Used TEGAL 903E #293654462 for sale

URL successfully copied!

Tap to zoom

ID: 293654462

Wafer Size: 6"

Etcher, 6"

Through the wall

Handles: 3"-6" Silicon

Reactor chamber with upper and lower electrode

Super spatulas

Shuttle wafer transfer

Typical temperature controller

JULABO Chiller: 0-80°C

ENI ACG-10B Solid state

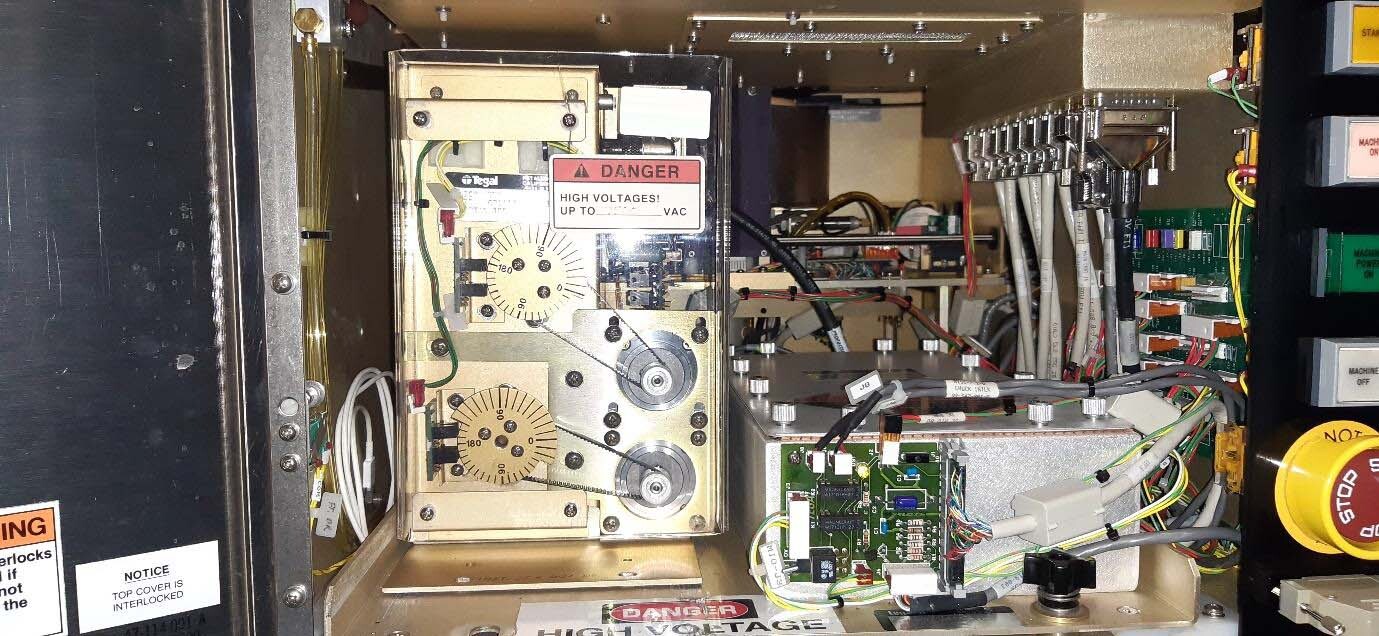

RF Matching network, 13.56 MHz (Fully automated)

ENI ACG-10B RF Generator 13.56 MHz

RF Power: 50-1,000 W

Wafer quartz pin: Up / Down

Calibration and built-in diagnostic function

SEC / GEM Communication function

Multi-level password protection

Distilled water

Capacity: 2.8 gal

Outlet pressure: 40 psig, 45 psig max

Flow connecting hose must withstand coolant at 40 psig at 80°C

Display: Real-time graphic

Storage capacity: 20 Recipes

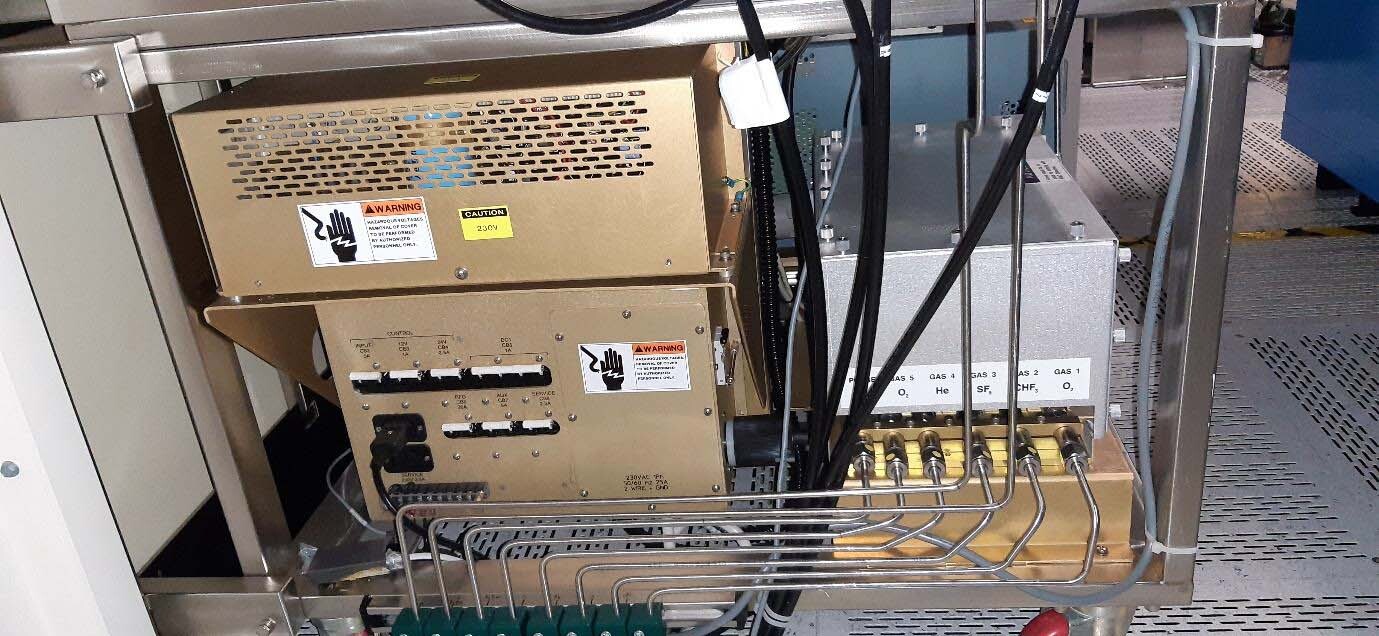

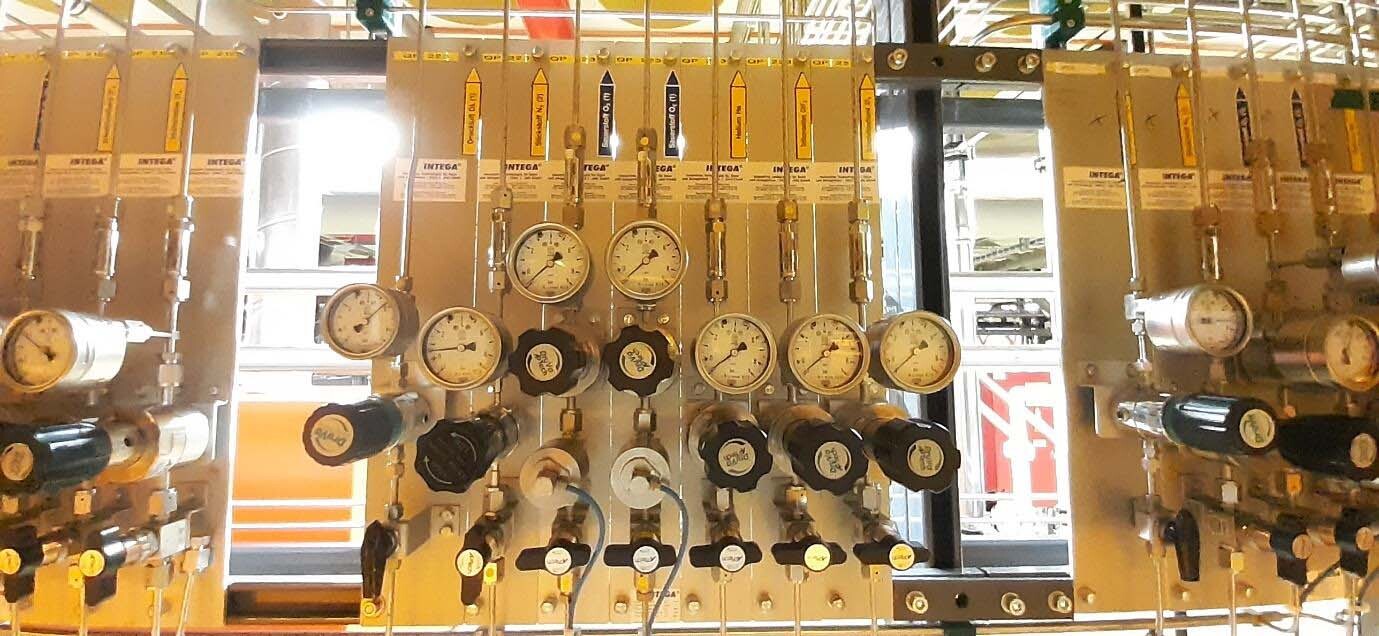

Gasses:

Gas 1: 15-20 psig +/- 5psig

Gas 2: 15-20 psig +/- 5psig

Gas 3: 15-20 psig +/- 5psig

Gas 4: 15-20 psig +/- 5psig

Clean channel needle valve O2: 20-30 psig +/- 5psig

Cabinet exhaust: 100 CFM (2.832 LPM) min

Typical process:

Material etched: Silicon oxide, polyimide, SOG and PECVD nitride

Gases: CHF3, SF6, Helium

Typical process pressure: 1600-3000 m Torr

Typical RF-power level: 400-600 W

Typical temperature: Upper electrode, 24/30°C, Lower electrode, 19/23°C

Power supply: 200-240 VAC, 50/60 Hz, 30 Amp, 3 Wire, 1 Phase, 2 Pole.

TEGAL 903E is an etcher / asher specifically designed for use in the commercial semiconductor manufacturing industry. It is a high-performance, automated etching solution that can handle various etching processes - from dry etching of silicon oxide layers, dry etching of SiC, to stripping of circuit lines, as well as other task functions as will be shown below. TEGAL 903 E provides a fully automated etching solution. It offers a wide range of etching recipes and recipes that can be tailored to specific applications. The etching process is done with minimal human intervention and is designed to keep the following features in peak condition: etching uniformity, throughput and reduced contamination. 903E is constructed using robust materials to enable it to withstand tough industrial environments and can accommodate both single and multi-stage processes. It has a three chamber/double load lock equipment which ensures quicker processing of wafers, while optimizing effluents. The etching process is controlled through the use of an interactive graphical user interface. 903 E can operate within a variety of temperature ranges and is equipped with a heated low pressure etching source. TEGAL 903E can work with a variety of container shapes depending on the specification requirements. It also includes an on-board laser protection system as well as an automatic wafer end-point tracker. TEGAL 903 E also includes several other distinct functionalities, such as Auto-tune, advanced etch recipe storage and retrieval capabilities, automatic cassette movement, and local/remote monitoring capabilities. Additionally, 903E is coupled with several advanced features, such as a fast and accurate 7nm end-point tracking unit, a high-speed wafer handling mechanism, a real-time machine diagnostics and monitoring unit, as well as data-logging capabilities. These features combine to make 903 E one of the most robust, reliable and efficient asher/etcher solutions on the market, making it suitable for use in the commercial semiconductor manufacturing sector.

There are no reviews yet