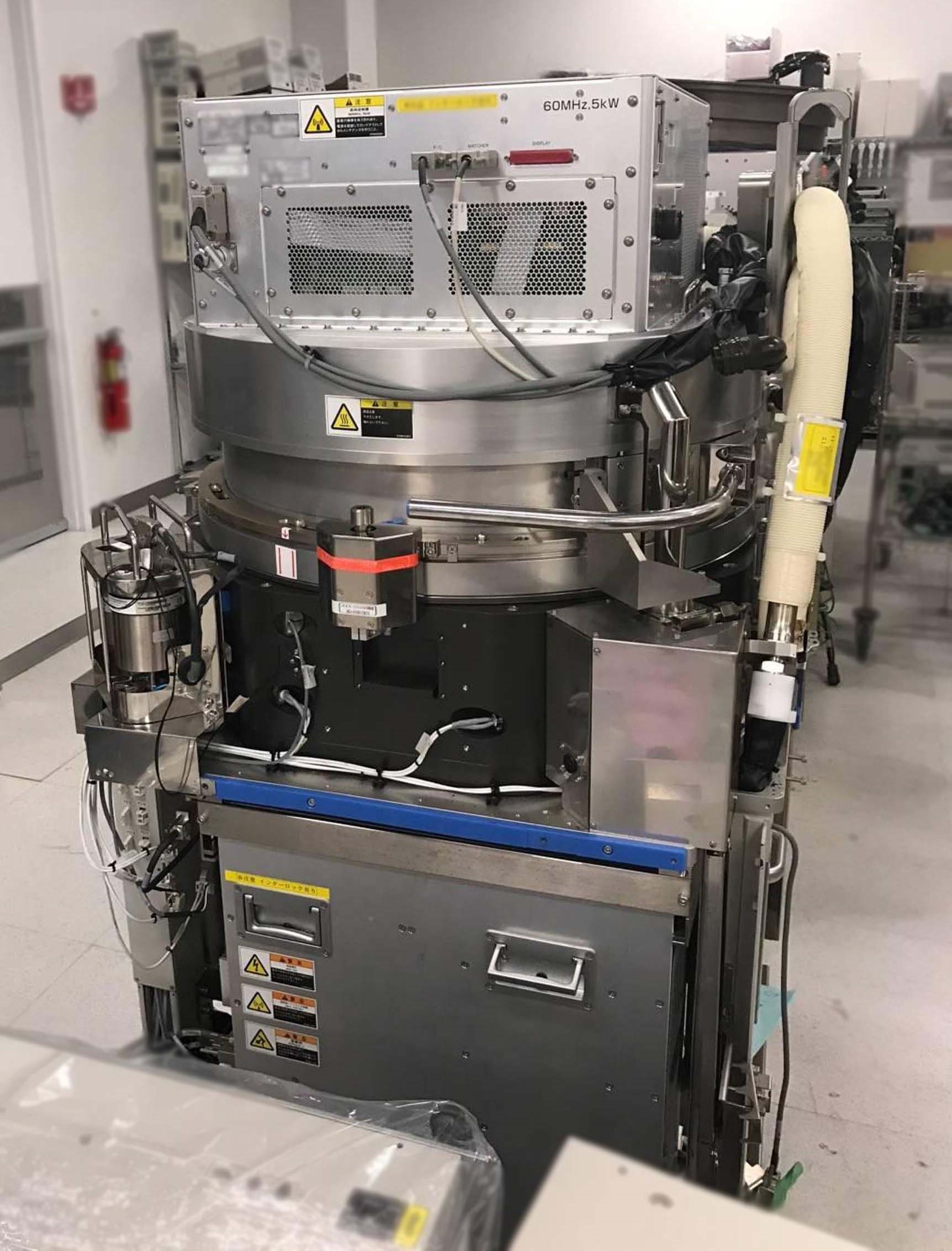

Used TEL / TOKYO ELECTRON Chamber for SCCM #9226603 for sale

URL successfully copied!

Tap to zoom

TEL (TOKYO ELECTRON/TE) TEL / TOKYO ELECTRON Chamber for SCCM (Sub-Critical Chemical Mechanical Polishing) is an etcher/asher that utilizes a chemical mechanical process to polish and etch micro-structures on substrates. This advanced equipment enables production of advanced micro-structured features with high precision and quality. TEL / TOKYO ELECTRON/TE TEL Chamber for SCCM has a patented process that utilizes both chemical and mechanical interactions to polish and etch micro-structures on substrates. In this process, the target material is positioned on top of a multi-level rotating platen, and the substrate is first treated with a chemical solution for a period of time. Then, the substrate is exposed to a high speed polishing environment, wherein an abrasive slurry is driven by a platen spin and pressurized with precise pressure. The abrasive slurry contains diamond abrasive materials that are precisely controlled by a dosing mechanism. This is then followed by a gentle etch process utilizing a sacrificial layer of soft material formed in the gap between the two platen levels. After the polishing process is complete, the substrate is exposed to a rinse step, followed by a drying step, to remove any residue. To ensure superior quality, TEL/TE TOKYO ELECTRON Chamber for SCCM is equipped with a range of advanced features. These include: a temperature and hydraulic pressure control system for the precision adjustment of the platen spin and pressure; a continuous monochrome monitor for process stabilization; an advanced motion controller for substrate travel and control; integral gas-flow channels and valves; a subsystem for controlling the composition and characteristics of the chemical solutions; and, a leak detection and monitoring unit to monitor the cleanliness of the etching chamber. Furthermore, TOKYO ELECTRON/TE Chamber for SCCM is designed to effectively prevent contamination from dust and particles with the help of a differential pressurization machine. With its precise and efficient process control and advanced features, TEL / TOKYO ELECTRON/TE TEL / TOKYO ELECTRON Chamber for SCCM provides predictable and repeatable results, making it an ideal solution for producing micro-structured features with high precision and quality. Aside from being highly reliable and efficient, this tool is also low on maintenance and offers a user-friendly operation interface, making it an ideal choice for both small and large-scale operations. Furthermore, this etcher/asher is fully compliant with applicable international standards and guidelines, such as SEMI/ESF and ESD protection.

There are no reviews yet