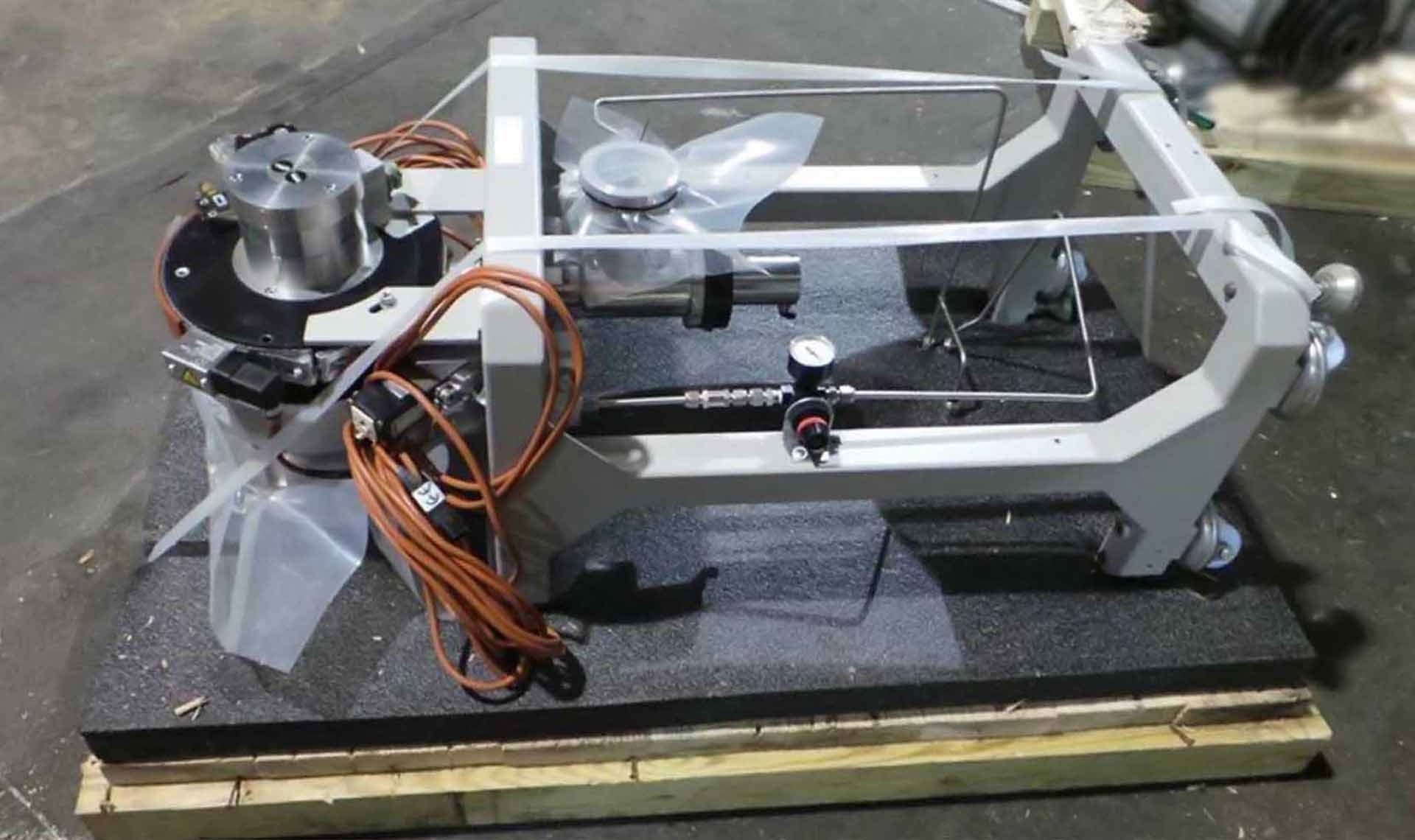

Vacuum load locks & transfer chamber

Roughing pump

(2) Load locks pumps

(2) Chamber pumps

THERMCO Chiller

BROOKS MX600 With (2) VCE

Operating system: Windows

1998 vintage.

STS / CPX Multiplex ICP (Inductively Coupled Plasma) is an advanced etch/ash option for the processing of thin-film structures. This equipment is designed to be highly efficient when patterning short, narrow lines (<15 microns) and etching materials such as Si, SiOx, and polyimides. This system is centered around a series of multiplexed power supplies that allow for precise control of multiple etch/ash chambers, each one managed by an intricate network of feedback loops. At the heart of the unit is the etching chamber, which is designed with a combination of transparent electrodes and dielectric films that control the RF energy delivered to the wafer surface. The chamber contains the inductively coupled components that form a plasma-like environment that is highly reactive to process materials. RF pulses are applied to the extended portion of the electrodes in the chamber for a precise amount of time, allowing ions to be formed from the reactants in the process mixture. The ions then interact with the wafer surface to cause etching. The chamber also contains a TiN-coated platen, which consists of two vertically aligned plates connected with an insulating material inside the chamber. This platen is used to mechanically hold the substrate in place while RF energy is applied to it, thus allowing better electrical contact between the substrate and the plasma. This platen is also used to heat the substrate, allowing the process temperature to be precisely controlled. In order to maintain optimal operating conditions, the etching chamber is equipped with several different sensors, including gas temperature, pressure, and chemical species sensors. These sensors allow feed-forward and feed-back control of the process parameters to ensure that all pieces of the substrate are exposed to the same environment. Finally, STS Multiplex ICP etching machine is highly versatile, allowing for the etching and/or ashing of almost any material with excellent repeatability. This makes it ideal for a variety of different processes, including thin-film patterning, photoresist etching, deep-through-silicon etching, and dielectric etching.

There are no reviews yet