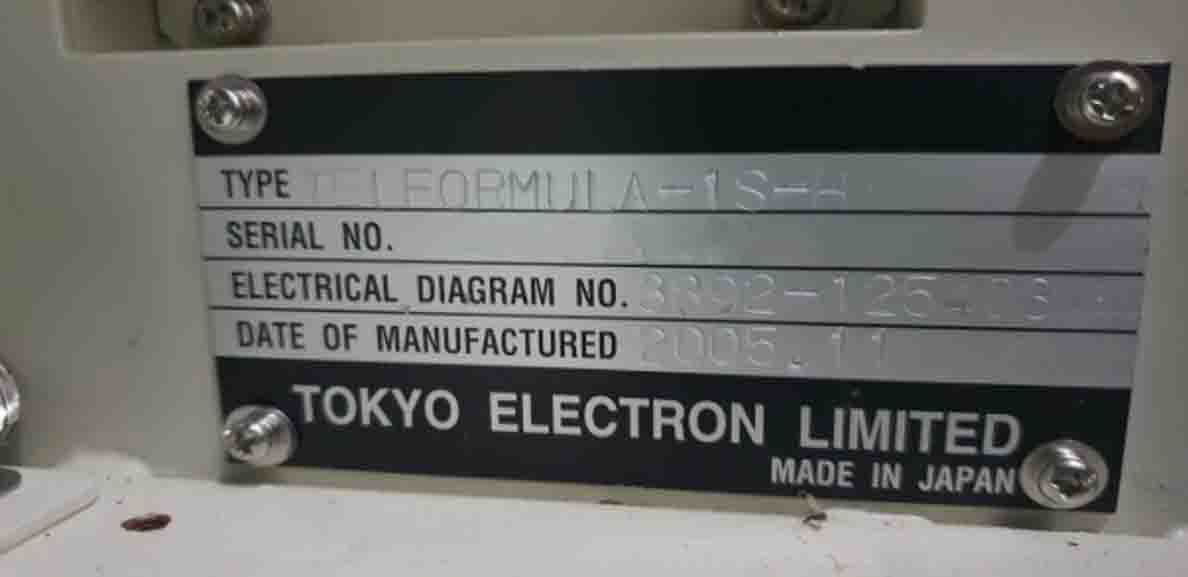

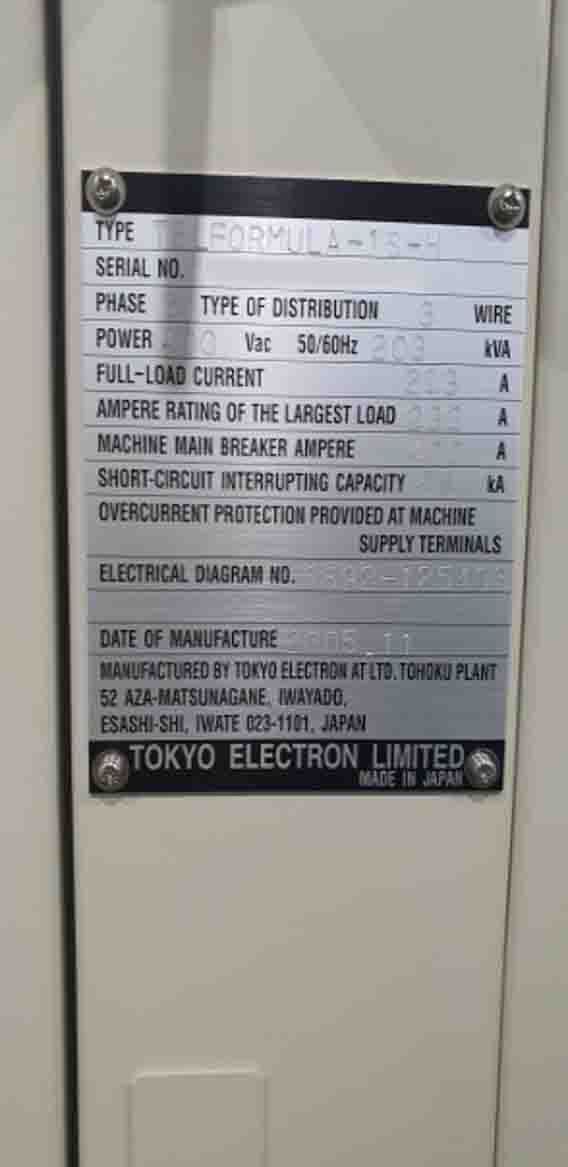

Used TEL / TOKYO ELECTRON Formula-1S-H #293625497 for sale

URL successfully copied!

Tap to zoom

ID: 293625497

Vintage: 2005

Diffusion furnace

Control system

Heater temperature: 600°C-900°C

Load port

FIMS

Wafer transfer

Boat elevator / Seal cap rotation

Auto shutter

Heater model

N2 Load lock

Boat operation

Process: LPCVD

Si SEMI STD-Notch, 12"

Furnace temperature controller: M780

HTR

Power box

Carrier transfer

Mechanical driver

Exhaust box

Front and rear upper cover

Final valve box

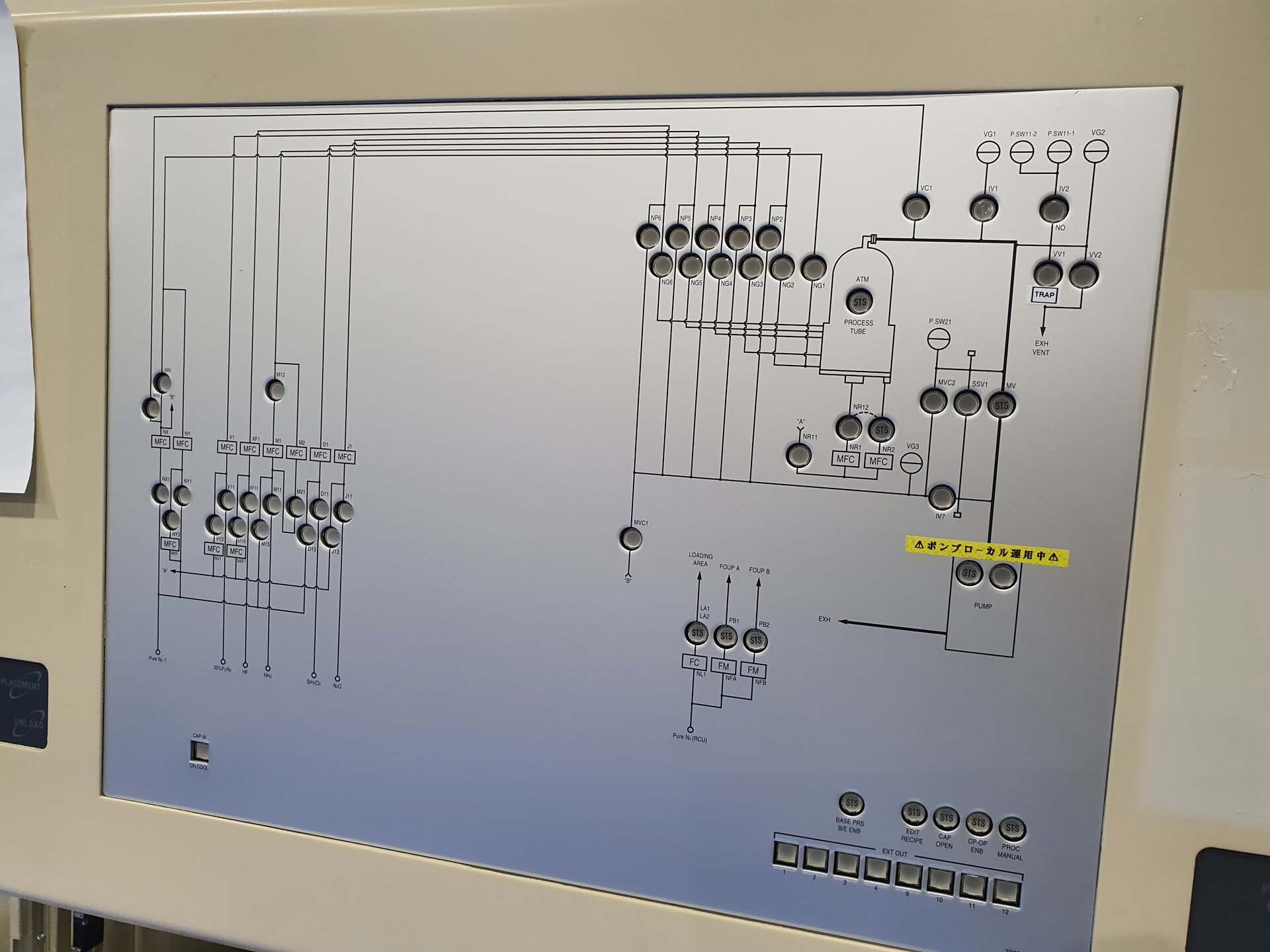

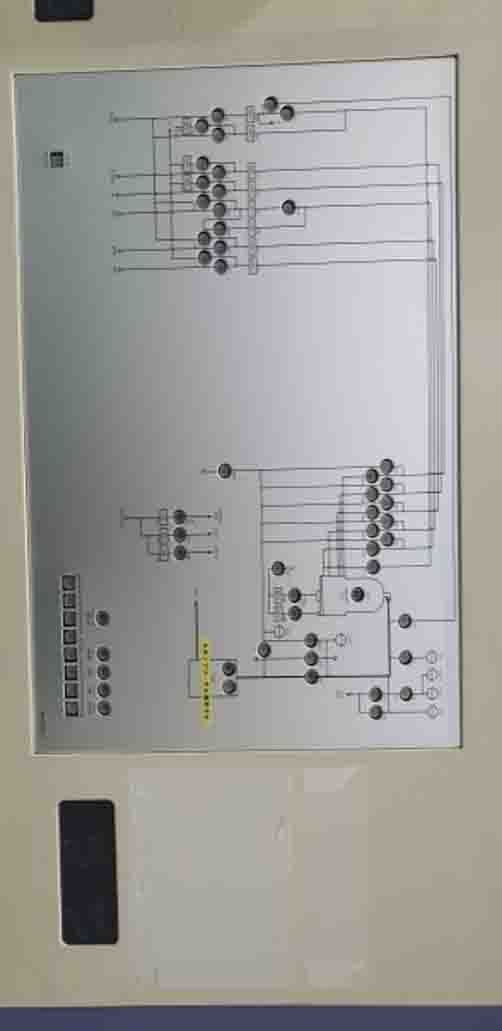

Gas flow chart

O2 Analyzer

Hard Disk Drive (HDD)

Does not include HCT

User interface:

MMI and gas flowchart: Gas box and front operation panel installed

Pressure display Unit: Mpa / Torr

Carrier type: FOUP / 25slots SEMI STD

Fork meterial: Al203 and PEEK

W/T Type: 1+4 Edge grip

16-Carrier stage capacity

Wafer notch aligner

RCU

UPS

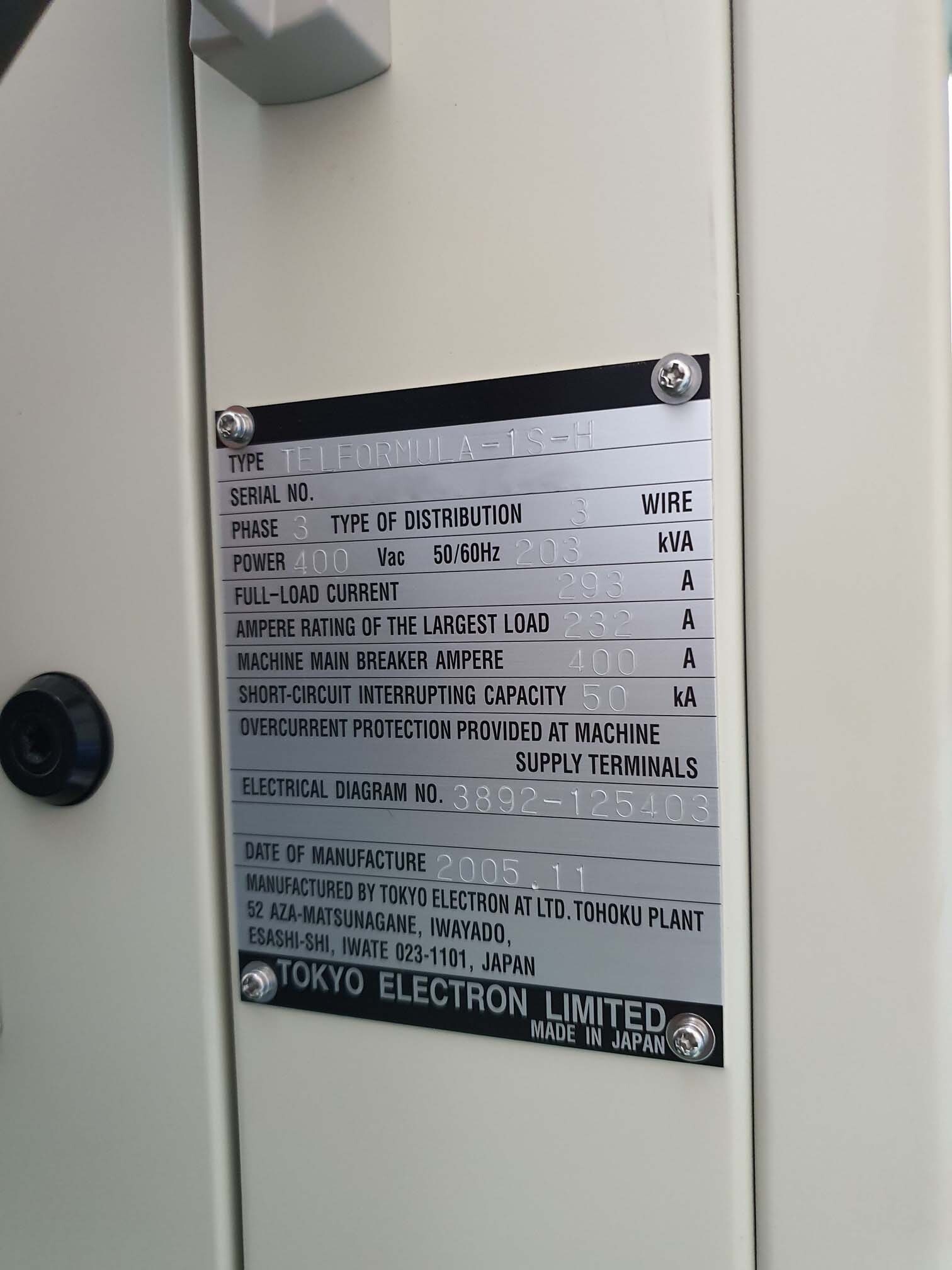

Power distribution system:

3-Phase connection type: Star connection

Single-Phase connection: Grounded

Single-Phase voltage

Gas distribution system:

FUJIKIN Integrated Gas System (IGS)

IGS Final filter, regulator: MFC Z500 Type

MKS Capacitance manometer vacuum gage - press monitor (133 Kpa)

Power supply: 400 VAC, 3 Phase, 50/60 Hz

2005 vintage.

TEL / TOKYO ELECTRON Formula-1S-H is a one-chamber, computer-controlled etcher/ asher. It is designed to provide high precision results when etching and ashing process in microfabrication and semiconductor applications. The equipment is equipped with multiple options and comprehensive features to ensure accuracy and repeatability of the process. The main component of TEL Formula-1S-H is the etching/asching chamber. It is constructed from stainless steel and has a maximum capacity of 600 liters. Inside the chamber, a source gas is introduced and a vacuum atmosphere is maintained for precise etching and ashing process. The temperature inside the chamber is also regulated via a precise electronic temperature controller. The precise control of the temperature ensures precise results as well as repeatability of the process. The system also provides several optional accessories to enhance the process. It can be equipped with a water chiller to prevent cross contamination and provide precise control of the process. For better resolution, a secondary platen can be added to the unit for precise etching at higher resolution. A rollover plate is also available for precise vertical etching. TOKYO ELECTRON Formula-1S-H has several advantages: it is simple to use and offers precise results; it is versatile, allowing different parameters to be adjusted according to the requirements; it is compatible with different etching and ashing parameters, including high-density etching; and its safety features ensure minimal exposure to hazardous gases. The machine is easy to integrate into existing production line. It can be connected to a computer to provide process data, monitor the process and ensure repeatability of results. It also can be integrated with other systems such as SEM, AFM, and wafer steppers to further increase process efficiency. Overall, Formula-1S-H is a reliable and precise etcher and asher. Its high performance and a number of additional features make it the perfect choice for various microfabrication and semiconductors applications.

There are no reviews yet