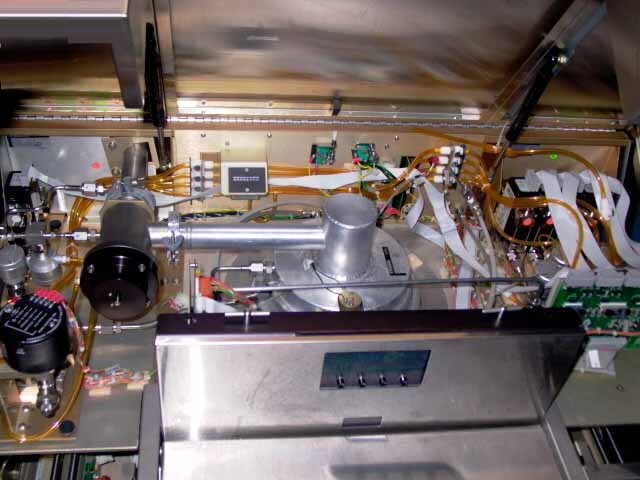

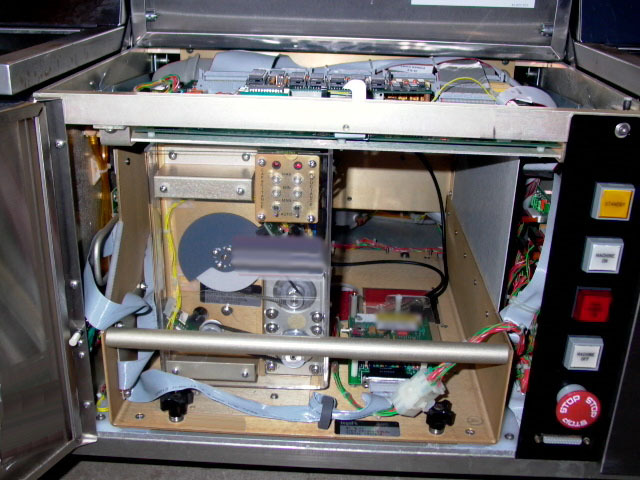

Used TEGAL 903 #9152161 for sale

URL successfully copied!

Tap to zoom

TEGAL 903 is an etcher and asher that provides an advanced platform for the manufacture of integrated circuits with the highest levels of reliability and performance. It is a reliable platform that supports etch and ash processes with consistent repeatability and yield across a wide range of semiconductor process parameters. 903 features a modern User Interface (UI) and intuitive GUI, along with advanced distributed memory technology, matrix-based recipes, and a comprehensive list of process parameters for precision and control, providing a flexible platform for a variety of process needs. Additionally, TEGAL 903 offers full process uniformity, fast recovery with tight process control specifications, and multi-etched process capability. 903 feature robust durability and reliable performance across the full spectrum of semiconductor manufacturing operations, from dielectric polycide to RIE and array ashing applications. TEGAL 903 utilizes a user-friendly graphical interface and offers a range of equipment automation features that help quickly and easily set up recipes for etching and ashing operations. The system's distributed memory technology ensures reliable and repeatable patterns from products as small as 2µm up to 8µm features. 903 also features multi-process capability for multiple etch and ash operations, such as RIE shallow trench isolation (STI) applications. The robust control and data acquisition (CDA) unit of TEGAL 903 provides precision and repeatability to meet the most demanding semiconductor processing needs. The advanced architecture of 903 enables precise process control and complete control of all parameters during process runs. It is also capable of providing process optimizations via the comprehensive Process Data Acquisition Machine (PDS) or by the command line. TEGAL 903 provides superior performance and cost-effectiveness when foundry and assembly operations demand high levels of etching and ashing complexity and precision. It is equipped with a full complement of controls and software programs for both automated and manual operation, enabling users to optimize their efficiency and yield performance. The ultimate goal of 903 is to provide reliable and cost-effective manufacturing processes for the highest quality end products.

There are no reviews yet