Used TEGAL 915 #158859 for sale

URL successfully copied!

Tap to zoom

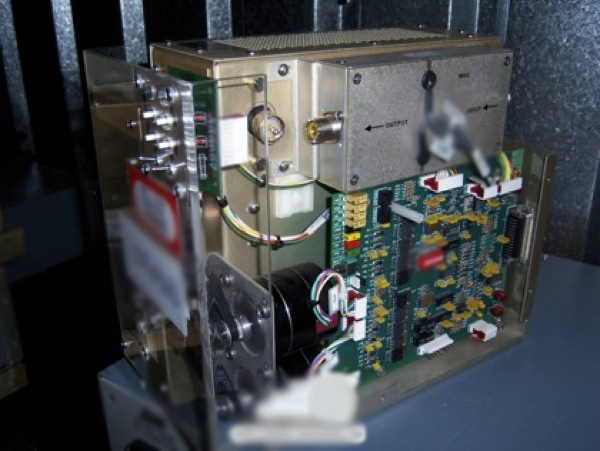

TEGAL 915 is an etcher/asher manufactured by TEGAL Corporation, a global leader in semiconductor fabrication equipment. This etcher/asher is used in MEMS and semiconductor fabrication and is designed to deliver superior performance and scalability through efficient, cost-effective processing. 915 is a multi-chamber etcher/asher with an optimized single-chamber layout. It features a combined etch/ash process, allowing users to simultaneously etch and clean the substrate in the same chamber. It has a high throughput capability and can process up to 130 substrates for each etching cycle. TEGAL 915 is powered by a high-performance, low-power, high-density DC magnetron sputter equipment, and also includes an advanced load/unload transport system for improved throughput. The etch/ash process utilizes a combination of high-density plasma, pre-etch, and post-ash processes, resulting in superior etch rates and excellent results. Its multi-chamber design is optimized to enable Precision Punch feature resulting in superior edge definition of features. 915 features top-of-the-line in-situ diagnostics and is designed to automatically compensate for defects, minimize defects, and optimize process performance. It is designed to enable Virtual Endpoint for optimal process control and repeatability. It also includes Cool Chamber for precise control of chamber temperature. In addition, TEGAL 915 includes a range of safety features, such as a safety interlock unit and chemical inerting capability. Its advanced shutter machine ensures that the substrate is not exposed to plasma or etchant until the substrate is securely held in the chamber. Furthermore, 915 features a range of customization features, such as multiple recipe storage and easy optimization tools. It is designed to be easy-to-use, with a dynamic interface and remote control capabilities, making it ideal for remote monitoring and process control. TEGAL 915 is designed to deliver outstanding performance and scalability through efficient, cost-effective processing, making it an ideal choice for today's semiconductor production needs.

There are no reviews yet