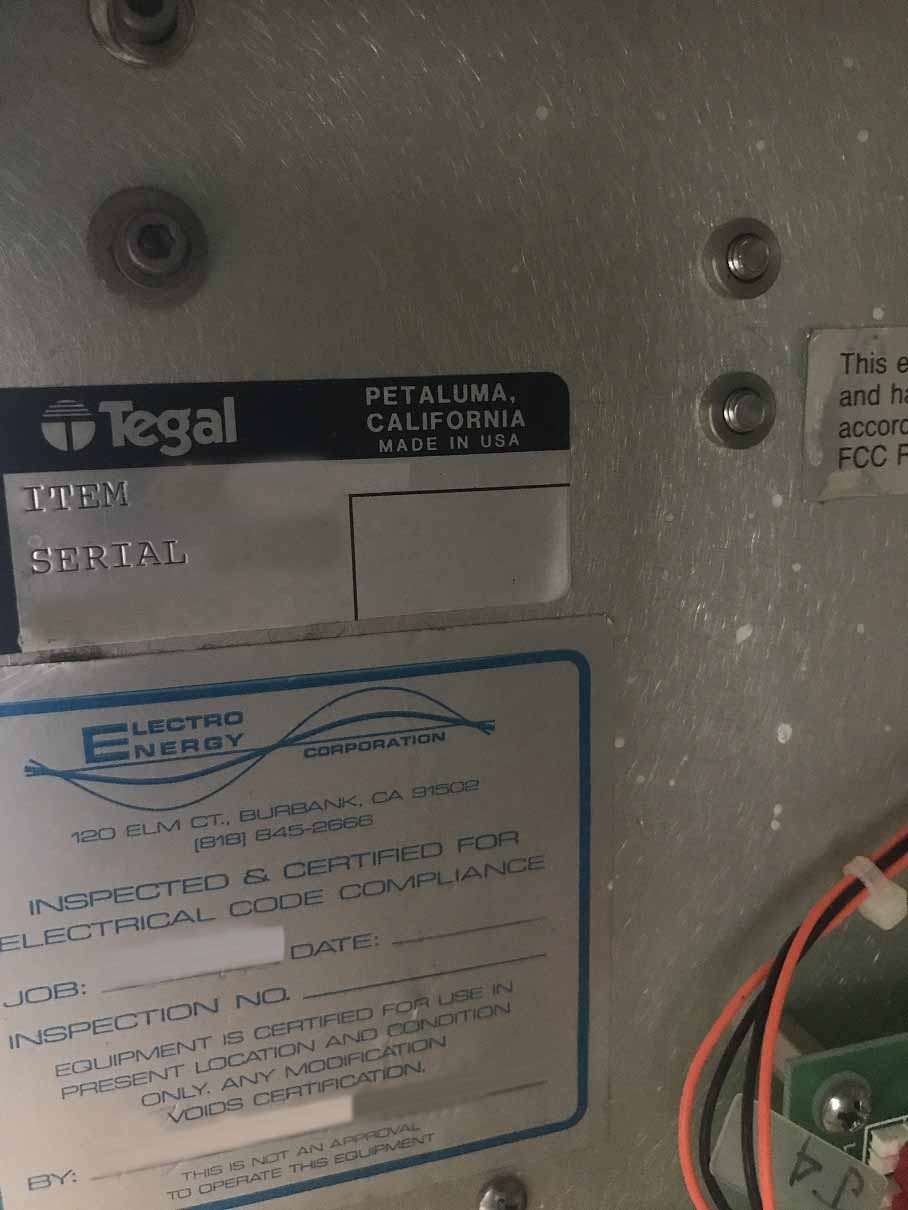

Used TEGAL 901e TTW #9248952 for sale

URL successfully copied!

Tap to zoom

ID: 9248952

Wafer Size: 5"

System, 5"

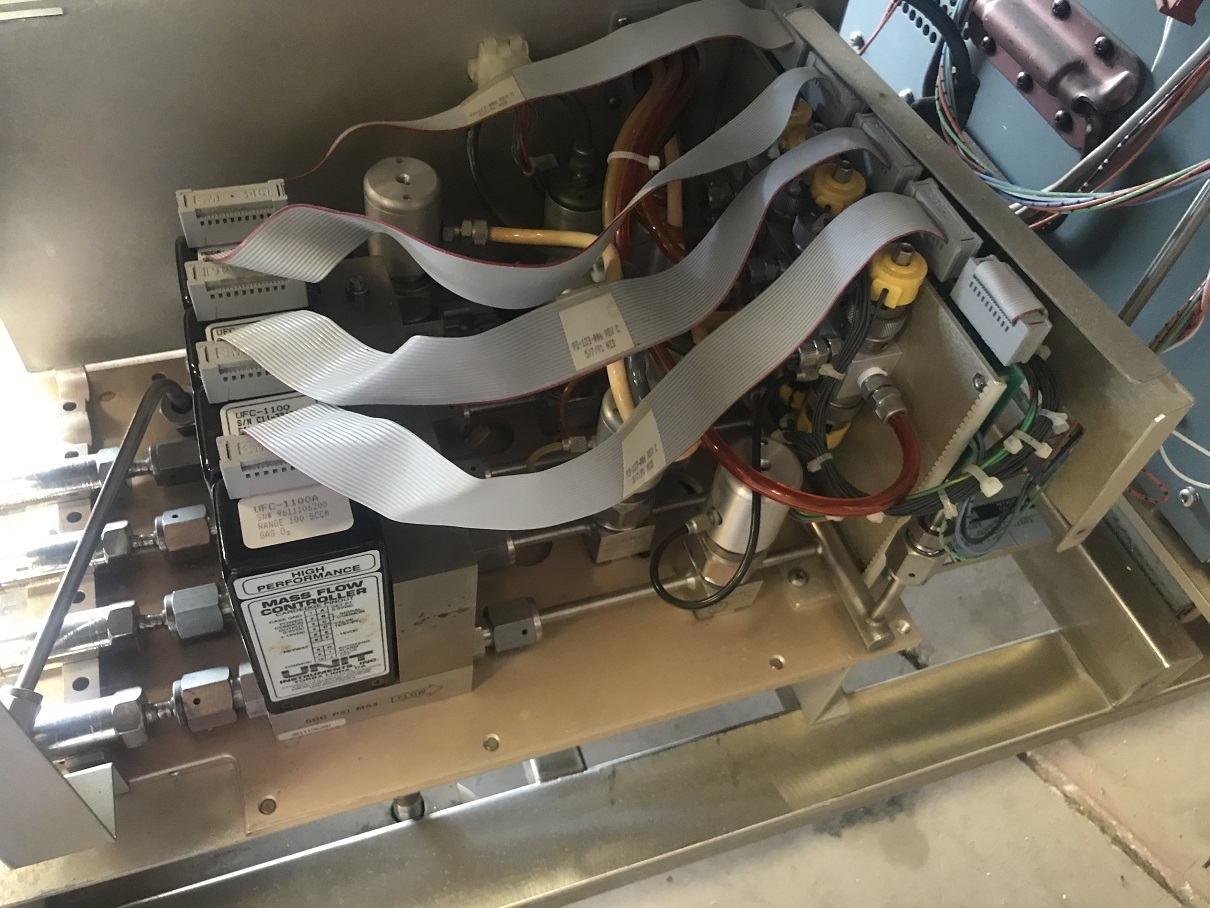

Missing parts:

Process chamber

Lower chuck

Shuttle assy

Sender and receiver modules

AC Module

Dacscan controller

Matching network.

TEGAL 901e TTW is an etcher/asher that is designed for etching and alloying of small wafers and substrates. It offers single-chamber processing that supports thermal processes such as RTP (Rapid Thermal Processing), ion assisted deposition (IAD) and bio film deposition, proven high yields and fast turn-around times. 901e TTW features a 12-zone, quartz tube furnace with unique baffle designs to maximize uniformity and excellent pressure control to minimize leakage. The furnace has a generous process envelope that can accommodate 6-inch substrates with up to 12-in. (300mm) equivalent lateral uniformity. It also provides excellent temperature uniformity, excellent repeatability and high throughput. The 901e includes a computer-controlled, high-precision, high-speed x-y positioning precision of 0.5 microns, and an advanced TEOS (Tetraethyl Orthosilicate) source for high-density dielectric deposition. The equipment is controlled by a high-performance software package designed to provide process automation and flexibility, as well as a user-friendly graphical user interface for efficient substrate metrology. The system also features an integrated plasma source with quartz tube plasma technology to provide fast and repeatable plasma deposition of dedicated target films for both ashing and deposition processes. With its high deposition rates, the unit is highly suited for high-performance MEMS and logic devices. TEGAL 901e TTW provides fast response time, consistent uniformity and high throughput. The innovative design uses an advanced thermal management machine to minimize cycle times and avoid surface contaminates. The tool is highly reliable and consistent, and is rigorously tested with each new process recipes. Its low-cost operation, combined with a proven track record of success, makes 901e TTW a highly desirable tool for various wafer and substrate processing applications.

There are no reviews yet