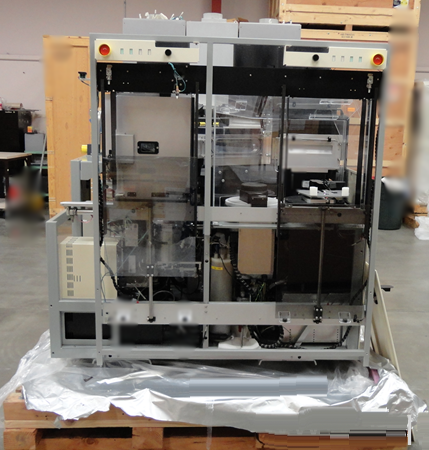

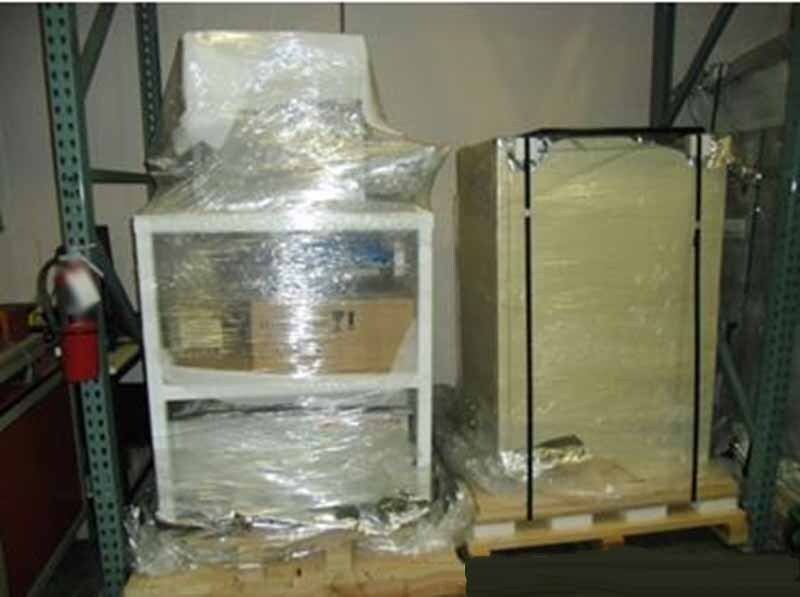

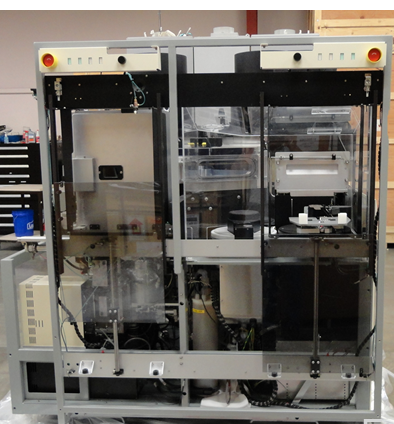

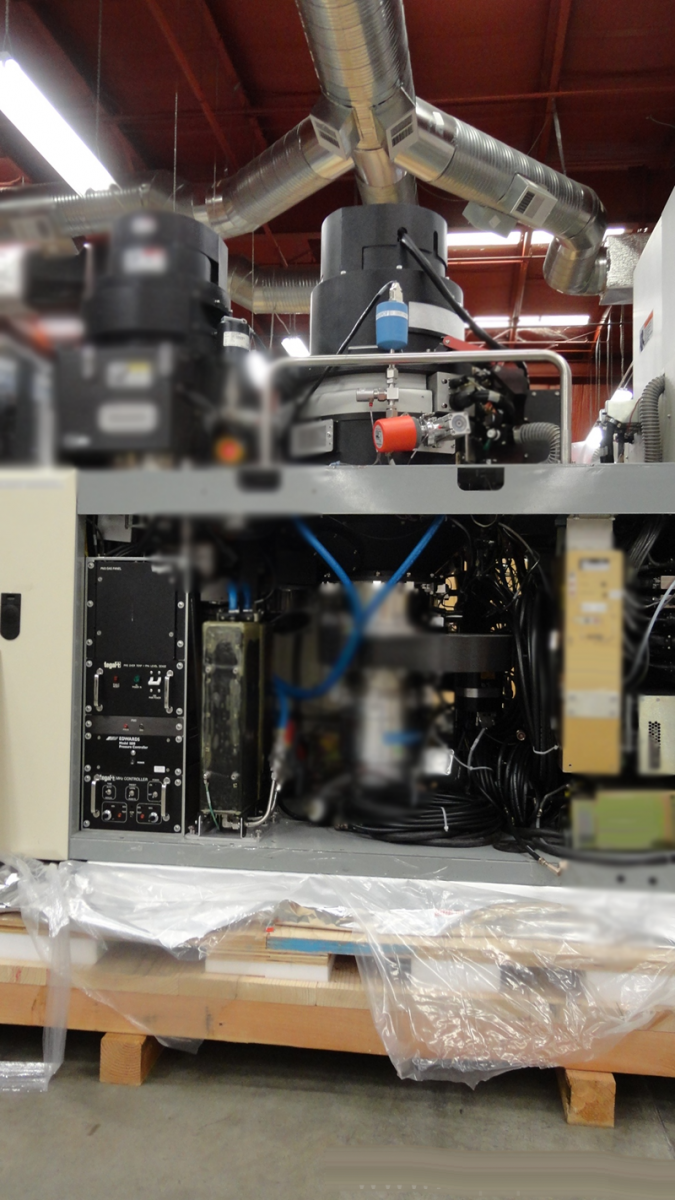

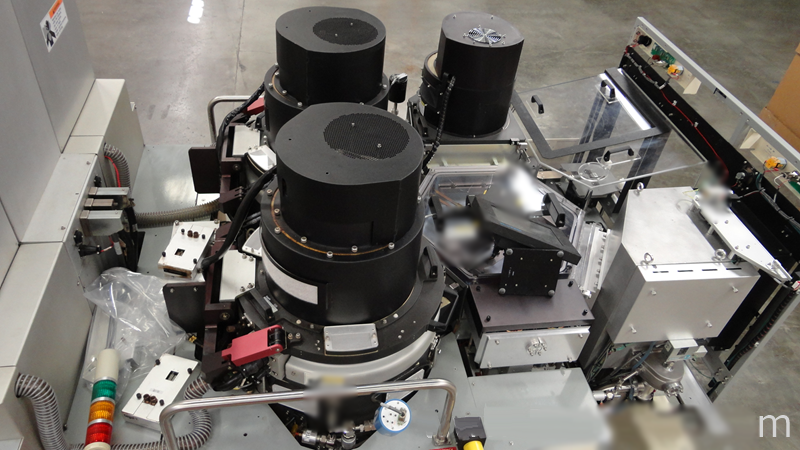

Used TEGAL 6550 #9155217 for sale

URL successfully copied!

Tap to zoom

ID: 9155217

Wafer Size: 8"

Vintage: 2003

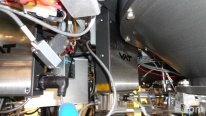

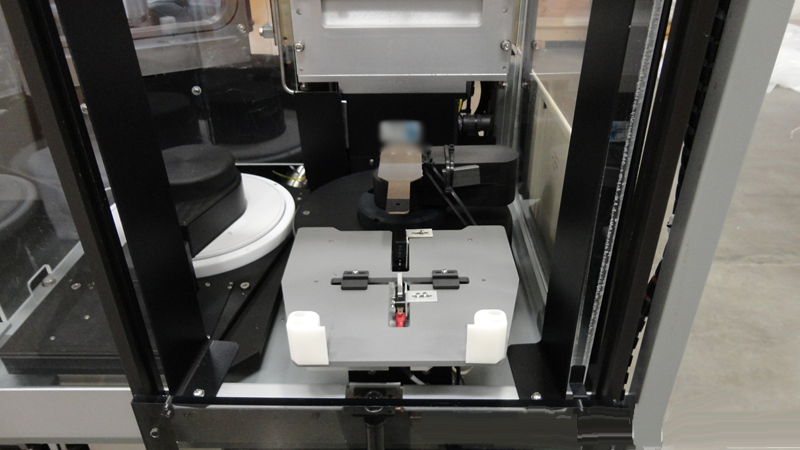

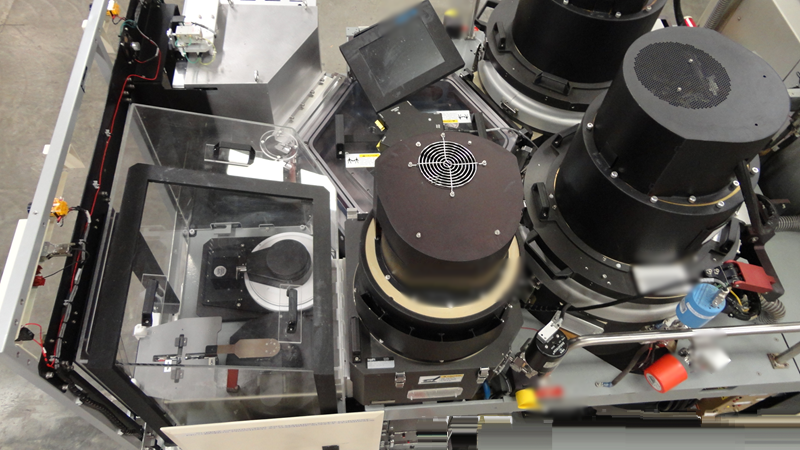

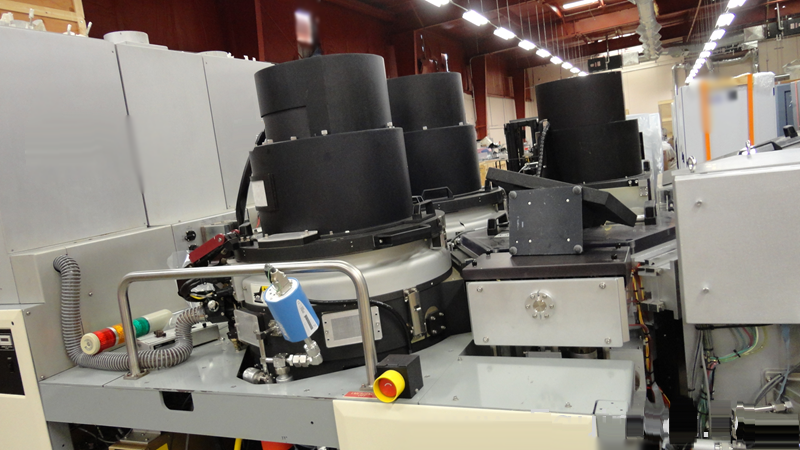

Reactive Ion Etcher (RIE) system, 8"

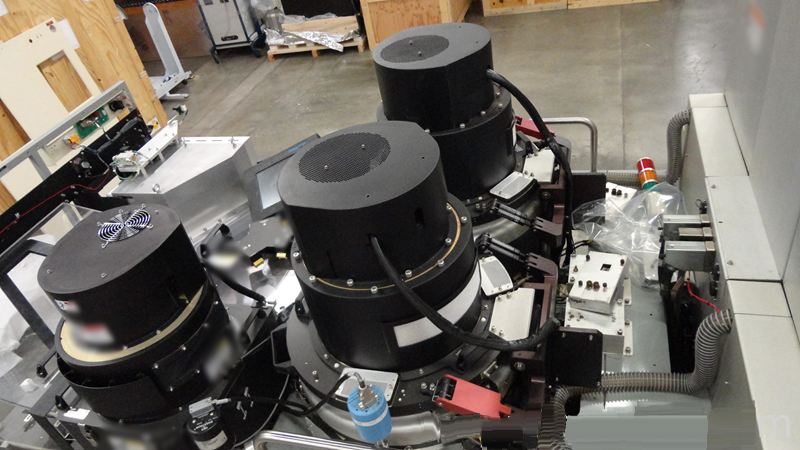

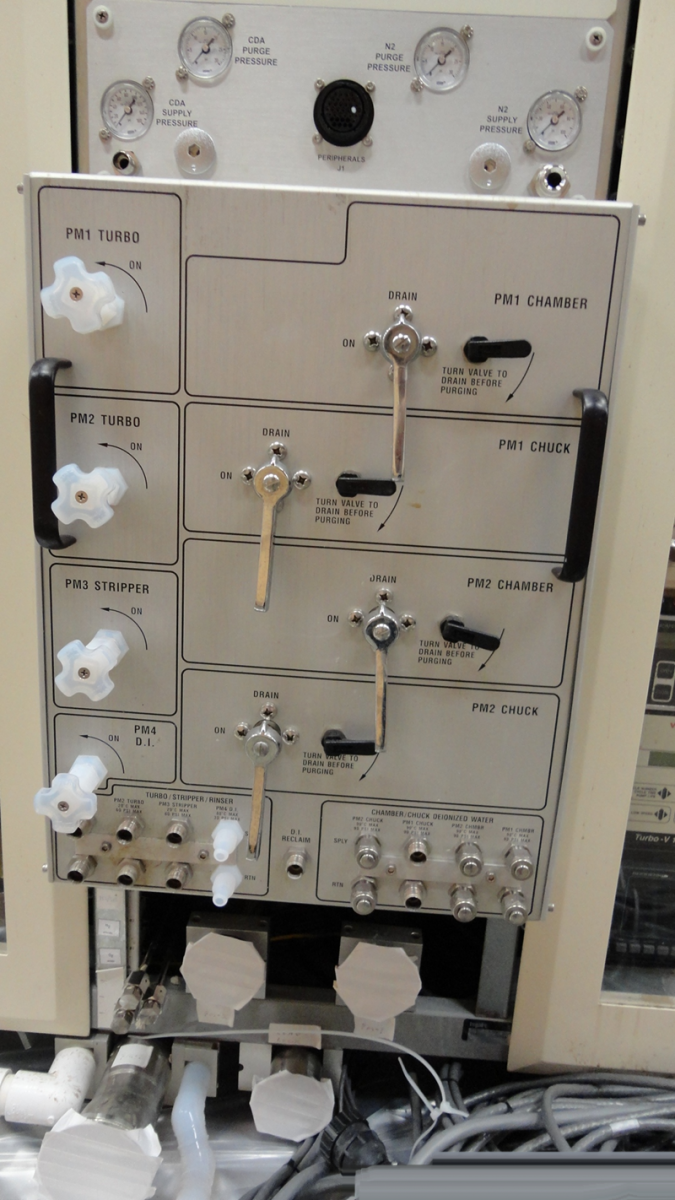

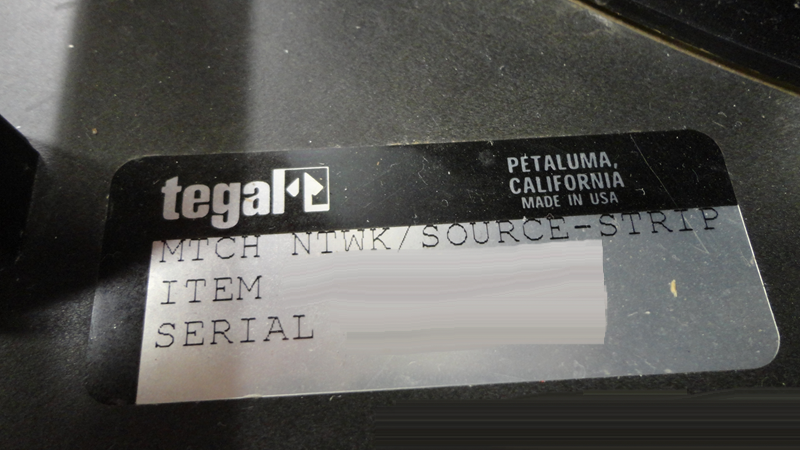

Platform: Rinse / Strip, through-the-wall, signal tower

PDM: Standard

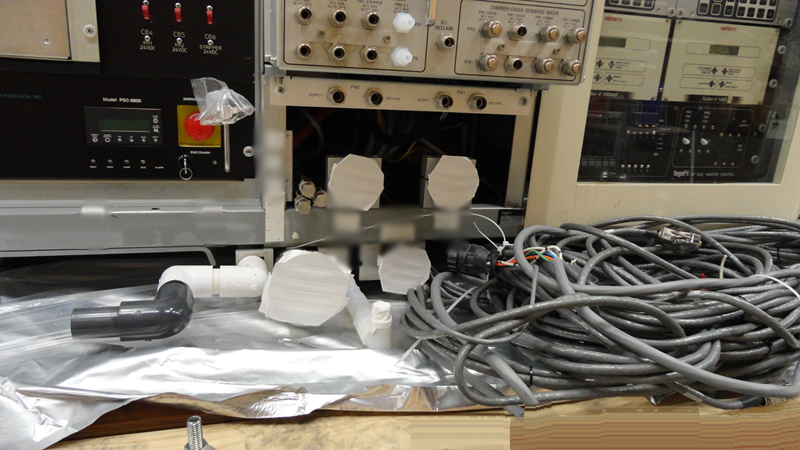

System includes:

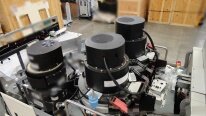

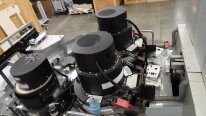

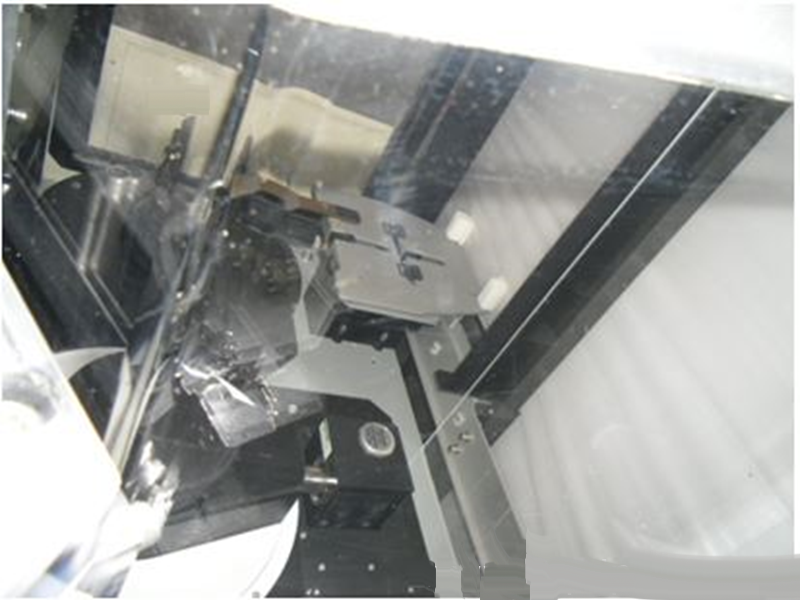

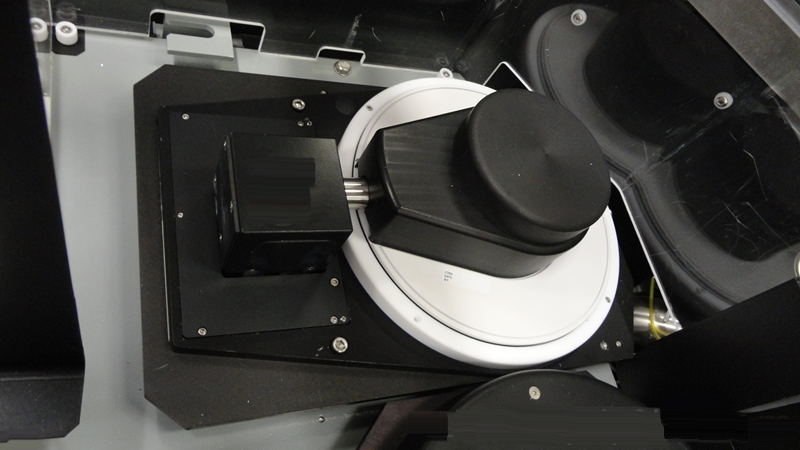

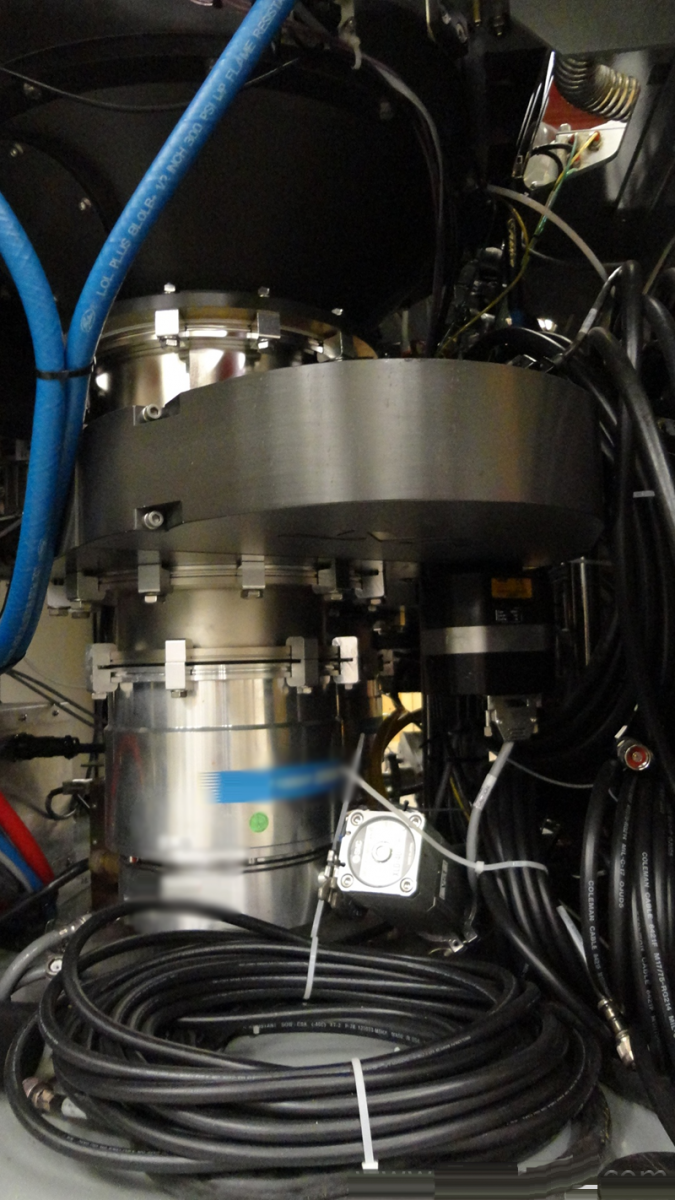

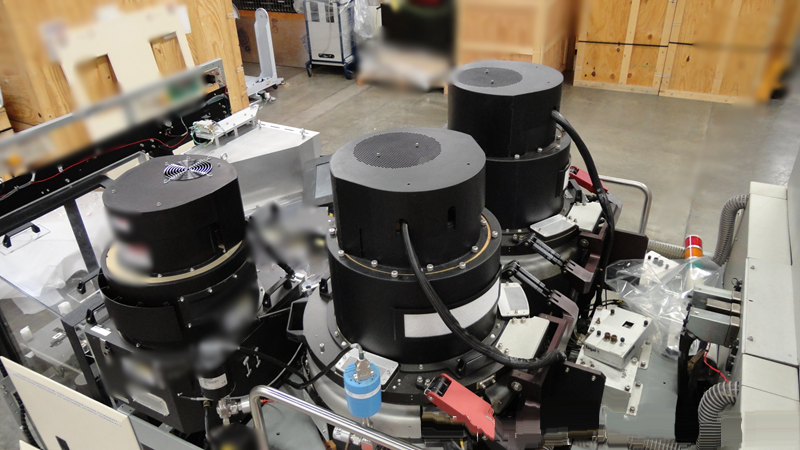

(2) Patented spectra plasma process modules

Standard ceramic electrostatic clamp (200 mm)

High temperature electrostatic clamp (200 mm)

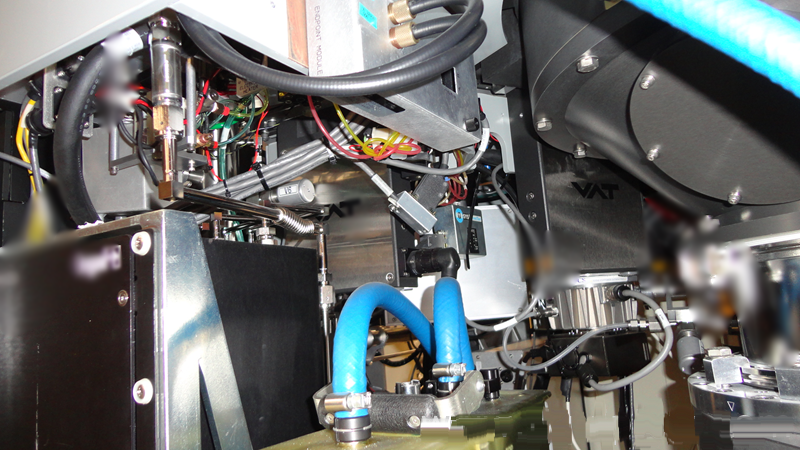

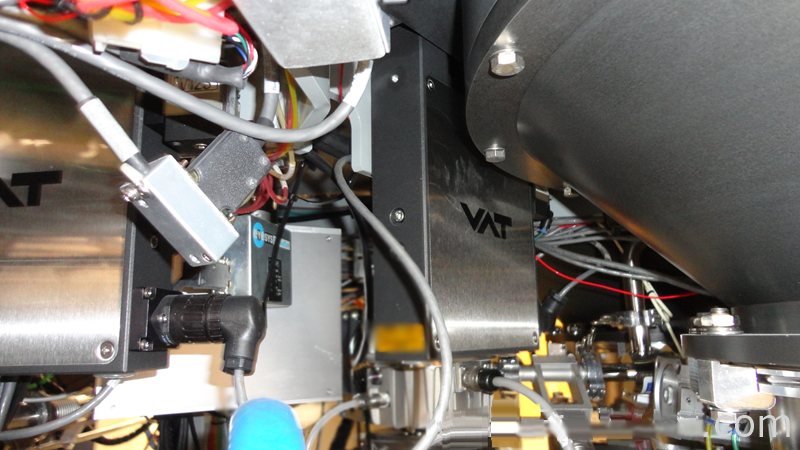

(2) Integrated diode array optical analyzers

(2) Recirculating temperature control units

Vacuum cassette elevator loadlock

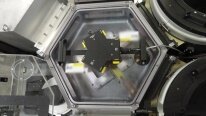

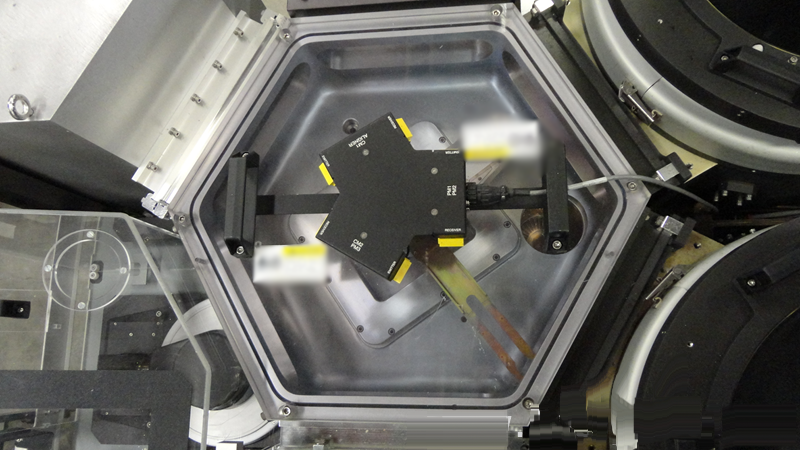

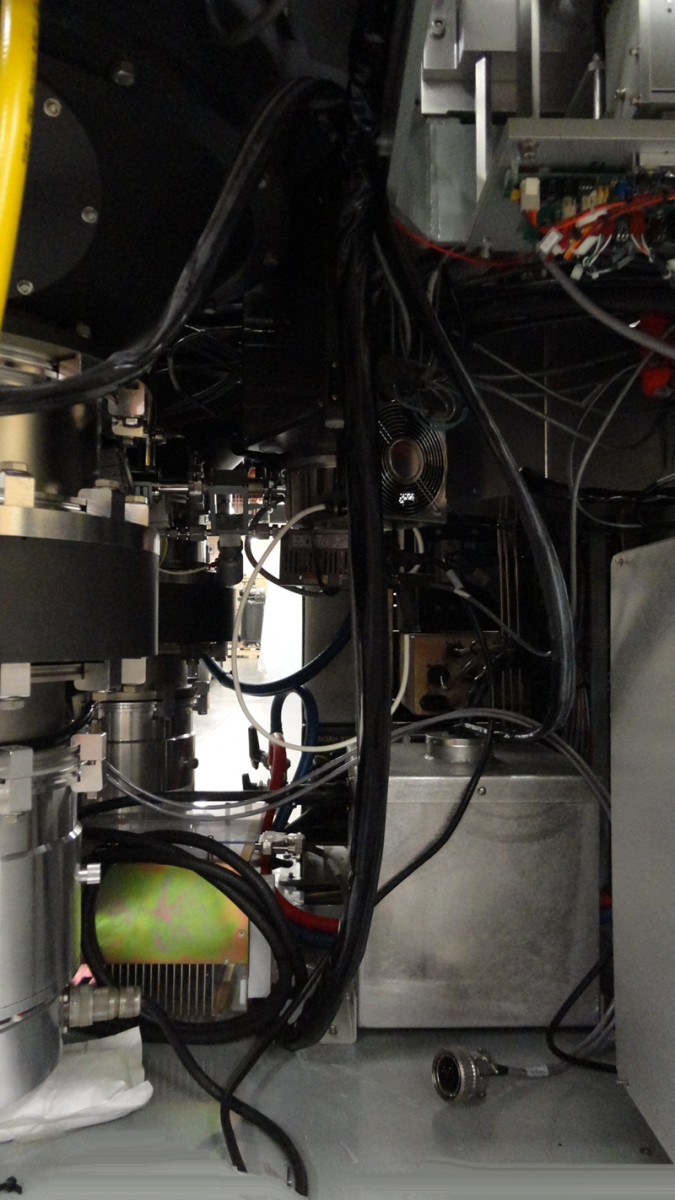

Core vacuum transport module with robot

Wafer aligner module

ICP Strip process module

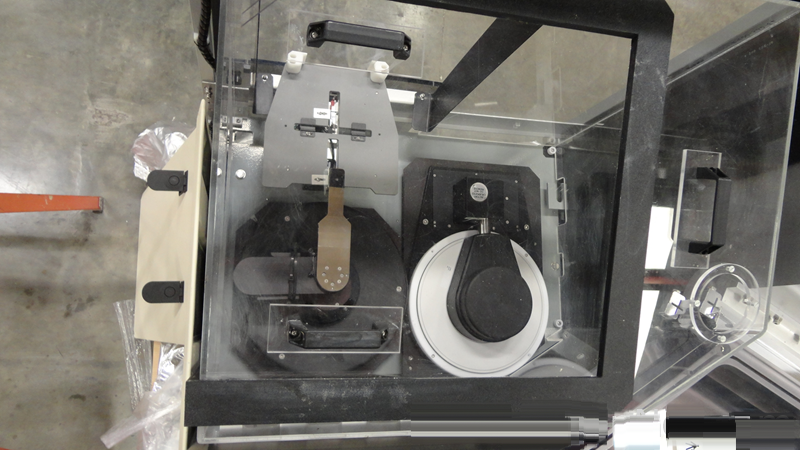

Spin rinse / Dry process module

Atmospheric transport module with robot

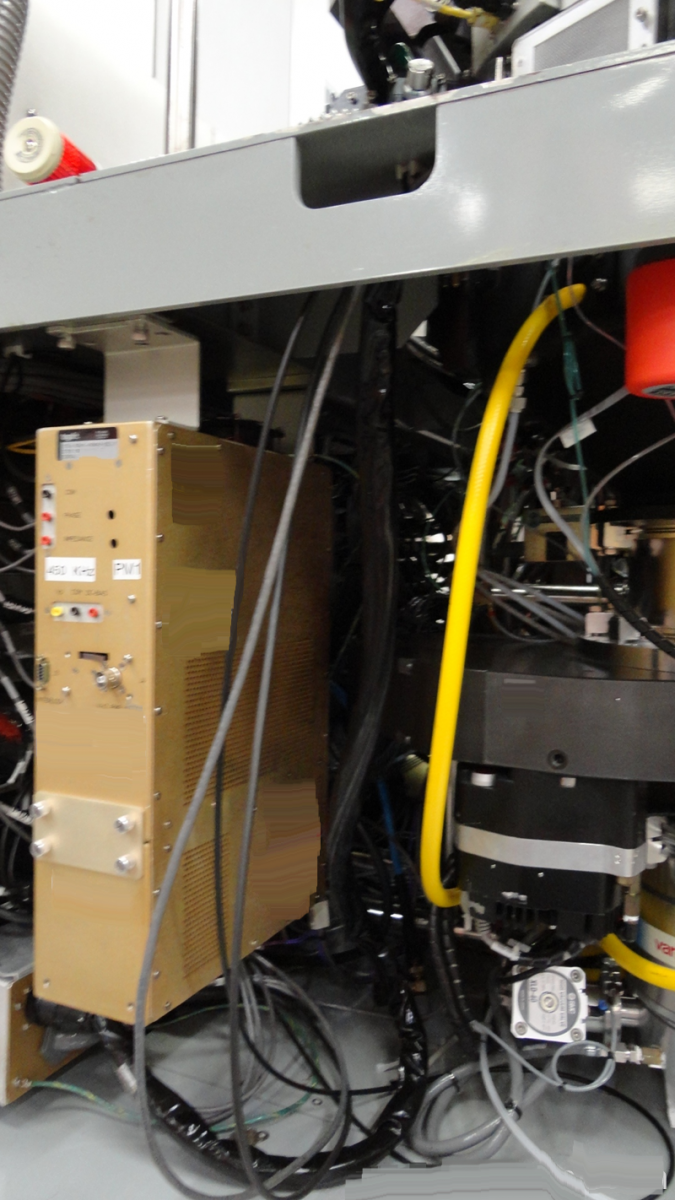

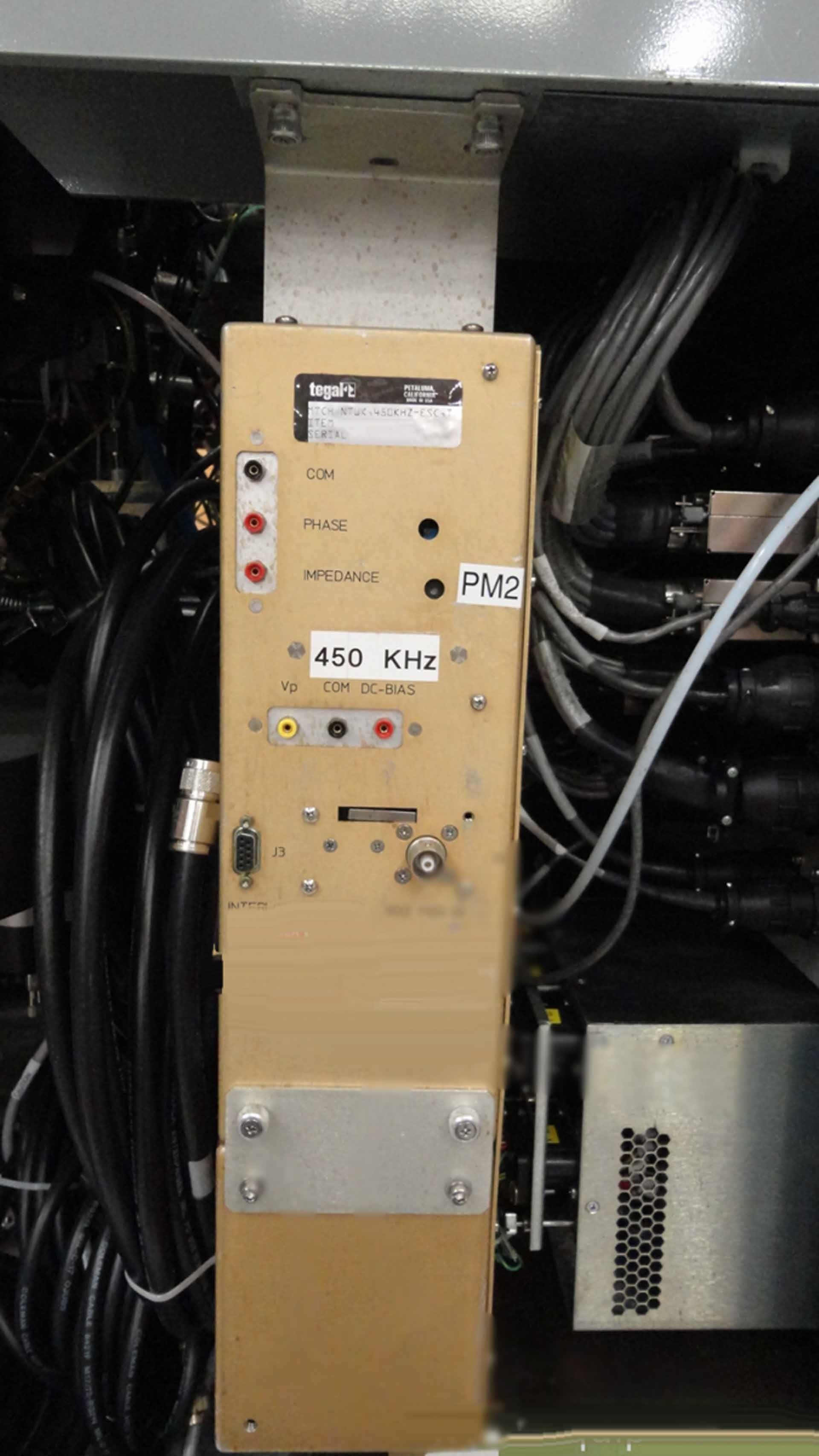

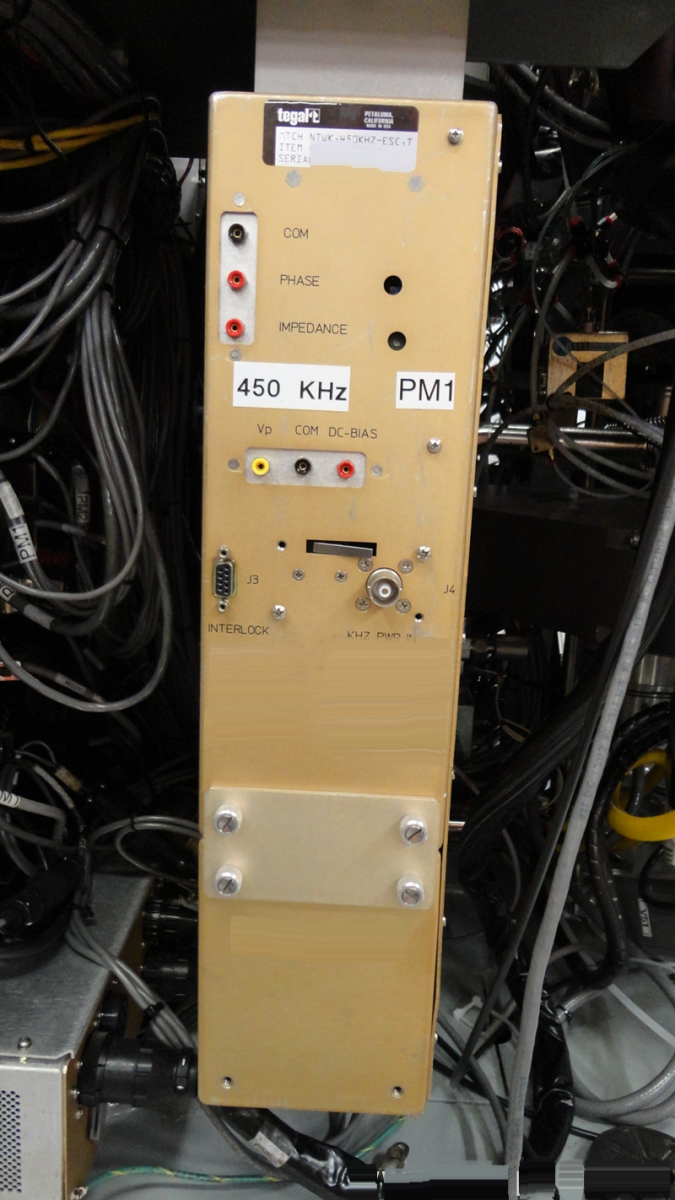

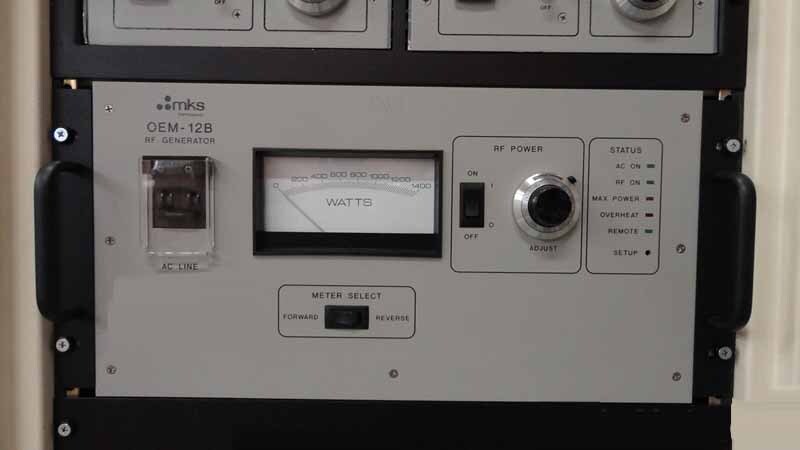

Remote RF generator cabinet

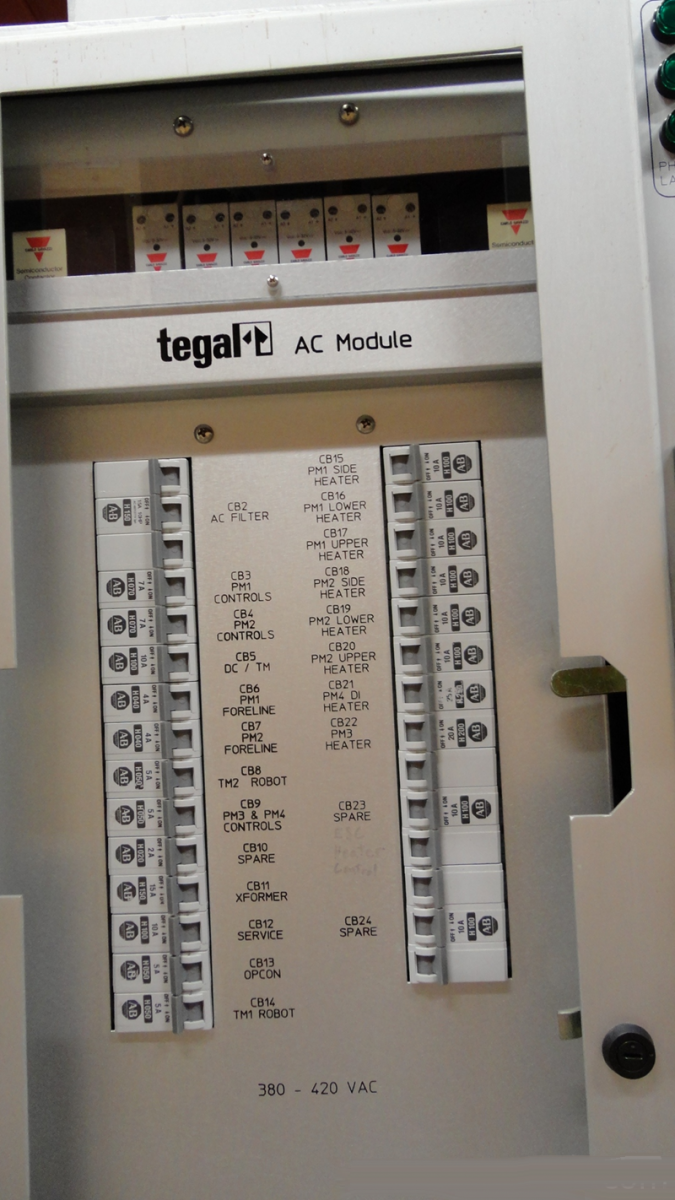

Remote power distribution module

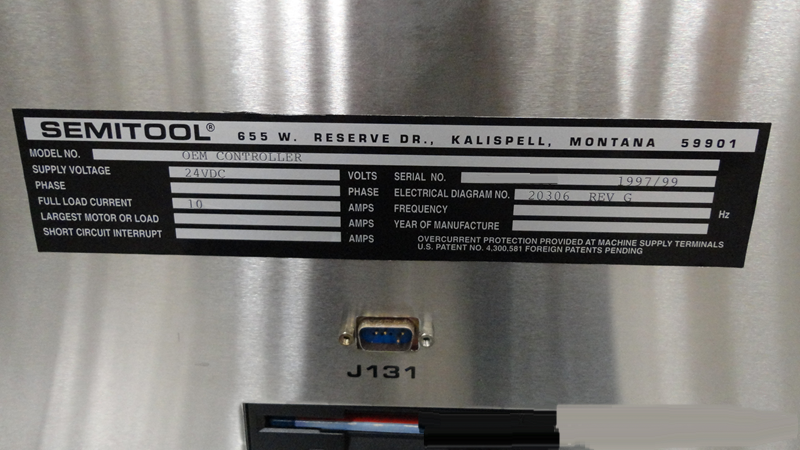

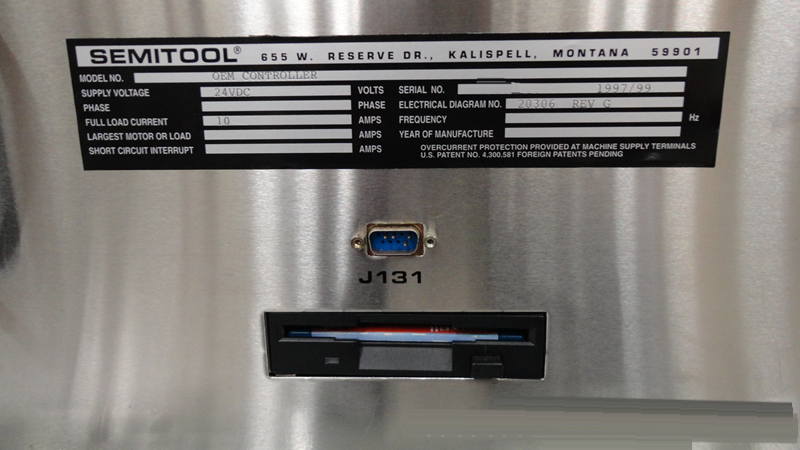

Integrated human interface and control system

Remote LCD interface module

Cleanroom signal tower (3 Color standard)

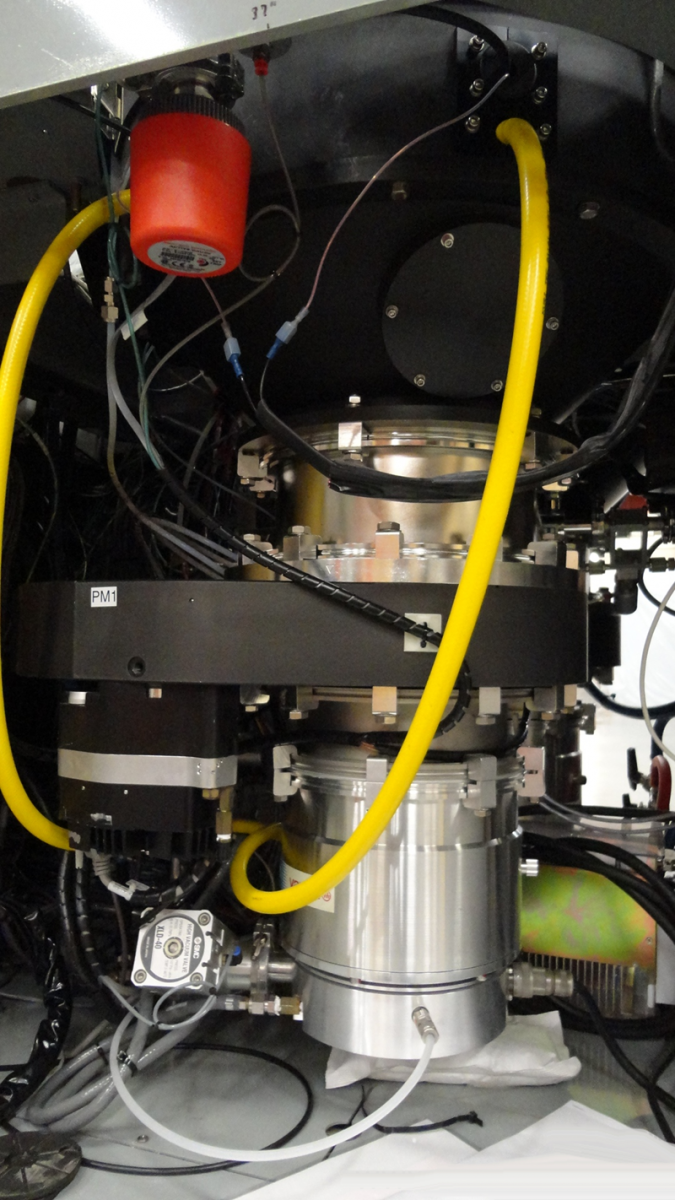

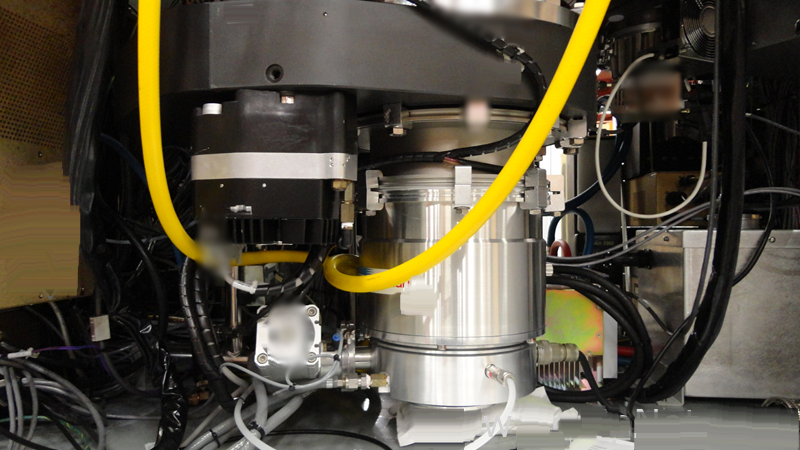

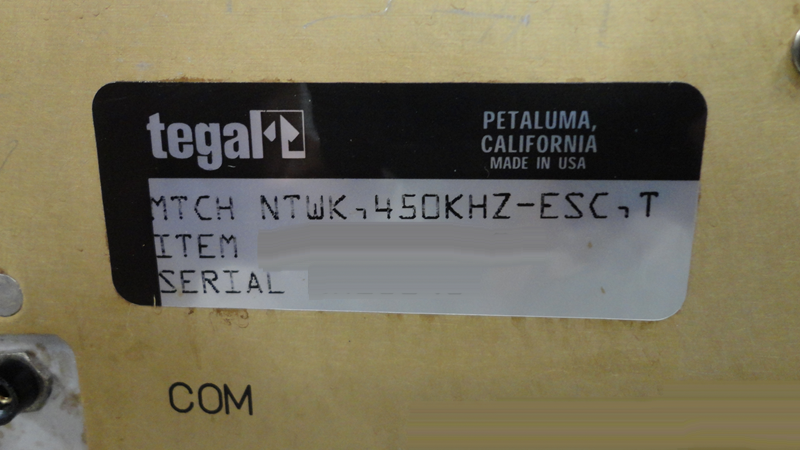

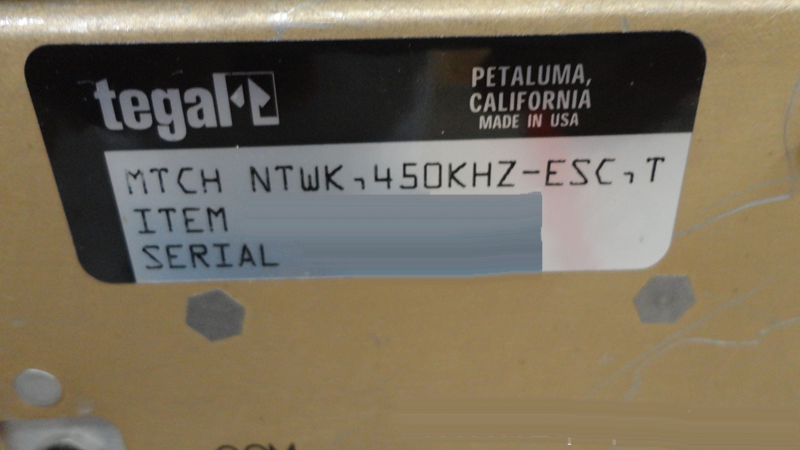

PM 1: Spectra 1.0, Special HT-ESC

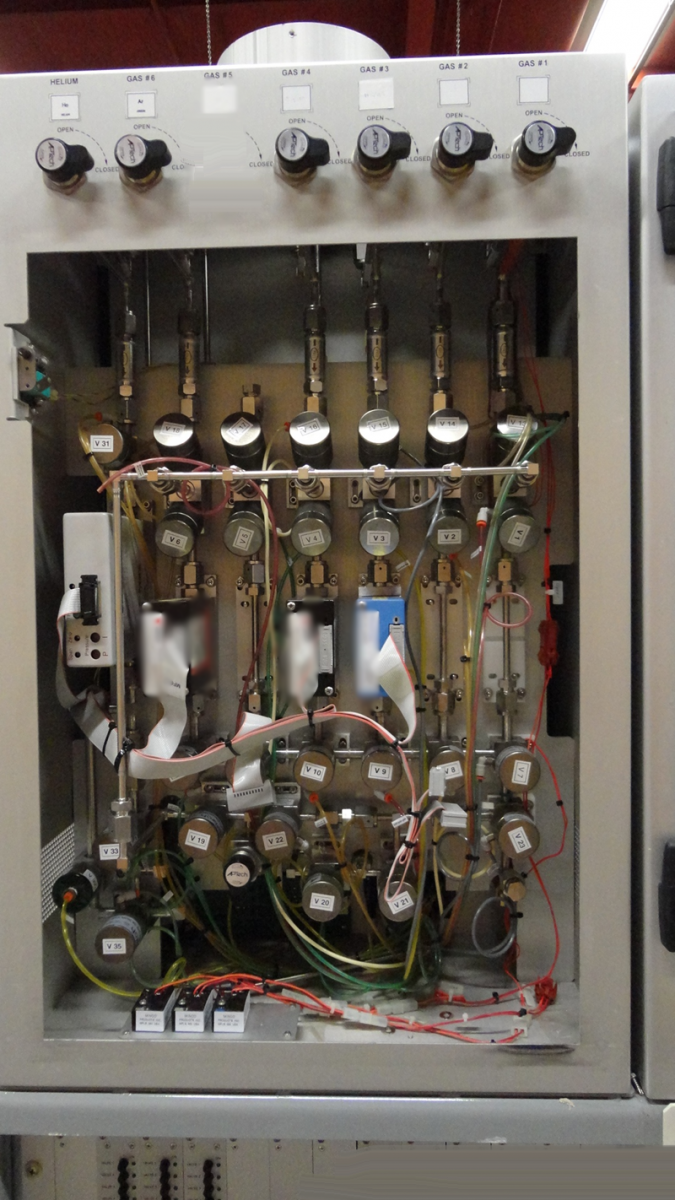

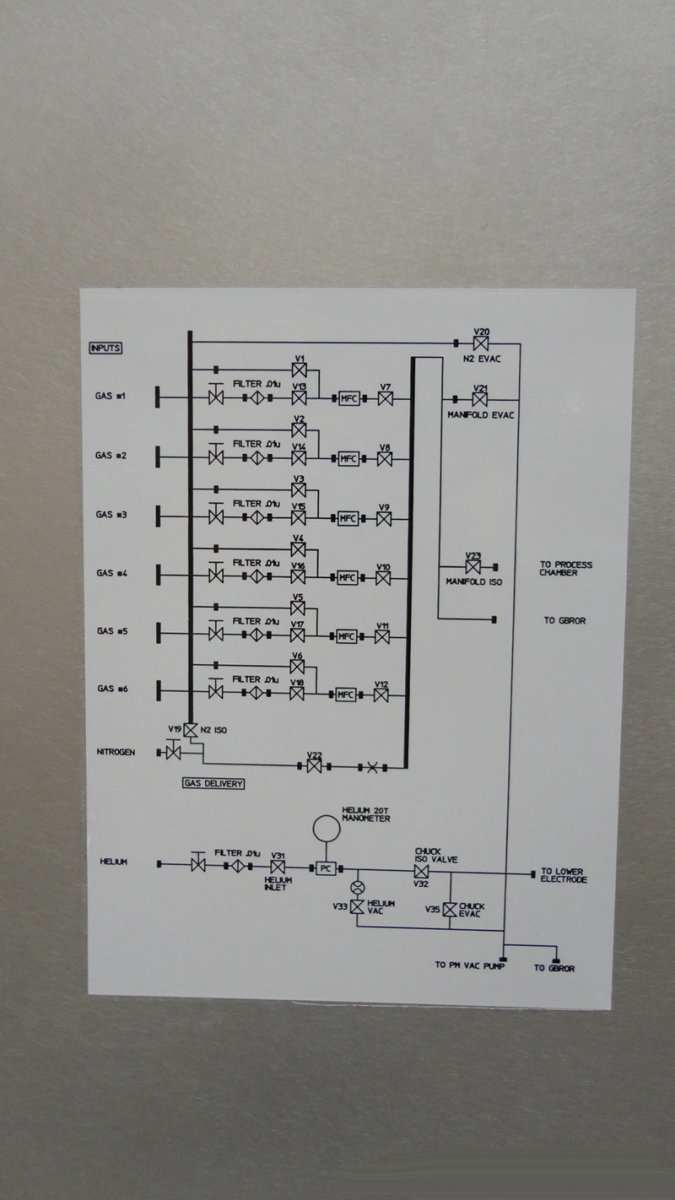

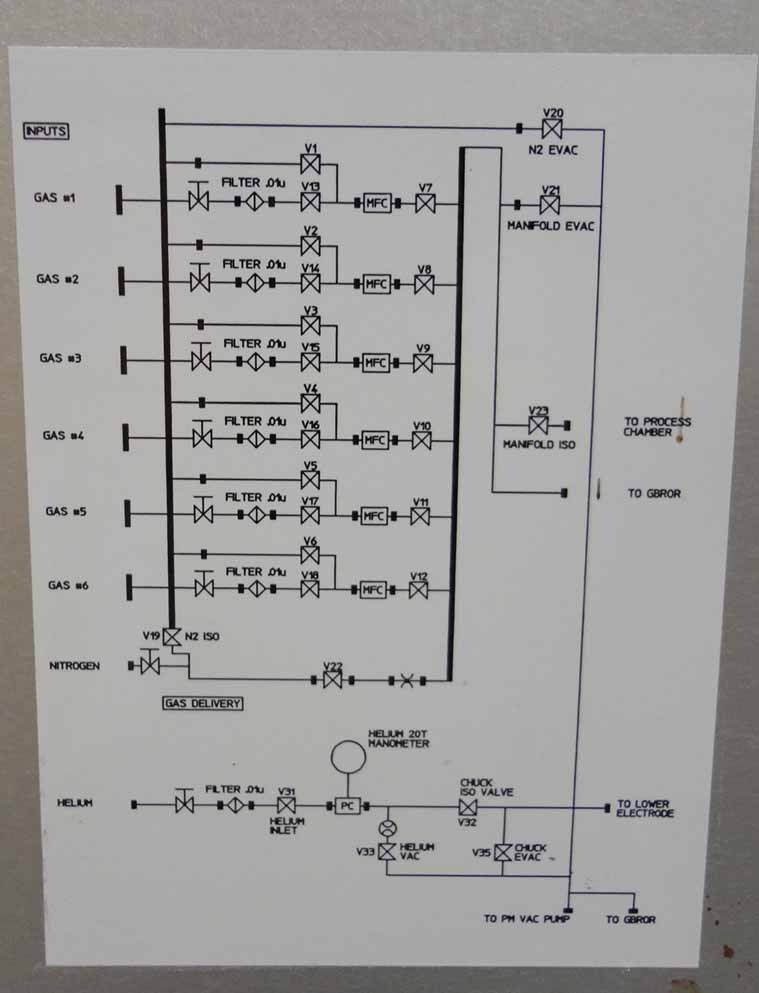

MFC Type: MYKROLIS TYLAN FC2900

Gas 1: BCl3, 0-200sccm

Gas 2: Cl2, 0-50sccm

Gas 3: SF6, 0-50sccm

Gas 4: HBr, 0-50sccm

Gas 5: CF4, 0-50sccm

Gas 6: Ar, 0-200sccm

Gas 7: He (Water temperature control)

LF Generator: 600 watts

HF Generator: 1200 watts

Gas injection: Open ring

PM Turbo pump: 1000L/s

End point: Diode array

LE Temp range: Filtered house cooling water

PM 2: Spectra, special high vacuum mod's

MFC Type: MYKROLIS TYLAN FC2900

Gas 1: Spare

Gas 2: Spare

Gas 3: He, 0-200sccm

Gas 4: Spare

Gas 5: Ar, 0-100+sccm

Gas 6: Ar, 0-500+sccm

Gas 7: He (Water temperature control)

LF Generator: 300 watts

HF Generator: 1200 watts

Gas injection: Open ring

PM Turbo pump: 1000L/s

End point: Diode array

LE Temperature range: Noah precision: GALDEN PFPE HT170

PM 3: ICP Strip module

MFC Type: MILLIPORE TYLAN 2900

Gas 1: O2, 0-2000sccm

Gas 2: N2, 0-500sccm

Gas 3: He, 0-500sccm

PM4: DI Water rinse module

Gas 3: PM3 (strip)

Gas 4: PM2 (etch)

Gas 5: PM2 (etch)

Chambers:

ICP Cl2 / CFxHy Etch chamber (primary etch chamber)

ICP Low-voltage Ar mill "SOM"

Anti-corrosion treatment used with He / H2 or N2 / H2

Anti-corrosion water rinser

O2-Based asher

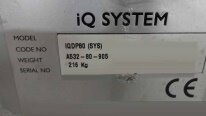

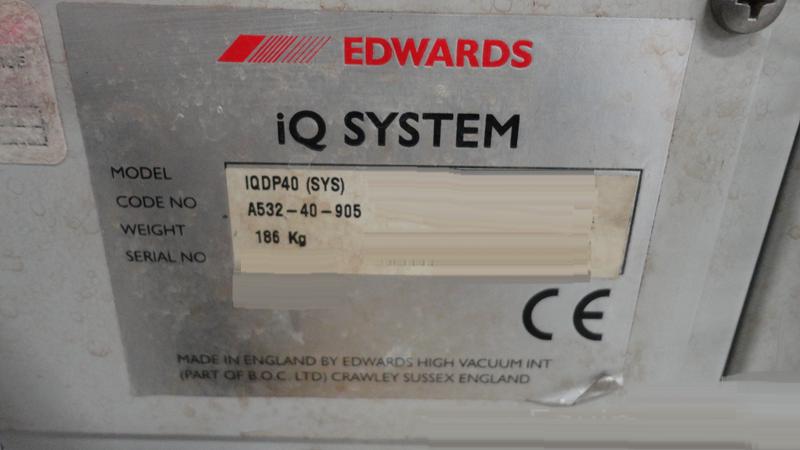

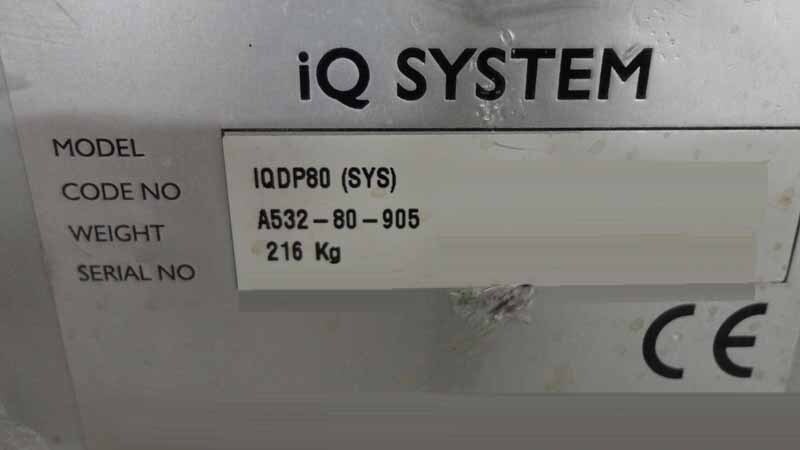

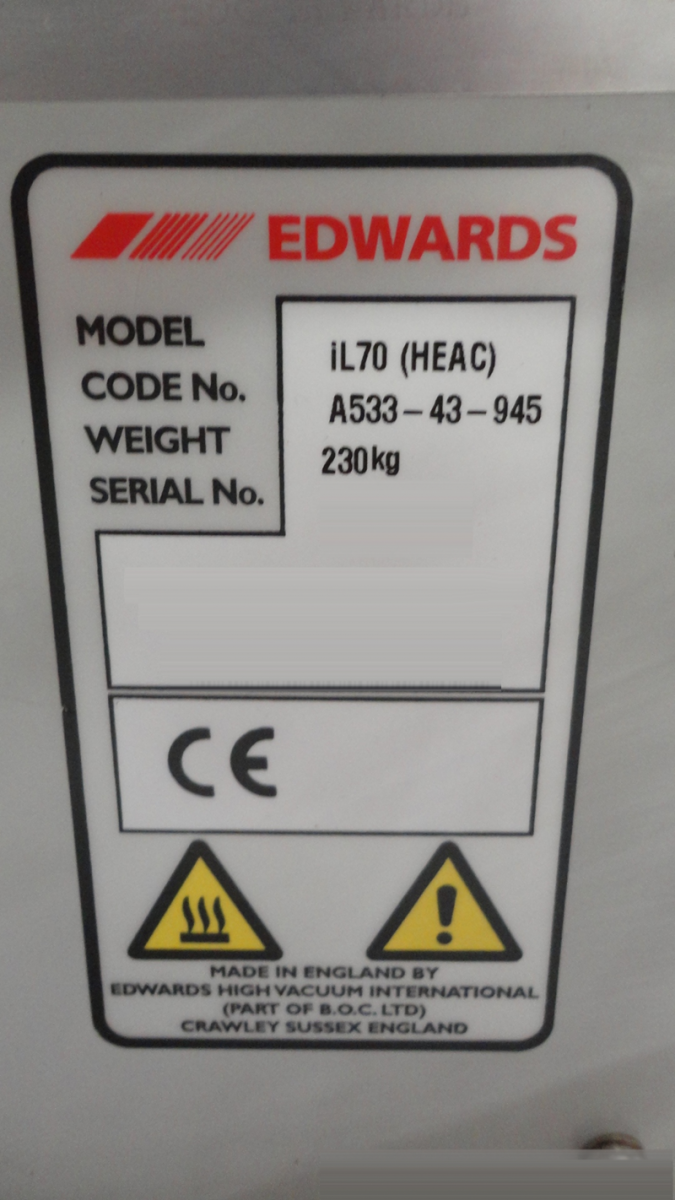

EDWARDS QDP-40,80

Gas reactor column EDWARDS M150

CE Marked

AC Supply: 400 V, 3 Phase, 50 Hz, 5 wire

2003 vintage.

TEGAL 6550 is an etcher/asher, designed for both frontside and backside wafer processing. This system offers a highly efficient and cost effective way of creating 3-dimensional patterns within the substrate layer. 6550 enables highly selective processing, utilizing both dry and wet etching. The etcher/asher features a 3-dimensional field of view within the substrate, creating precise patterns without causing any physical distortion of the layer. It also features a 6-position high-resolution mechanical shift, which is ideal for automatic and manual alignment. TEGAL 6550 has an adjustable speed for the substrate shift rate, as well as a laser scanning system for tracking wider patterns. The etcher/asher utilizes an advanced computer-controlled platform, with networking capabilities available for integration into other systems. In addition, 6550 is equipped with a built-in software package for performing different etching tasks. This package is user-friendly and intuitive, making it easy for users to understand and optimize the etching procedure. TEGAL 6550 comes with a wide variety of components, including driver boards, power supplies, and cooling systems. It also offers an integrated, isolated RF generator to boost the throughput of the etch process. This feature ensures the maximum level of control over the etching process. 6550 also features a number of advanced safety features, including an automatic power-off feature, which turns the system off when not in use, as well as a built-in ETCHER security switch which enables access to only approved users. All in all, TEGAL 6550 is an advanced etcher/asher designed for high-precision substrate processing. It is highly reliable and cost-effective, and comes with all the features needed for precise and accurate etching.

There are no reviews yet