Used TEGAL 903E #115926 for sale

URL successfully copied!

Tap to zoom

ID: 115926

Wafer Size: 4"

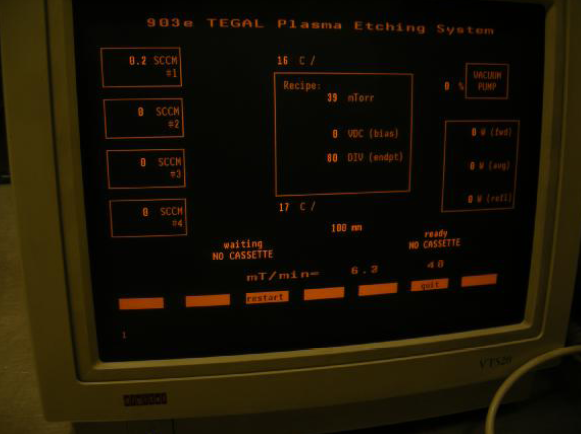

Plasma etcher, in-line single wafer, 4"

Can handle 3" to 6" wafers, currently configured for 4"

Cassette to cassette

Etches silicon dioxide, silicon nitrides, and polyamid es

Microprocessor control

ENI 1,000 Watt 13.56 MHz RF Generator

20 Process recipe capability

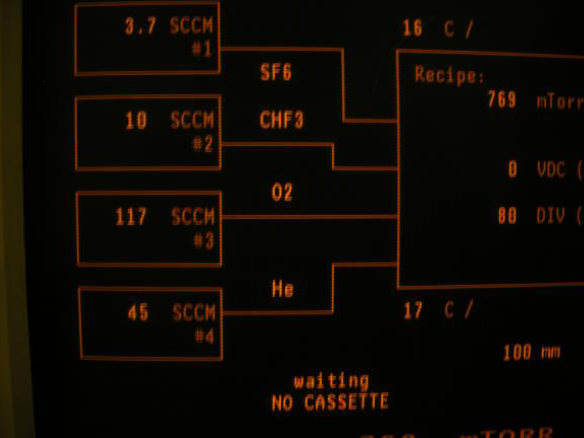

Process gases controlled by Tylan MFC’s

Non-friction spatula pick and place wafer transport.

LEYBOLD D65 oxygen service pump (optional dry pump available)

Two Tegal closed loop temperature controllers

DEC Monitor and keyboard

Non-friction spatula pick and place wafer transport

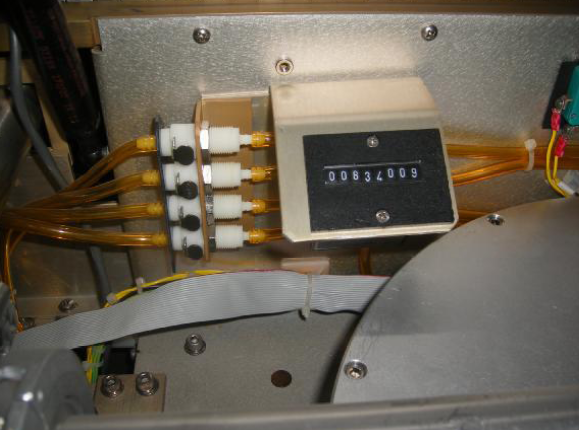

Wafer count: 834,009

Manuals included

CDA / N2 regulated to 80 +/- 5 psi

N2 regulated to 15 to 30 psi

Process gas's regulated to 15 +/- 5 psig

O2 clean regulated to 10 +/- 5 psi

903e vacuum pump connection: KF-40 flange

903e cabinet exhaust connection: 4", 100 cfm

Leak-back rate: 5.3 mTorr per minute

System: 200 to 240 VAC selectable, 50 / 60 Hz

RF generator: 200 to 240 VAC selectable

Monitor: 115 VAC

Vacuum pump: 200 to 230 VAC, 3-phase

Temperature controllers: 115 VAC

Demonstrable.

TEGAL 903E is a state of the art etcher/asher system for semiconductor fabrication. It is designed to replace costly ICCP systems, which can often damage delicate wafers and require the use of harsh chemicals in order to etch patterns onto them. Instead, TEGAL 903 E uses an ion beam to etch precisely controlled patterns onto the wafer's surface, using physical vapor deposition (PVD). This process is more efficient than other etching techniques, resulting in better uniformity, high productivity, and minimal waste of expensive chemicals. 903E features a flexible and high-resolution end effector with three linear axes. This end effector is responsible for the patterning and focuses the ion beam onto the wafer in order to etch a desired pattern. The system also incorporates an array of automatic set-up tools, as well as an intuitive graphical user interface (GUI) which allows for easier operation. 903 E is designed to etch on up to eight four-inch square wafers, with each wafer fitted into its own glass holder for precise positioning. This ensures that only the target area of the wafer is etched, and reduces the amount of inaccessible residues which can occur in weaker systems. The user can also customise the ion beam profile, allowing them to precisely tailor the depth and spread of the pattern being etched. TEGAL 903E also uses advanced Argon ICP mode to monitor etching progress in real-time, with the support of a dust-free environment. The system has built-in safety features and is compliant with SEMATECH OCSMS-95 standard and SOP-002 environmental regulations. TEGAL 903 E is an incredibly versatile and reliable etcher/asher. Its ability to precisely control patterns ensures that it is an ideal choice for complex IC fabrication processes, and its user-friendly interface makes it accessible to users of all skill levels. Its combination of technological excellence and cost-effectiveness make it the perfect choice for advanced semiconductor research and manufacturing.

There are no reviews yet