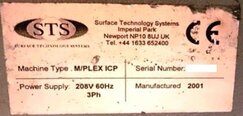

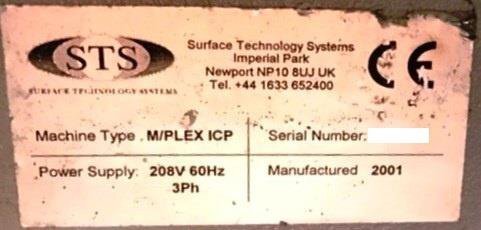

Used STS MACS ICP HR #9384086 for sale

URL successfully copied!

Tap to zoom

ID: 9384086

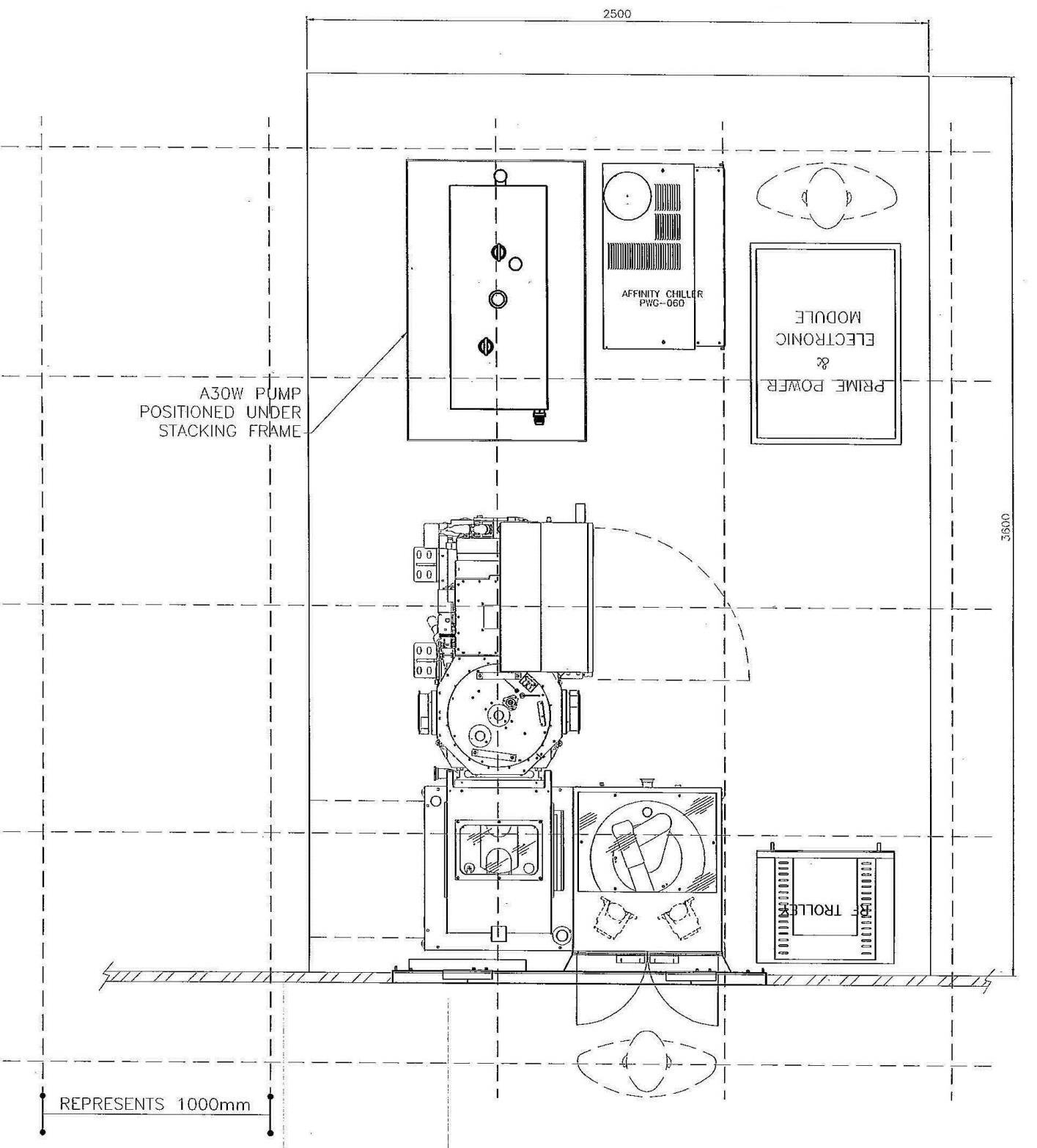

Wafer Size: 6"-8"

Vintage: 2001

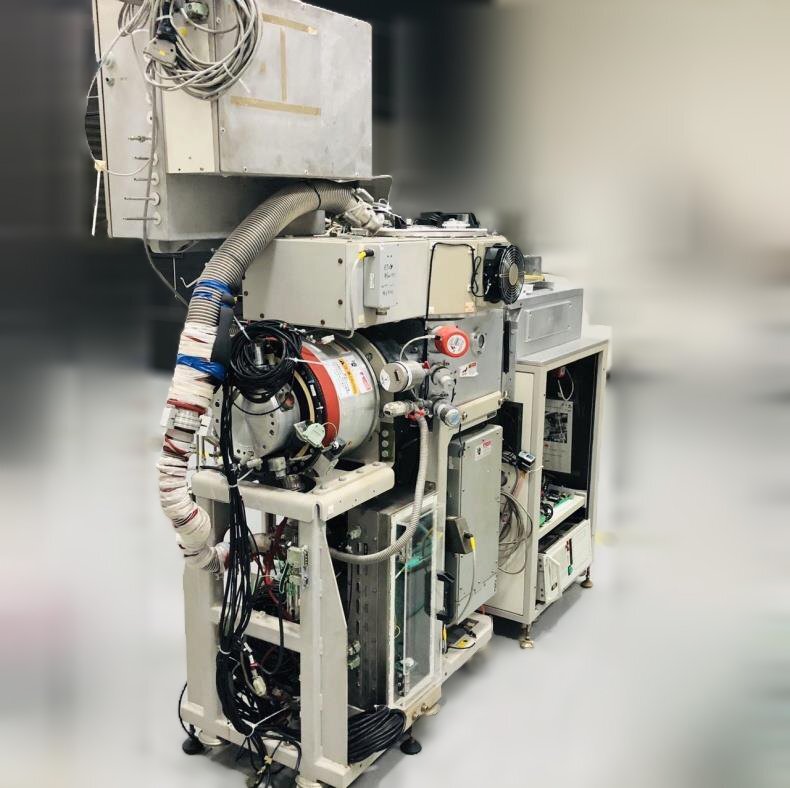

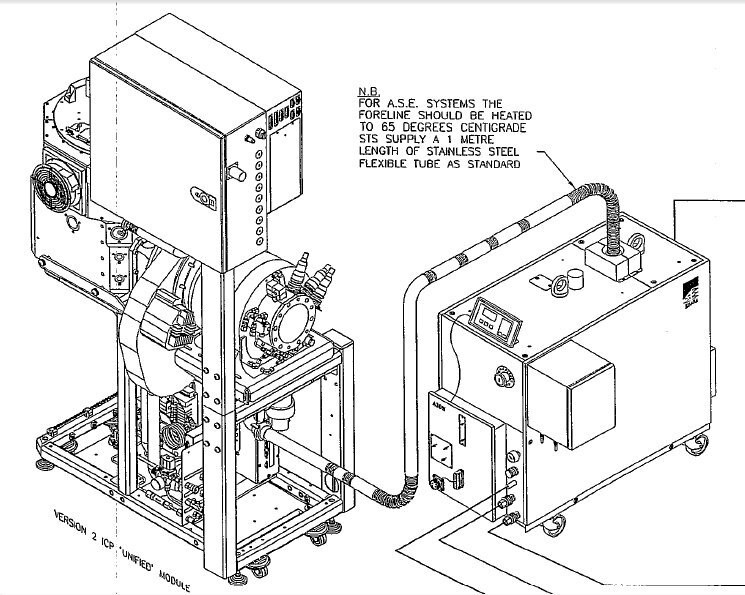

ICP Etcher, 6"-8"

Advanced Silicon Etch (ASE) with BOSCH process

HR Chamber for high rate etch

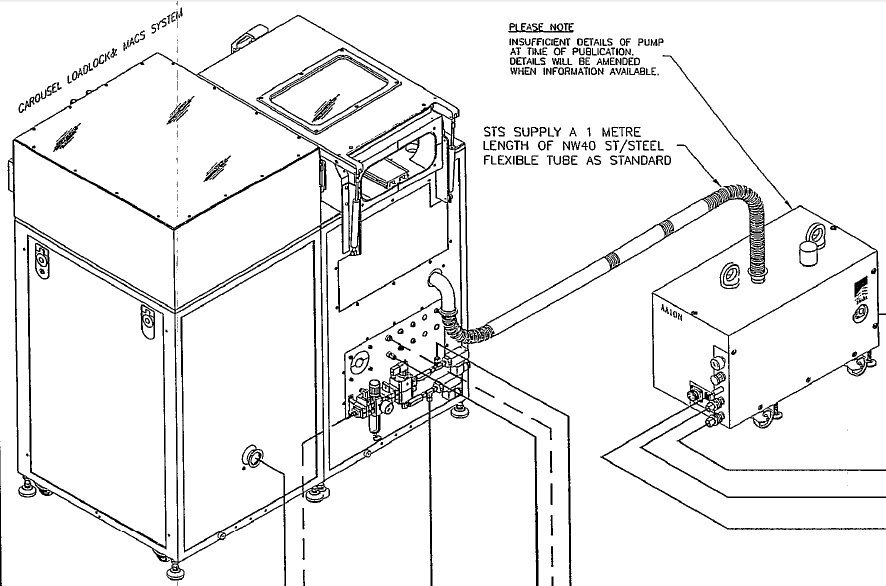

Carousel vacuum load lock

Helium Backside Cooling (HBC)

Clamp type: Standard WTC

MACs Loader for cassette to cassette operation ((2) Load stations)

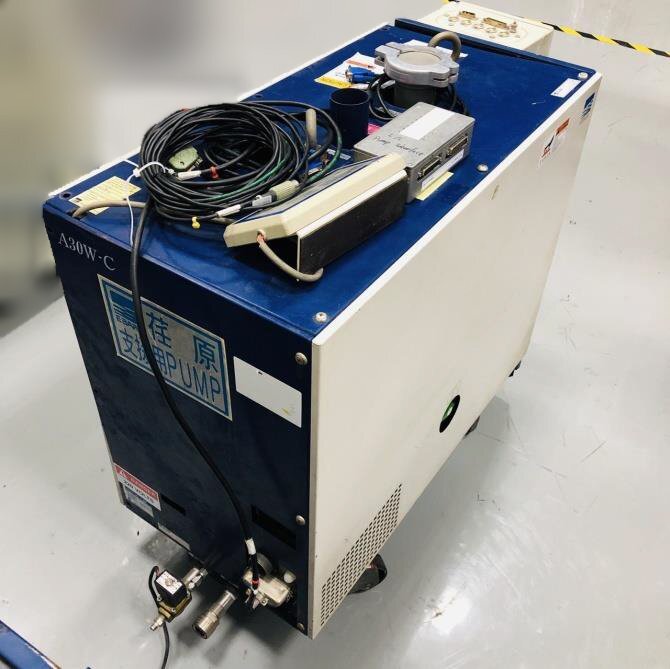

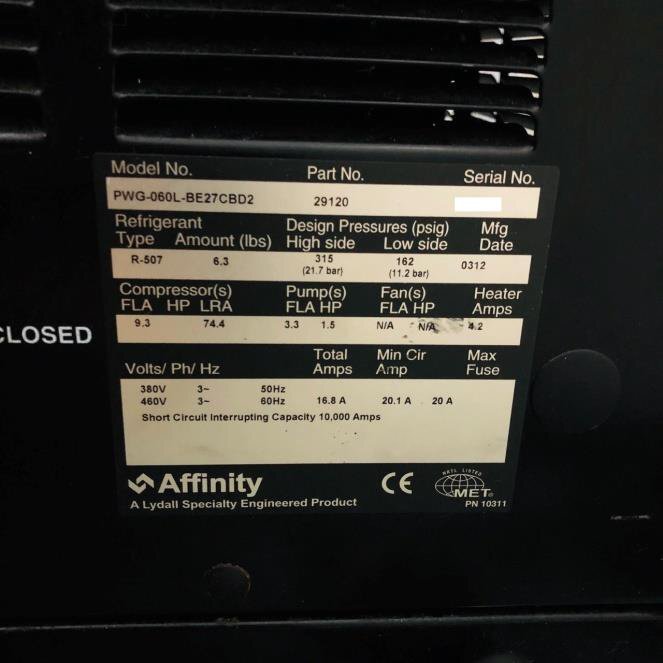

AFFINITY PWG-060L-BE27CBD2 Chiller

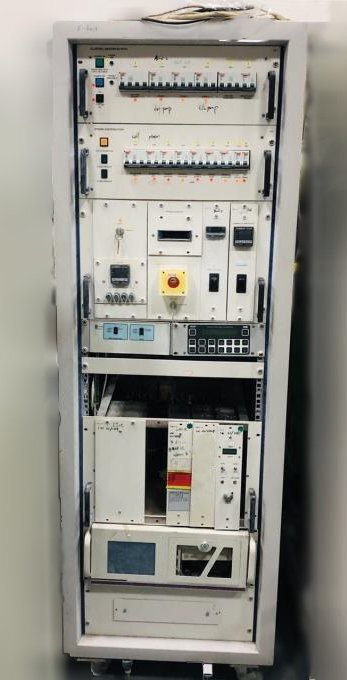

RF Generators:

ADVANCED ENERGY RFG3001 Coil RF power: 3 kW

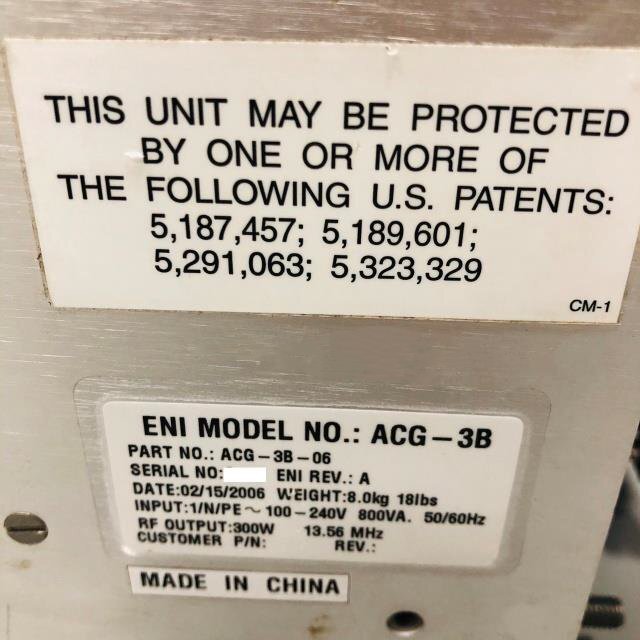

ENI ACG-3B Platen RF power: 13.56 MHz, 300 W

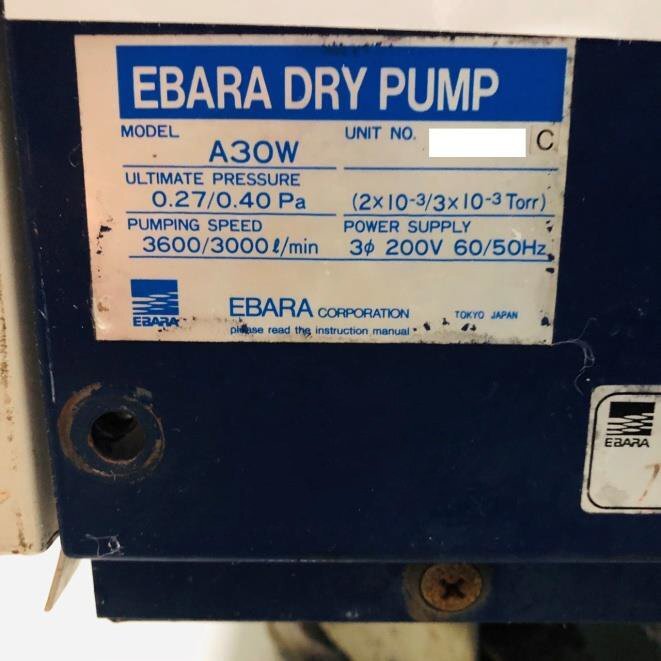

Vacuum system:

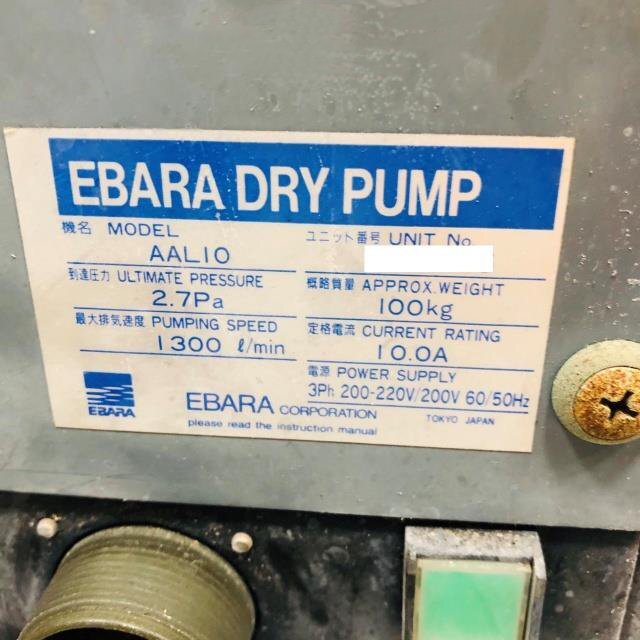

Load lock pump: EBARA AAL10

Chamber pump: EBARA A30W

Power: 208 V, 60 Hz ,40 Amps, Single phase

2001 vintage.

STS MACS ICP HR (Semi-automatic Chip Placement/High Resolution Asher) is an etching equipment designed to provide high-quality, high-volume fabrication of semiconductor chips. The system features a large oven which is used to melt and soften a variety of metals and materials, allowing for the accurate placement of a large, complex components on a single substrate. The etching is done using a process known as Inductively Coupled Plasma-High Resolution (ICP-HR). This process works by propogating a wave of high energy electrons from the plasma etch source to the substrate surface. The plasma energy acts to interact with the substrate material to cause changes in the physical structure, such as etching out specific patterns or etching in lines for printed circuit boards. The ICP-HR process ensures a higher etch rate and improved yields in the final product. This is particularly useful when producing complex components, which require higher precision and accuracy than what traditional etch techniques can provide. The process begins by loading the atmospheric argon gas into the etcher, which is then heated to a set pressure based on the material being placed. The etching source is placed on the substrate material and adjusted to regulate the power of the electrons being delivered from the source. The etch is then regulated using a number of parameters, such as temperature, pressure, and etch rate, to ensure the precision of the etch. Once the desired characteristics have been set, the substrate is placed into the oven and the etch occurs. The etch ends when the desired etch depth is achieved. MACS ICP HR is capable of completing up to 900 parts per hour with a high degree of accuracy, providing instant feedback on part production so any necessary adjustments can be made. The unit also features automatic temperature control and pressure regulation, providing a consistent etching process throughout the entire production run. Overall, STS MACS ICP HR etcher is an ideal machine for high-volume, high-precision production of semiconductor chips. It is reliable, efficient, and capable of producing a high-quality end product. As a result, it has become a popular choice for many chipmakers, offering a superior level of accuracy and reliability for complex chip designs.

There are no reviews yet